Patents

Literature

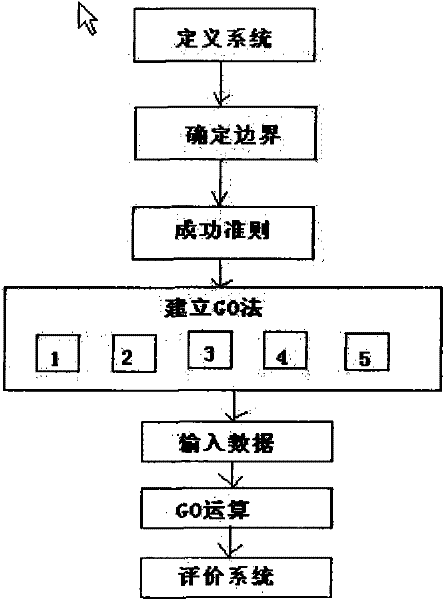

927 results about "Dependability analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In other words, dependability is an evaluation of the quality of the integrated processes of data collection, data analysis, and theory generation. Dependability could be looked at as the researcher’s account of the changes built into any setting in addition to changes to the research design as learning unfolded.

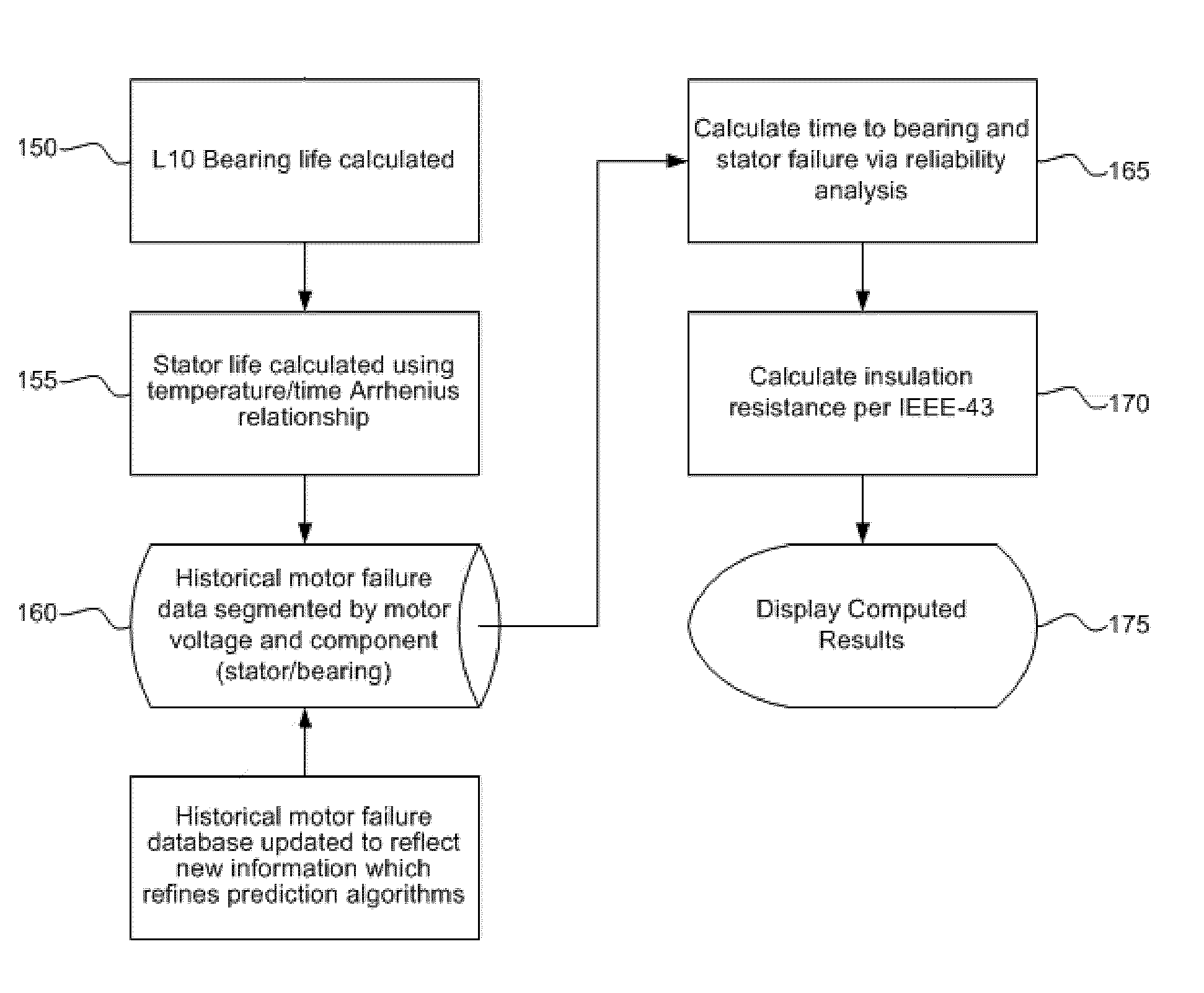

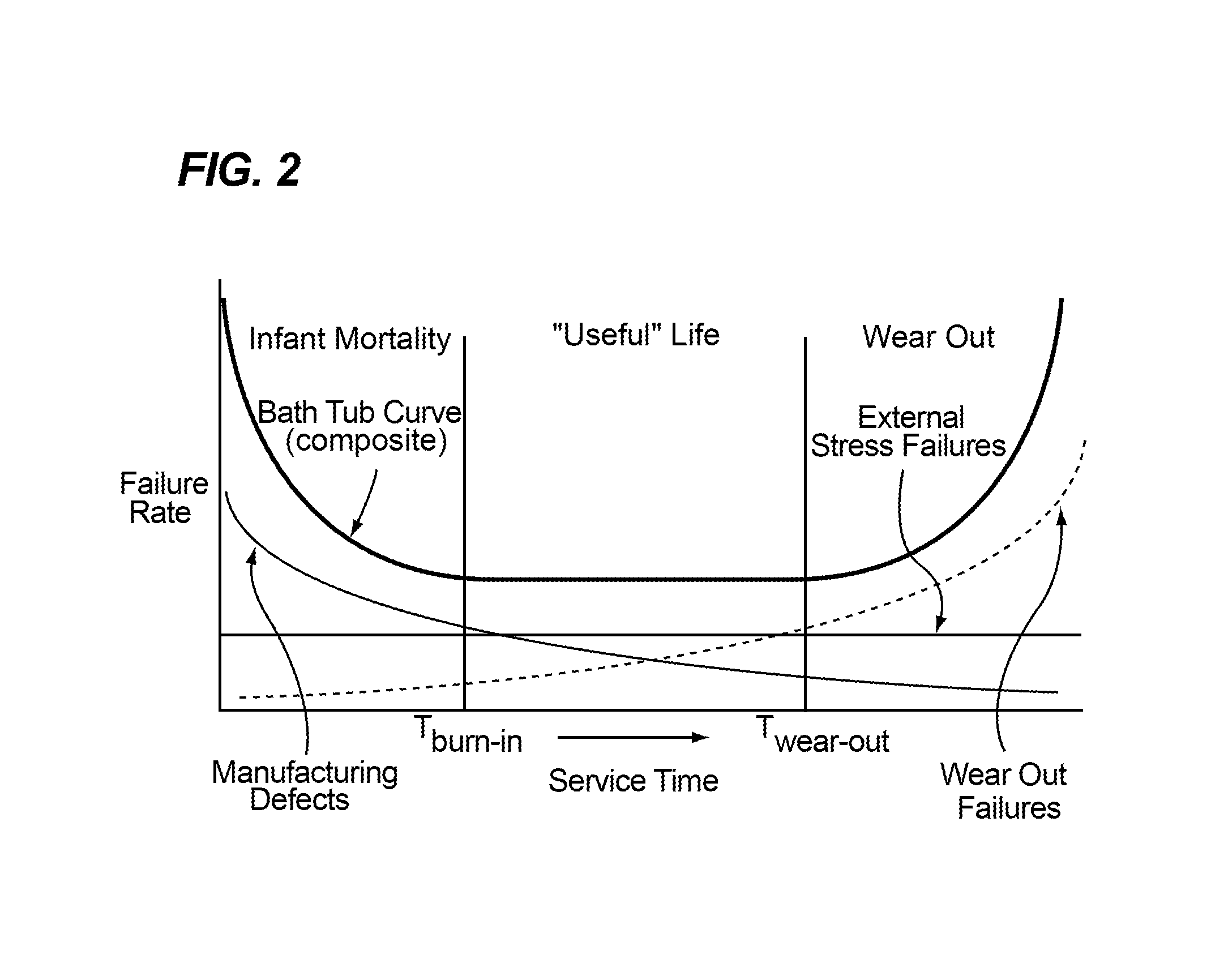

Method and system for predicting remaining life for motors featuring on-line insulation condition monitor

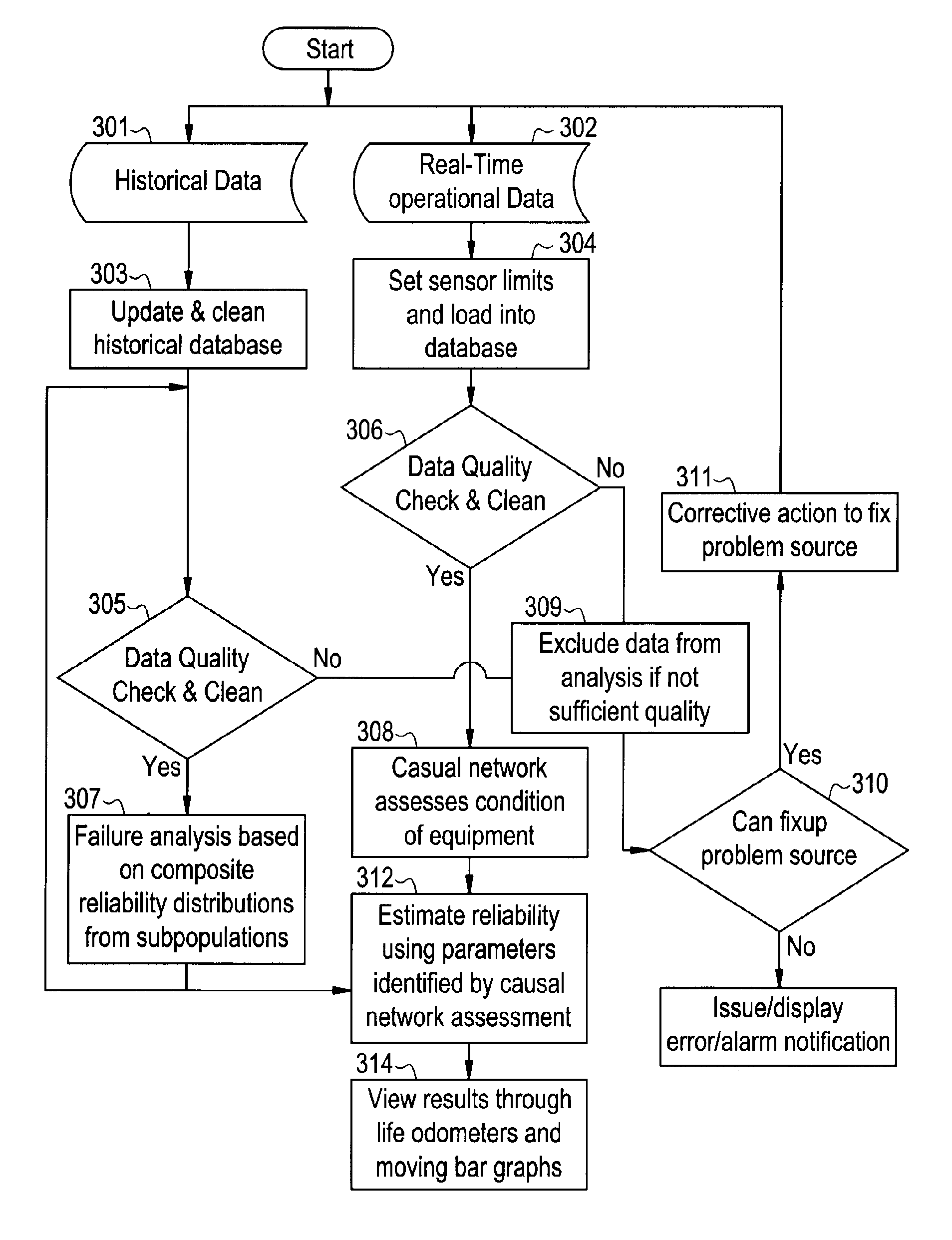

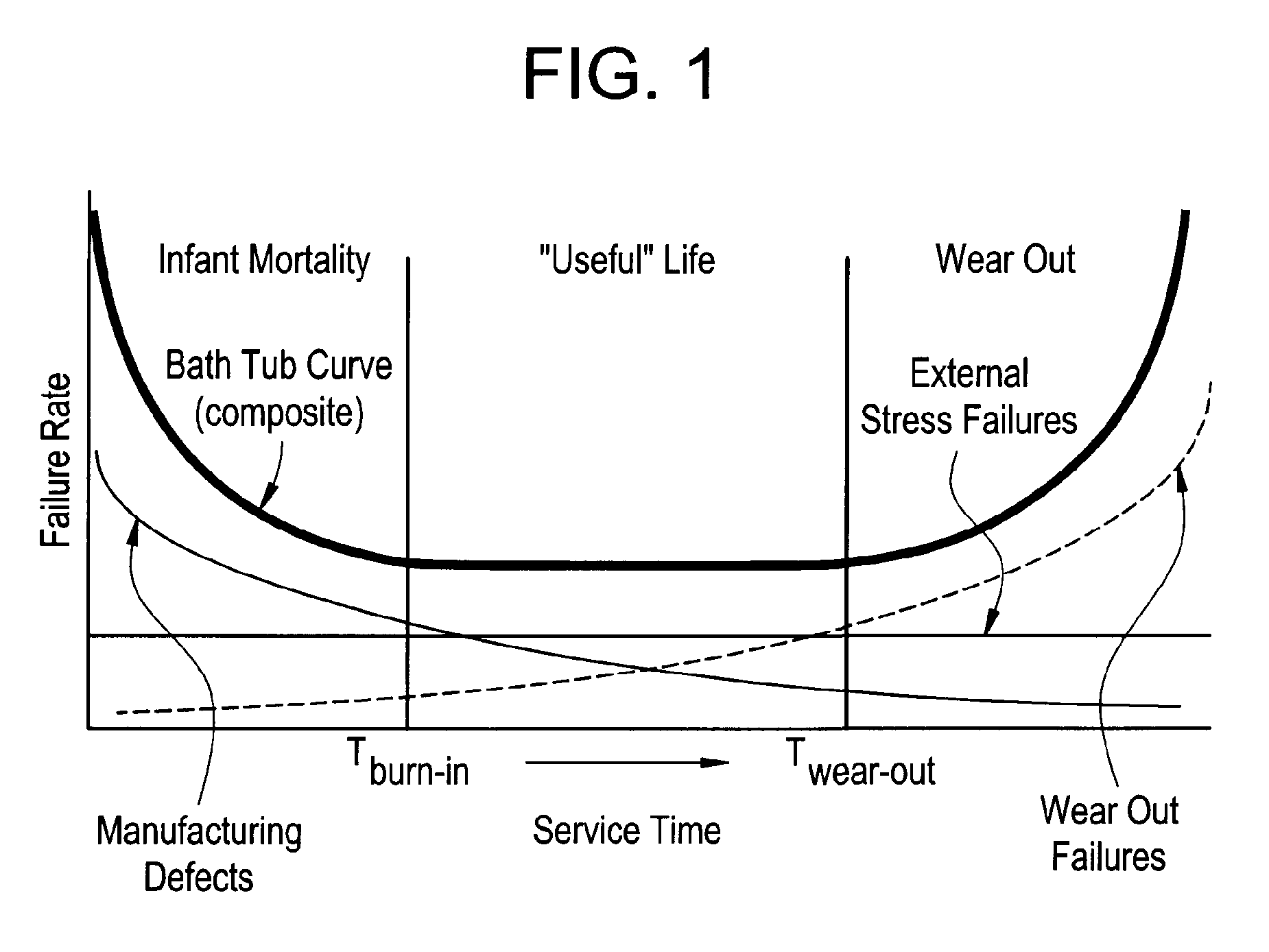

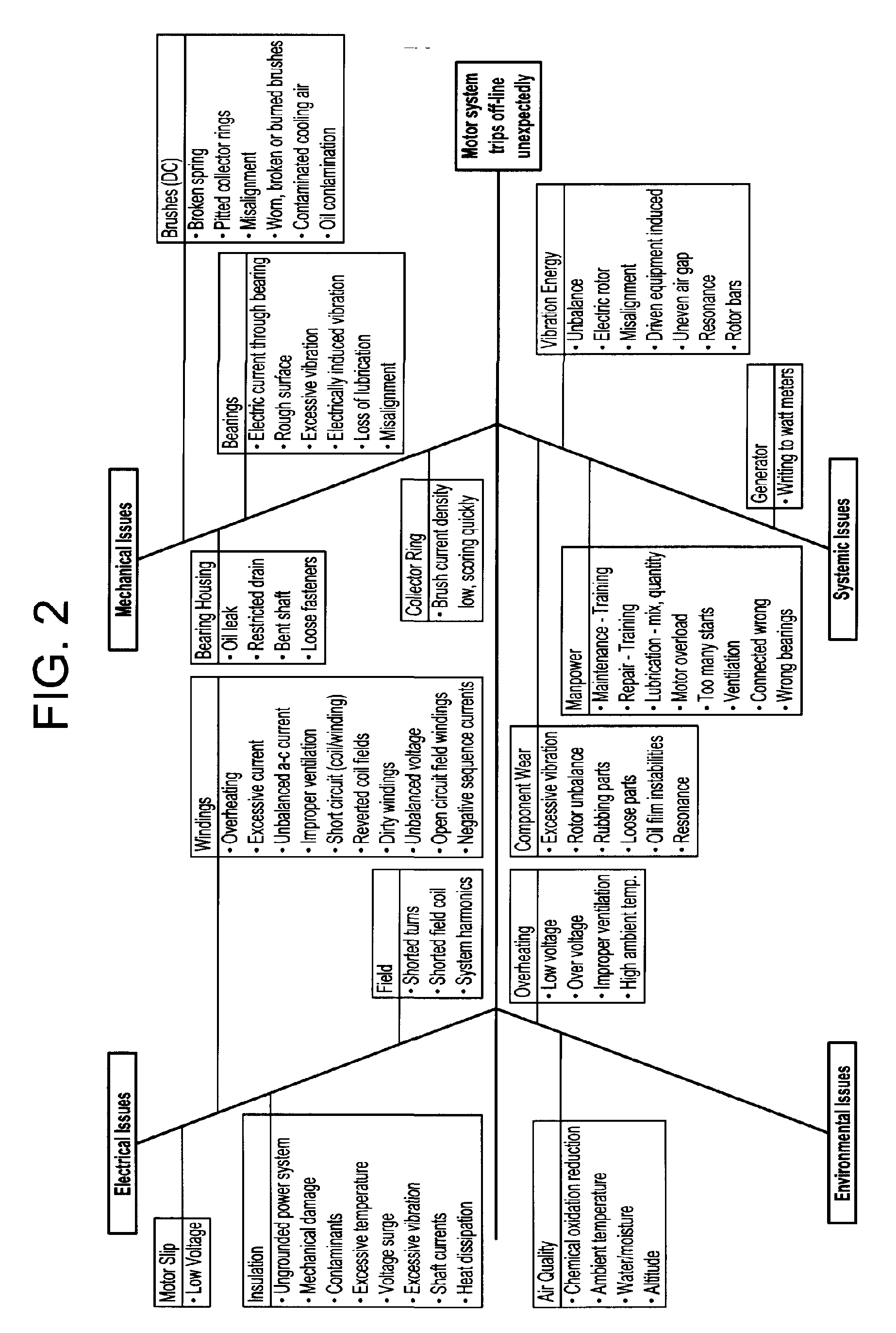

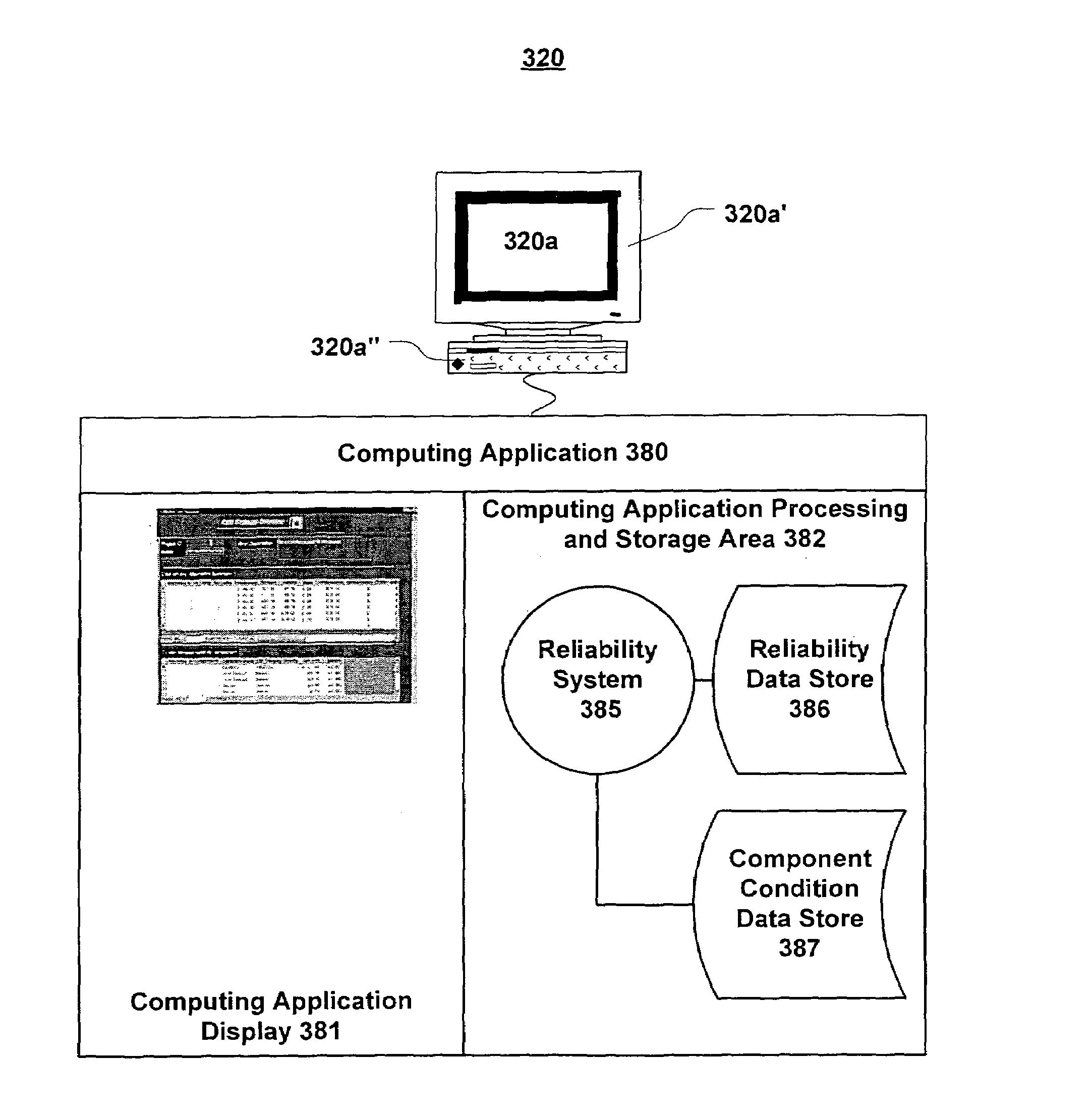

A method for determining reliability and a remaining time before failure with statistical confidence for a motor system includes acquiring historical motor data in a computer system, obtaining operational parameter data, uploading the operational parameter data to the computer system, performing failure analysis, developing a causal network, and performing an integrated causal network and reliability analysis of the motor system. The historical motor data corresponds to the motor system. The operational parameter data is obtained from sensors at the motor system. The sensors include a tan delta sensor. The failure analysis is performed based on a composite of reliability probability distributions corresponding to predetermined sub-populations of historical motor system failure causes. The causal network is developed for modeling reliability of one or more motor system components and assessing motor system component condition based on the causal network. Results from the performing failure analysis are integrated with results from the assessing motor system component condition based on the causal network to compute a quantitative value for a time remaining before failure with an ascertained statistical confidence.

Owner:GENERAL ELECTRIC CO

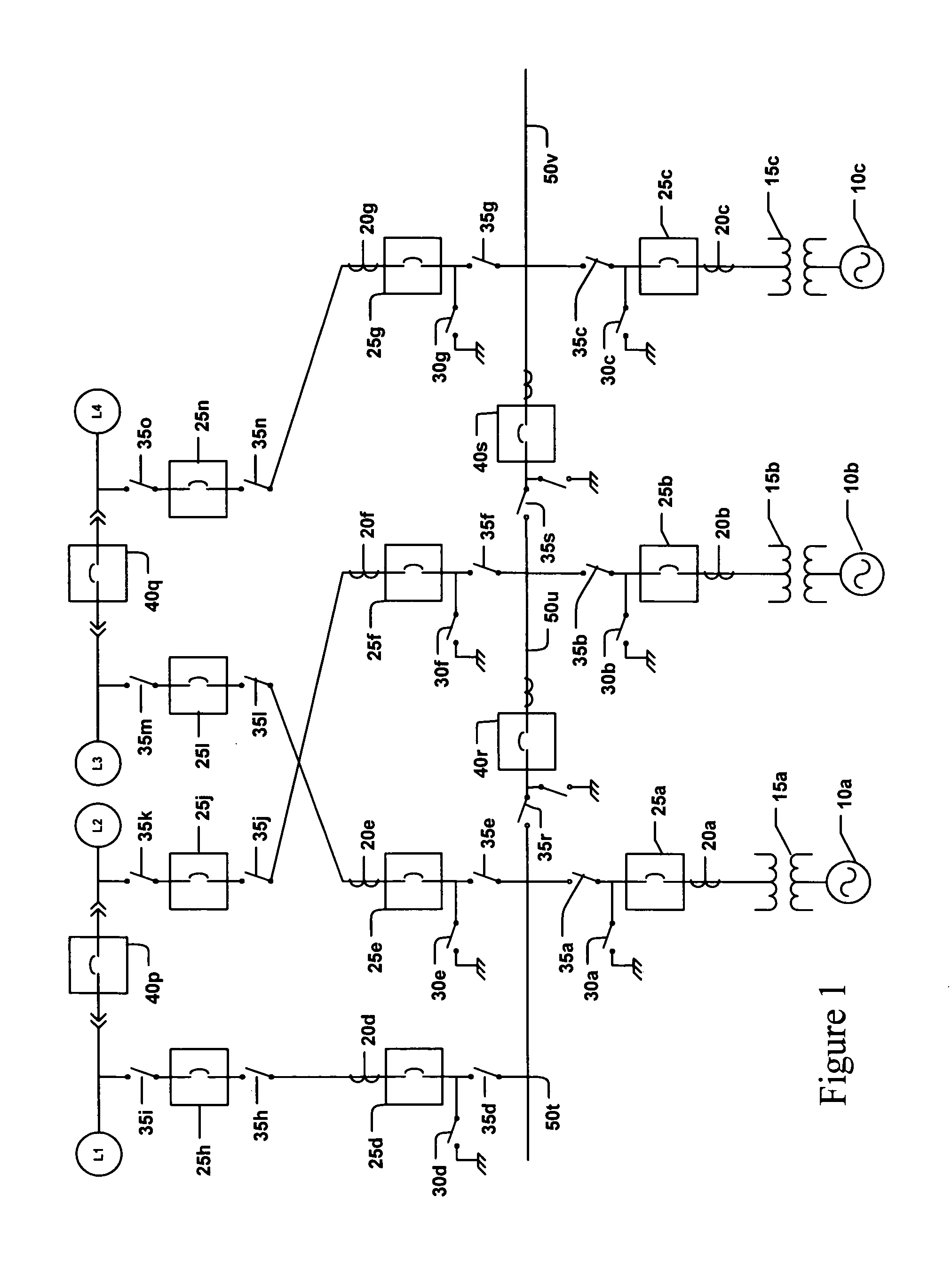

Failure rate adjustment for electric power network reliability analysis

Methodologies adjust a component failure rate for electric power network reliability analysis. A component may include subcomponents and the failure of each subcomponent may be feature dependent. Features are measurable or observable inputs, which can affect the life of one or more subcomponents. The failure rate of a particular component may be obtained according to its real conditions. The methodologies can be used to do condition-based reliability analysis for electric power networks, in order to obtain a maintenance / replacement / operation strategy.

