Elevator component improvement plan system and elevator component improvement plan method

A technology for components and elevators, applied in elevators, transportation and packaging, etc., to solve problems such as failure of components, time-consuming components, and insufficient replacement of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, this embodiment will be described with reference to the drawings.

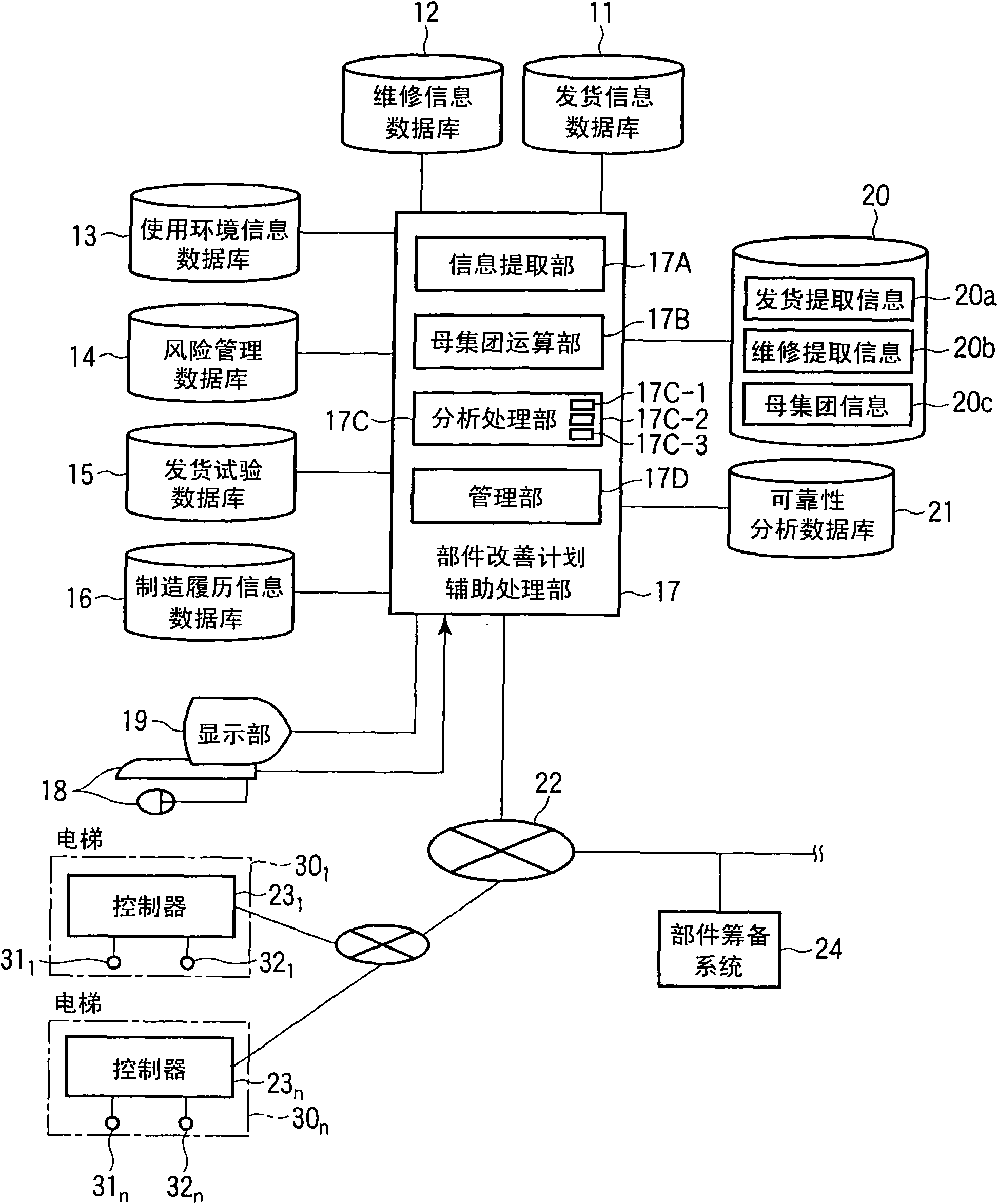

[0037] figure 1 It is a block diagram showing the configuration of an elevator component improvement planning system according to the present embodiment.

[0038] The component improvement planning system of the elevator of this embodiment is realized by the computer system comprised by CPU, ROM, RAM, etc. This elevator component improvement planning system includes a delivery information database 11, a maintenance information database 12, a usage environment information database 13, a risk management database 14, a delivery test database 15, a manufacturing history information database 16, and a component improvement plan auxiliary process. unit 17 , input unit 18 , display unit 19 , extraction result database 20 and reliability analysis database 21 .

[0039] In addition, in this elevator parts improvement planning system, the elevators 30 in various places are connected via a network 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com