Printed circuit board service life assessment method based on salt-spray environment test

A printed circuit board and salt spray test technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting environmental adaptability, printed circuit boards are susceptible to corrosion, and printed circuit boards are used in low frequency. Achieve the effect of improving service life verification level, ensuring integrity and mission success, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

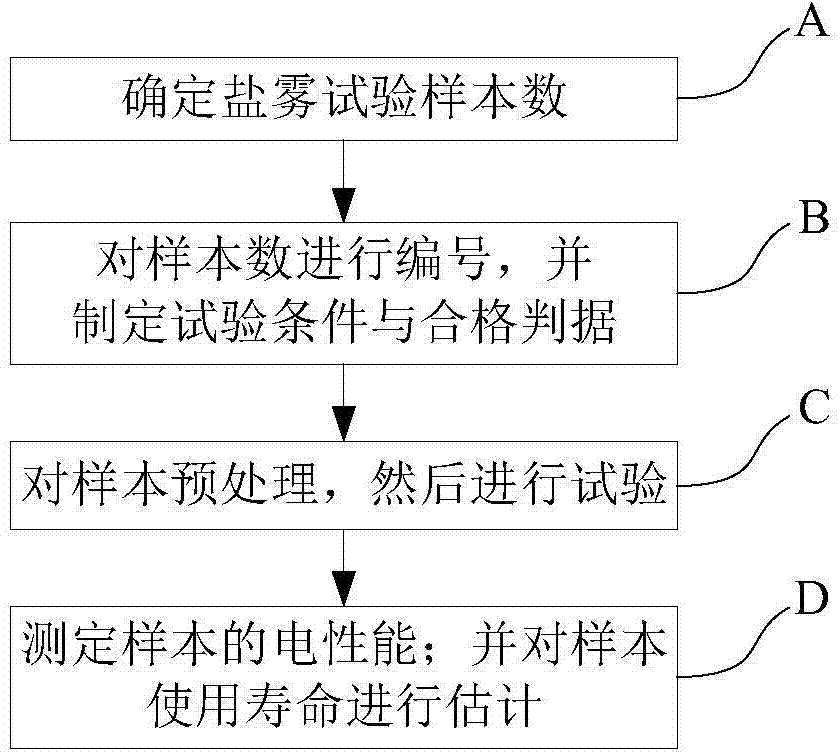

[0033] Such as figure 1 Shown is the flow chart of the printed circuit board service life verification method based on the salt spray test of the present invention, including the following steps:

[0034] A: Refer to the failure rate test of electronic components and determine the number of salt spray test samples according to the specific requirements of the test.

[0035] First, it is assumed that the printed circuit boards of maritime weapons and equipment obey exponential distribution, and its failure distribution function is

[0036] F(t)=1-e -λt (1)

[0037] Its reliability is

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com