Small push force tap for water drinking machine

A faucet, small thrust technology, applied in mechanical equipment, engine components, diaphragm valves, etc., can solve the problems of laborious use, complex and difficult assembly process, large thrust or pressing force, etc., to achieve product quality assurance, assembly process is simple, speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

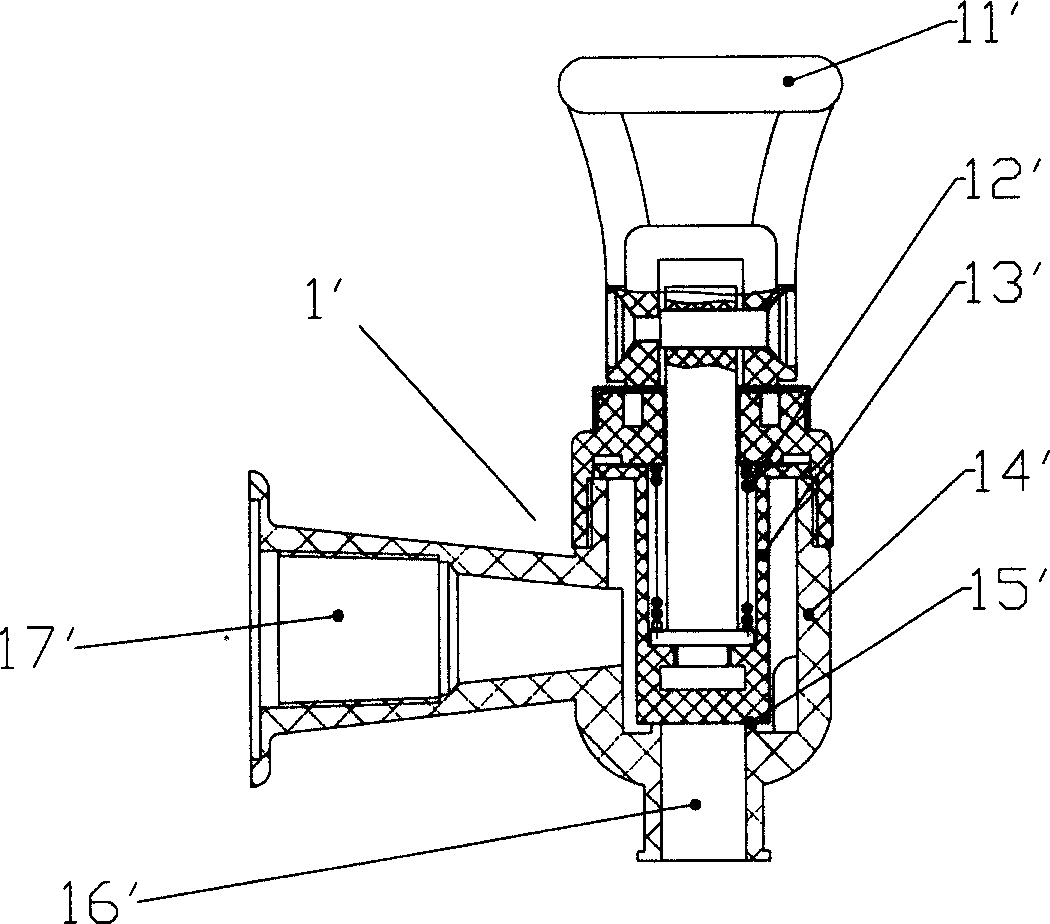

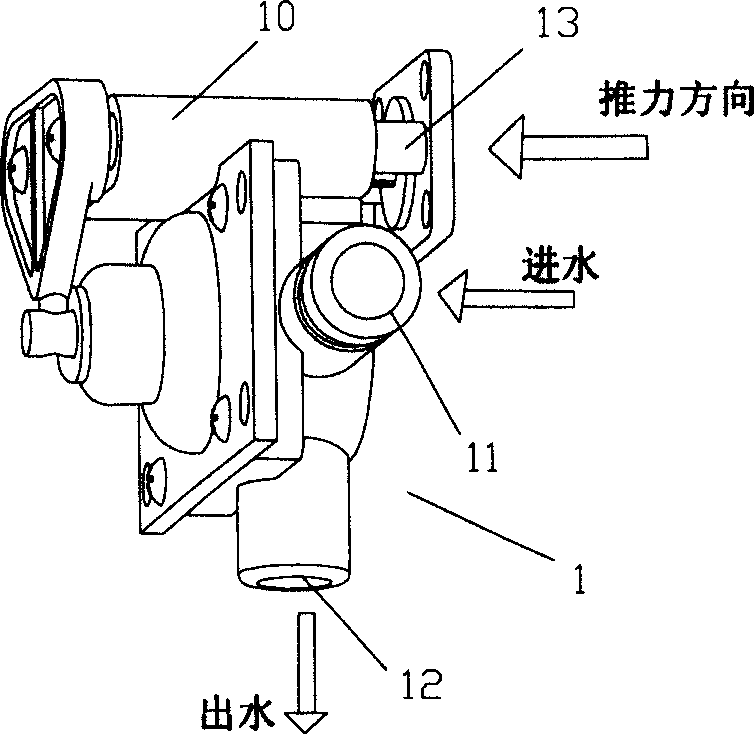

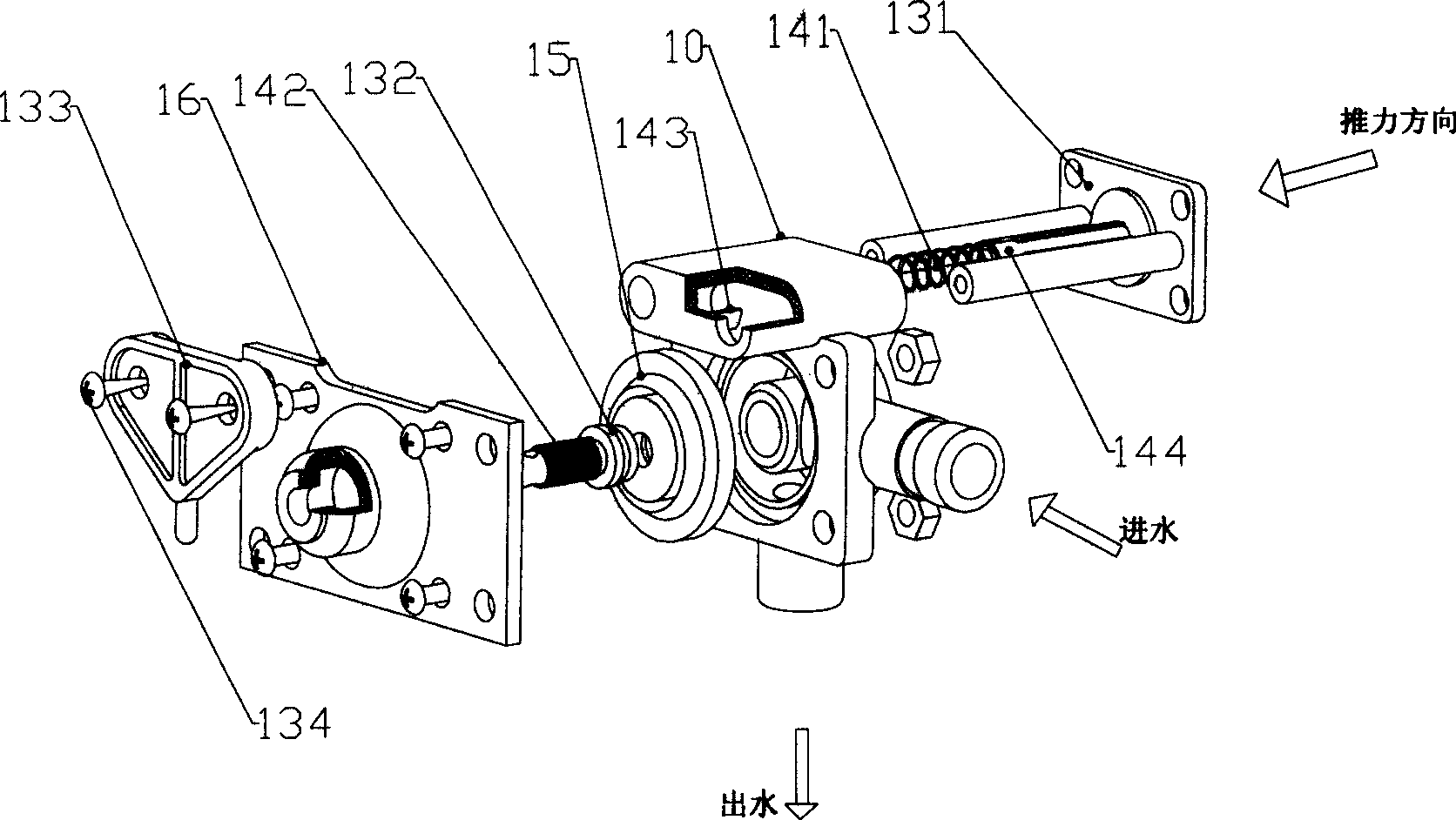

[0021] based on the following Figure 2 to Figure 5 , illustrating a best embodiment of the present invention.

[0022] Such as figure 2 As shown, it is a main body outline view of a small-thrust water dispenser faucet 1 provided by the present invention, which includes a valve body 10, which is provided with a water inlet pipe 11 and a water outlet pipe 12, and the water inlet pipe and water outlet pipe Connected by pipes; the cavity of the valve body 10 contains a connecting rod device 13, a reset elastic element and an elastic corrugated sealing element (not in the figure 2 shown in and described below).

[0023] Such as image 3 As shown, it is a three-dimensional exploded view of a small-thrust water dispenser faucet provided by the present invention. The linkage device 13 includes a movable push rod 131, a valve rod 132 and a connecting rod 133; the valve rod 132 is connected with the connecting rod 133, and the The connecting rod 133 is fixed on the movable push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com