Owner:HITACHI ENERGY SWITZERLAND AG

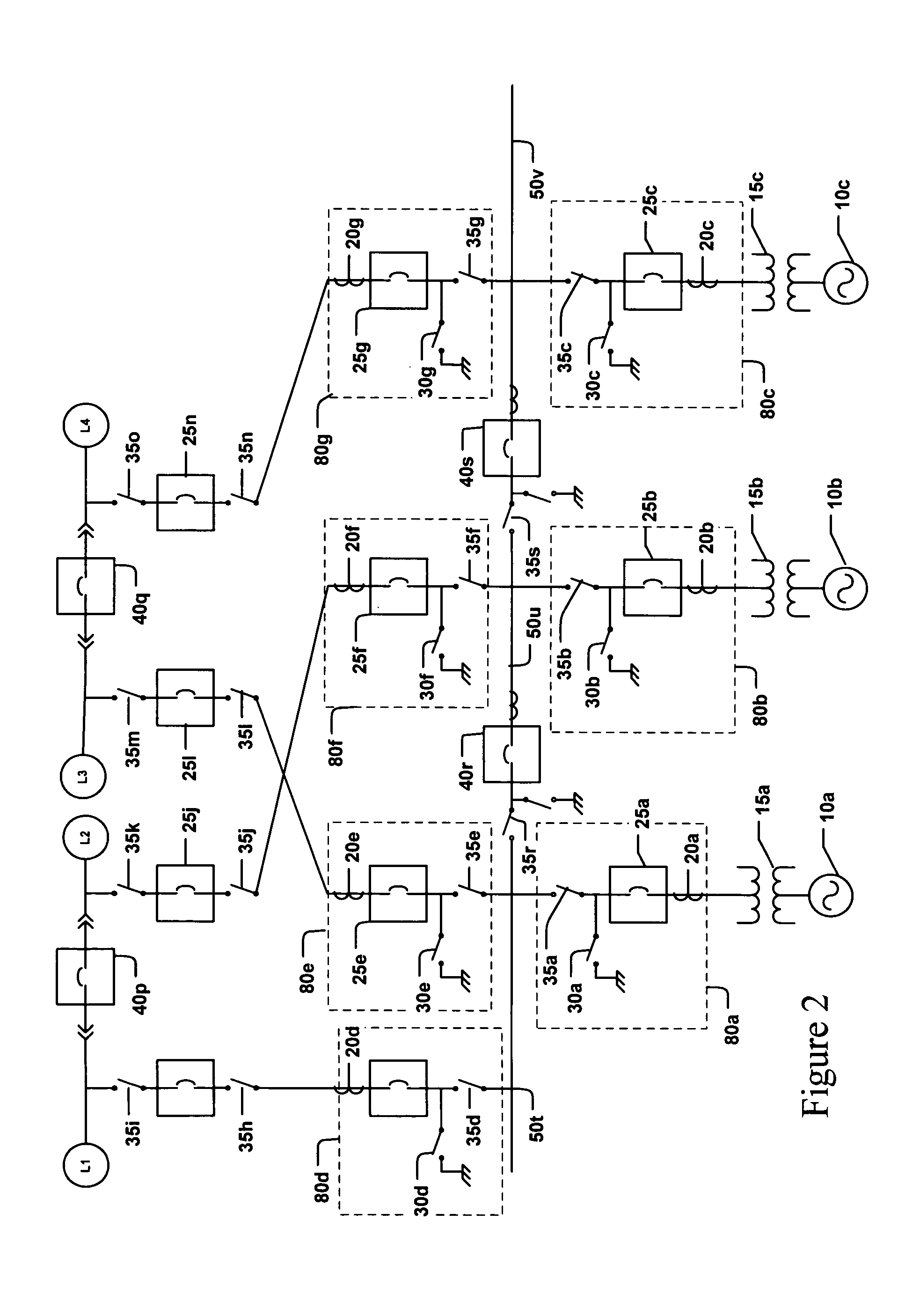

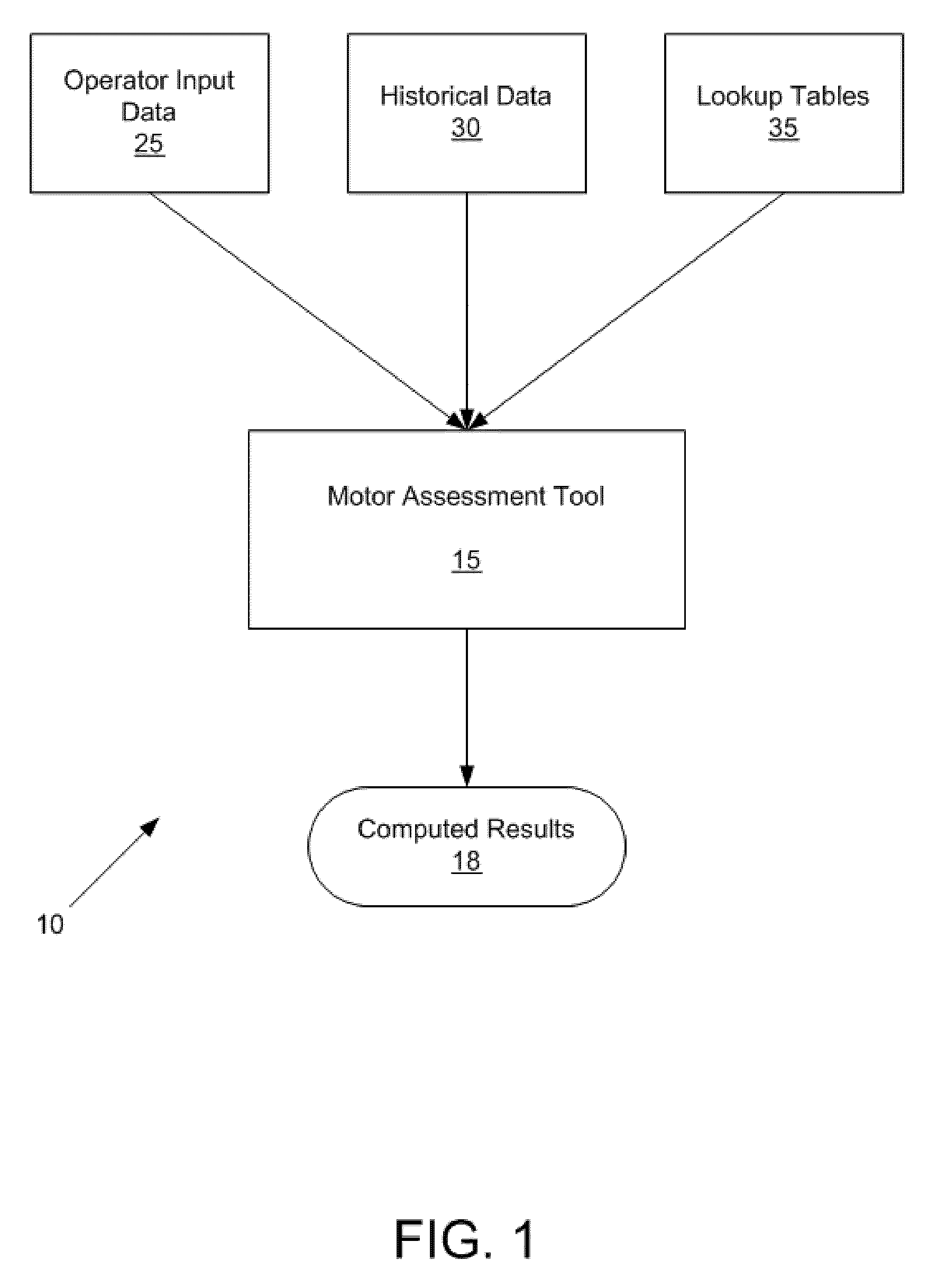

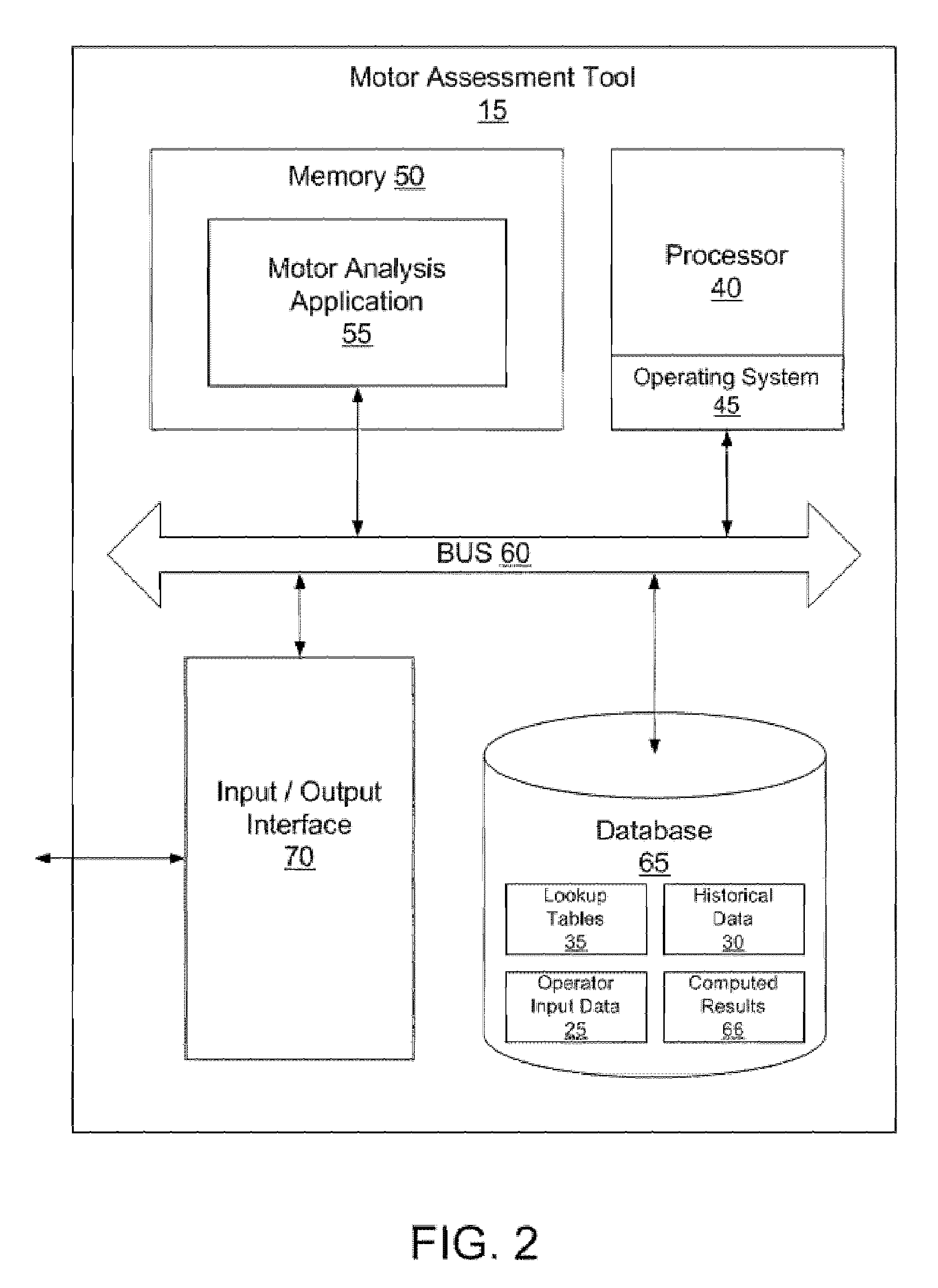

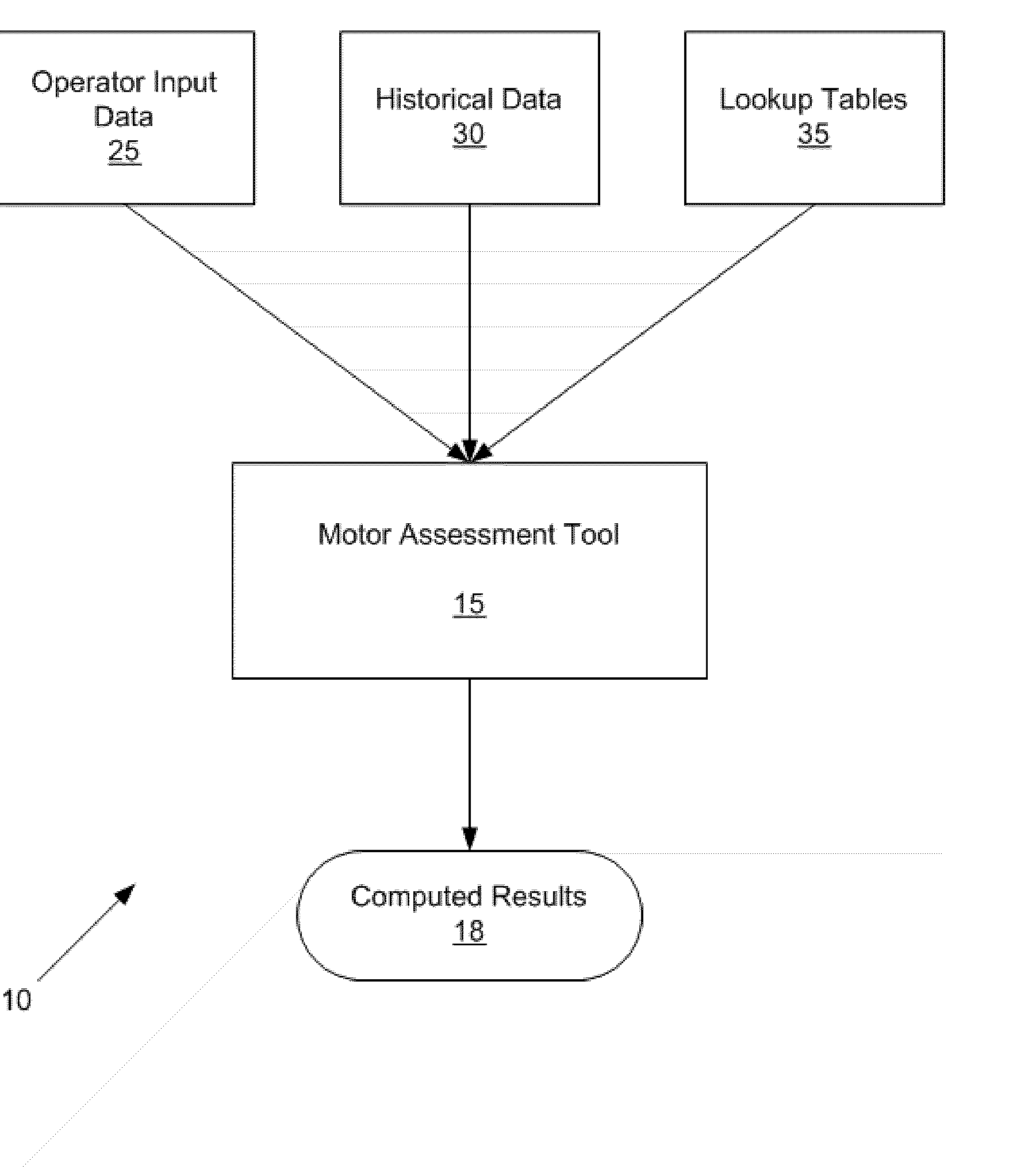

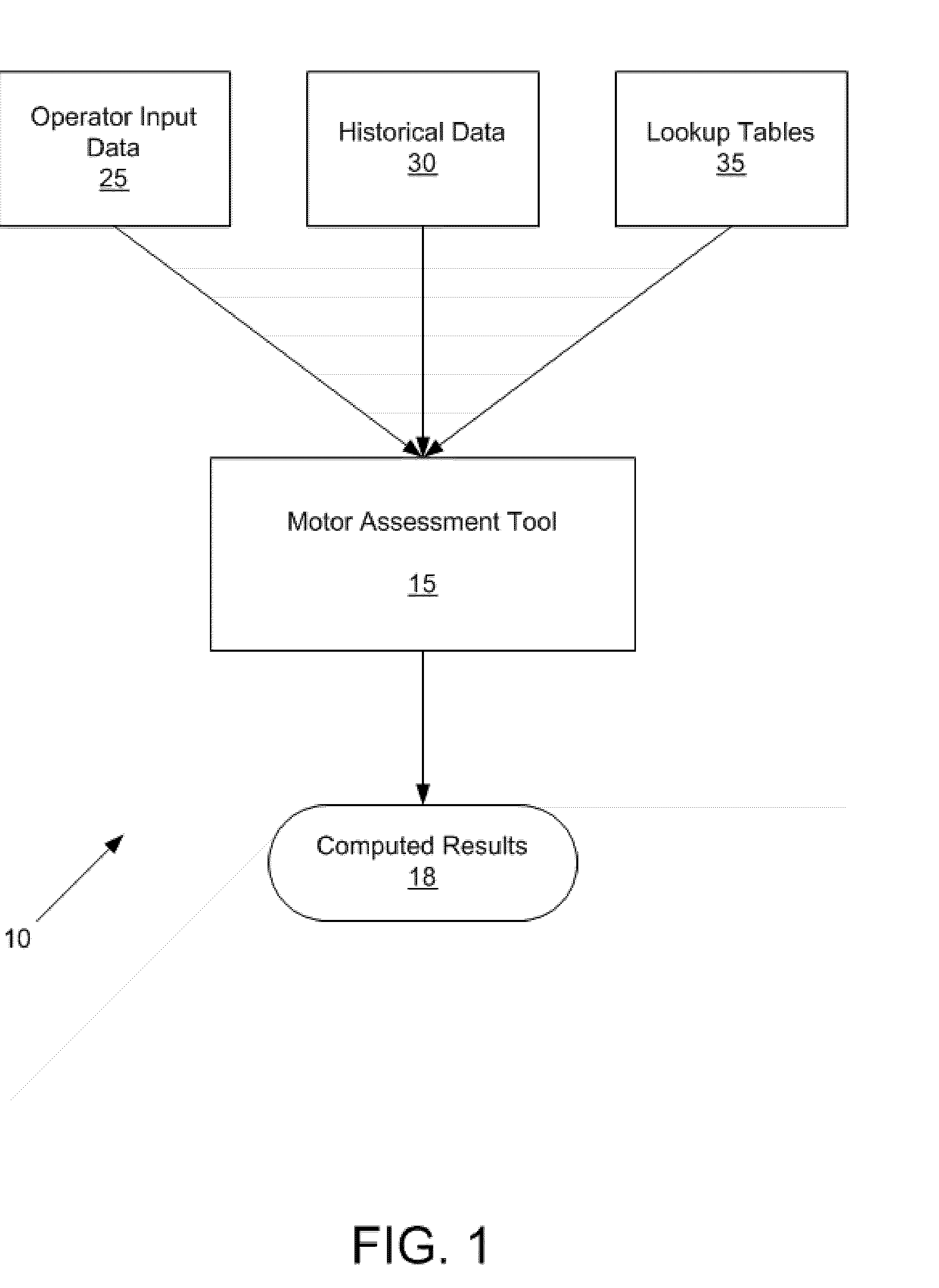

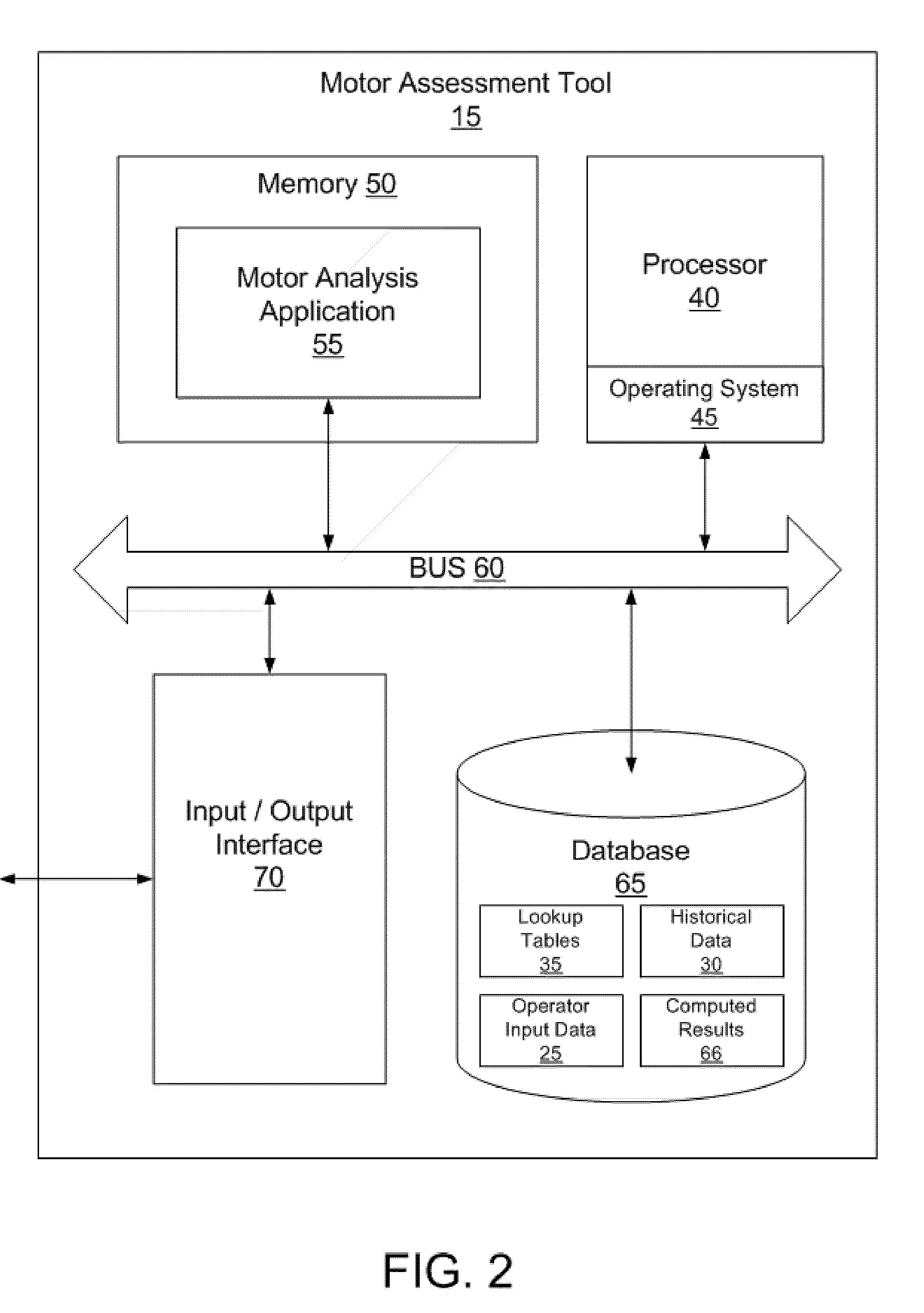

Systems, methods and computer program products for assessing the health of an electric motor

Systems, methods and computer program products calculate the life remaining in a machine, such as an electric motor, or the life remaining in individual components within a machine. Life remaining calculations are based on information collected from multiple sources, including operator input data, historical data, and lookup tables. Using this information the remaining useful life of the machine is calculated based on quantitative data, standard design life limits and on reliability analysis such that continuous historical parameter data is not required to analyze or assess the life of the machine.

Owner:GENERAL ELECTRIC CO

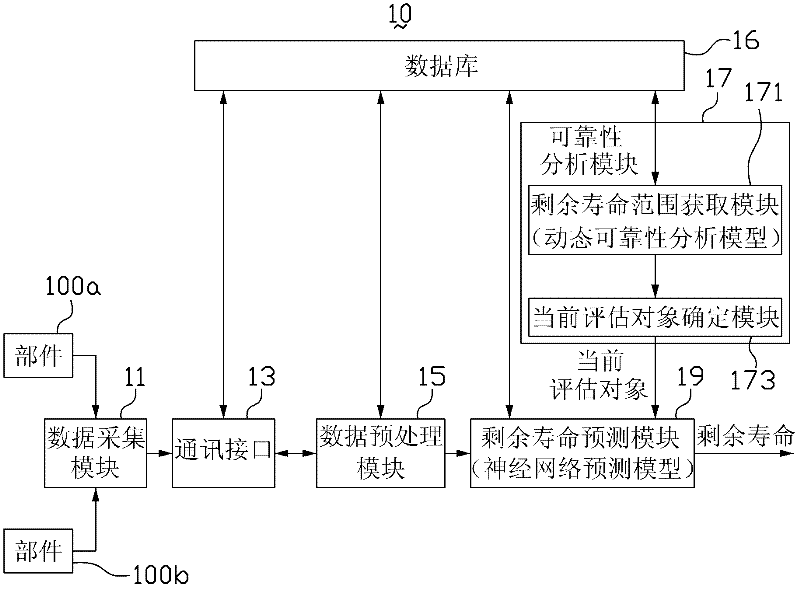

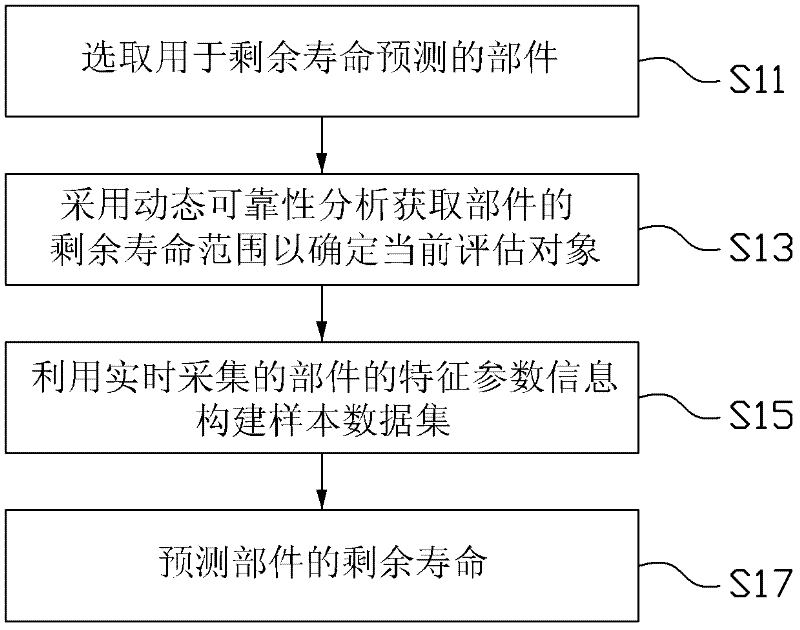

System and method for predicting residual life of part of engineering machine

InactiveCN102402727ARealize predictive maintenanceAccurately predict remaining lifeBiological neural network modelsForecastingData setPre treatment

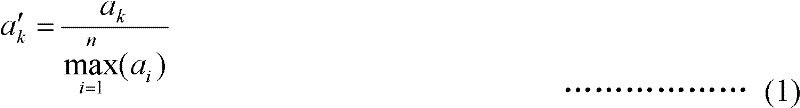

The invention relates to a system and a method for predicting residual life of a part of an engineering machine. The system comprises a reliability analysis module, a data pre-processing module and a residual life prediction module. The reliability analysis module comprises a residual life range acquisition module and a current evaluation object determining module which are respectively used for acquiring the residual life range of the part and determining whether the part serves as the current evaluation object. The data pre-processing module is used for receiving real-time acquired characteristic parameter information of the part serving as the current evaluation object, extracting characteristic parameter values in the characteristic parameter information and pre-processing the extracted characteristic parameter values to construct a sample data set. The residual life prediction module is used for acquiring predicted characteristic parameter values according to the sample data set by using a neural network prediction model and acquiring the residual life of the part by using the predicted characteristic parameter values and consulting the characteristic parameter values of the part in a fault state. By using the system and the method, the residual life of the part can be accurately predicted, and basis is provided for maintenance of the engineering machine.

