High/low-temperature controllable multi-specification rolling bearing test bench

A bearing test and rolling bearing technology, applied in mechanical bearing testing and other directions, can solve the problems of poor versatility and high research and development costs, and achieve the effects of high fixing efficiency, increasing test range and improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

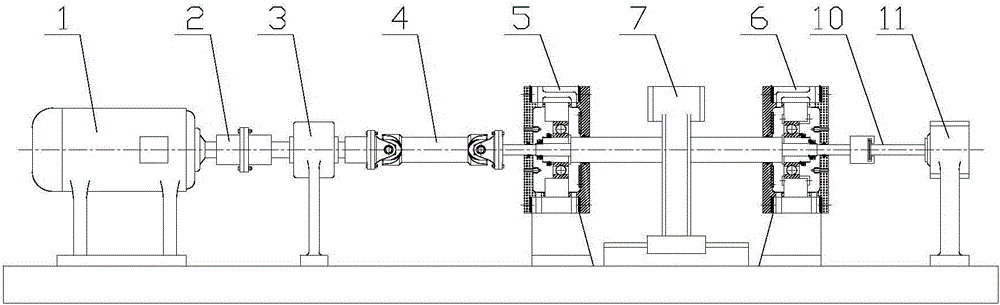

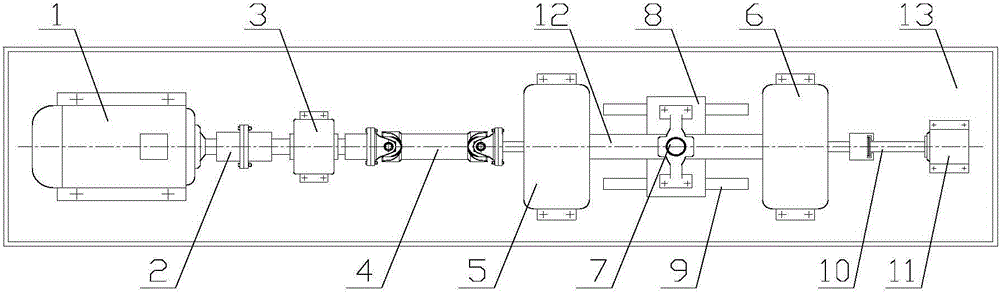

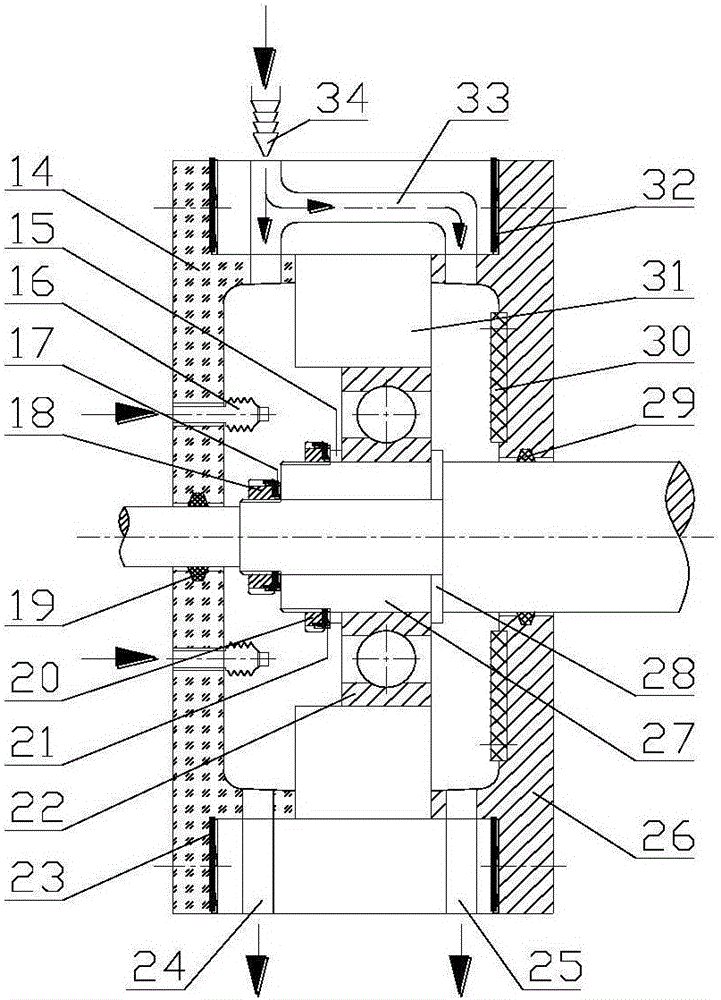

[0037] Such as Figure 1-5 Shown is the first embodiment of the present invention. The high-low temperature controllable multi-specification rolling bearing test bench of this embodiment is a high-temperature friction test for angular contact ball bearings, including a base 13 and a drive motor 1 arranged on the base 13, a bearing Test device, heating and cooling device and detection device, the bearing test device includes a bearing test box for fixing the test bearing to carry out the bearing test, the left bearing test box 5 and the right bearing test box 6 included in the bearing test box, in the left Between the bearing test box 5 and the right bearing test box 6, there is a test spindle 12 for testing the test bearings in the box. One end of the test spindle 12 extends out of the left bearing test box 5 and is fixed with the motor spindle, and the other end extends The right bearing test box 6 is fixed with an axial loading device, and the axial loading device includes a...

no. 2 example

[0048] Figure 6 It is a schematic structural diagram of the left bearing test box of the second embodiment of the present invention. The difference from the first embodiment is that the diameter adjustment ring of the inner ring of the bearing and the diameter adjustment ring of the outer ring of the bearing in this embodiment are provided with a diameter adjustment mechanism. The diameter adjustment mechanism on the diameter adjustment ring of the inner ring of the bearing includes at least three expansion blocks one 56 and the traction cylinder one 58 for expanding and pulling the expansion block one 56, and the diameter adjustment mechanism on the diameter adjustment ring of the bearing outer ring includes at least three Three expansion blocks 2 57 and the traction cylinder 2 59 for expansion and traction of the expansion block 2 57, in order to facilitate fixing, a traction cylinder fixing hole can be processed on the test spindle to fix the diameter adjustment ring of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com