Test structure for dielectric breakdown reliability analysis in integrated circuit and test method thereof

A dielectric breakdown and integrated circuit technology, applied in the direction of circuits, testing dielectric strength, electrical components, etc., can solve the problem where the dielectric withstand voltage capability cannot be fully tested, where the F3 position is easy to be broken down, and the mutual protection cannot be guaranteed. Problems such as the accuracy of connection reliability analysis are achieved to reduce the possibility of burnout, ensure smooth progress, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

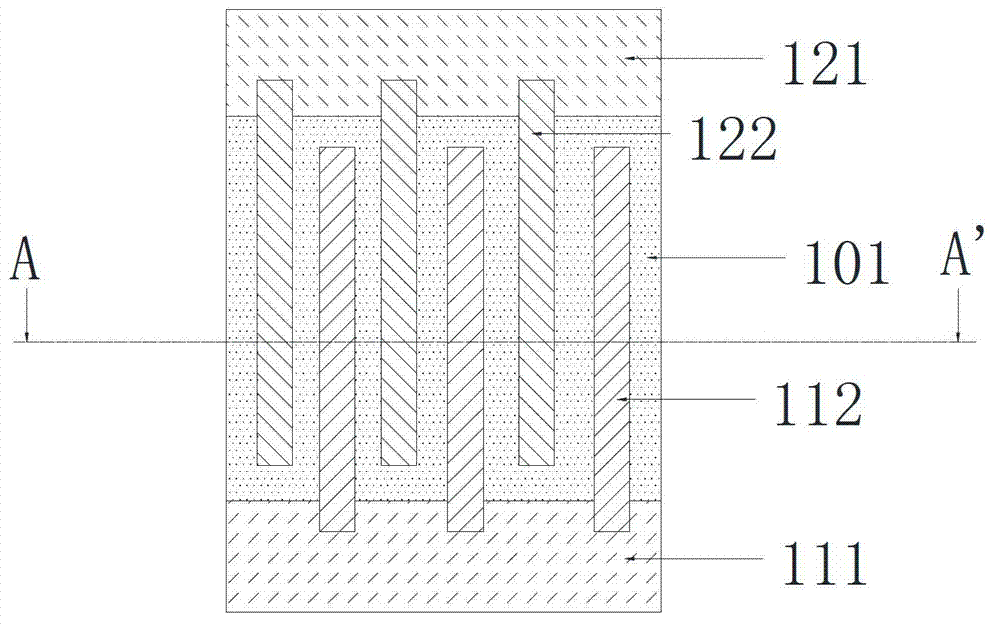

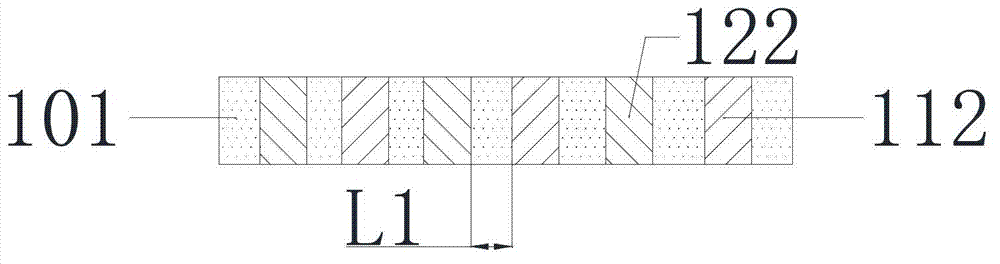

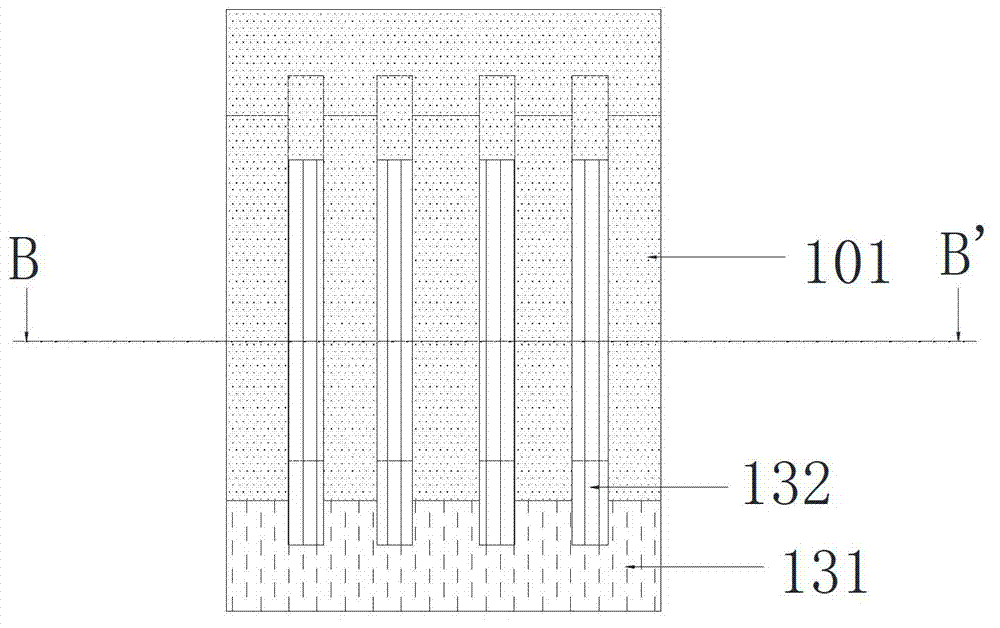

[0055] In the first embodiment, the lower metal wire structure and the upper metal wire structure include several linear metal wires arranged in parallel. Please refer to the following Figure 6-Figure 8 ,in, Figure 6 It is a top view of the test structure of the dielectric breakdown reliability analysis in the integrated circuit in an embodiment of the present invention, Figure 7 It is a right view of the test structure for the reliability analysis of the dielectric breakdown in the integrated circuit in an embodiment of the present invention, Figure 8 for Figure 6 Sectional view along cutting line C-C'. In the figures, the same reference numerals represent equivalent Figure 1-Figure 5 label in .

[0056] Such as Figure 6 As shown, the underlying metal wire structure 102 includes a first metal wire structure 112 and a second metal wire structure 122 arranged at intervals. In a preferred embodiment, the first metal wire structure 112 and the second metal wire stru...

no. 2 example

[0069] Please refer to the following Figure 11 , Figure 11 It is a top view of a test structure for dielectric breakdown reliability analysis in an integrated circuit in another embodiment of the present invention. In the figure, the same reference numerals represent the same as Figure 1-Figure 7 label in . The second embodiment is based on the first embodiment, the difference is that the first metal wire structure 112 and the second metal wire structure 122 are comb-shaped, and the first metal wire structure 112 includes more than one metal wire and one metal connection wire 201, the second metal wire structure 122 includes more than one metal wire and one metal connection wire 202, and each of the more than one metal wires included in the first metal wire structure 112 is connected to the metal connection wire 201 included in the first metal wire structure 112 through its one end. Each of the one or more metal wires included in the second metal wire structure 122 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com