Owner:ZOOMLION HEAVY IND CO LTD

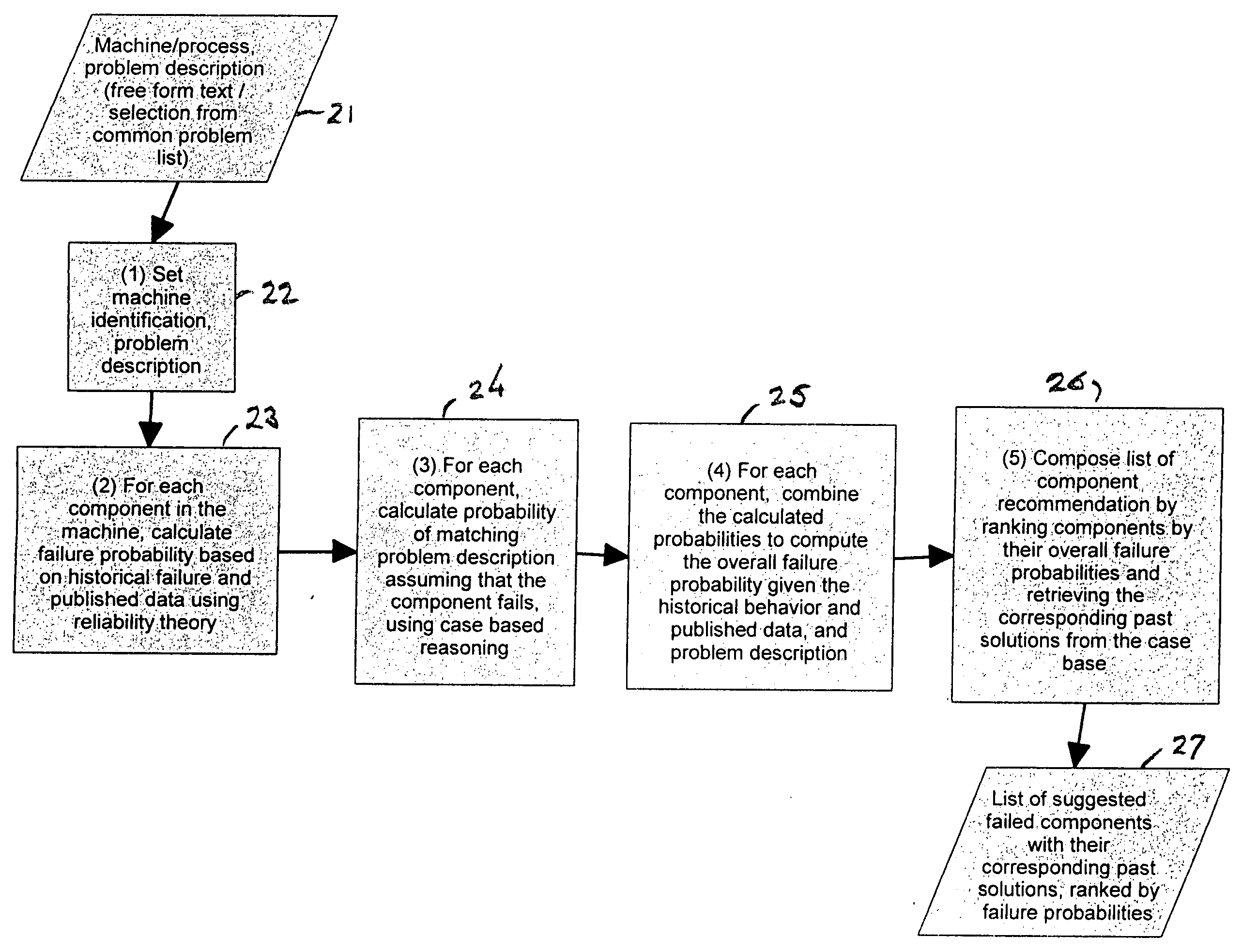

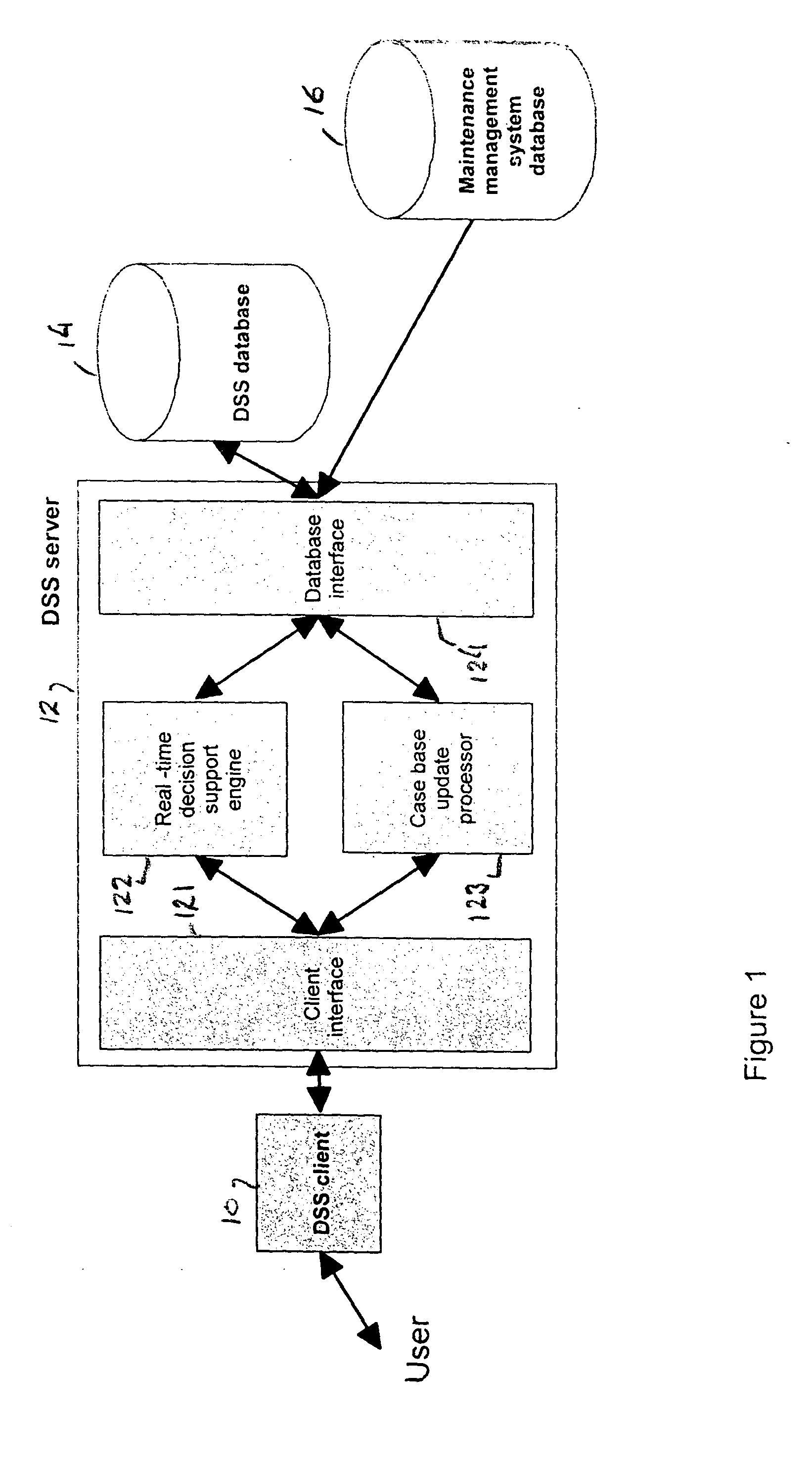

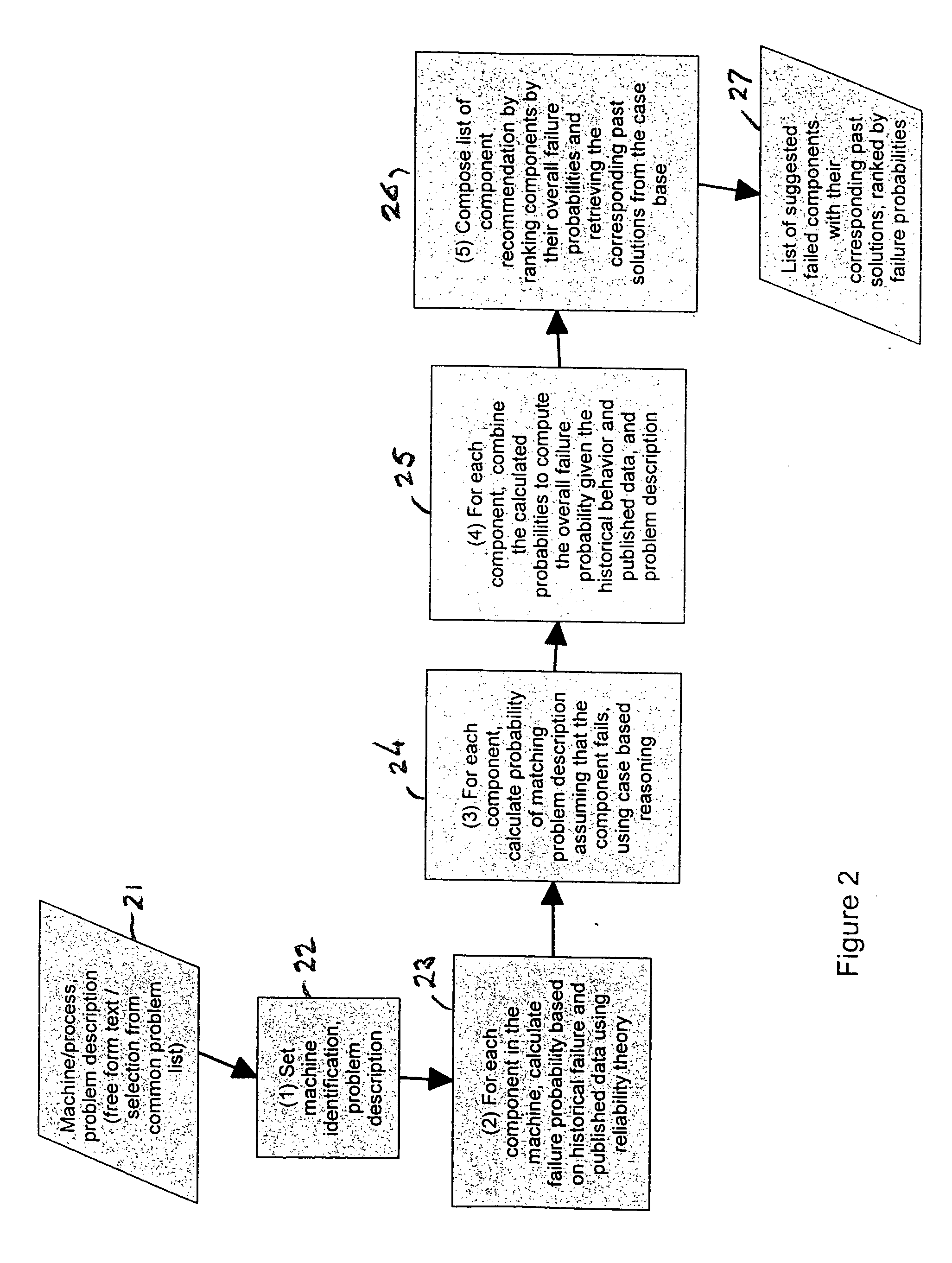

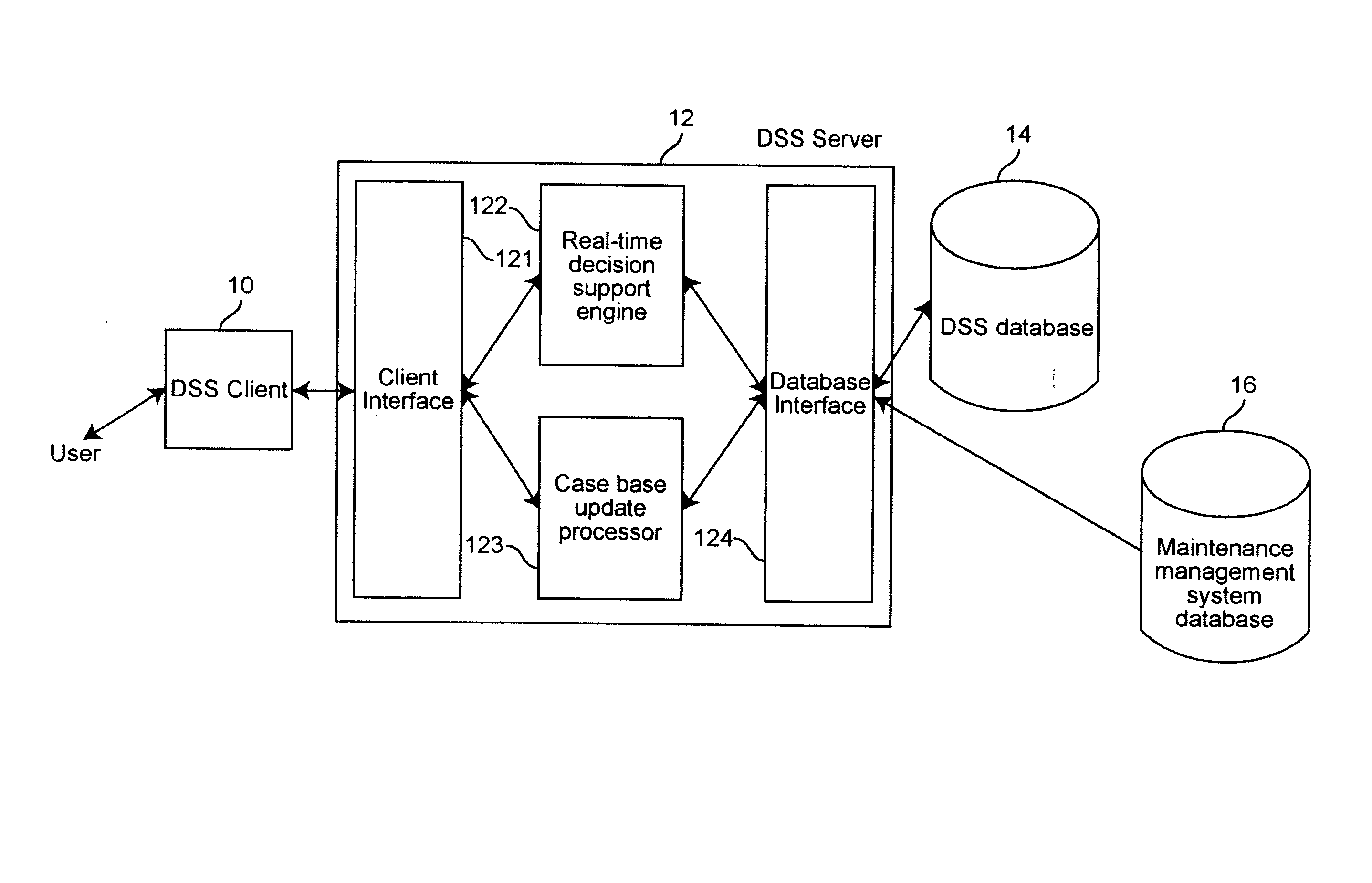

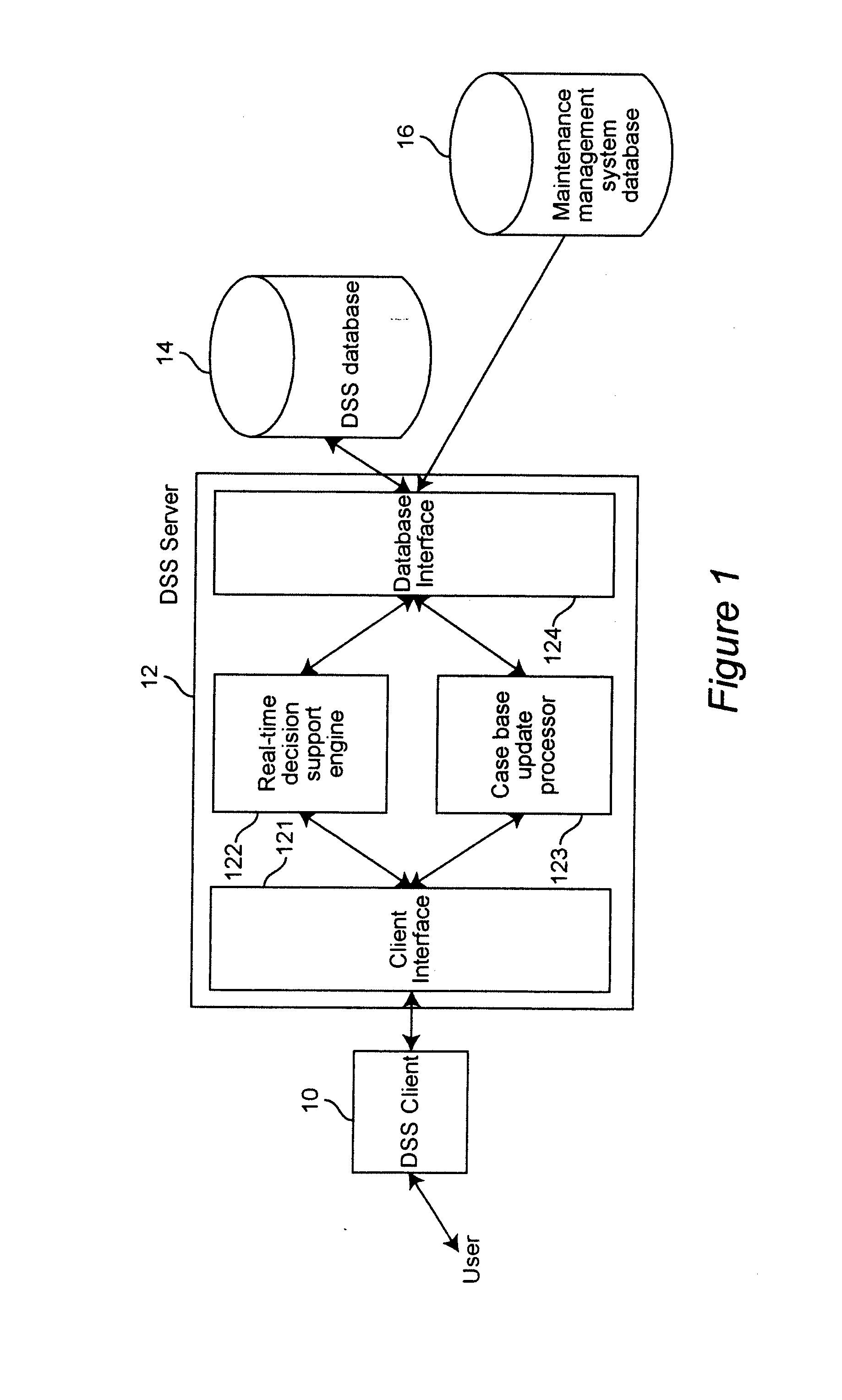

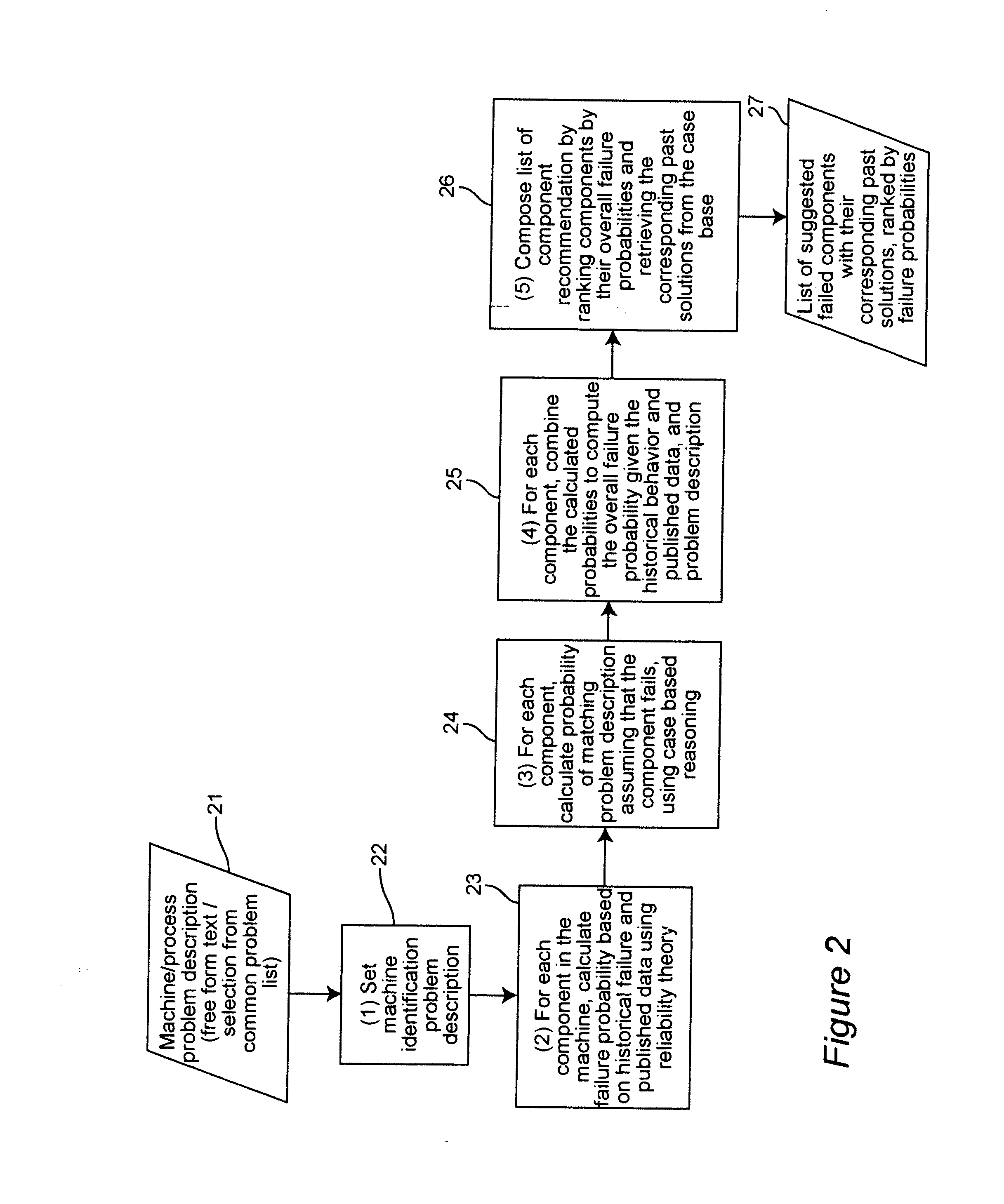

Diagnosis of equipment failures using an integrated approach of case based reasoning and reliability analysis

InactiveUS20050060323A1Shorten diagnostic timeIncrease probabilityData processing applicationsElectric testing/monitoringComputer scienceFailure probability

Equipment failures are diagnosed using an integrated approach of case-based reasoning (CBR) and statistical reliability analysis. The method outputs a single list of suggested failed components, ranked by an overall probability of failure, and their associated past solutions from the case base. The overall probability of failure is calculated using the combined logic of case based reasoning and statistical reliability analysis. The method is typically used in a real-time decision support system to aid equipment diagnosis by a maintenance technician working in the field.

Owner:GLOBALFOUNDRIES INC

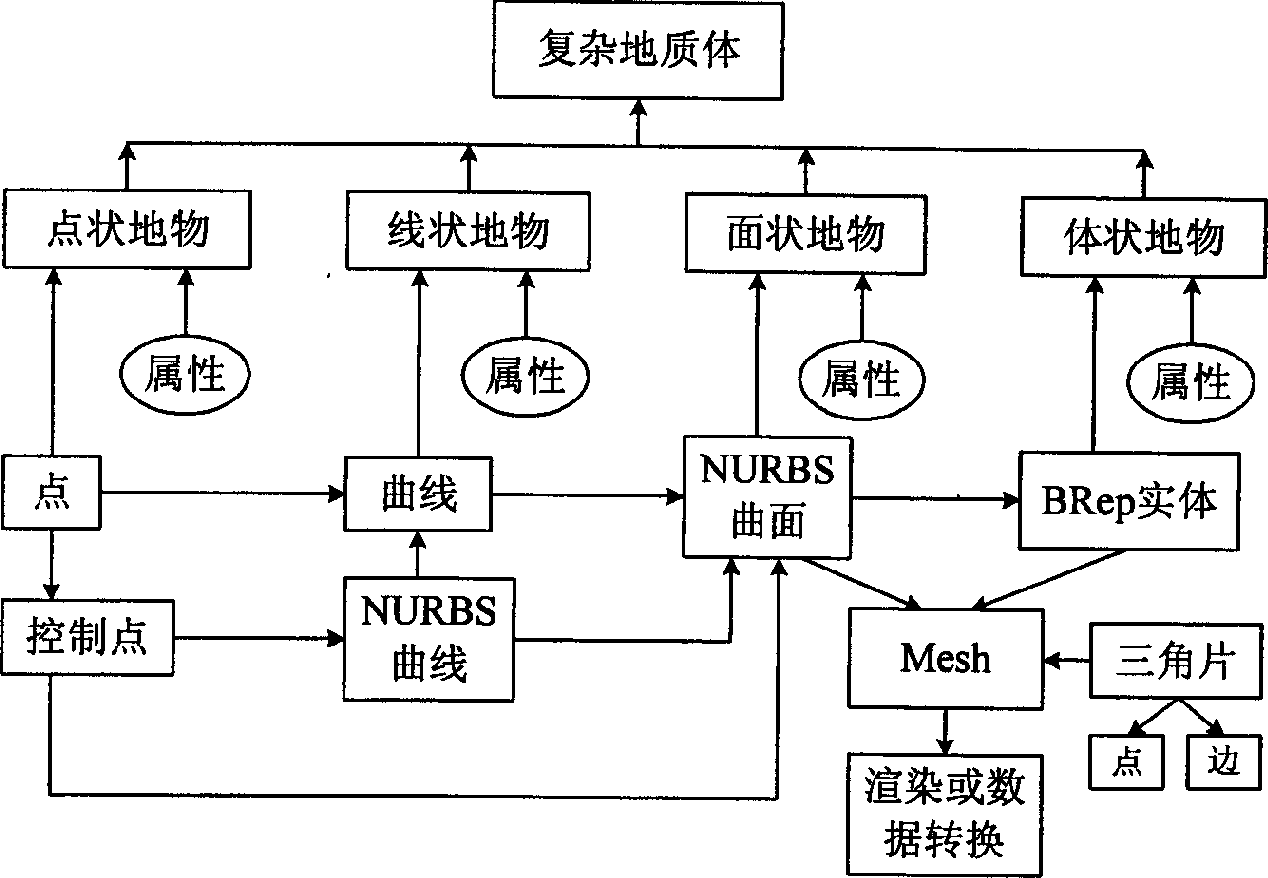

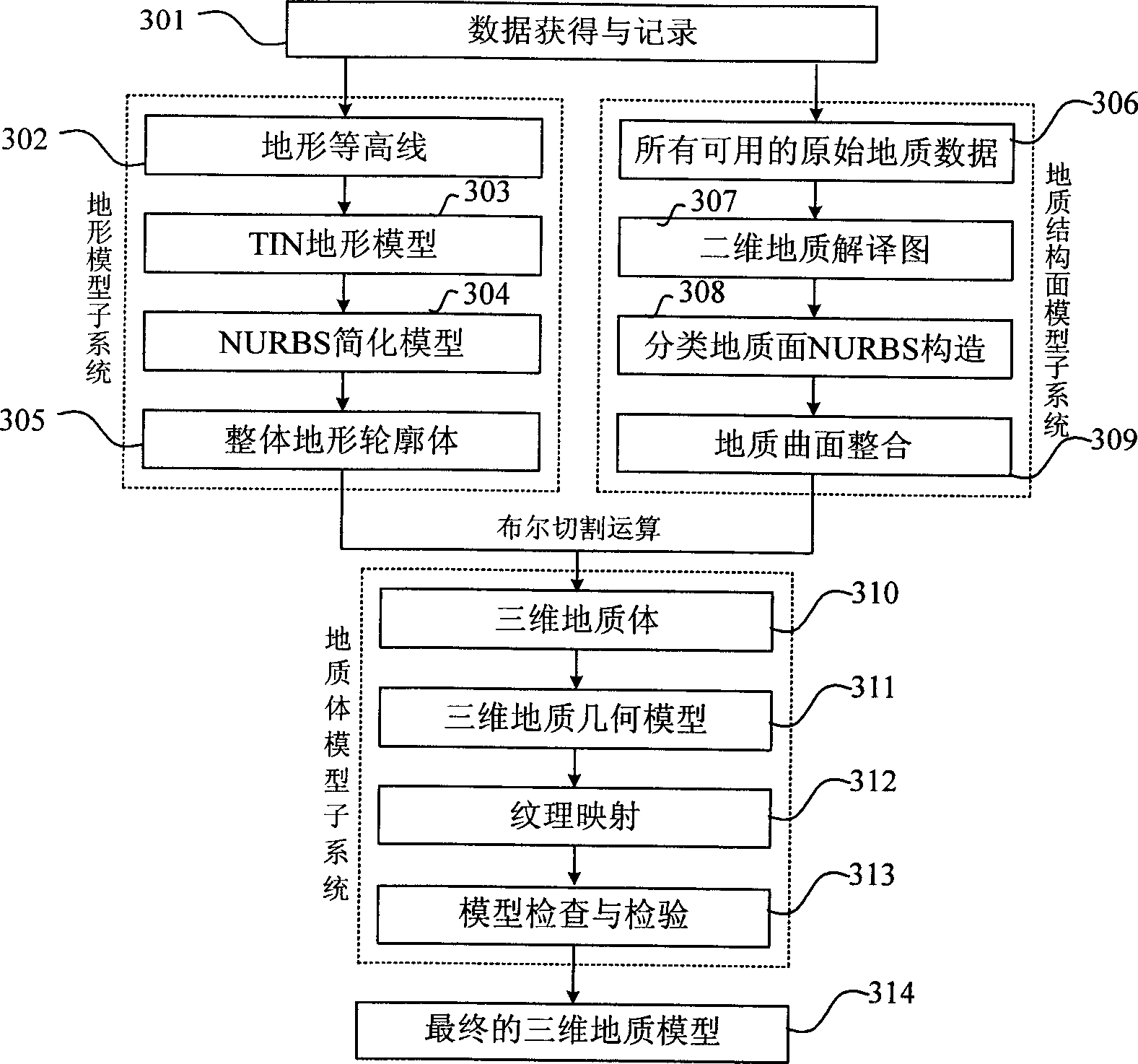

Three dimension uniform model construction method of water conservancy hydropower engineering geological information

InactiveCN1858803ASolve the problem of large storage capacitySolve the request3D modellingBoundary representationUnified Model

This invention relates to a structure and analysis method for geographical 3-D unified models of water conservancy and water and electricity engineering, which couples multi-source data by the mixed data structure of NURBS YIN and BRep to realize 3-D unified modeling to all modeling objects and analyze said 3-D model including: analyzing the space geographical structure of the coupled multi-source data, carrying out sorted geometry modeling based on the mixed data structure of the NURBS, TIN and the BRep, carrying out Boolean operation based on the space relation among them and analysis and test for reliability to finish the structure of the 3-D unified model and finish the geographical analysis to water conservancy and water electricity engineering.

Owner:TIANJIN UNIV

Diagnosis of equipment failures using an integrated approach of case based reasoning and reliability analysis

InactiveUS20070288795A1Increase probabilityReduce needData processing applicationsDigital data processing detailsComputer scienceFailure probability

Equipment failures are diagnosed using an integrated approach of case-based reasoning (CBR) and statistical reliability analysis. The method outputs a single list of suggested failed components, ranked by an overall probability of failure, and their associated past solutions from the case base. The overall probability of failure is calculated using the combined logic of case based reasoning and statistical reliability analysis. The method is typically used in a real-time decision support system to aid equipment diagnosis by a maintenance technician working in the field.

Owner:GLOBALFOUNDRIES INC

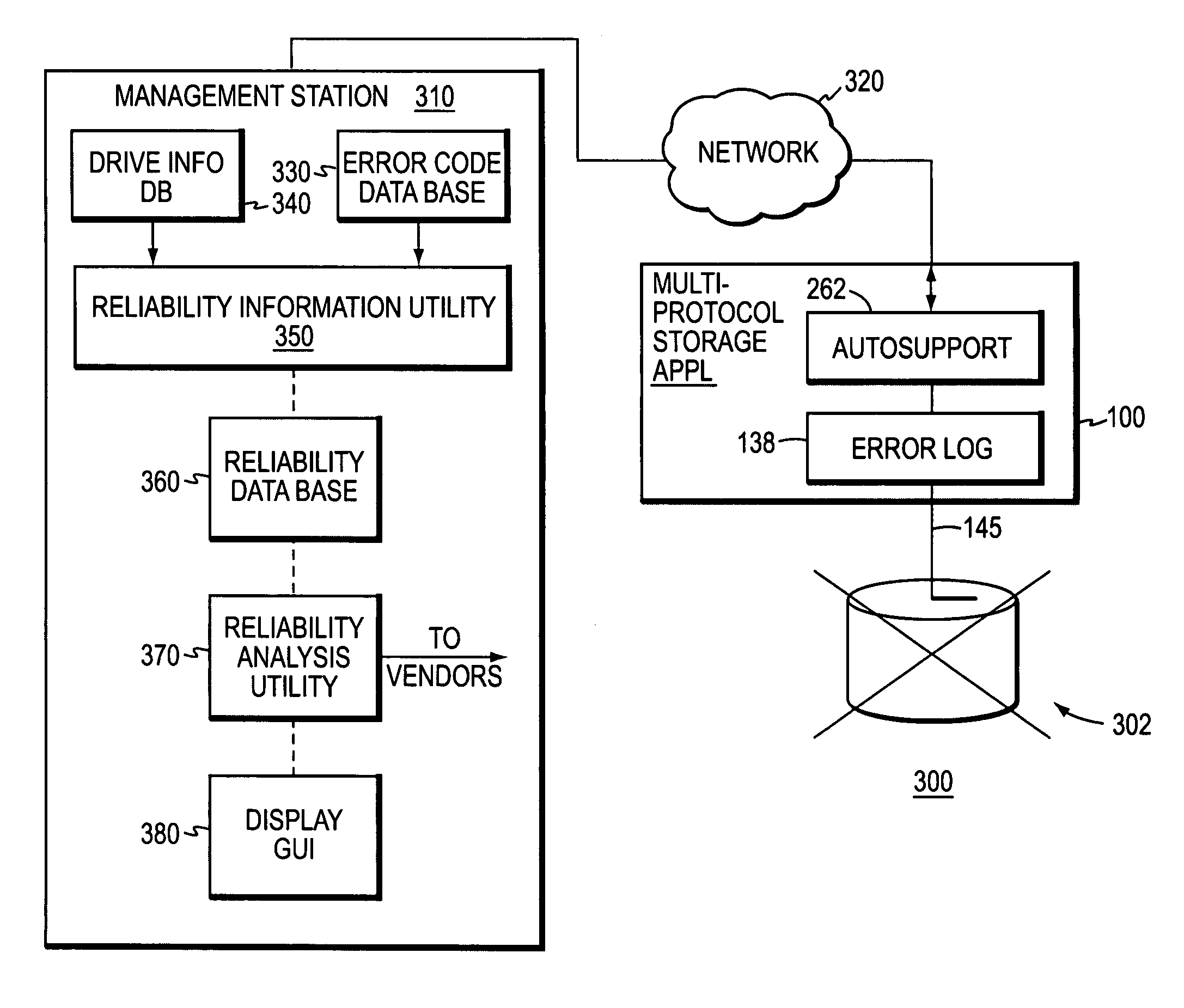

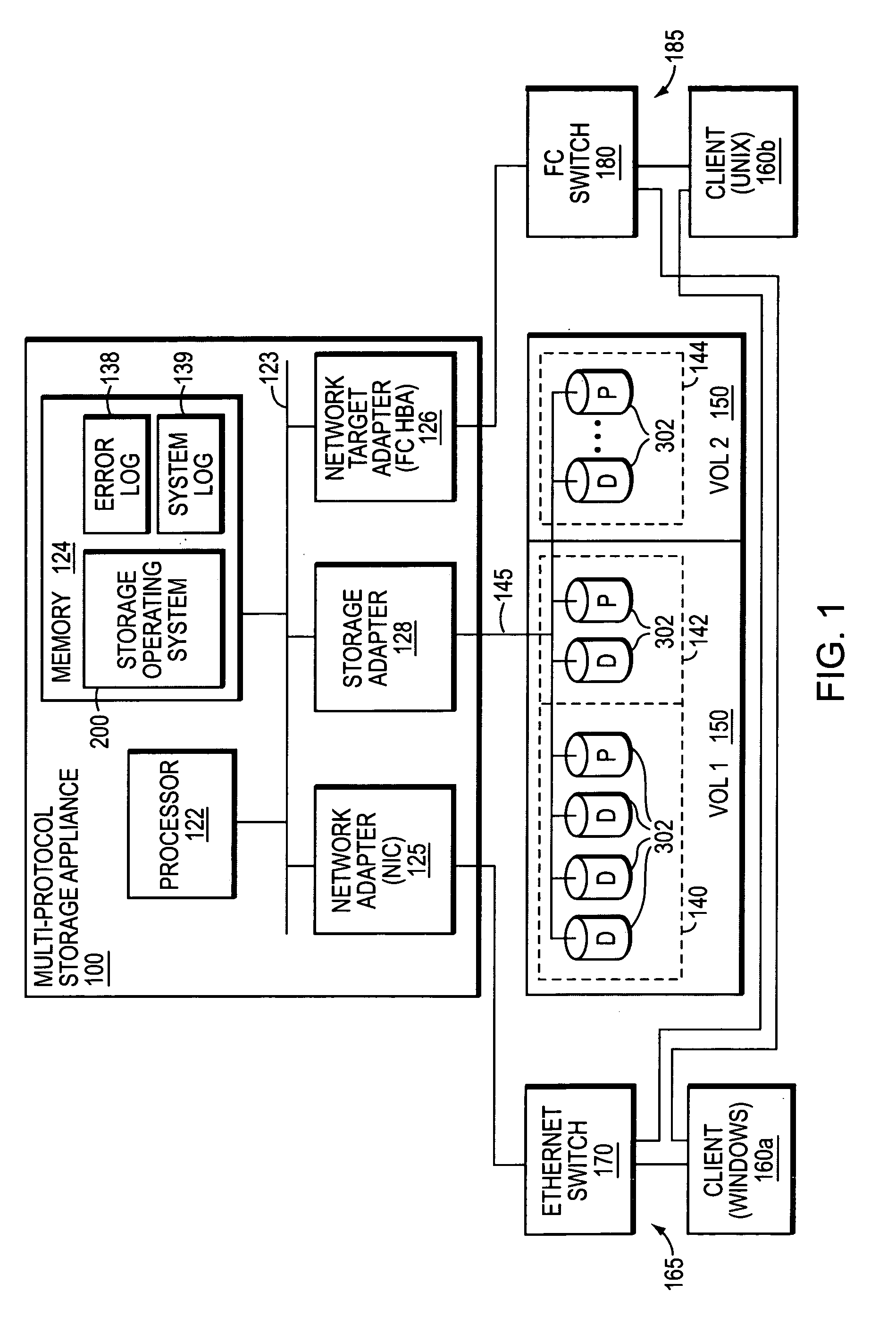

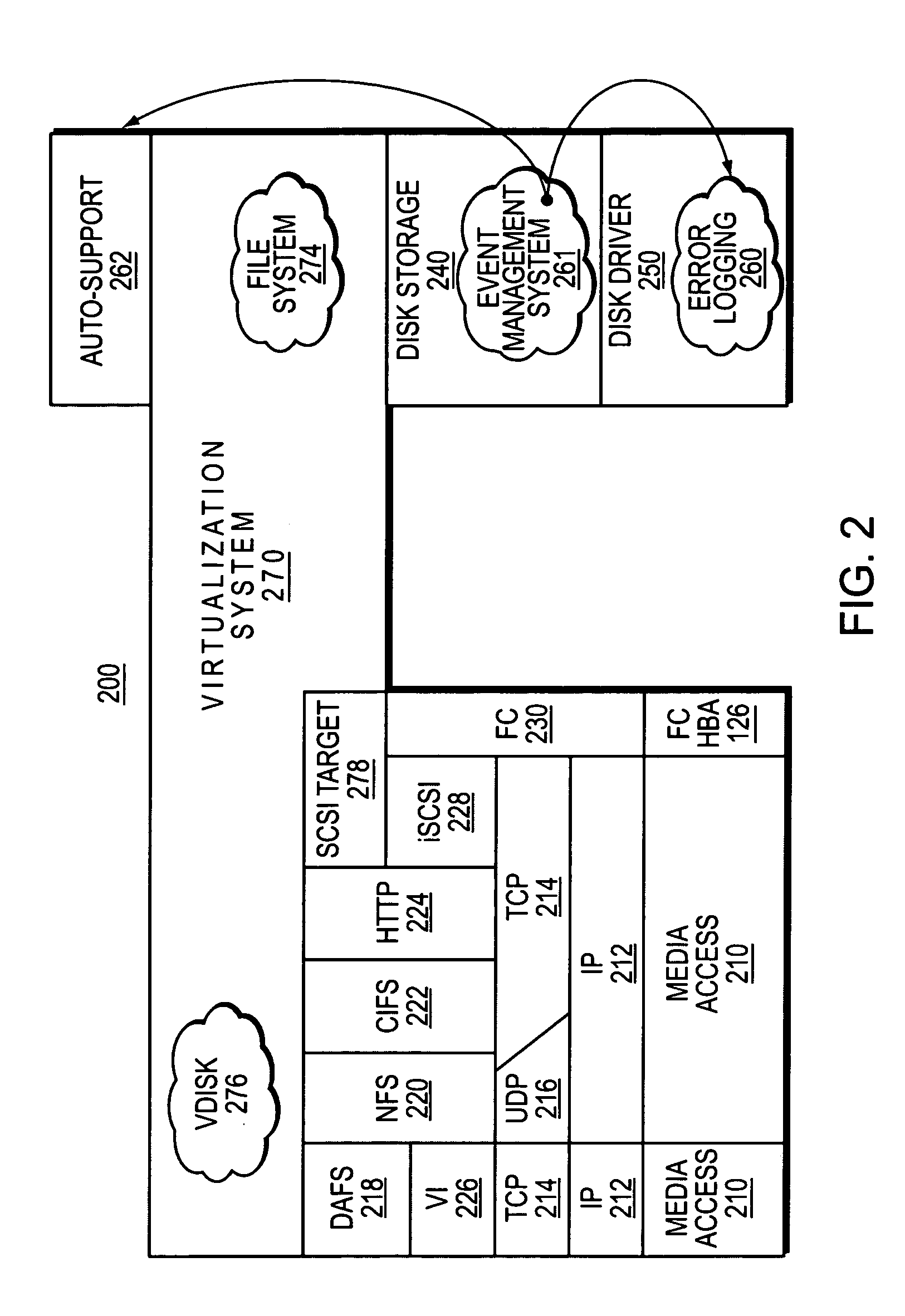

Method and system for reliability analysis of disk drive failures

ActiveUS7136768B1Improve disk drive reliabilityImprove driving reliabilityVehicle testingAerodynamic testingFault indicatorCode conversion

