Method for estimating reliability of numerical control machine tool cutting tool based on logistic model

A CNC machine tool and reliable technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of high price of direct method, interference processing, intermittent measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Accompanying drawing is the concrete implementation example of the present invention.

[0052] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] A method for evaluating the reliability of CNC machine tools based on the Logistic model, comprising the following steps:

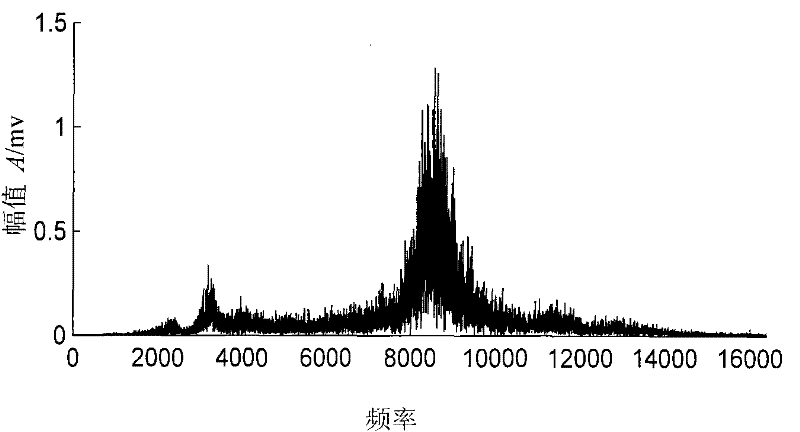

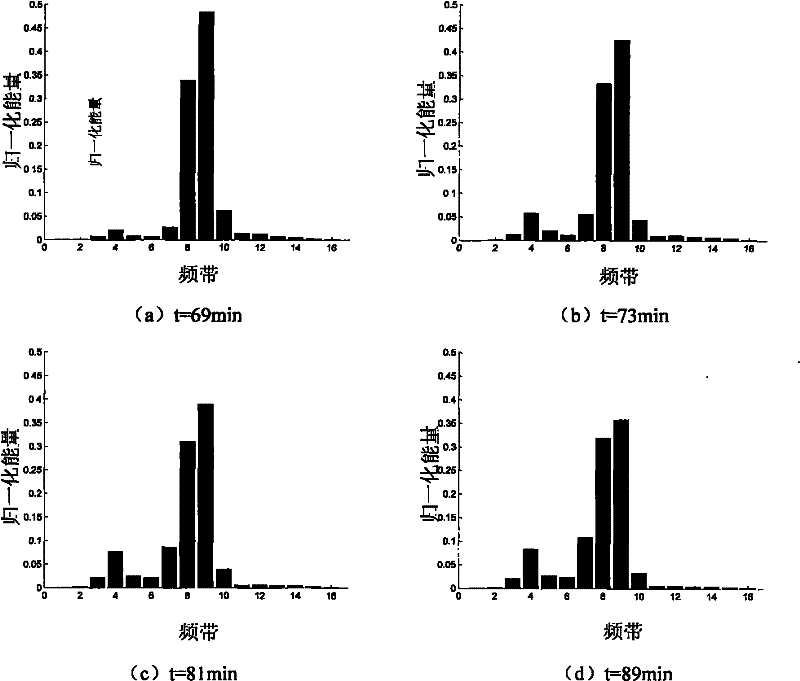

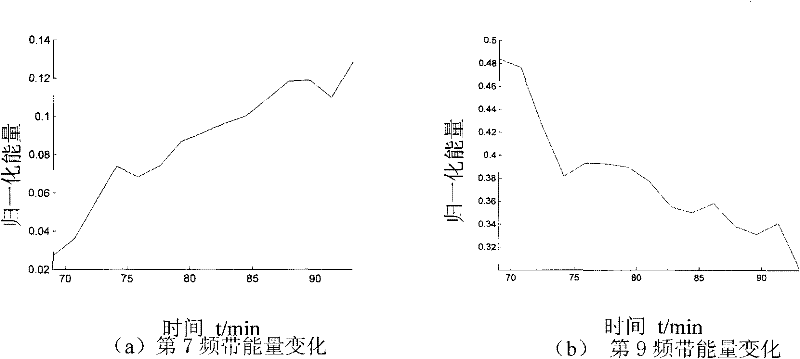

[0054] 1. Signal analysis and feature extraction: Vibration signals and corresponding wear data during turning tool processing are measured through experiments, and orthogonal wavelet basis functions are used to decompose and reconstruct the vibration signals by wavelet packets, so that the coupled multi-carrier The vibration signal is decomposed into multiple single-carrier vibration signals;

[0055] 1) Wavelet packet decomposition and reconstruction

[0056] Assume that the size space of an energy-finite signal is Through packet transformation, is binary decomposed into multiple subspaces. Its iteration formula i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com