Novel lift check valve

A lift type, check valve technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of poor sealing performance between the valve body and the valve disc, slow valve opening and closing speed, and reduced service life. Good performance, rapid opening and closing, and the effect of reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

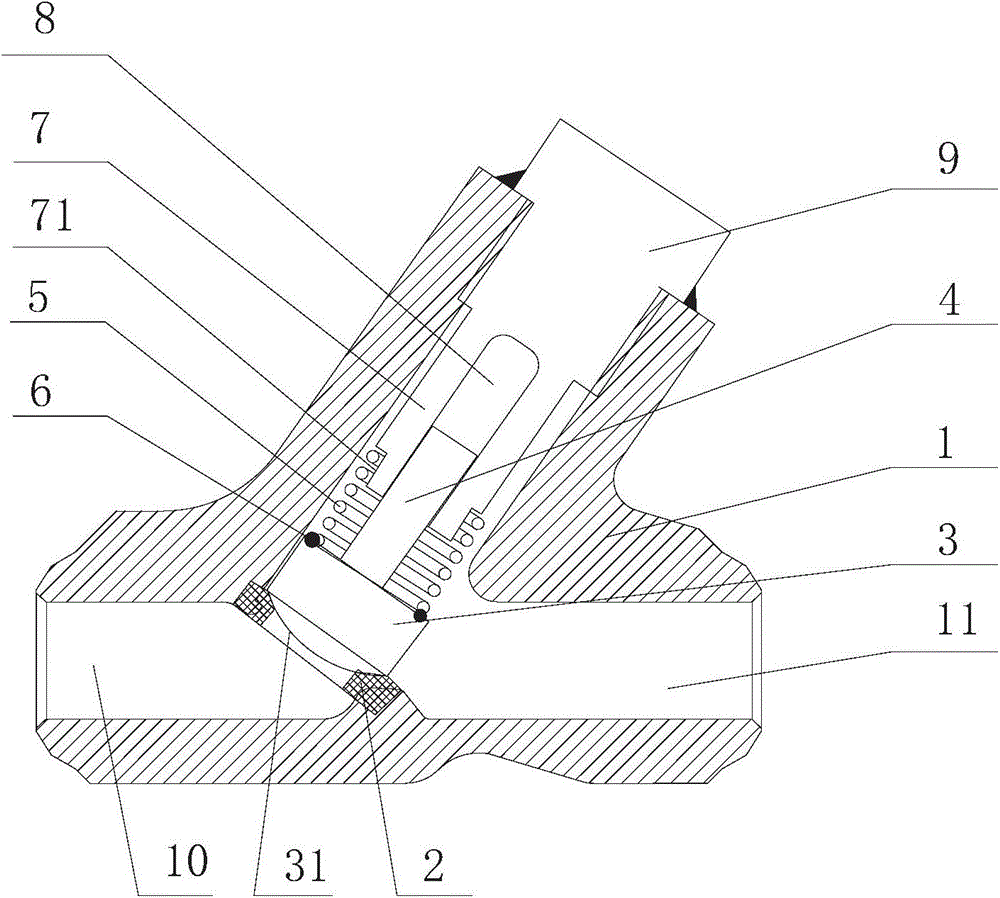

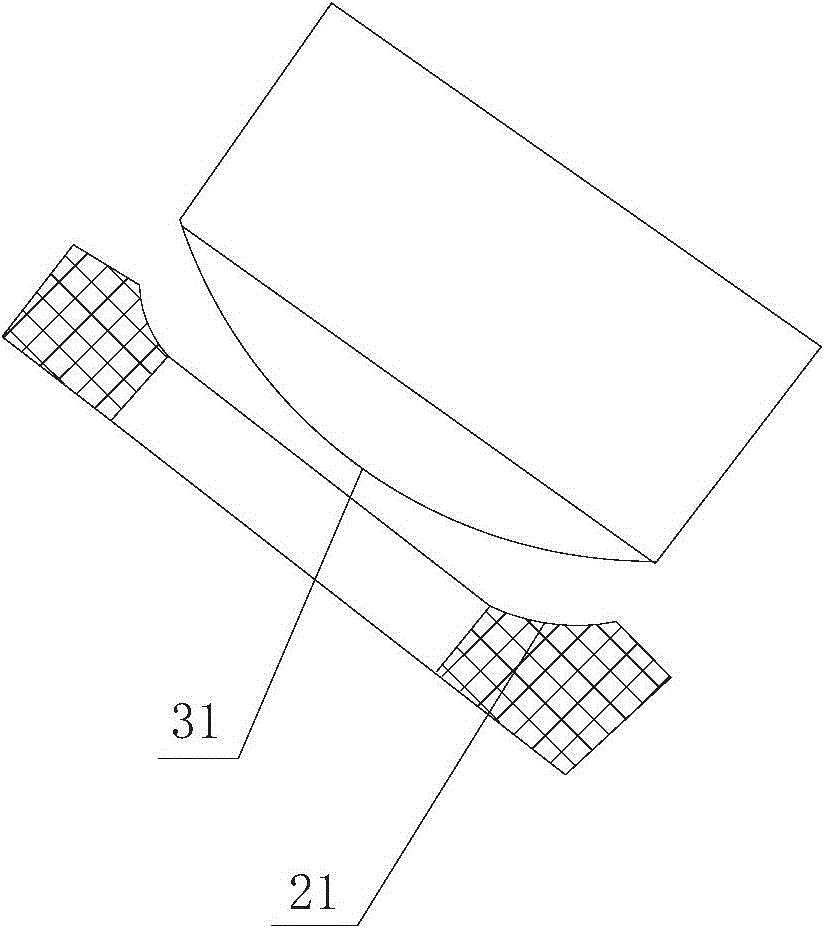

[0019] Such as figure 1 , figure 2 As shown, a new lifting check valve includes a valve body 1, a valve seat 2, a valve disc 3 and a valve stem 4, and the valve seat 2, valve disc 3 and valve stem 4 are all arranged inside the valve body 1; the valve disc One end of 3 is connected to the valve stem 4, and the other end is connected to the valve seat 2. The new lift check valve also includes a self-sealing device, which includes a spring 5, a collar 6 and a guide shaft 7, the spring 5, the collar 6 and The guide shaft 7 is sheathed upwards on the valve stem 4 sequentially from the joint between the valve disc 3 and the valve stem 4 ; a cavity 8 is provided inside the guide shaft 7 to make the valve stem 4 move back and forth in the cavity 8 . Along the axial direction of the guide shaft 7 , the length of the cavity 8 is not greater than the length of the valve stem 4 .

[0020] The lower end of the guide shaft 7 is provided with a stepped surface 71 along its circumference a...

Embodiment 2

[0023] The rest are the same as the above-mentioned embodiment, the difference is that, as figure 1 As shown, the new lifting check valve also includes a bonnet 9 threadedly connected to the valve body 1, and the bonnet 9 is welded together with the external connection of the valve body 1, so that the valve is in a sealed state and completely isolated from the outside world. One end of the guide shaft 7 is connected to the valve cover 9, and the guide shaft 7 and the valve cover 9 are integrally structured.

Embodiment 3

[0025] The rest are the same as the above-mentioned embodiment, the difference is that, as figure 1 As shown, the valve flap 3 and the valve stem 4 are of an integral structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com