A method and system for performing reliability analysis of disk drive failure mechanisms is provided. The information for performing the analysis is obtained in accordance with the invention from a database generated from identification information stored about individual drives, and drive families, that are deployed in the field. An error database stores error codes that are issued by a disk drive upon a particular event. These error codes are reported to a storage system administrator and recorded in the error database. The disk drive information and the error codes are mapped, and error codes are translated into failure mechanisms for a particular drive family. An analysis is performed whereby a hazard rate plot is provided for either all failure indicators or selected failure indicators or subpopulations for a particular drive family over a given time.

Owner:NETWORK APPLIANCE INC

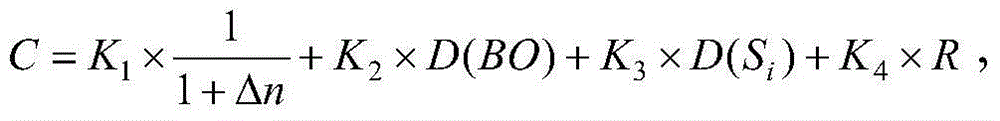

Route selection method under reliability restraint condition

InactiveCN104468355AMeet reliability requirementsReliable reference dataData switching networksResource utilizationComputer science

The invention relates to the field of route selection, in particular to a route selection method under the reliability restraint condition. The method includes the obtaining step for obtaining topological information, the analyzing step for conducting reliability analysis on node equipment and optical cable links according to the topological information, the selecting step for selecting respective shortest routes for different types of services to form the shortest route list with the bandwidth resource utilization rate as the main measurement according to the result of reliability analysis, and the determining step for conducting inspection and comparison on the shortest route list for different service types according to the distribution condition of the services of the types on the basis of the service balance degree and the route reliability and selecting the shortest route with the highest reliability according to service requirements. According to the route selection method, the network bandwidth resource utilization rate is taken into consideration, and meanwhile the reliability restraint condition of nodes and the links is introduced in; the shortest route is selected, and meanwhile the requirement for the route reliability of the services is met.

Owner:STATE GRID CORP OF CHINA +1

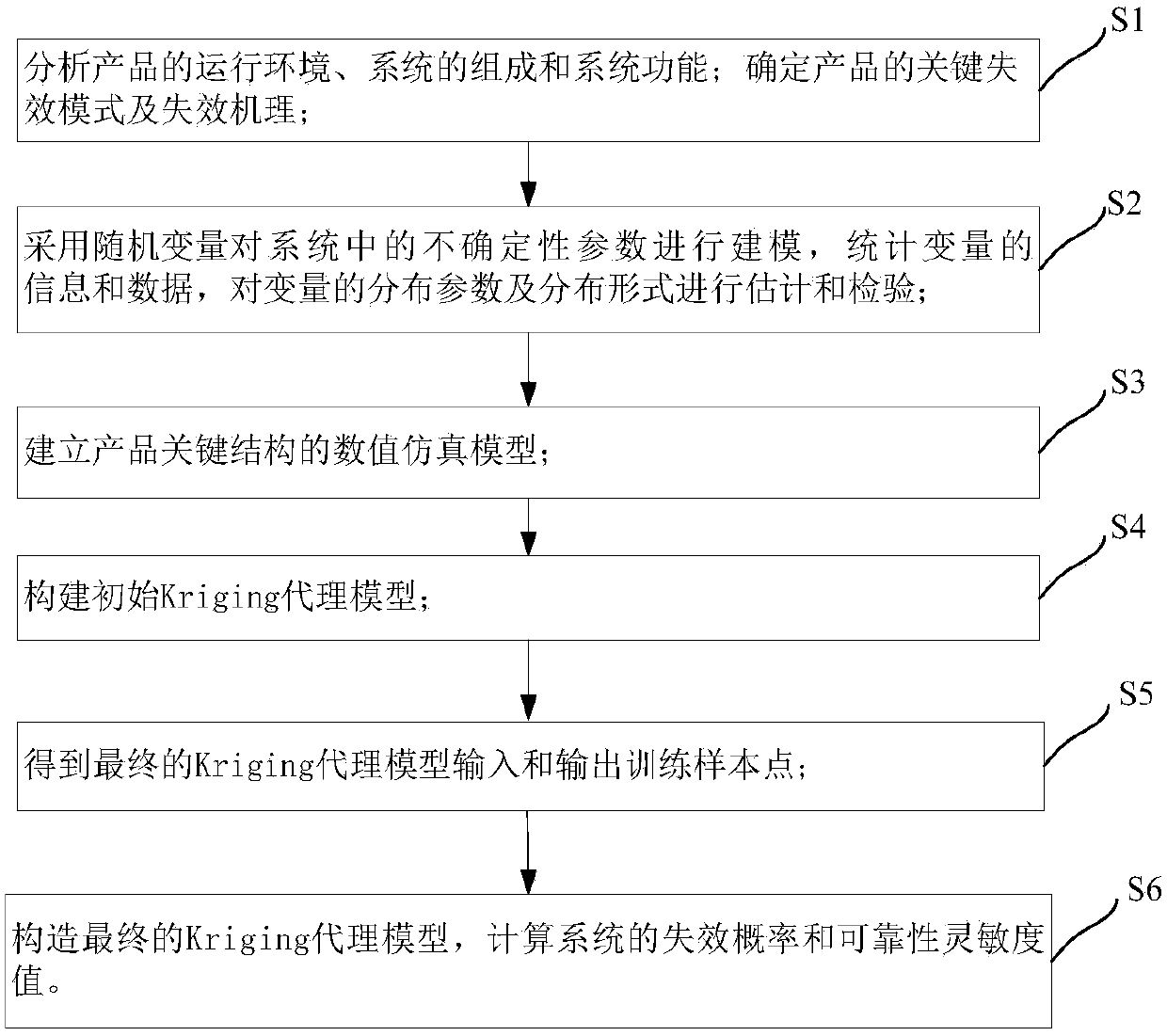

Structural reliability analysis method based on self-adaptive agent model

InactiveCN107563067AHigh precisionOvercome limitationsSpecial data processing applicationsStructural reliabilityAlgorithm

The invention discloses a structural reliability analysis method based on a self-adaptive agent model. The method includes the following steps that firstly, according to distribution form of random variables, a small amount of initial input sample points are generated, and the response value of the system is calculated, and the obtained initial input and output sample points serve as initial training sample points for building a Kriging agent model; secondly, a newly added training sample point selection criterion is created, according to the distribution of random variables, a large amount ofrandom candidate training samples are generated and substitute into a learning function for calculation, candidate sample points with the smallest learning function value serve as newly added training sample points, and loop iteration is conducted until convergence occurs; finally, according to obtained final input and output training sample points, a final agent model is constructed, a Monte Carlo simulation method is adopted, the system failure probability and the reliability sensitivity are calculated, and the problems that an existing method only considers the limitations of the characteristics of sample points in an input space, and the accuracy is low and the calculation amount is large in the reliability analysis are solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

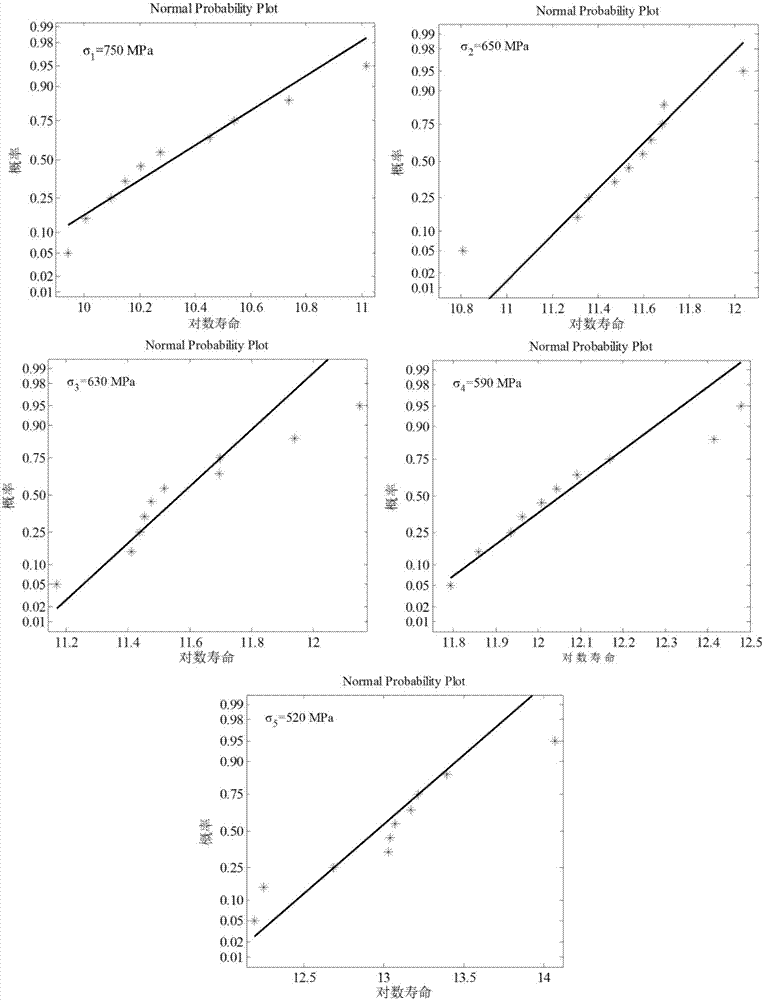

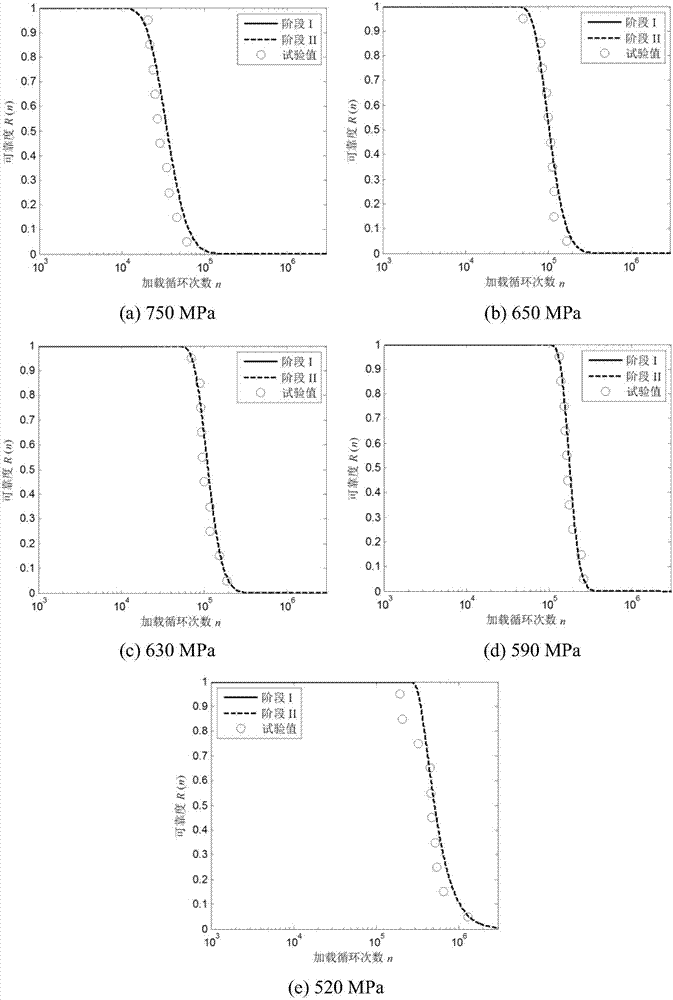

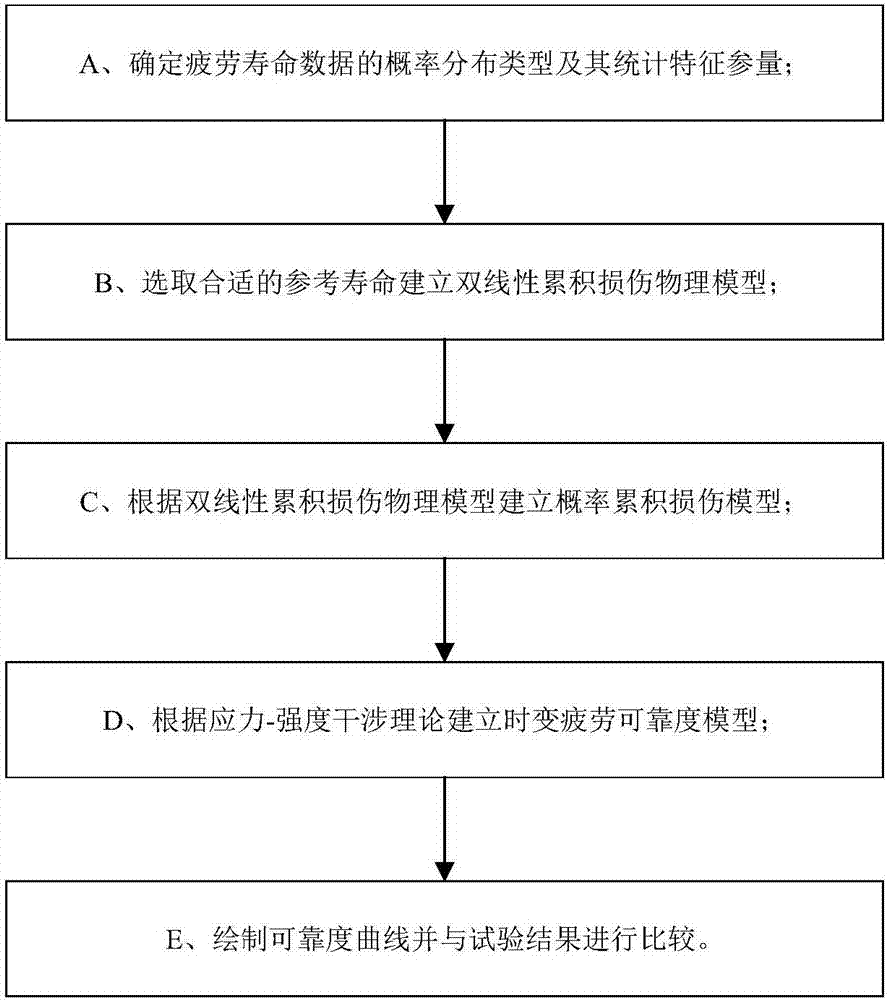

Time-dependent fatigue reliability analysis method based on bilinear cumulative damage

InactiveCN107103140AReflect time-varying characteristicsAchieving Reliability PredictionGeometric CADDesign optimisation/simulationFatigue loadingPhysical model

The invention discloses a time-dependent fatigue reliability analysis method based on bilinear cumulative damage. The method includes the steps that 1, the probability distribution type and statistical characteristic parameter of fatigue life data are determined; 2, the appropriate reference life is selected, and a bilinear cumulative damage physical model is built; 3, according to the bilinear cumulative damage physical model, a probability cumulative damage model is built; 4, according to the stress-strength interference theory, a time-dependent fatigue reliability model is built; 5, a reliability curve is drawn and compared with an experimental result; the characteristics of a crack initiation stage and a crack propagation stage in the fatigue failure process and the randomness in the damage accumulation process are comprehensively considered, the bilinear damage theory serves as a modeling base, the probability cumulative damage model is built, through the combination with the stress-strength interference theory, the time-dependent fatigue reliability model based on cumulative damage and critical damage is built, the time-varying characteristics of fatigue loading and the dynamic behavior of the damage accumulation process are reflected, and the reliability prediction in the whole fatigue life cycle is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

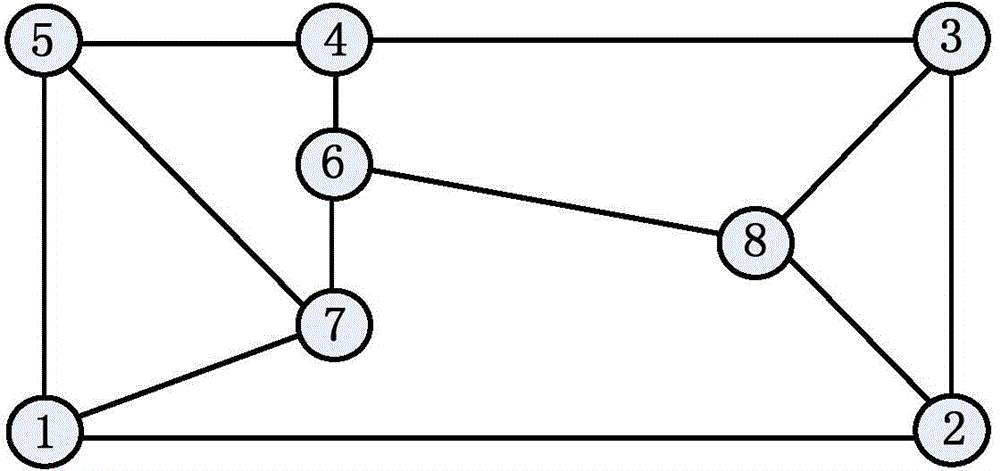

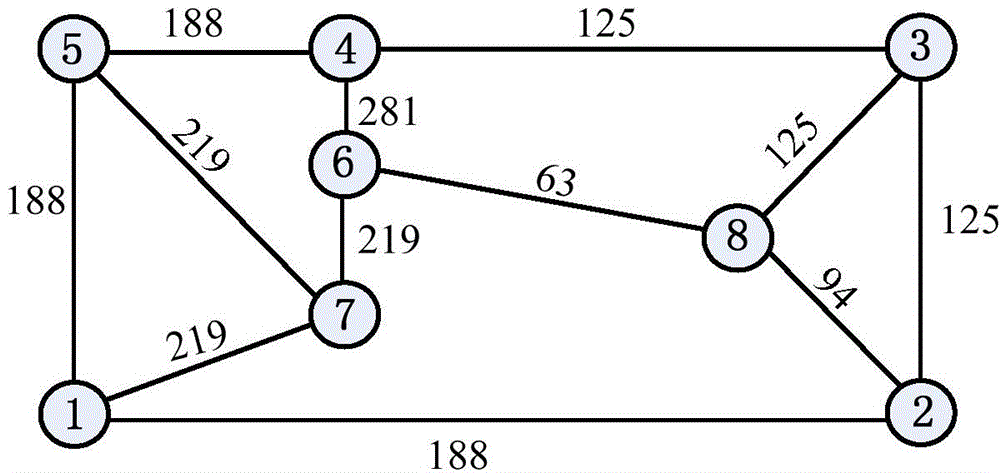

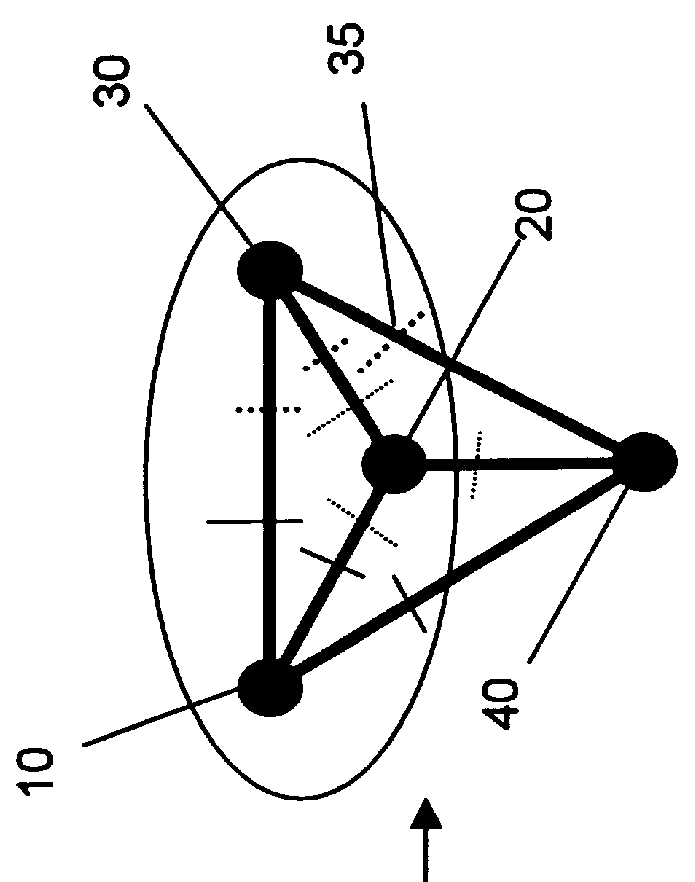

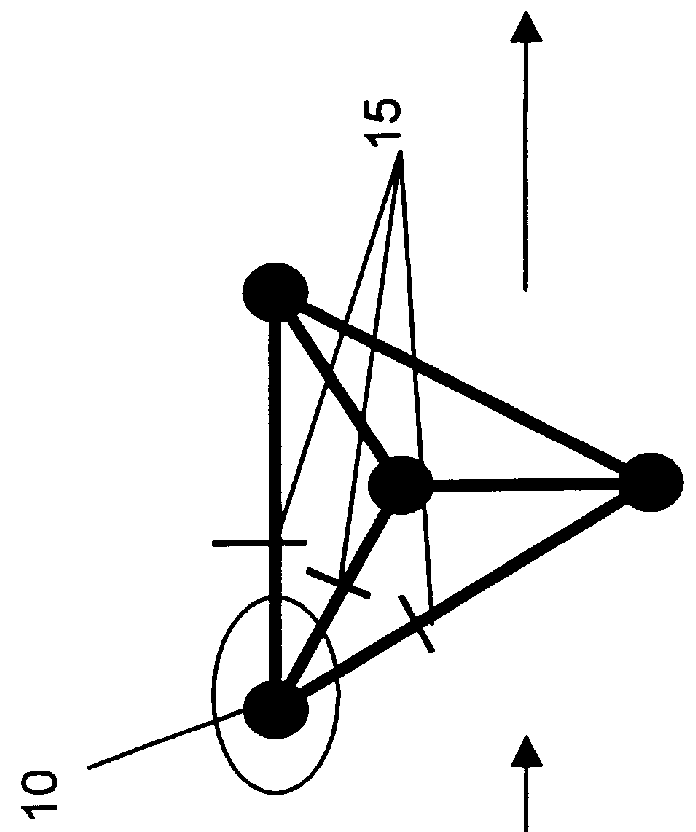

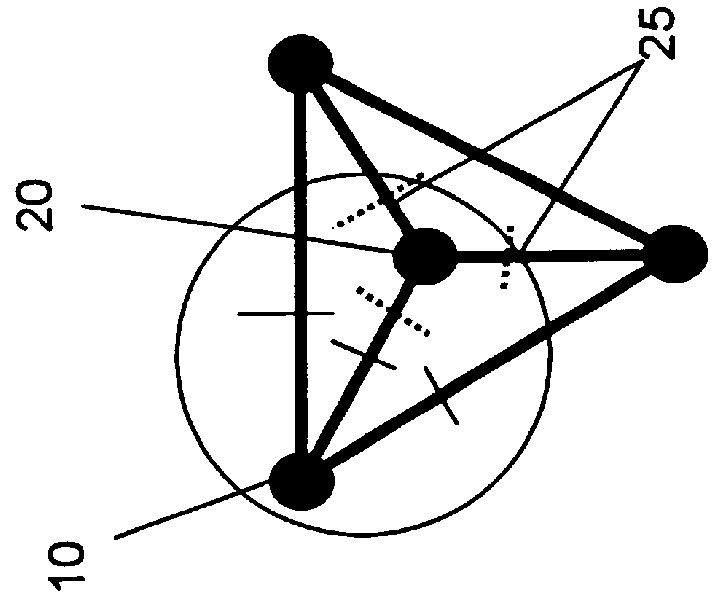

Cut set-based risk and reliability analysis for arbitrarily interconnected networks

InactiveUS6125453AError detection/correctionMultiple digital computer combinationsNODALPlanar network

Method for computing all-terminal reliability for arbitrarily interconnected networks such as the United States public switched telephone network. The method includes an efficient search algorithm to generate minimal cut sets for nonhierarchical networks directly from the network connectivity diagram. Efficiency of the search algorithm stems in part from its basis on only link failures. The method also includes a novel quantification scheme that likewise reduces computational effort associated with assessing network reliability based on traditional risk importance measures. Vast reductions in computational effort are realized since combinatorial expansion and subsequent Boolean reduction steps are eliminated through analysis of network segmentations using a technique of assuming node failures to occur on only one side of a break in the network, and repeating the technique for all minimal cut sets generated with the search algorithm. The method functions equally well for planar and non-planar networks.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

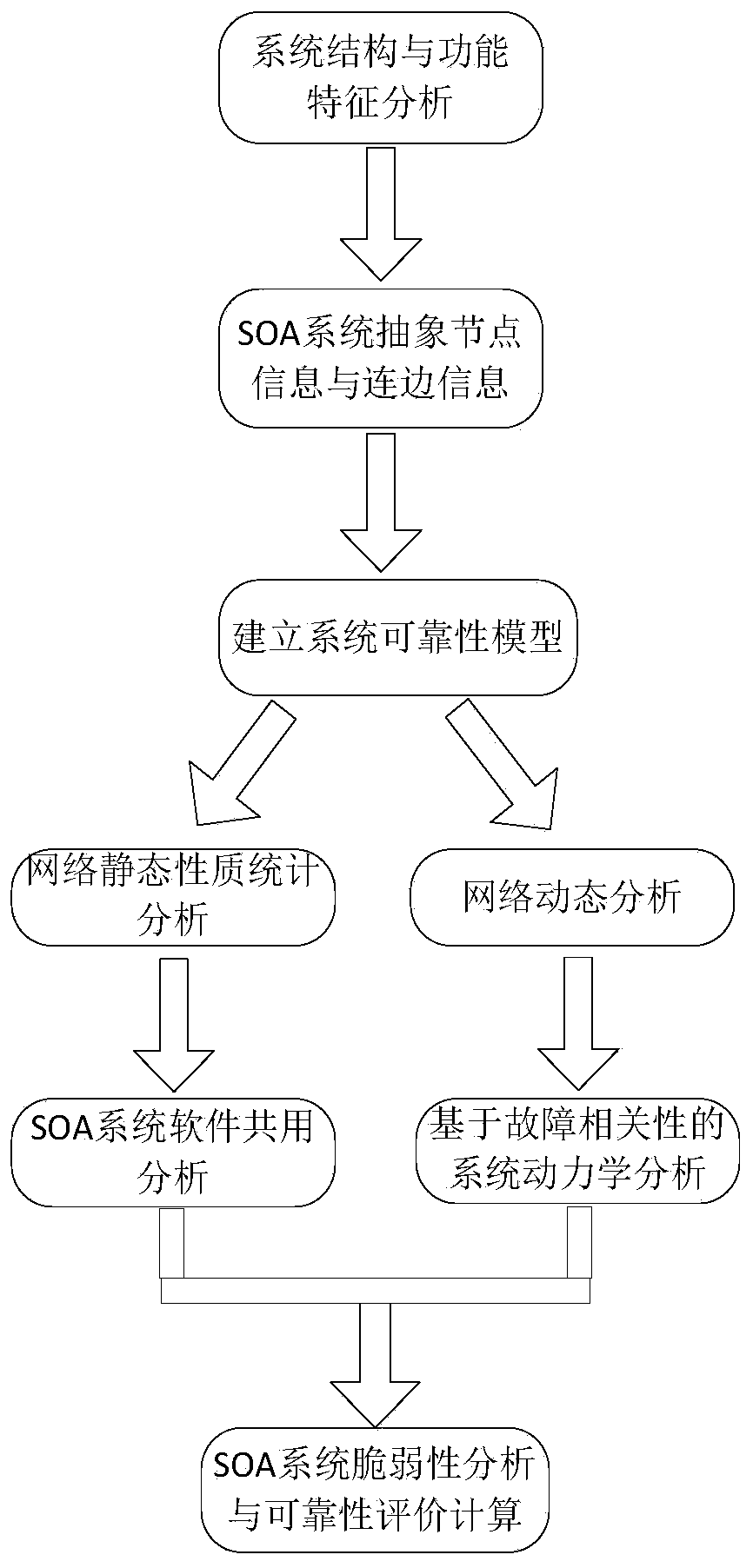

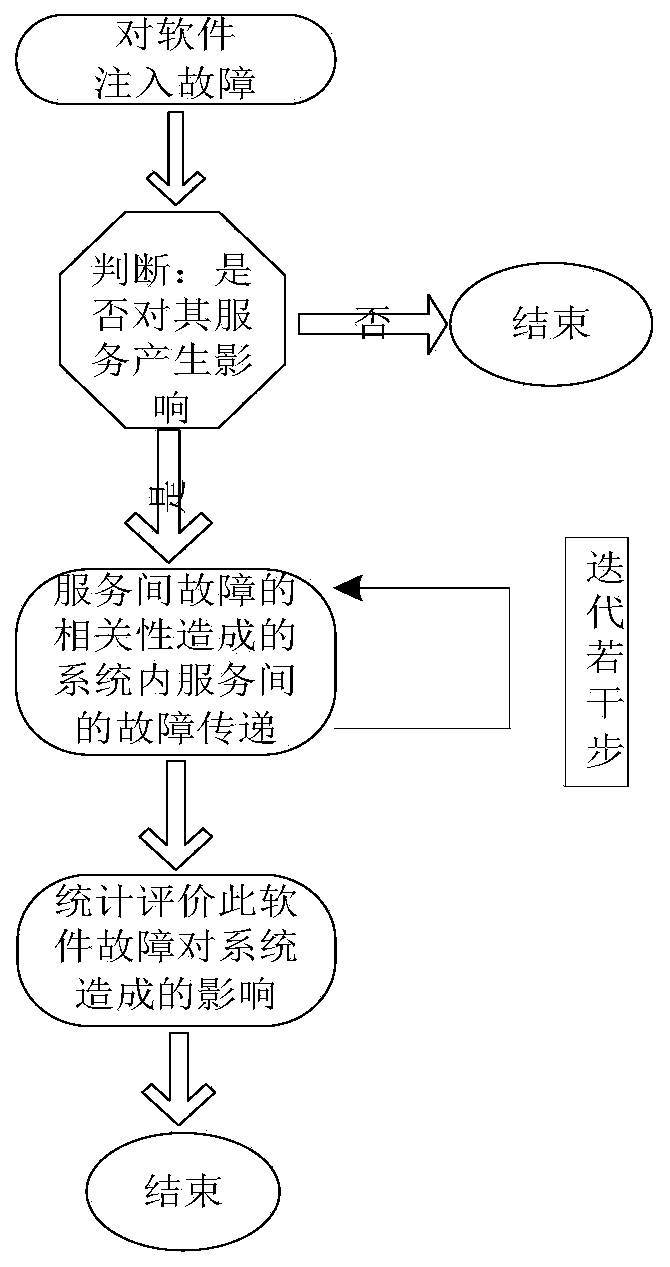

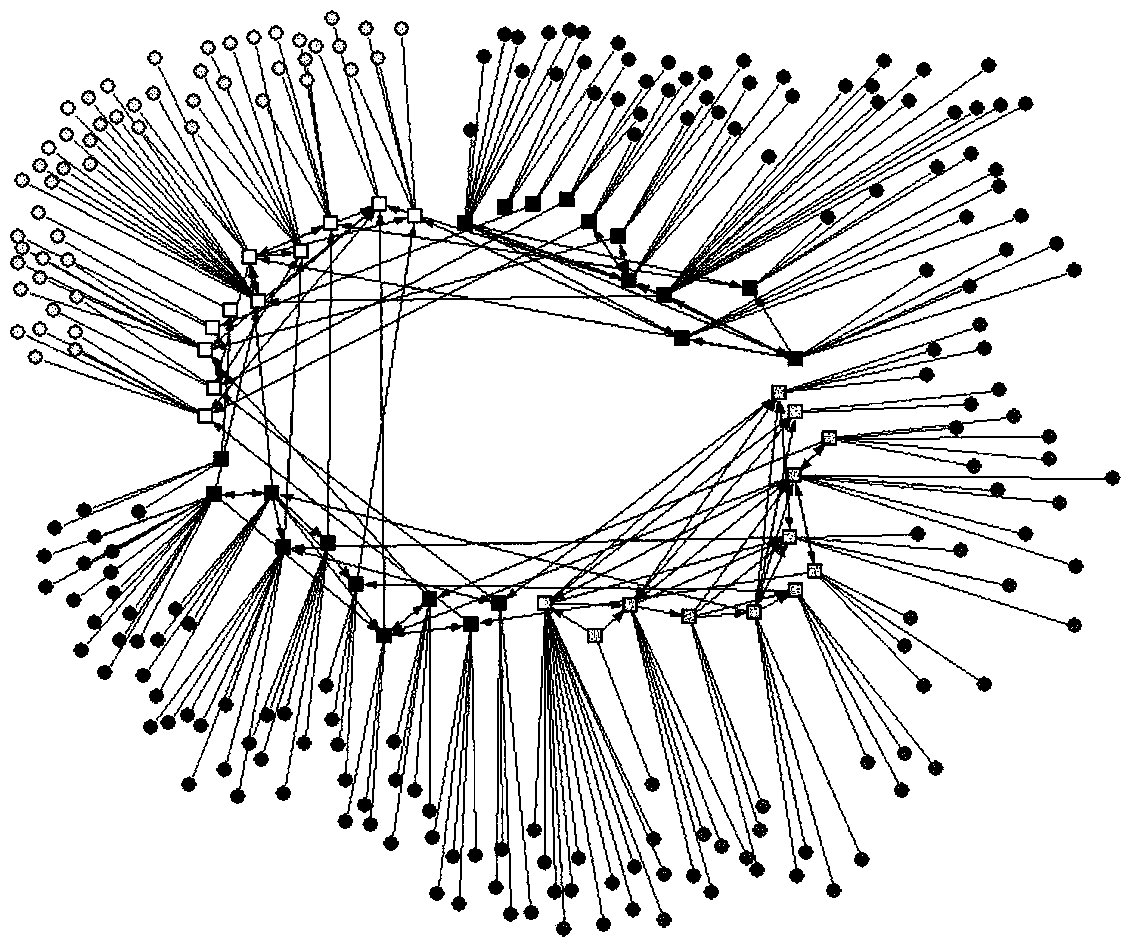

SOA system reliability evaluation method based on complex network theory

ActiveCN104298593AEmphasis on topological featuresEasy to operateSoftware testing/debuggingCascading failureStructure and function

An SOA system reliability evaluation method based on a complex network theory comprises four steps, belongs to the technical field of complex system reliability and aims at solving the problem that an SOA system is complex in structure and function and a traditional reliability analysis method is difficult to implement and even cannot be implemented and putting forward a methodology for effectively analyzing the reliability of the complex SOA system. The SOA system reliability evaluation method is characterized in that the method is innovatively integrated with the complex network theory, objects in the SOA system and the mutual effect of the objects are abstracted to be nodes and connecting lines in a complex network so as to establish a complex network failure model, a cascading failure model for the SOA system is put forward, and reliability analysis work is completed by utilizing a Monte Carlo simulation experiment on the basis so as to find key software and a weak structure influencing the system reliability. The SOA system reliability evaluation method is not limited by system scale, and increase of the system scale does not enable the calculation complex degree of the method to be remarkably improved. The SOA system reliability evaluation method is clear in physical significance and easily operated and implemented by engineers.

Owner:BEIHANG UNIV

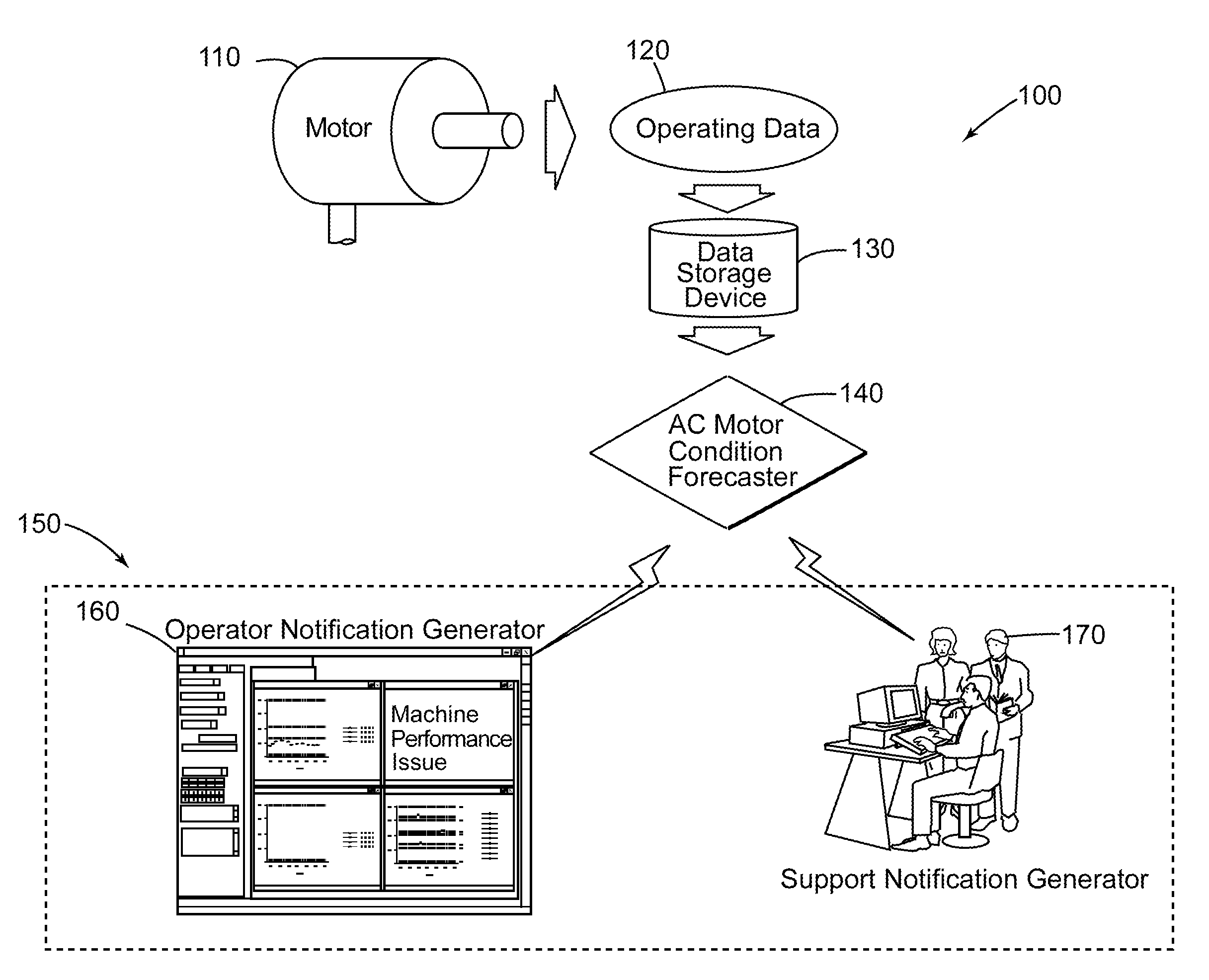

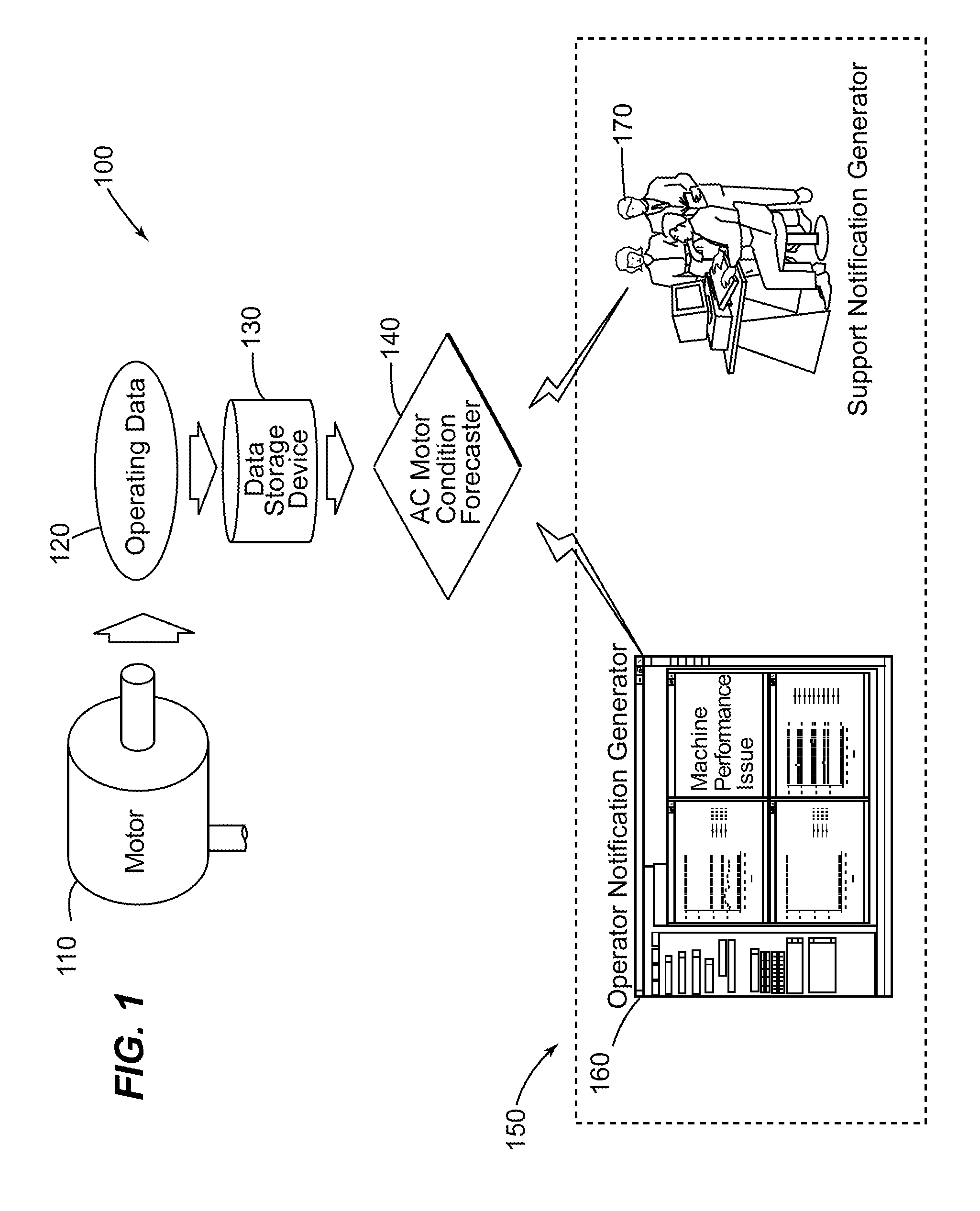

Method and system for remotely predicting the remaining life of an ac motor system

A method and system for remotely predicting the reliability and the remaining time before failure for an AC motor system is provided. The method and system may remotely determine the reliability and a remaining time before failure with a statistical confidence utilizing an AC motor condition forecaster. The method and system may include acquiring historical motor data, obtaining operational data, performing failure analysis, developing a causal network, and performing an integrated causal network and reliability analysis of the AC motor system. The method and system may provide at least one notification of an issue with the AC motor system or at least one component of the AC motor system.

Owner:GENERAL ELECTRIC CO

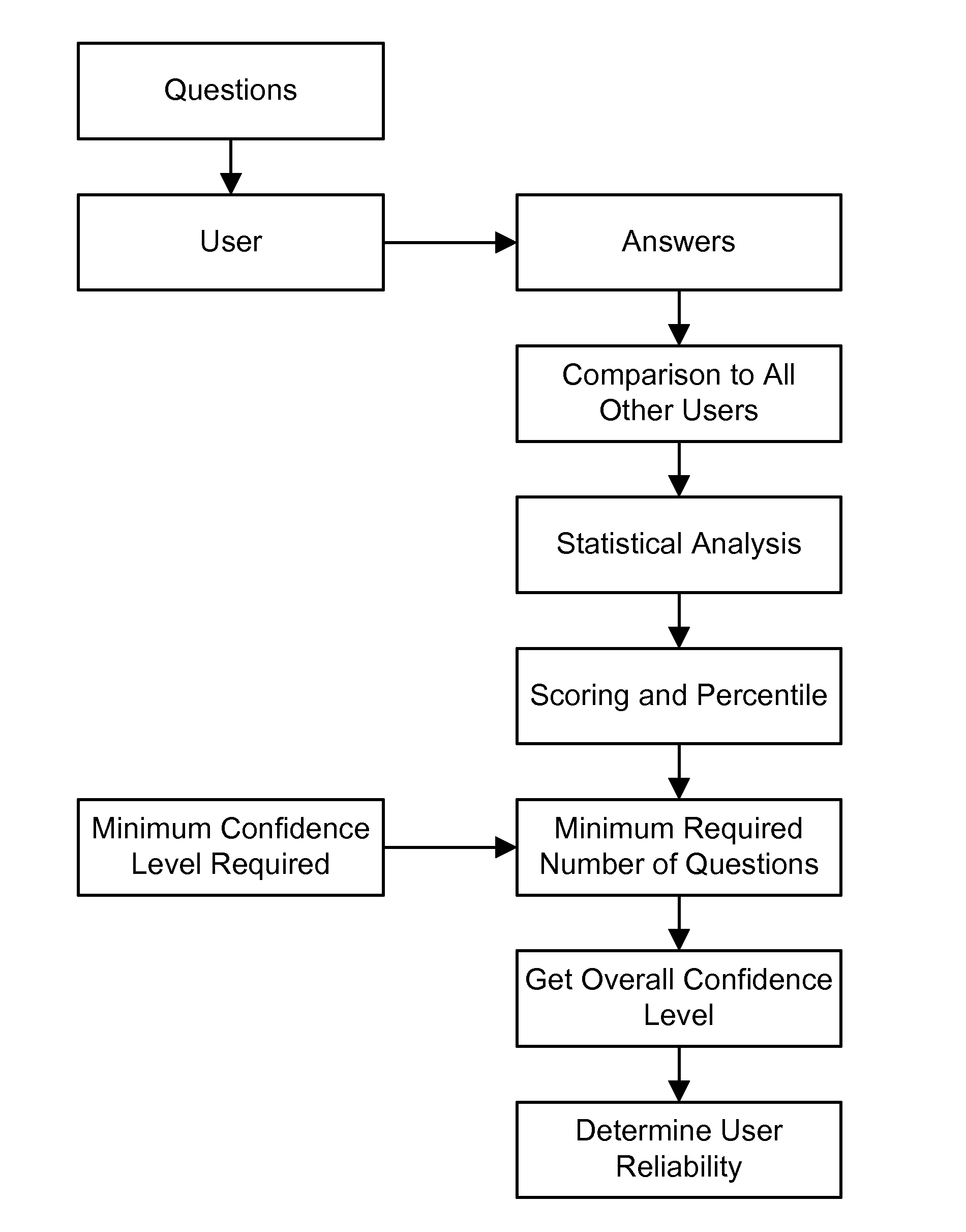

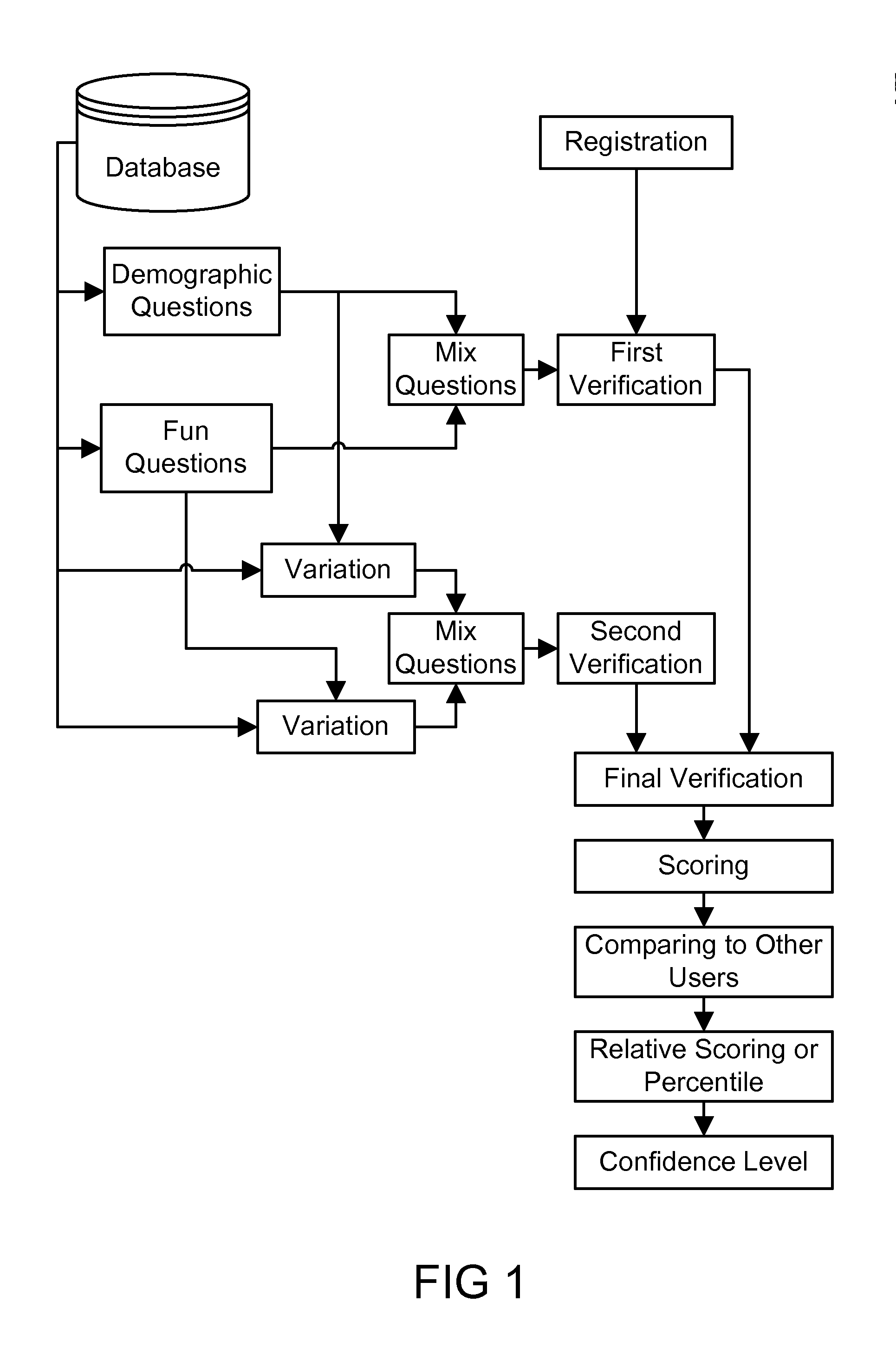

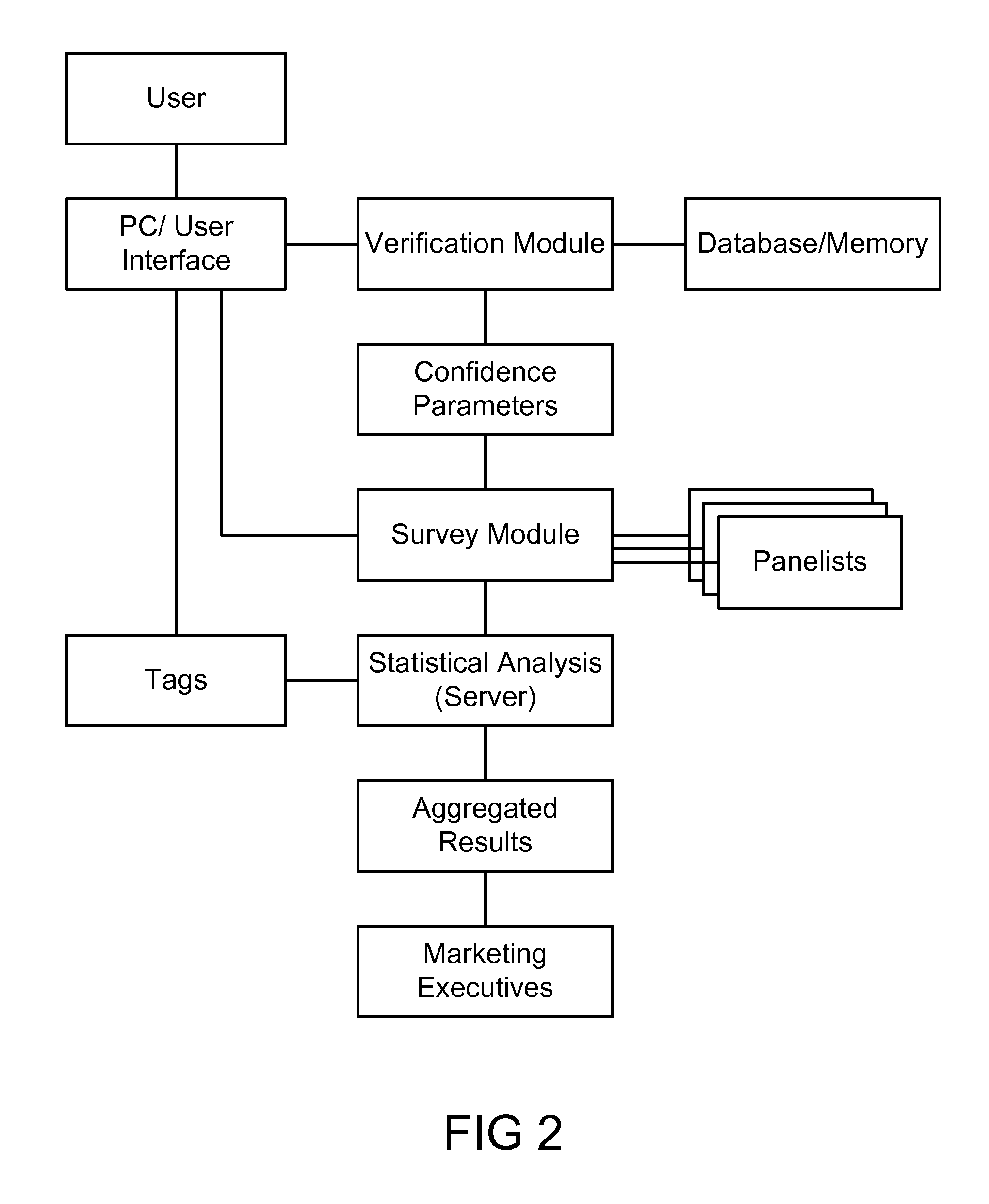

Method and System for Improving the Truthfulness, Reliability, and Segmentation of Opinion Research Panels

InactiveUS20110145043A1Increase valueQuality improvementMarketingSpecial data processing applicationsDemographic dataSurvey result

An example relates to survey analysis, survey panel members analysis, accuracy metrics, reliability analysis, and statistical analysis, to come up with confidence levels, and get an overall reliability of survey panel members, based on a score and percentile, and give incentives to the panel members, based on their reliability scores, to encourage them to be more reliable and truthful in the surveys, including their background and their demographics, increasing the values of the survey results drastically. In addition, this covers many separate embodiments: methods for improving and “incentivizing” truthful behavior in consumer panels; using Trustscore to measure and reward consistency and truthfulness; tag surveys to segment panels; and Doublecheck'd as a tool, to utilize the best responses through asking panel members twice (or more) with the same survey, and only including results from the members who answer the same both (or more) times.

Owner:HANDEL DAVID BRIAN

Systems, methods and computer program products for assessing the health of an electric motor

ActiveUS20050033557A1Ass healthElectric testing/monitoringDigital computer detailsLookup tableSystems approaches

Systems, methods and computer program products calculate the life remaining in a machine, such as an electric motor, or the life remaining in individual components within a machine. Life remaining calculations are based on information collected from multiple sources, including operator input data, historical data, and lookup tables. Using this information the remaining useful life of the machine is calculated based on quantitative data, standard design life limits and on reliability analysis such that continuous historical parameter data is not required to analyze or assess the life of the machine.

Owner:GENERAL ELECTRIC CO

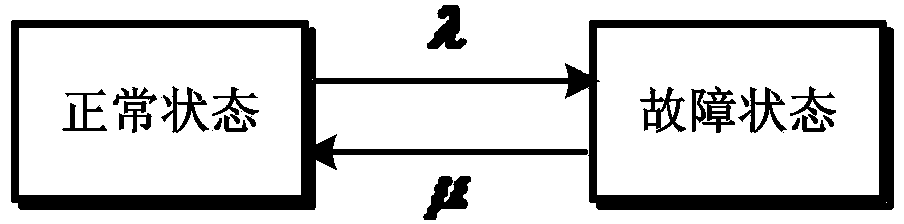

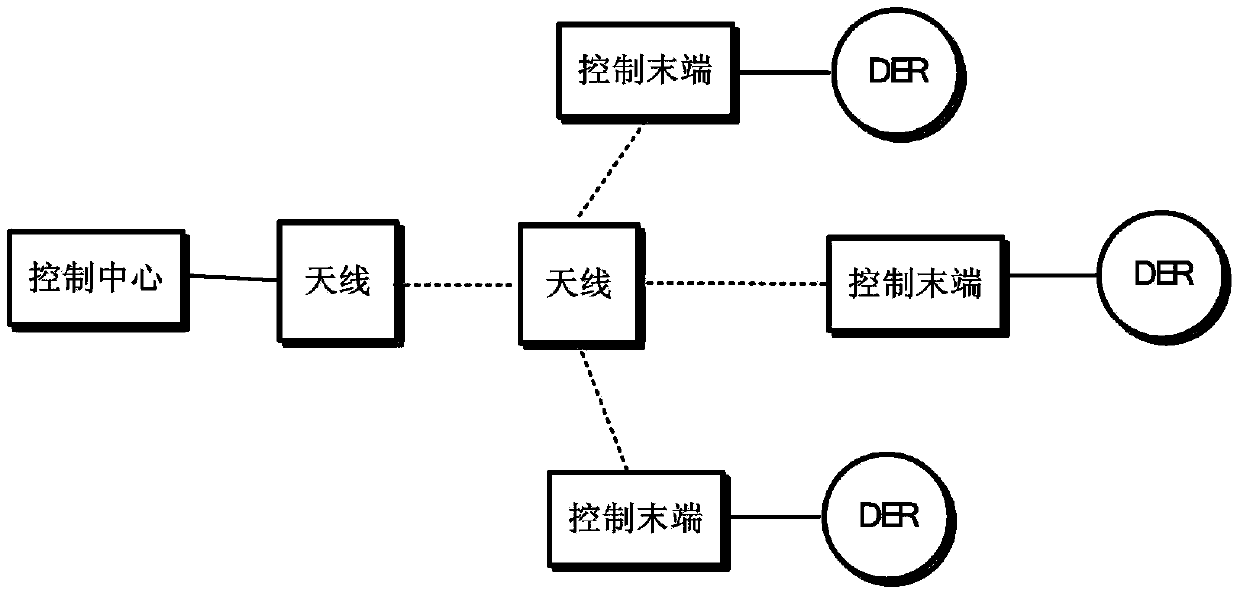

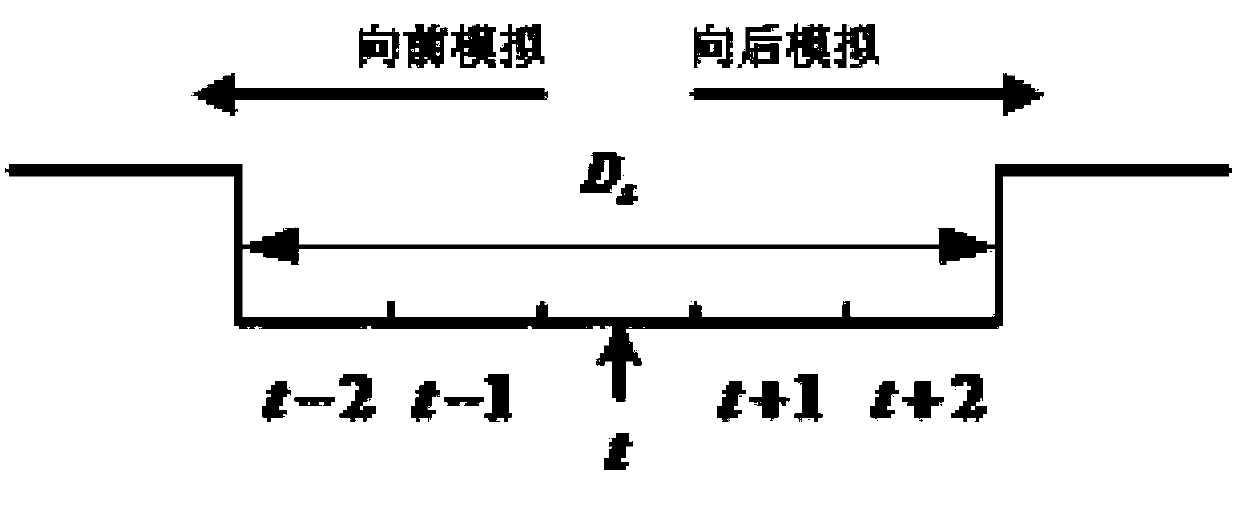

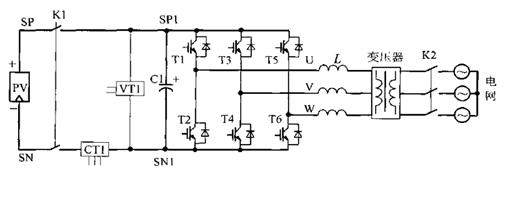

Active power distribution network reliability analysis method based on pseudo sequential Monte Carlo simulation

InactiveCN104218620AIn line with the actual situationCredibleAc-dc network circuit arrangementsCommunications systemElectric distribution network

The invention discloses an active power distribution network reliability analysis method based on pseudo sequential Monte Carlo simulation and belongs to the technical field of power system control. The method utilizes a pseudo sequential Monte Carlo simulation method to perform reliability analysis on an active power distribution network, the operation time is shortened, and the analysis accuracy is also improved. In addition, characteristics of the active power distribution network are further fully considered in the method, states of a communication system and power electronic devices in power distribution automation are involved in system state sampling, intelligent operation is performed on the system in a normal state, processing is performed through a traditional passive power distribution network during breakdown, the method is consistent with the actual situation of the active power distribution network, and obtained reliability data have confidence level.

Owner:STATE GRID CORP OF CHINA +3

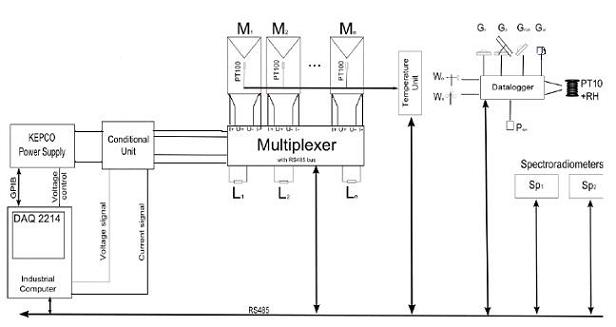

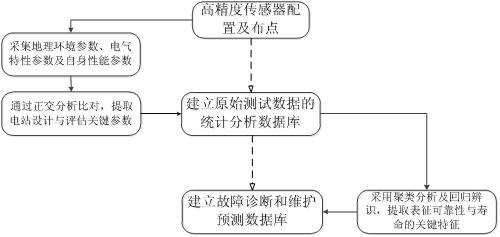

Demonstration-based photovoltaic power station testing diagnosis and forecasting database establishment method

ActiveCN102129466AAssessment reliabilityComprehensive evaluation of operabilityData processing applicationsSpecial data processing applicationsPhotovoltaic power stationBusiness forecasting

The invention discloses a demonstration-based photovoltaic power station testing diagnosis and forecasting database establishment method. In the method, deep mining and probability reliability assessment are performed on the statistical data of different components and balancing parts in a demonstration system based on long-term running performance testing data by using a reliability analysis principle to form reliability and economy-coordinated comprehensive evaluation mechanism and establish a photovoltaic power station field fault diagnosis and maintenance forecasting database. The method has the advantage of comprehensively evaluating the reliability, running performance and cost of photovoltaic components, the parts and the system.

Owner:STATE GRID ELECTRIC POWER RES INST

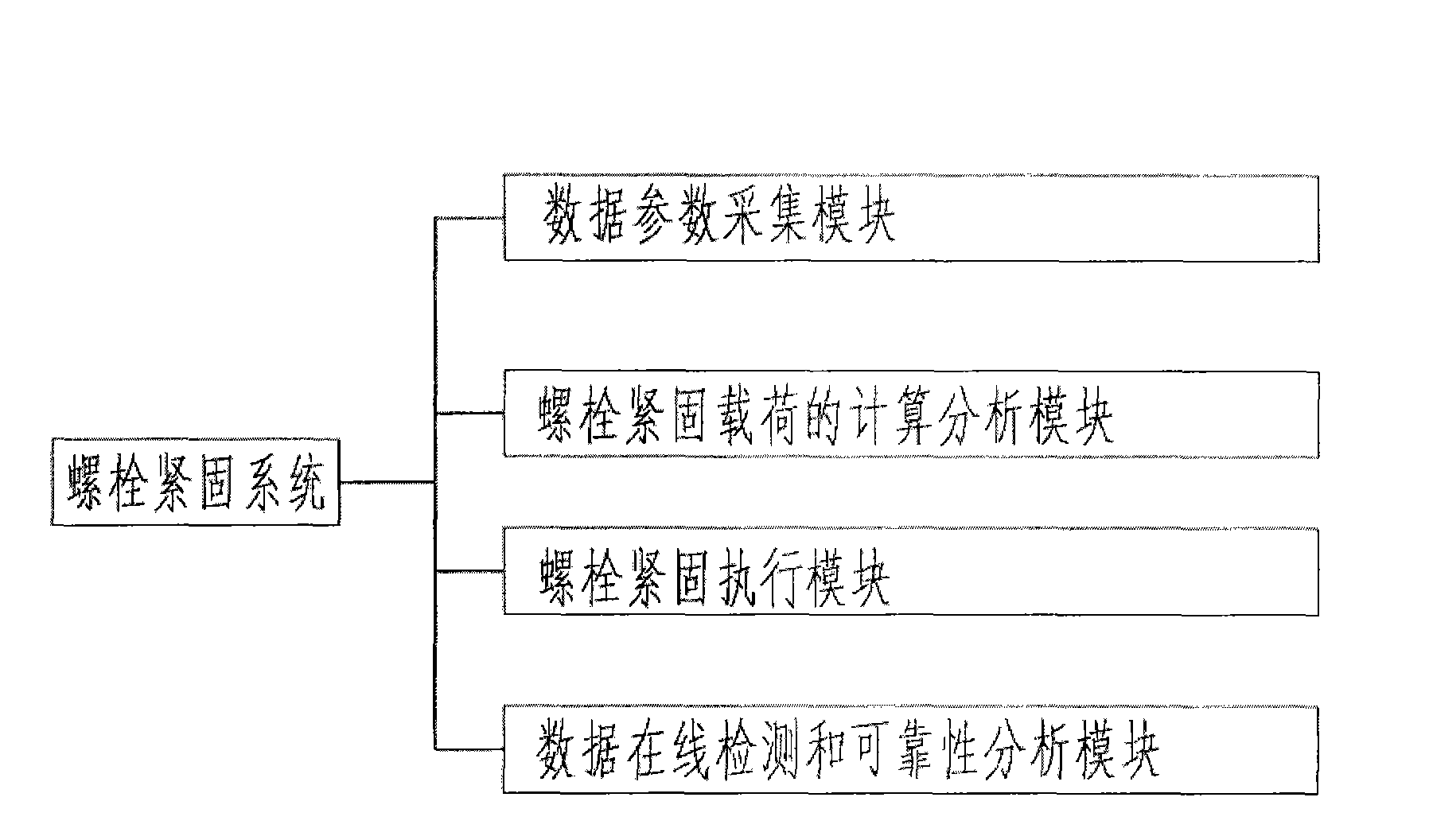

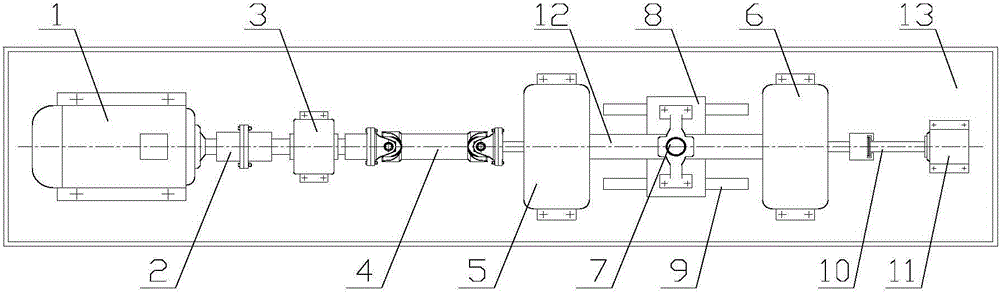

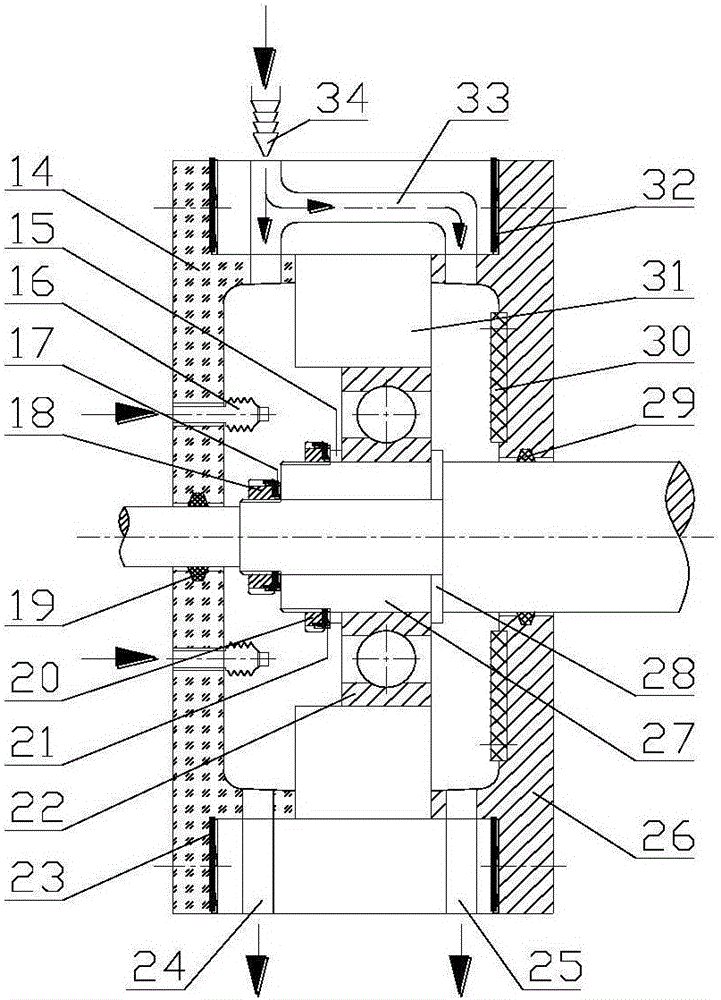

Bolt fastening system

InactiveCN101648336AEasy to operatePrecise operation controlMetal working apparatusStress conditionsSafety control

The invention provides a bolt fastening system which belongs to the safety control field of bolt flanges of petroleum and petrifaction devices. The bolt fastening device comprises a data parameter acquisition module, a computation analysis module of bolt fastening loads, a bolt fastening execution module and a data on-line detection and reliability analysis module. The computation analysis moduleof bolt fastening loads computes and analyzes load data required by fastening a bolt according to data parameters in a database and transmits the computed load data to the bolt fastening execution module; and the bolt fastening execution module automatically selects a used fastening mode according to the computed load data, thereby guiding the fastening execution operation. The bolt fastening system has convenient and reliable operation, accurately controls the bolt fastening operation, can reflect the stress condition of the bolt in real time and alarm when exceeding the safety guard, therebyradically controlling the safety of flanges.

Owner:北京海泰斯工程设备股份有限公司

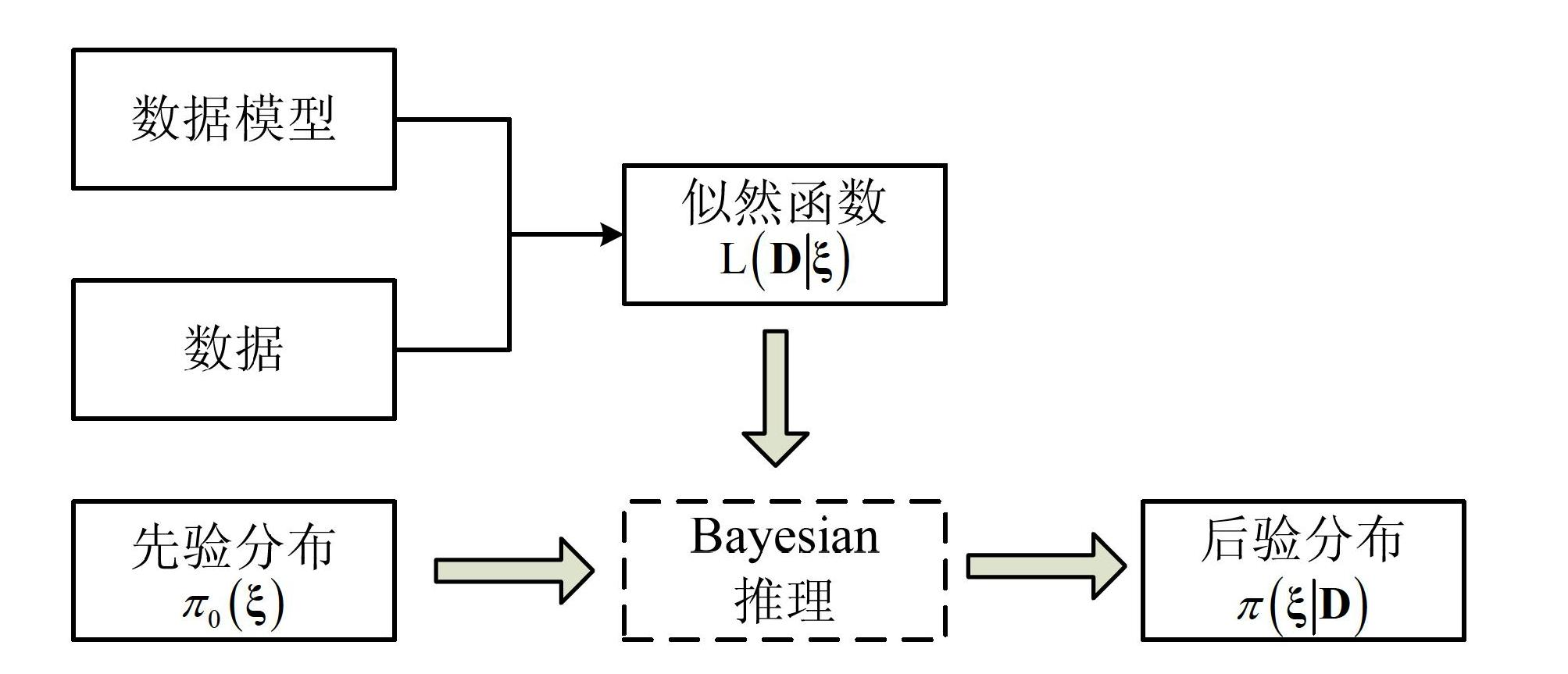

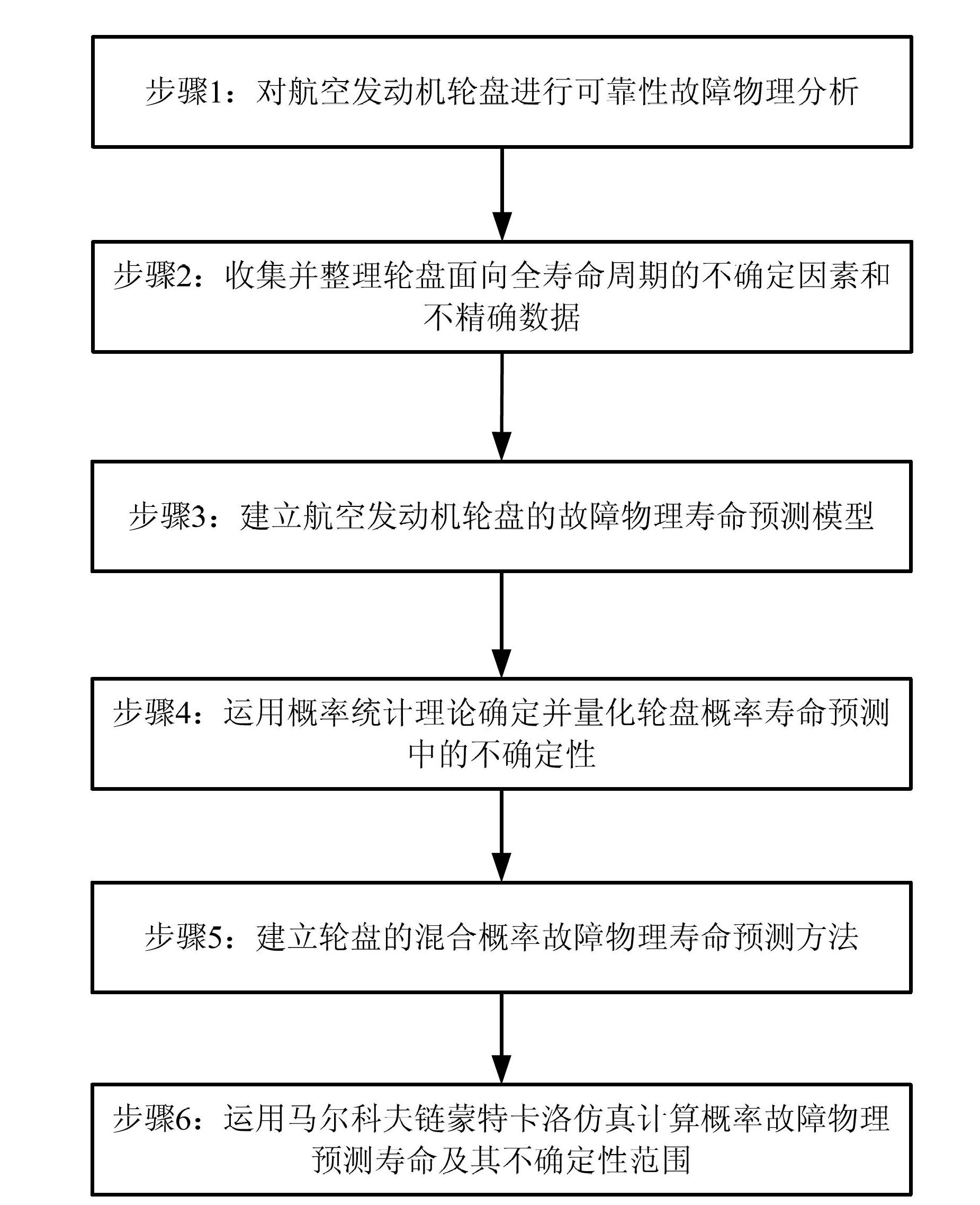

Turbine disk probability failure physical life predicting method based on Bayes information update

InactiveCN102682208AReduce the number of trialsLow costSpecial data processing applicationsAviationDesign cycle

The invention relates to a turbine disk probability failure physical life predicting method based on Bayes information update, which comprises the following steps that 1, failure physical information of a turbine disk is determined in a reliability analyzing method based on physics of failure according to the structural characteristics of the aircraft engine turbine disk; 2, the failure physical information of the aircraft engine turbine disk obtained in step 1 and the existing failure information obtained by maintenance data statistics are analyzed in an FTA (failure tree analysis) / FMECA (failure mode, effects & criticality analysis) method to obtain the main failure mode and the failure position of the turbine disk, and uncertain factors and inaccurate data of the turbine disk facing whole life cycle are collected and cleared up; and 3, a failure physical life predicting model of the aircraft engine turbine disk is established according to the main failure mode and the failure position of the turbine disk obtained in step 2. The method disclosed by the invention has the beneficial effects that the design cycle of the aircraft engine turbine disk can be obviously shortened, the development cost is reduced, and the life reliability of the aircraft engine turbine disk can be obviously improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

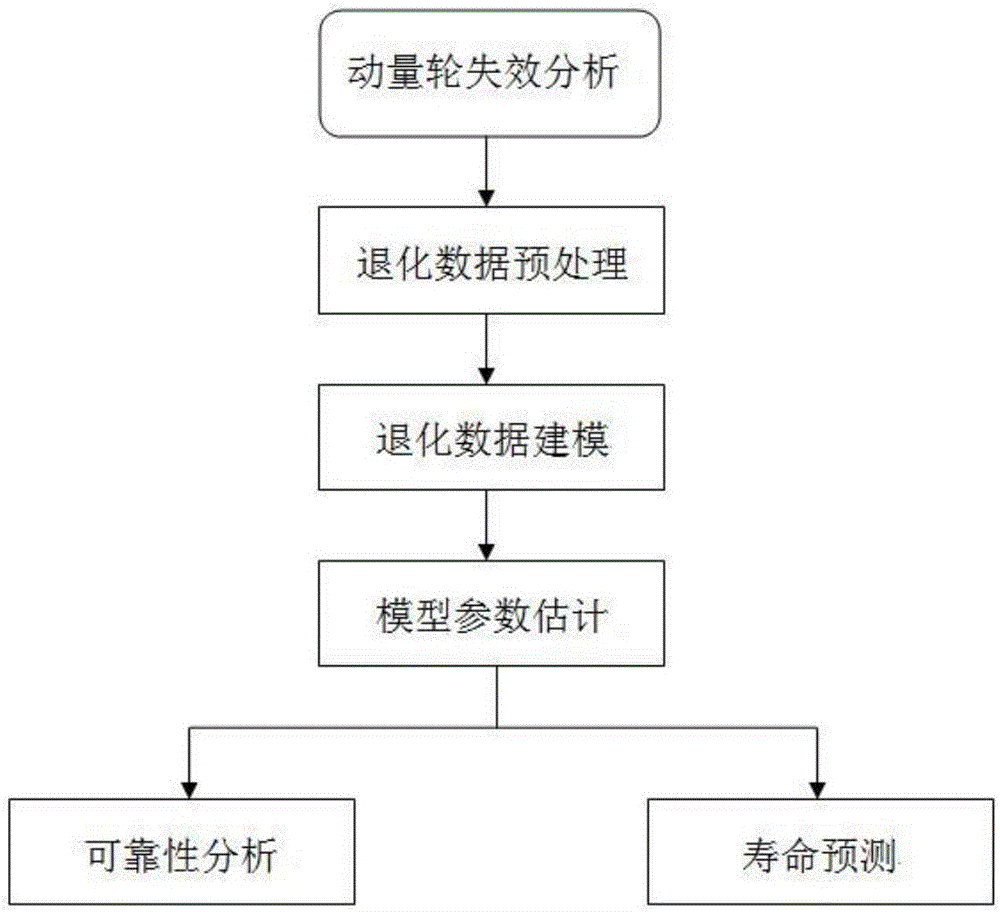

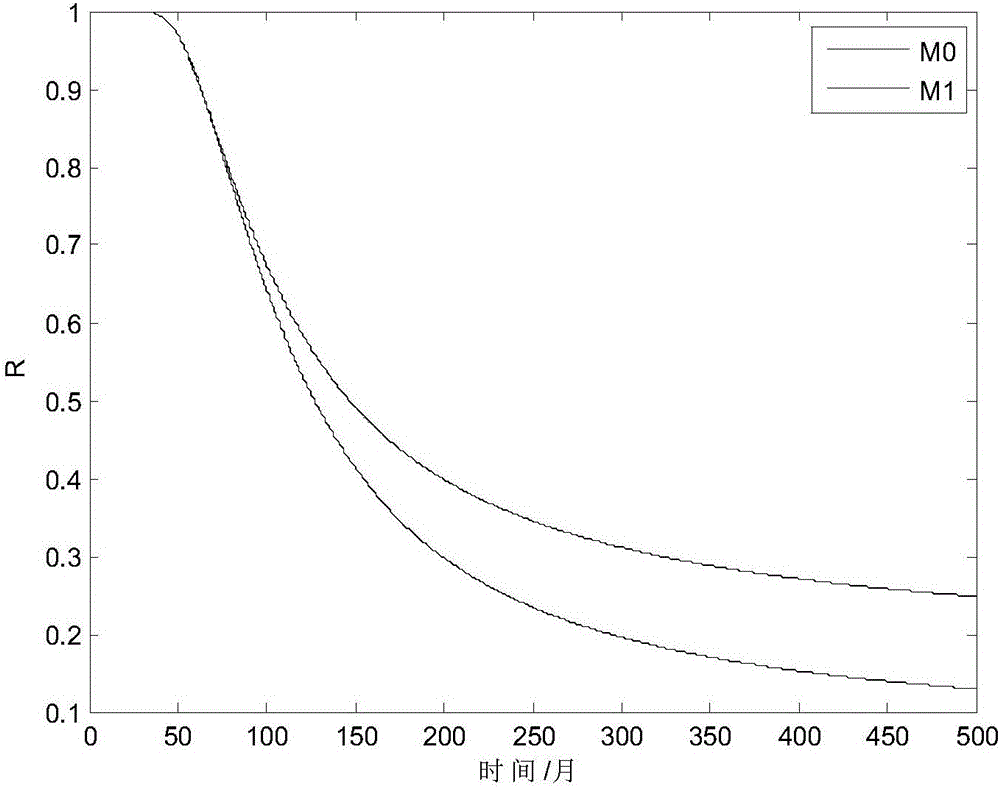

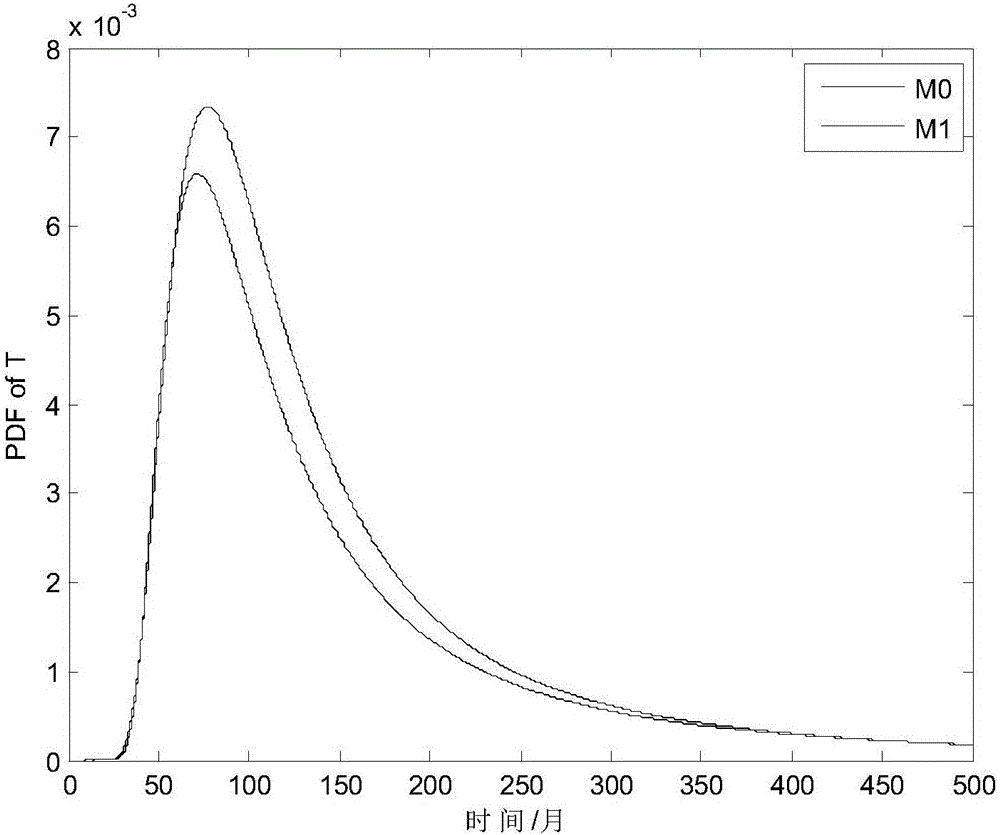

Method for analyzing reliability of momentum wheels and predicting remaining lives on basis of degradation data

ActiveCN106484949AAchieve reliabilityAchieve lifeGeometric CADSpecial data processing applicationsObservational errorMomentum

The invention discloses a method for analyzing the reliability of momentum wheels and predicting remaining lives on the basis of degradation data. The method includes analyzing performance degradation mechanisms of the momentum wheels, determining key performance degradation parameters and preprocessing the degradation data; analyzing characteristics of the degradation parameters, building appropriate performance degradation data models, estimating unknown parameters in the models by the aid of maximum likelihood processes and proposing probability density functions, reliability functions and remaining life probability density functions in regard to the lives of the momentum wheels according to properties of the models; substituting estimated parameter values into various function expressions and analyzing the reliability and the remaining lives of the momentum wheels at various measurement moments according to the functions. The method has the advantages that the reliability of the momentum wheels can be estimated, the remaining lives of the momentum wheels can be predicted, and problems of unreasonable degradation data selection and deficiency of consideration on actual measurement errors during momentum wheel life prediction at present can be solved.

Owner:XIAN UNIV OF TECH

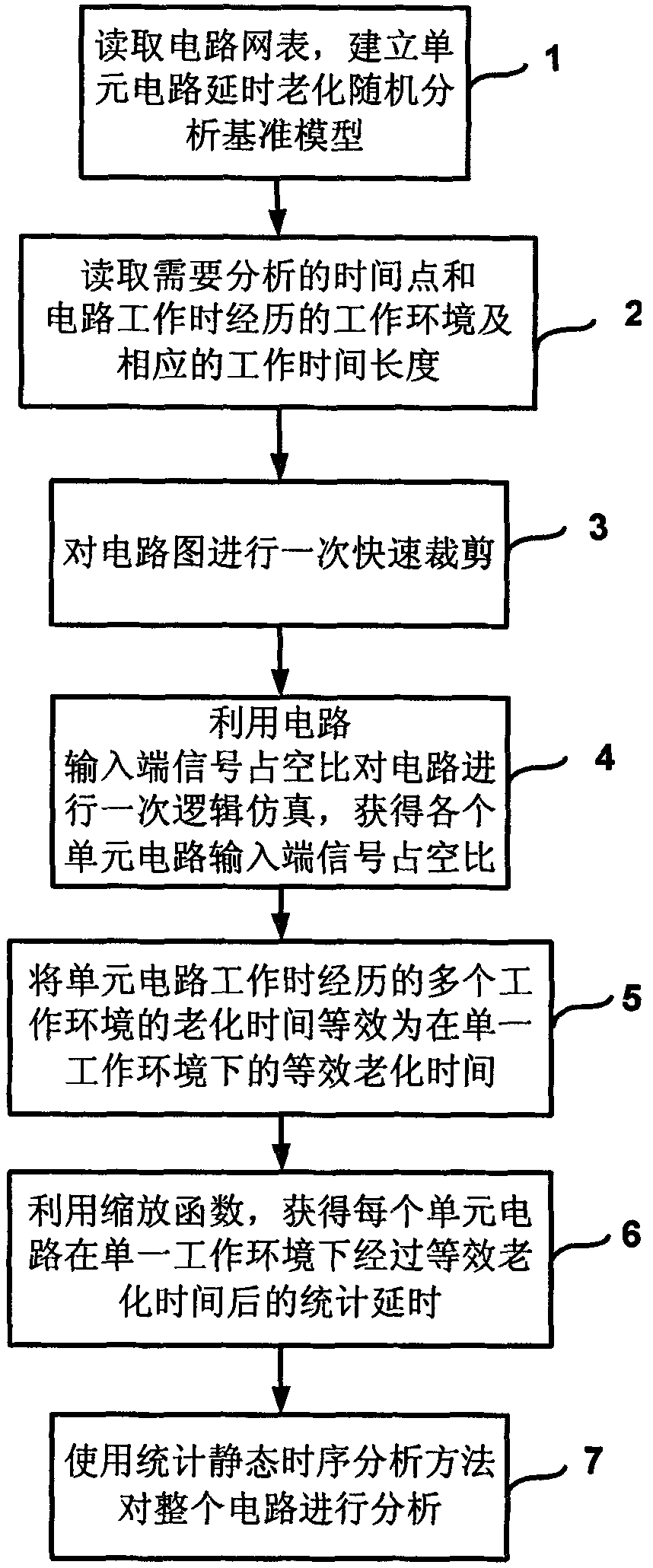

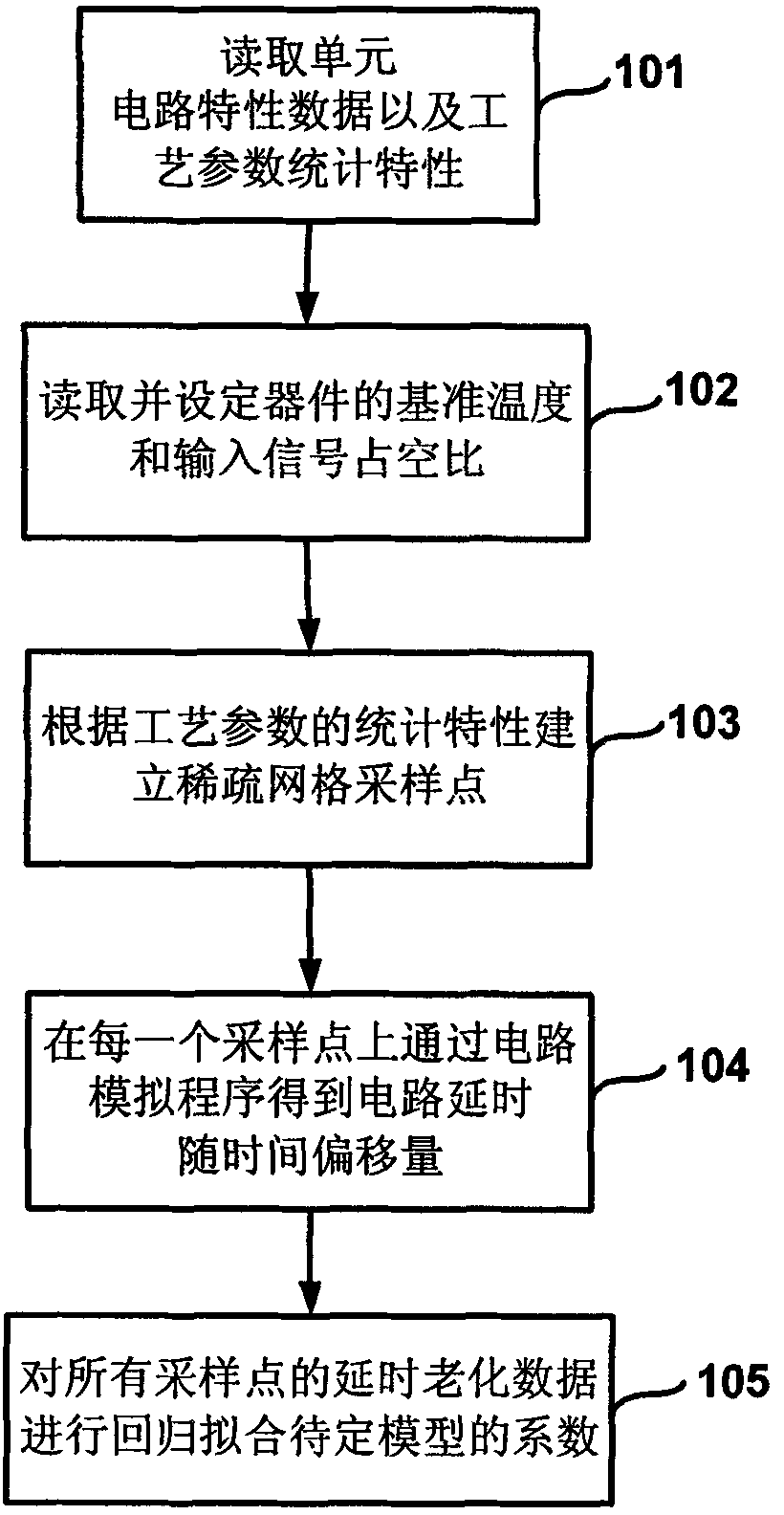

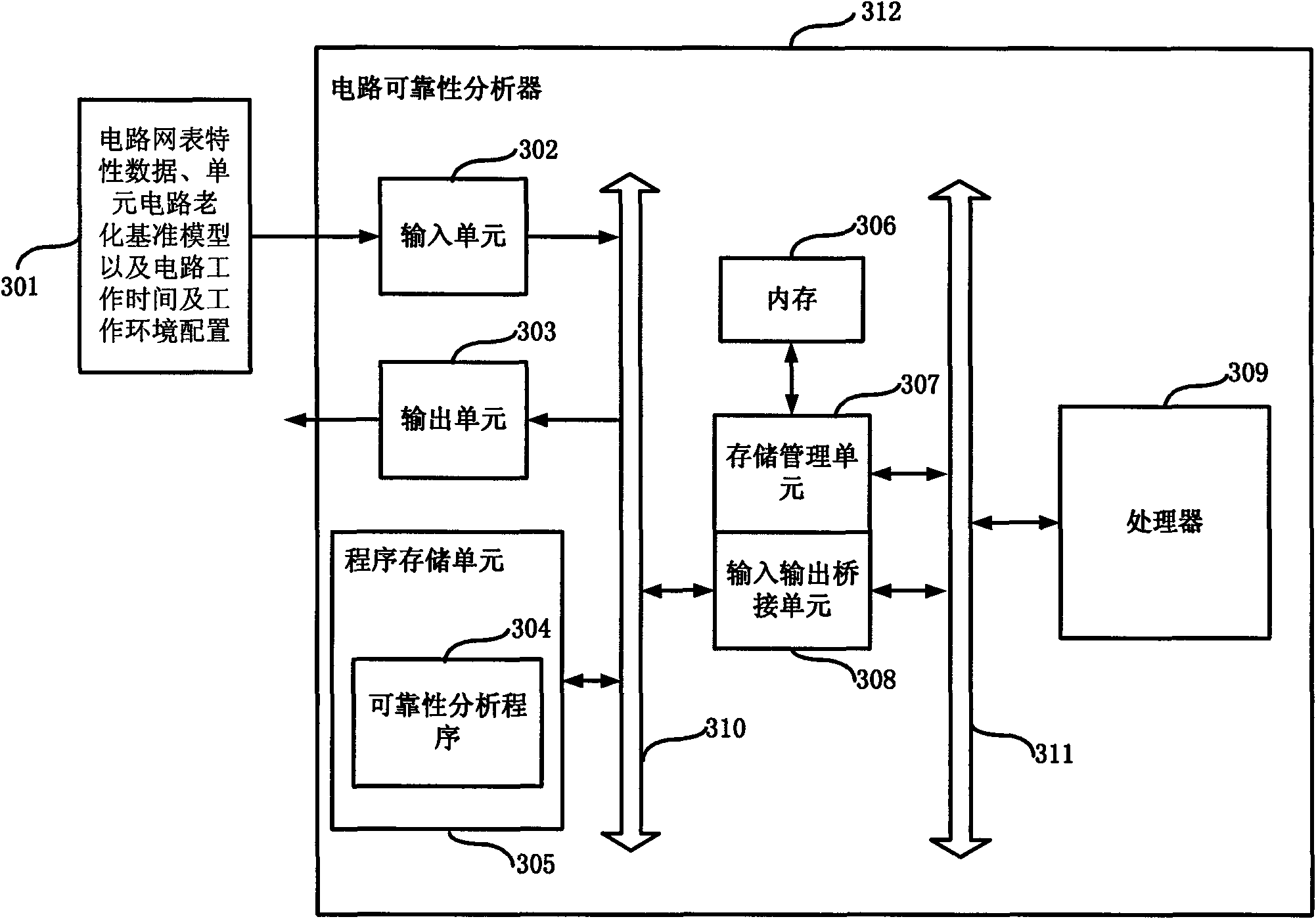

Method and device for analyzing reliability of integrated circuit

ActiveCN101964003AMeet analysis needsExtension of timeSpecial data processing applicationsProcess deviationsCircuit delay

The invention relates to a method and a device for analyzing the reliability of an integrated circuit. In the analytical method, a unit circuit delayed aging stochastic analysis reference model in consideration with both negative bias temperature instability (NBTI) effect and process parameter perturbation is established, a scaling function and an equivalent aging time concept are provided to solve the delayed statistical distribution of a unit circuit under the actual work environment quickly from the reference model, and the pre-clipping process of the circuit is provided to reduce the complexity of reliable analysis. The device of the invention comprises an input unit, an output unit, a program storage unit, an external bus, a memory, a storage administration unit, an input / output bridging unit, a system bus and a processor. In the method and the device, the effect of the process parameter perturbation, the NBTI effect and the work environment of the circuit on reliability are considered simultaneously, and the complexity of the reliable analysis can be reduced effectively by utilizing the scaling function, equivalent aging time and the pre-clipping technology so as to realize the quick analysis on the reliability of super-large-scale integrated circuits in consideration with process deviation.

Owner:FUDAN UNIV

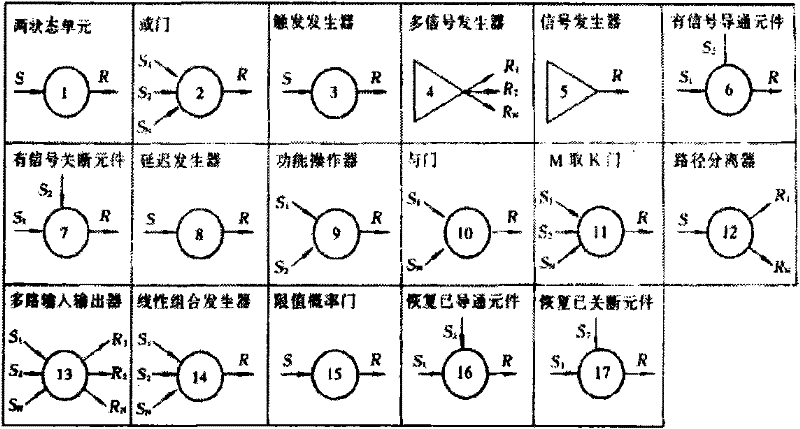

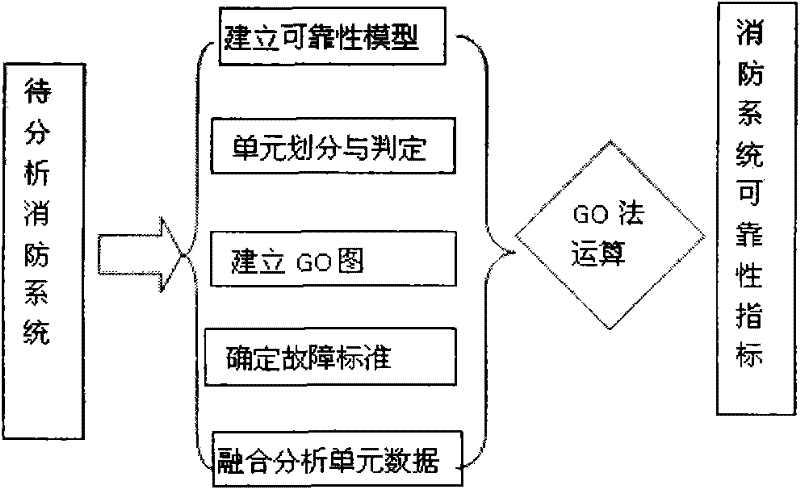

Fire fighting system reliability analysis and calculation method

InactiveCN102419799AObjective analysisFailure rate to be analyzedSpecial data processing applicationsTask analysisMean time to repair

The invention belongs to application of a reliability analysis technology to the technical field of fire engineering, and ensures that the using reliability of a fire fighting system is accurately analyzed and calculated. A fire fighting system reliability analysis and calculation method comprises the following steps of: establishing a fire fighting system reliability model and determining reliability units according to the working principle of the fire fighting system, forming a GO chart for establishing the fire fighting system according to the boundary of the fire fighting system and success criteria, and determining a fault judgment method for the reliability units of the fire fighting system according to task analysis of the system and fire code requirements; and substituting fault statistical data of the reliability units of the fire fighting system into a GO model of the fire fighting system to calculate corresponding reliability indexes of the fire fighting system, such as a fault rate, average maintenance time, availability and the like. By the method, the reliability of the fire fighting system can be objectively qualitatively evaluated or accurately quantitatively evaluated, and the method can be widely applied to reliability design, reliability manufacture, fault analysis and system evaluation of the fire fighting system.

Owner:杜玉龙

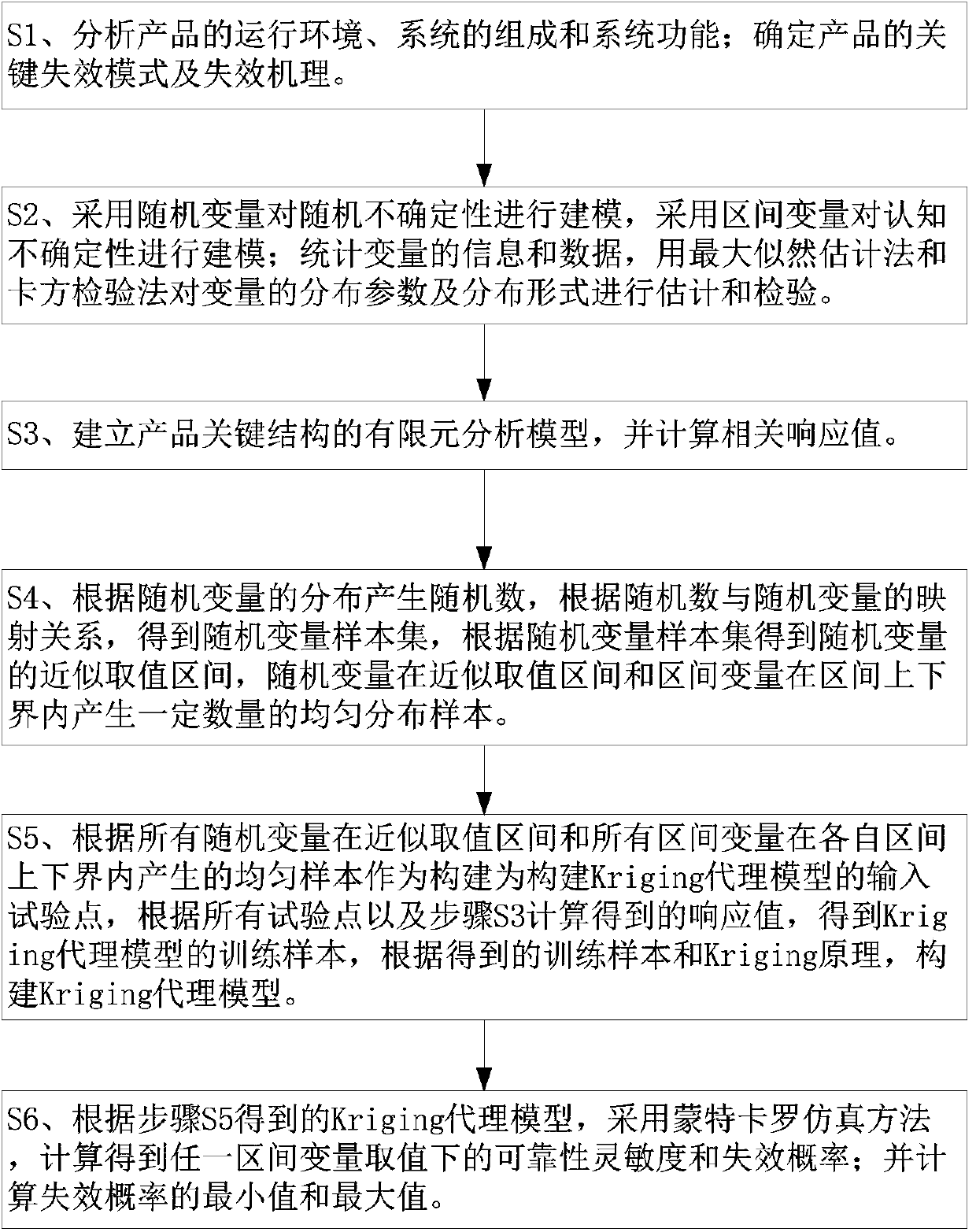

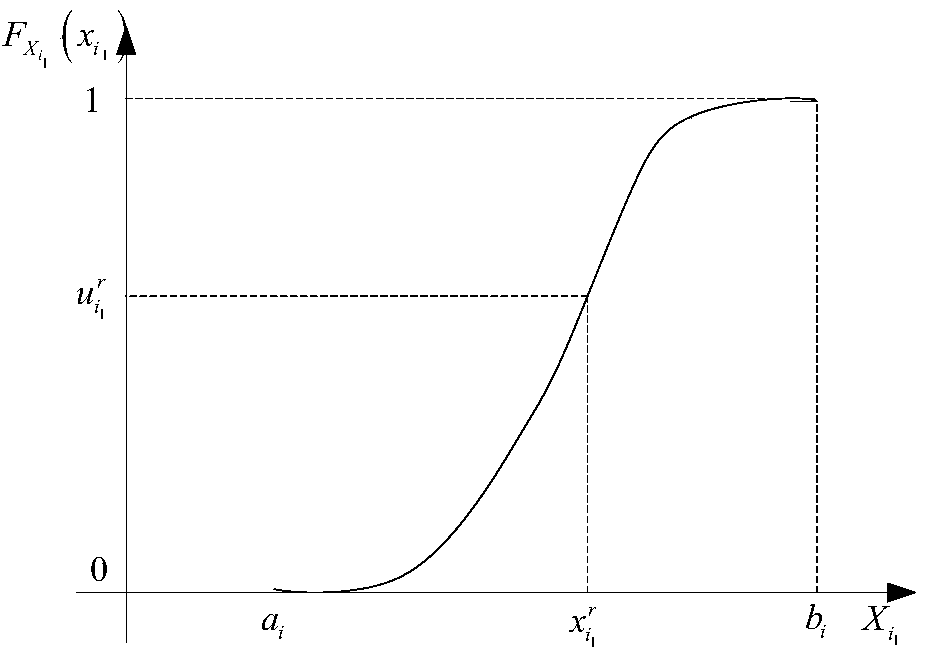

Structural reliability analysis method based on agent model under condition of hybrid uncertainty

InactiveCN104750932ASolve the accuracy problemAddress reliabilitySpecial data processing applicationsStructural reliabilitySystem failure

The invention discloses a structural reliability analysis method based on an agent model under the condition of hybrid uncertainty. The structural reliability analysis method comprises the steps that random uncertainty is modeled by adopting random variables, and epistemic uncertainty is modeled by adopting interval variables; uniform samples generated by the random variables in an approximate value section and all the interval variables within upper bounds and lower bounds of respective intervals and a system response value are used as training sample points for establishing a Kriging agent model, and according to the obtained Kriging agent model, the maximum values and the minimum values of the reliability sensitivity, the failure probability and the system failure probability under any interval variable value are calculated by adopting a Monte Carlo simulation method. By the adoption of the structural reliability analysis method, the problems that a traditional agent model under the condition of the hybrid uncertainty has a certain precision locally, and the traditional reliability analysis calculated quantity is larger are solved, and the structural reliability analysis method better accords with engineering practice.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

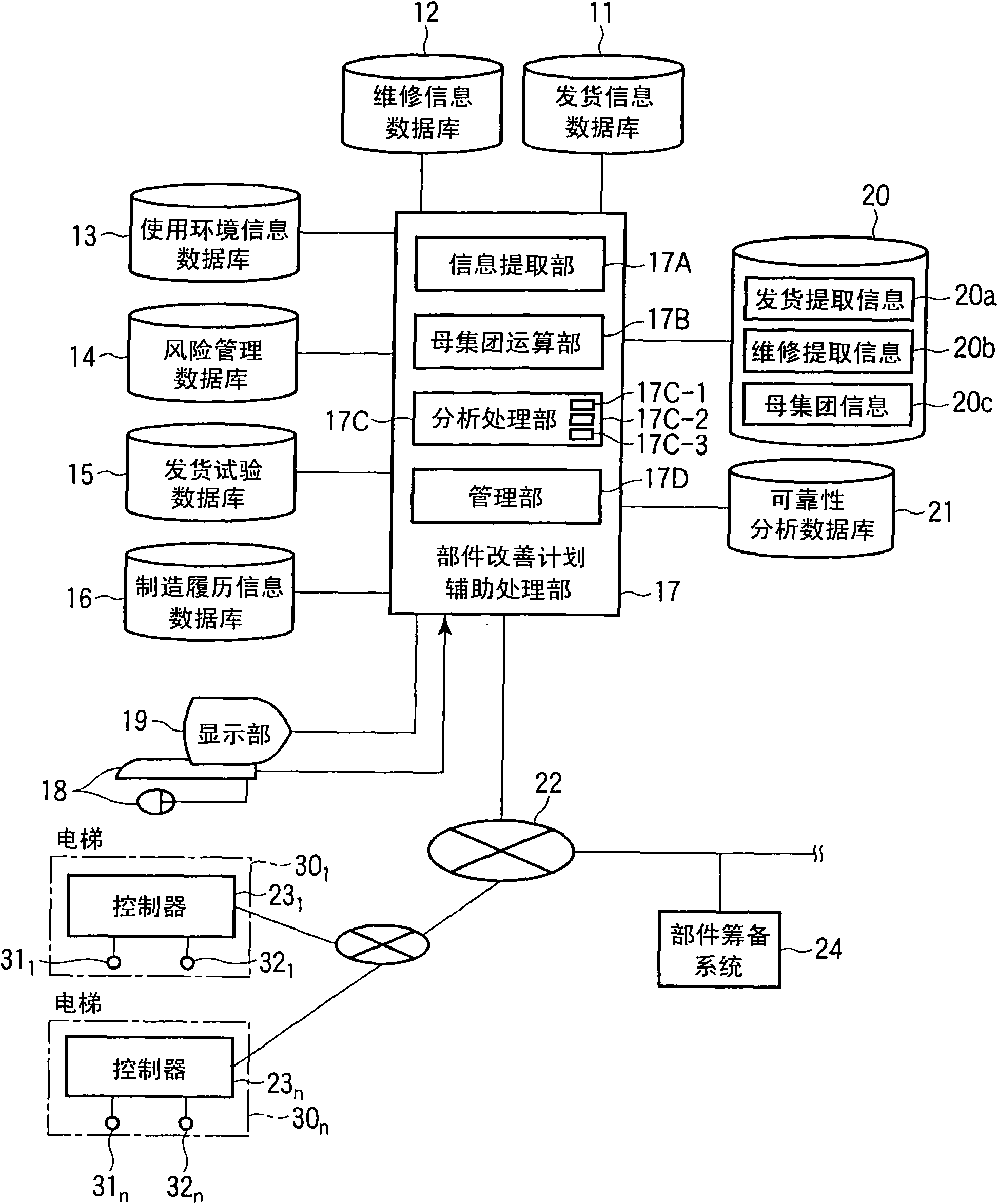

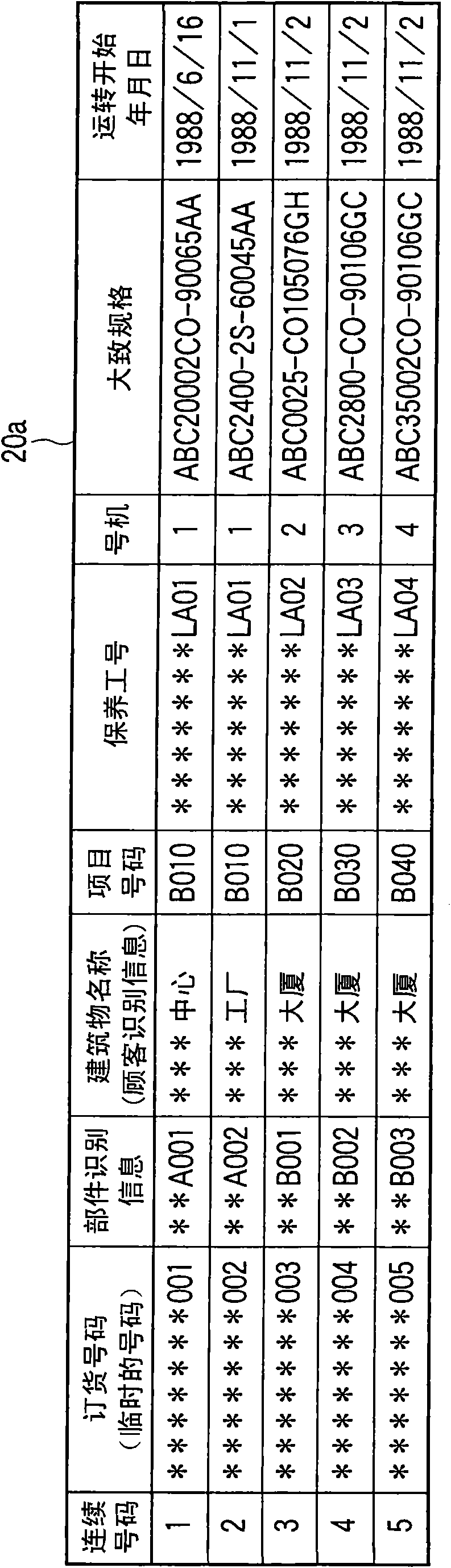

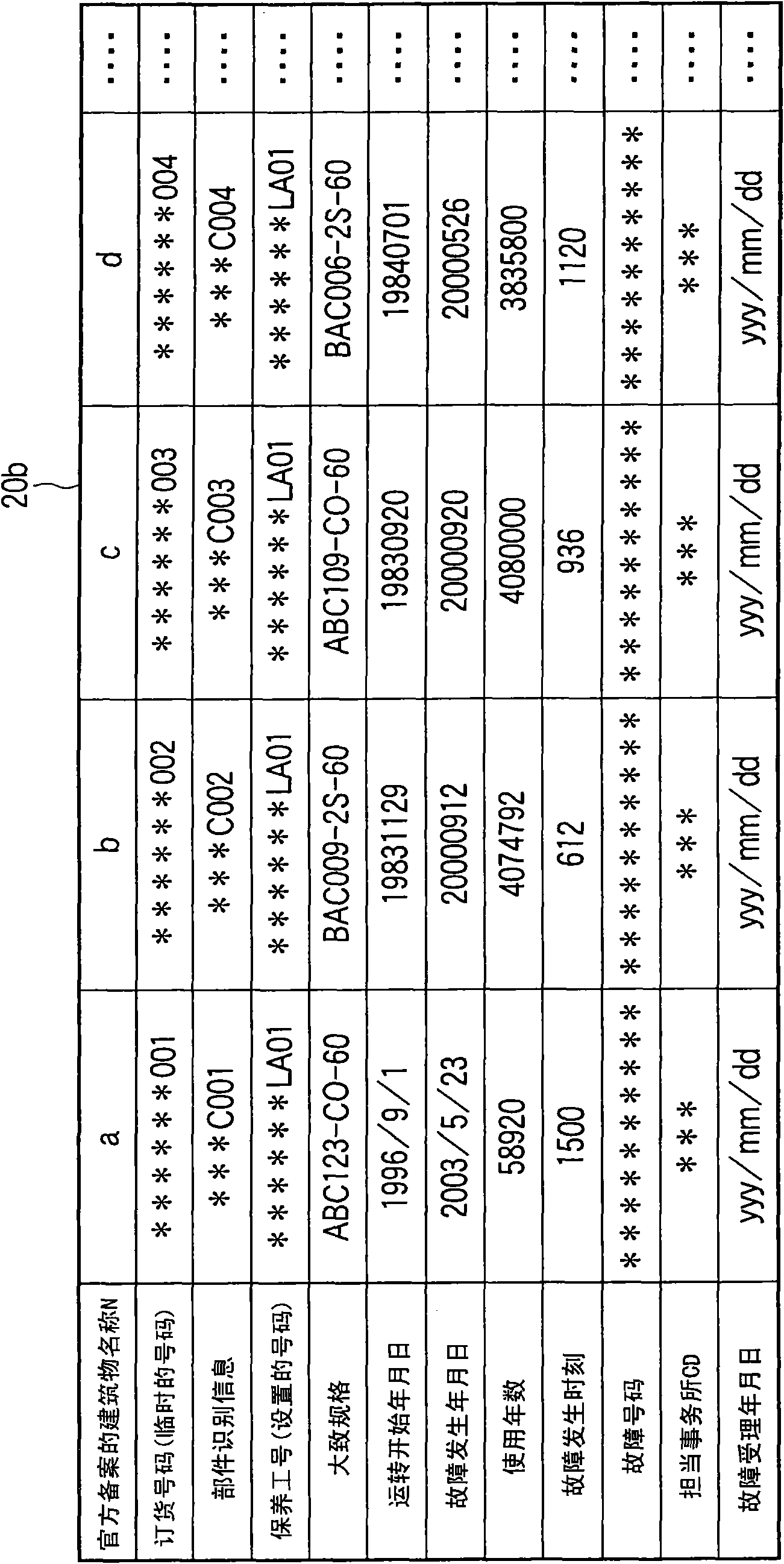

Elevator component improvement plan system and elevator component improvement plan method

The invention provides an elevator component improvement plan system and an elevator component improvement plan method. The system is provided with various databases which manage each component constituting the elevator; an information extraction part which extracts delivery information and maintenance information; an operational part which obtains the number of object components delivered to thesame destination; an analysis processing part which computes the number of faulty object components based on the delivery numbers and failure occurrence information, generates reliability analysis information using a plurality of functions for reliability analysis to implement Weibull analysis, computes the failure replacement timing of the object component, understands the working environment and the manufacturing record of the object component based on maintenance extraction information, working environment information, delivery test data and manufacturing record information of the object component to analyze failure causes, and computes the replacement forecast timing ahead of the failure replacement timing; and a management part which notifies the replacement timing of the object component when operation condition data of the object component collected at any time approach the replacement forecast timing.

Owner:TOSHIBA ELEVATOR KK

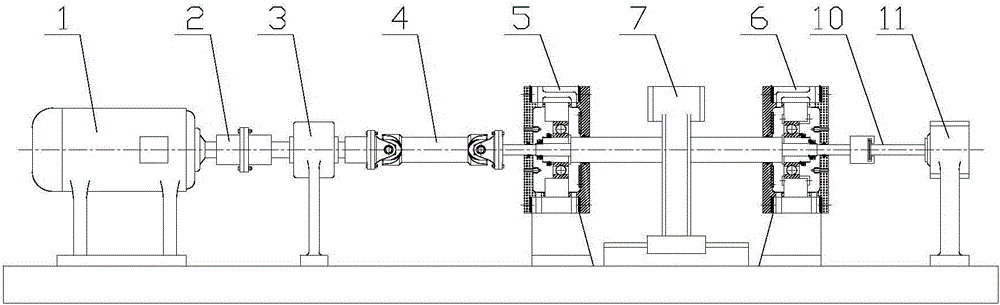

High/low-temperature controllable multi-specification rolling bearing test bench

InactiveCN105136457AExpand the scope of testingAchieve fixationMachine bearings testingRolling-element bearingSoftware engineering

The invention discloses a high / low-temperature controllable multi-specification rolling bearing test bench, and belongs to the technical field of bearing test benches. The high / low-temperature controllable multi-specification rolling bearing test bench comprises a base, and a driving motor, a bearing test device, a heating and cooling device, and a detection device which are arranged on the base. The bearing test device comprises a bearing test box used to fix a test bearing and test the bearing. The bearing test box includes a left bearing test box and a right bearing test box, and a test spindle is arranged between the left bearing test box and the right bearing test box in a penetrating mode. One end of the test spindle extends out of the left bearing test box and is fixed to a motor spindle, and the other end of the test spindle extends out of the right bearing test box and is fixed to an axial loading device. A radial loading device is arranged on the test spindle. The commonality of the test bench is improved greatly. Experimental study on different bearings, different loads and different targets can be competed with one set of equipment. Great engineering reference value is provided for optimized design, dynamic characteristic analysis, failure mechanism research and reliability analysis of rolling bearings.

Owner:CHONGQING UNIV +1

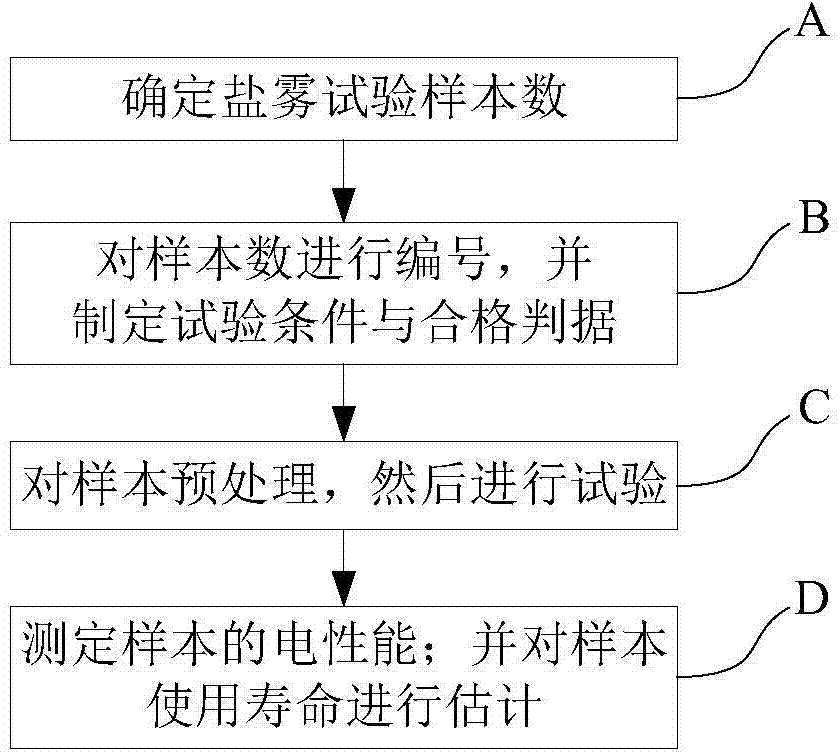

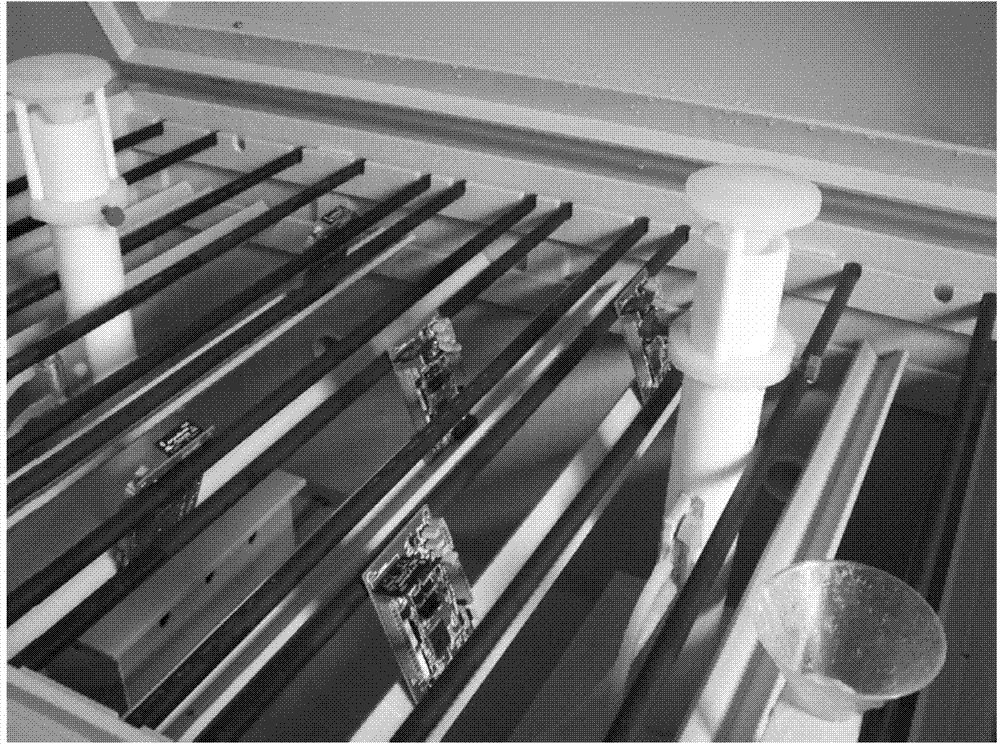

Printed circuit board service life assessment method based on salt-spray environment test

InactiveCN104777092AOvercoming Impossibility to Model AccuratelyRaise the level of service life verificationWeather/light/corrosion resistanceSmall sampleSalt spray test

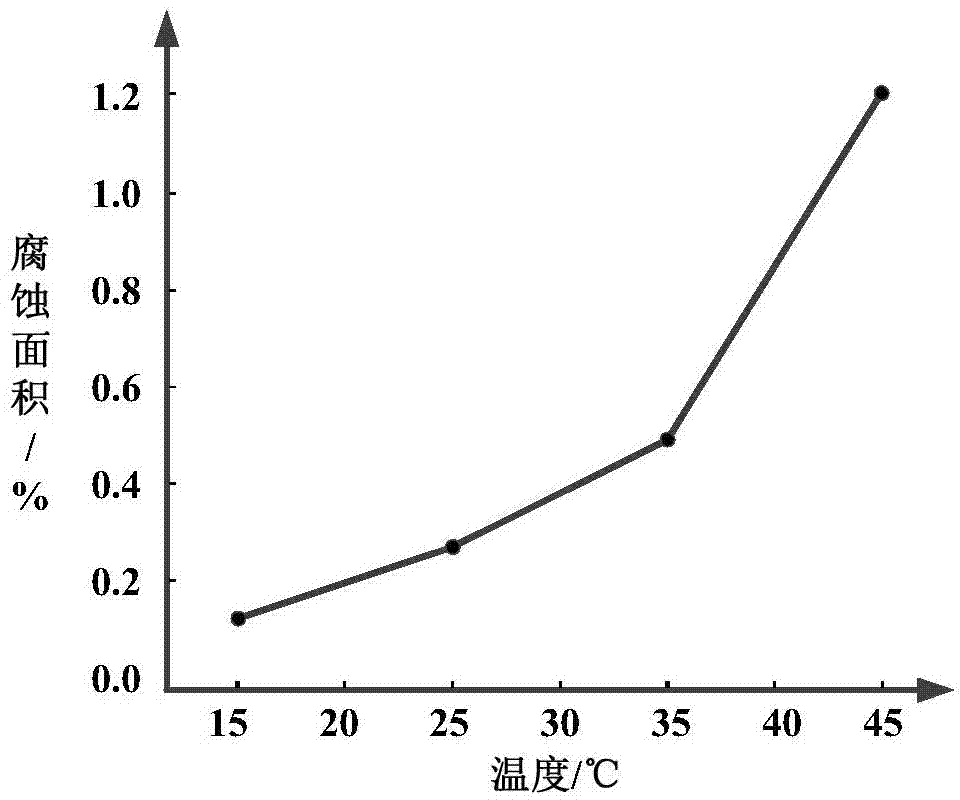

The invention discloses a printed circuit board service life assessment method based on a salt-spray environment test. The method comprises the following steps of associating the failure mode of the printed circuit board with a working condition, forming an accelerated life predication model based on the salt-spray test, drawing a changing curve between three environment factors of temperature, salt solution concentration and salt spray settling volume and test sample corrosion area by the method of combination of test data and Arrhenius accelerated life predication model, so as to predicate the service life of the printed circuit board under the salt-spray working condition. By utilizing the method, the problem that the accurate modeling is impossible in system with complex failure mechanism when analyzing small sample by traditional reliability analytical method is solved; secondly, during the researching stage of a device, through developing the accelerated life test, the test time is shortened, the service life assessment level of marine equipment is improved, the possible problems are exposed and solved completely before service, so as to formulate scientific and reasonable maintenance decision to save maintaining cost and guarantee complete war preparedness and successful task.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

System and method for forecasting service life and reliability of intelligent electric meter

InactiveCN103383445AReduce mistakesEffect scienceElectrical measurementsFailure rateMathematical model

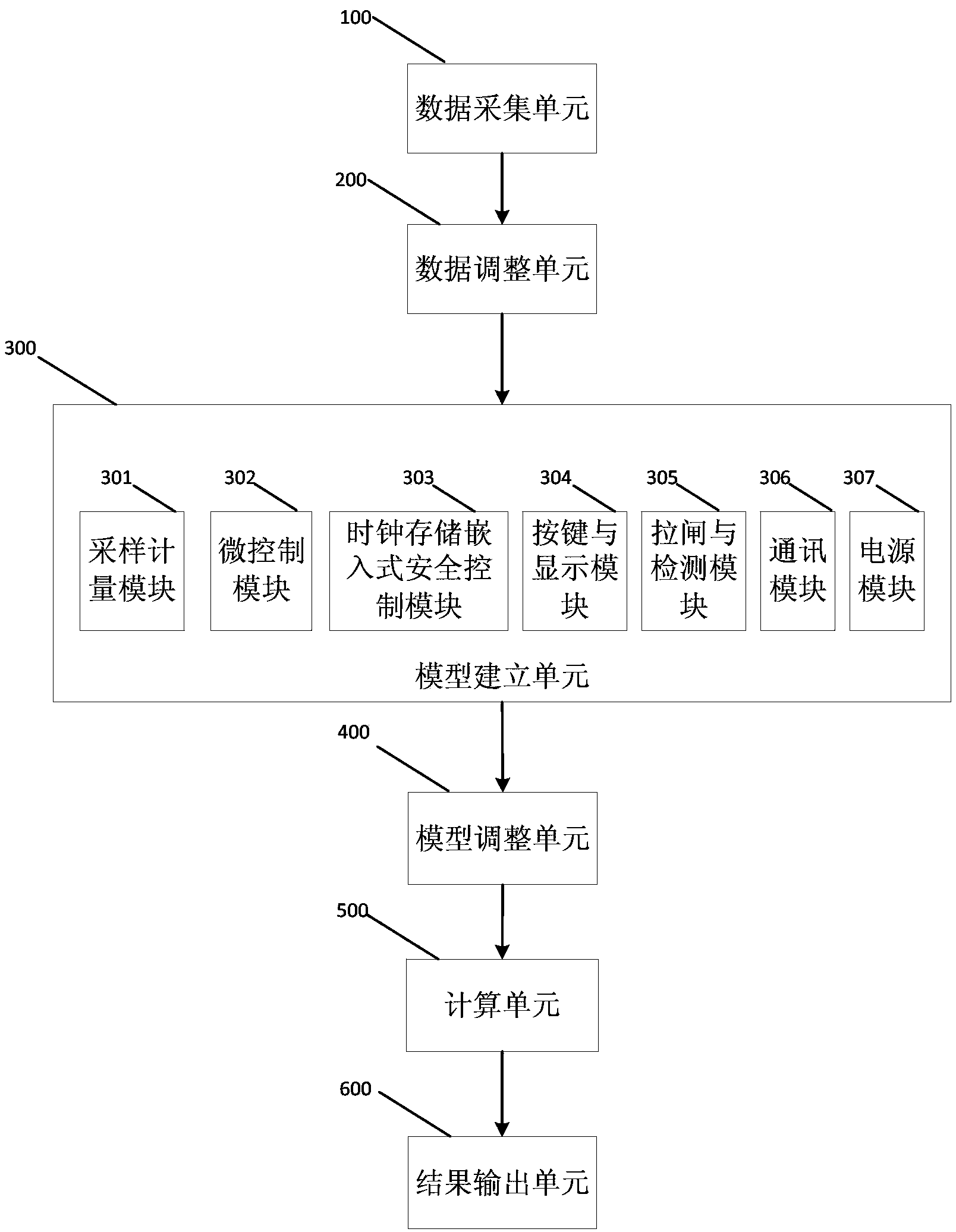

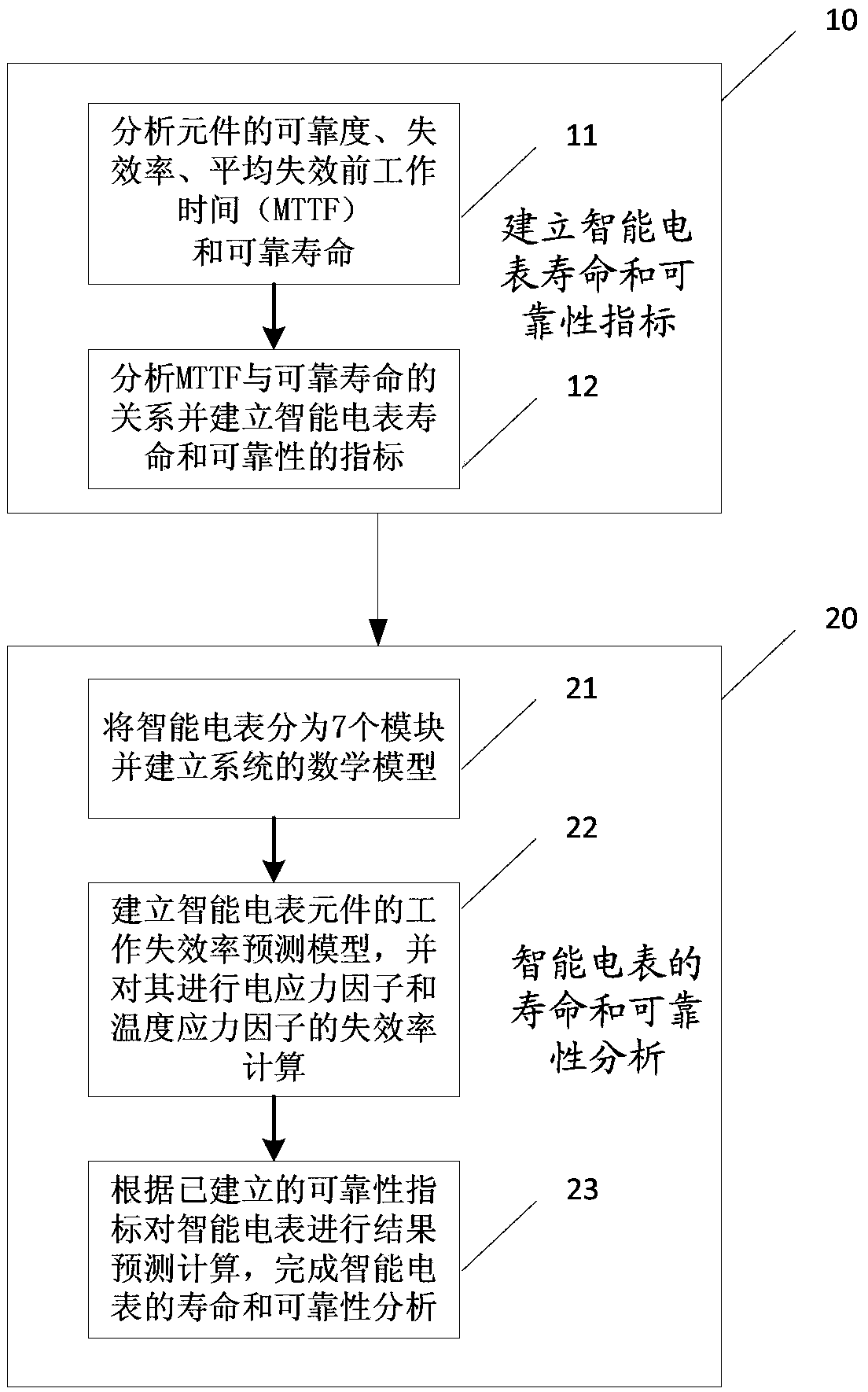

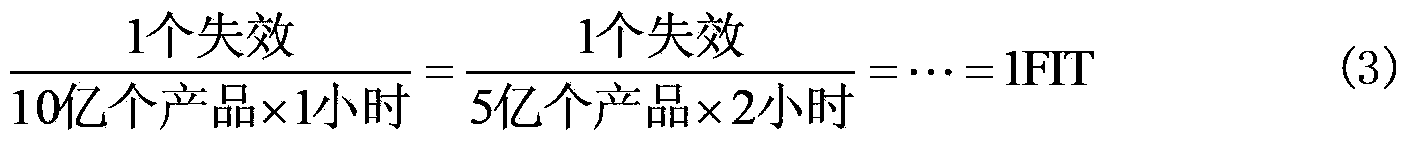

The invention discloses a system and a method for forecasting the service life and the reliability of an intelligent electric meter, and belongs to the field of electric power engineering detection. The system comprises a data acquisition unit (100), a data adjustment unit (200), a model building unit (300), a model adjustment unit (400), a calculation unit (500) and a result output unit (600). The method includes the steps: firstly, building service life and reliability indexes of the intelligent electric meter; secondly, building a mathematic model of the intelligent electric meter, calculating component failure rate and calculating a forecasting result by the aid of a failure rate result to analyze the service life and the reliability of the intelligent electric meter. The system and the method can solve the problems of low effectiveness, long test time, poor result consistency and the like of an existing traditional judgment method, and have the advantages of convenience in operation, less errors and economic feasibility.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +1

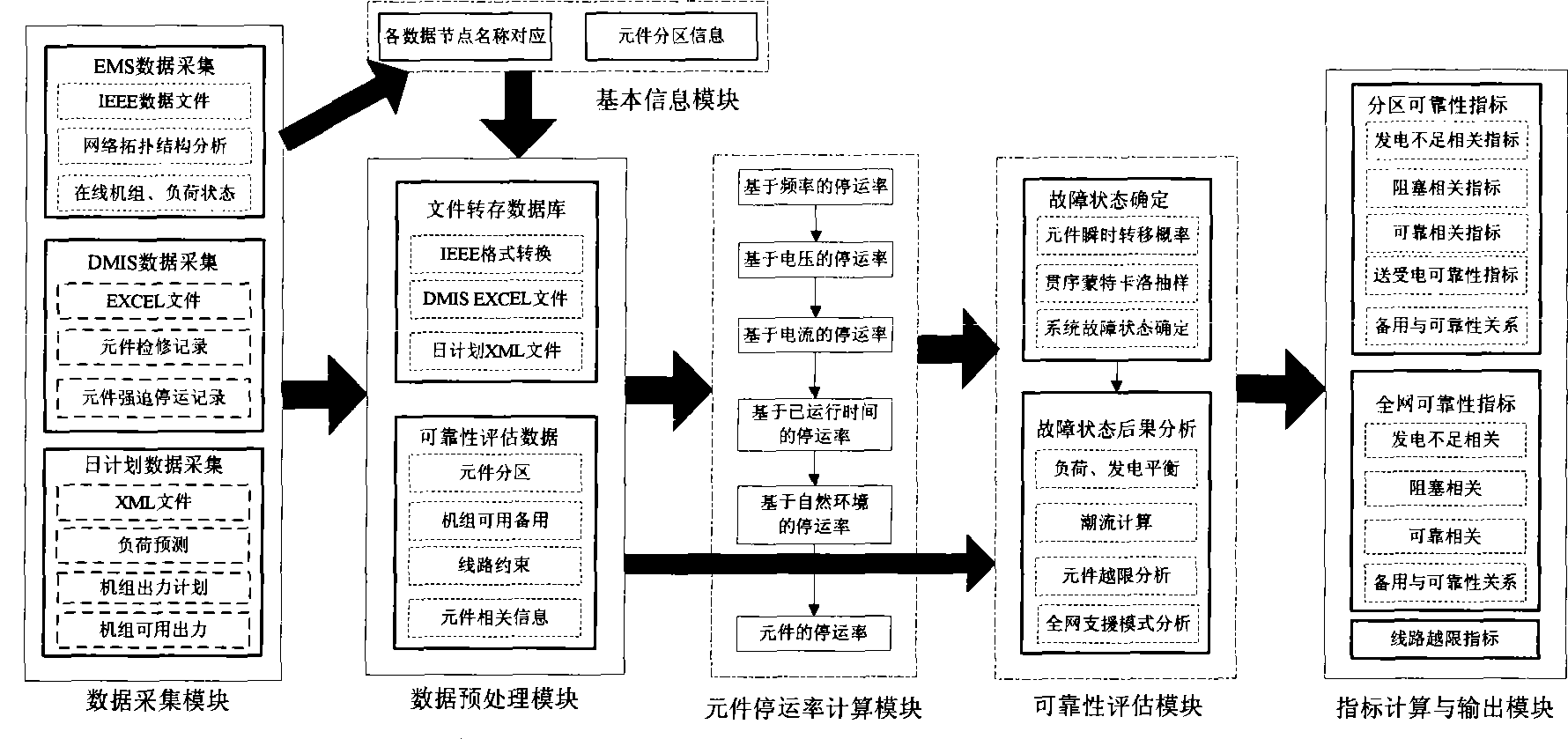

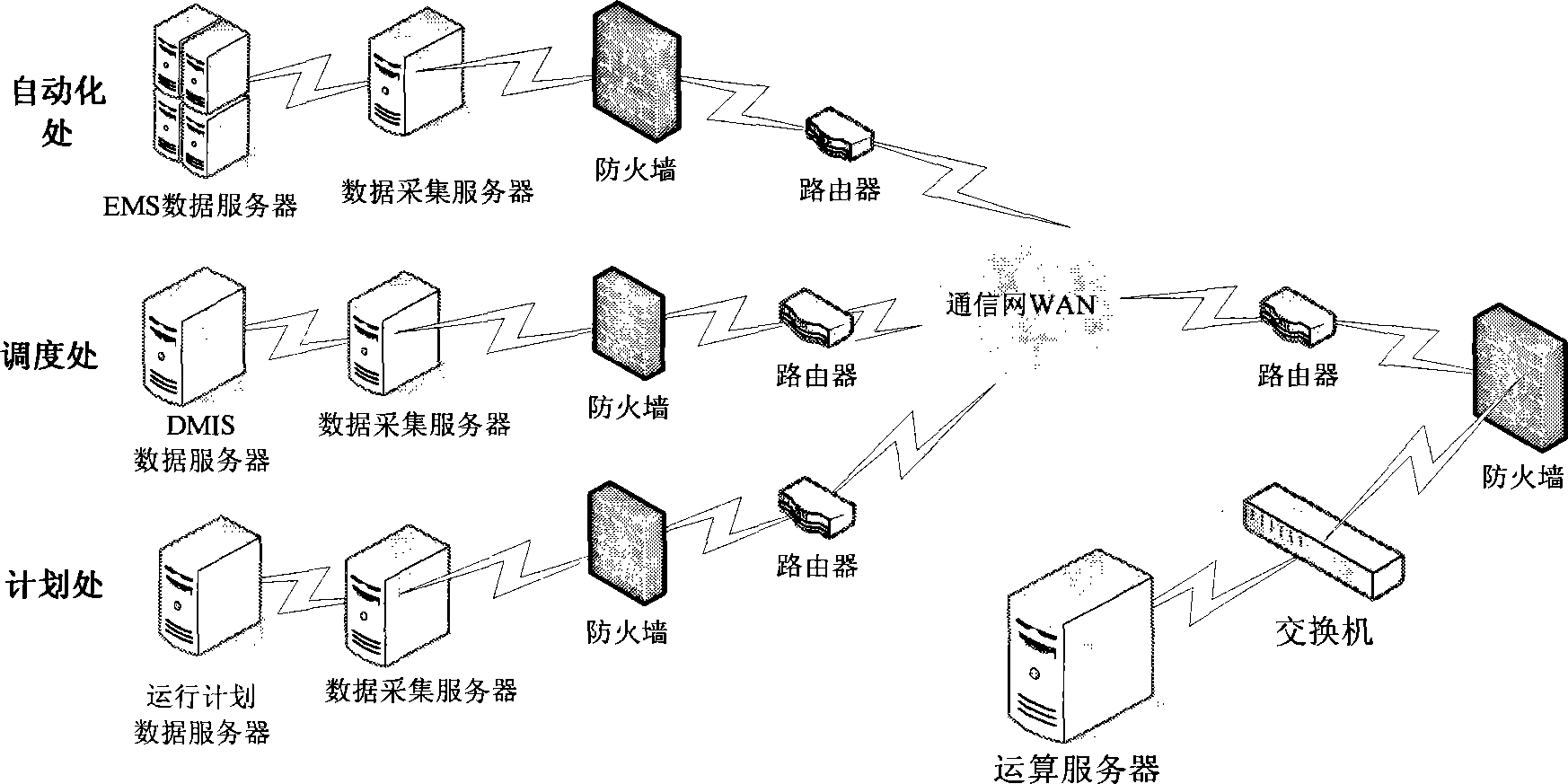

Electric power system operation standby reliability testing system

InactiveCN101413981AVersatileReduce instances of unreliable spare capacityFault locationAc network circuit arrangementsAnalysis dataElectric power system

The invention relates to a power system operational back-up reliability test system which belongs to the technical field of computer applications, wherein: a data acquisition module realizes the data acquisition across security subareas by setting a data acquisition server; a basic information module carries out the update of basic information of the system; a data pre-processing module analyzes data in a file which is obtained by the data acquisition module and carries out the pre-processing of element operational data; an element outage rate calculation module dynamically updates the real-time element outage rate; a reliability test module determines the fault states of the system according to the element outage rate in the element outage rate calculation module and the reliability analysis data in the data pre-processing module and tests the fault states; an indicator calculation and output module carries out the statistics of the test results of the fault states in the reliability test module, tests the operational reliability of the system and outputs early warning information. The power system operational back-up reliability test system can comprehensively measure the operational reliability of the system and timely update the reliability information of the system based on the real-time operational information of EMS power grid.

Owner:SHANGHAI JIAO TONG UNIV

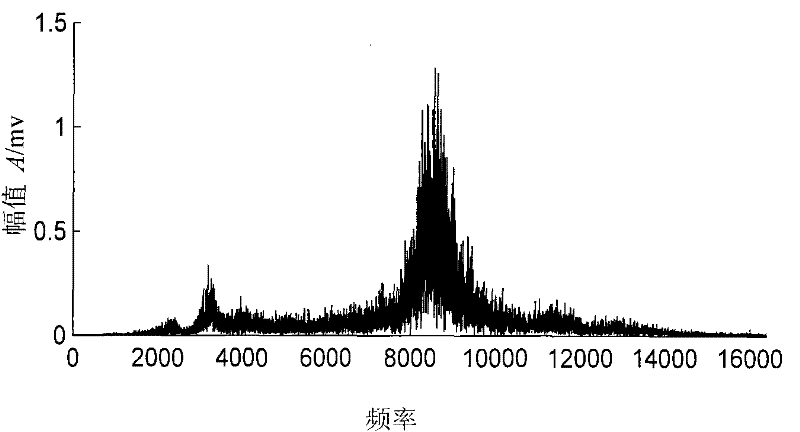

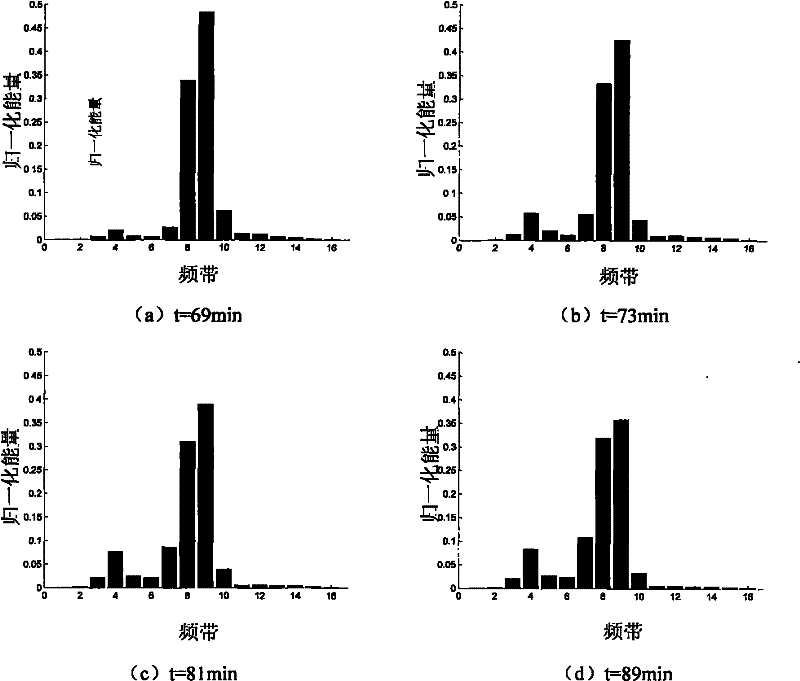

Method for estimating reliability of numerical control machine tool cutting tool based on logistic model

InactiveCN102176217AReflect dynamic operating characteristicsSpecial data processing applicationsNumerical controlEngineering

The invention provides a method for estimating the reliability of a numerical control machine tool cutting tool based on a logistic model. The method comprises the following steps: 1, signal analysis and characteristic extraction, in which, a vibration signal in a turning tool processing process and corresponding abrasion loss are measured through experiments, and wavelet packet decomposition andreconstruction are carried out on the vibration signal by utilizing an orthonormal wavelet basis function to ensure that coupled multi-carrier vibration signals are decomposed into a plurality of single-carrier vibration signal, and the time domain characteristic of a characteristic frequency band is calculated; related analysis is carried out on abrasion loss of the turning tool, remarkable indexes of the abrasion loss of the turning tool are extracted, and a failure threshold is determined; and 2, a logistic regression model is established by utilizing the remarkable indexes of the abrasionstate of the turning tool in the step 1, and reliability evaluation indexes and failed service life prediction are carried out on the running turning tool. By the method, the equipment operation status information is introduced to the performance evaluation and reliability analysis, so the dynamic operation characteristic of the equipment can be reflected more accurately.

Owner:XIAN RUITE RAPID MFG ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com