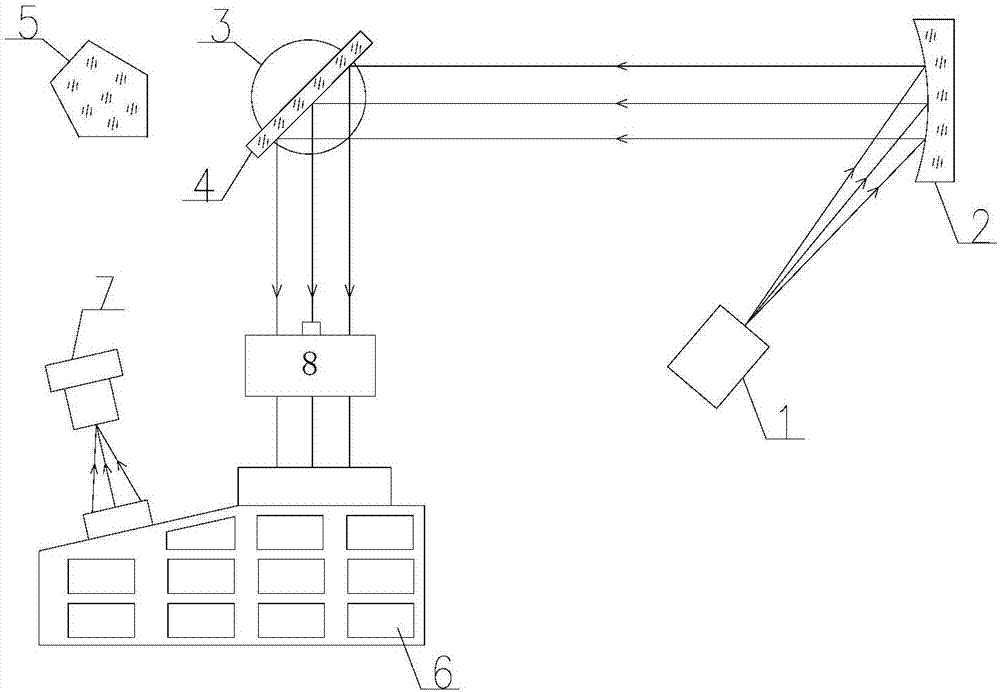

MTF test device and test method for off-axis three-mirror optical system with large field of view

An off-axis three-mirror optical system technology, applied in the field of optical inspection, can solve the problems of the difficulty of transfer function testing, the special optical path of the off-axis three-mirror optical system, and the inability to directly apply the MTF test of the off-axis three-mirror optical system. Achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

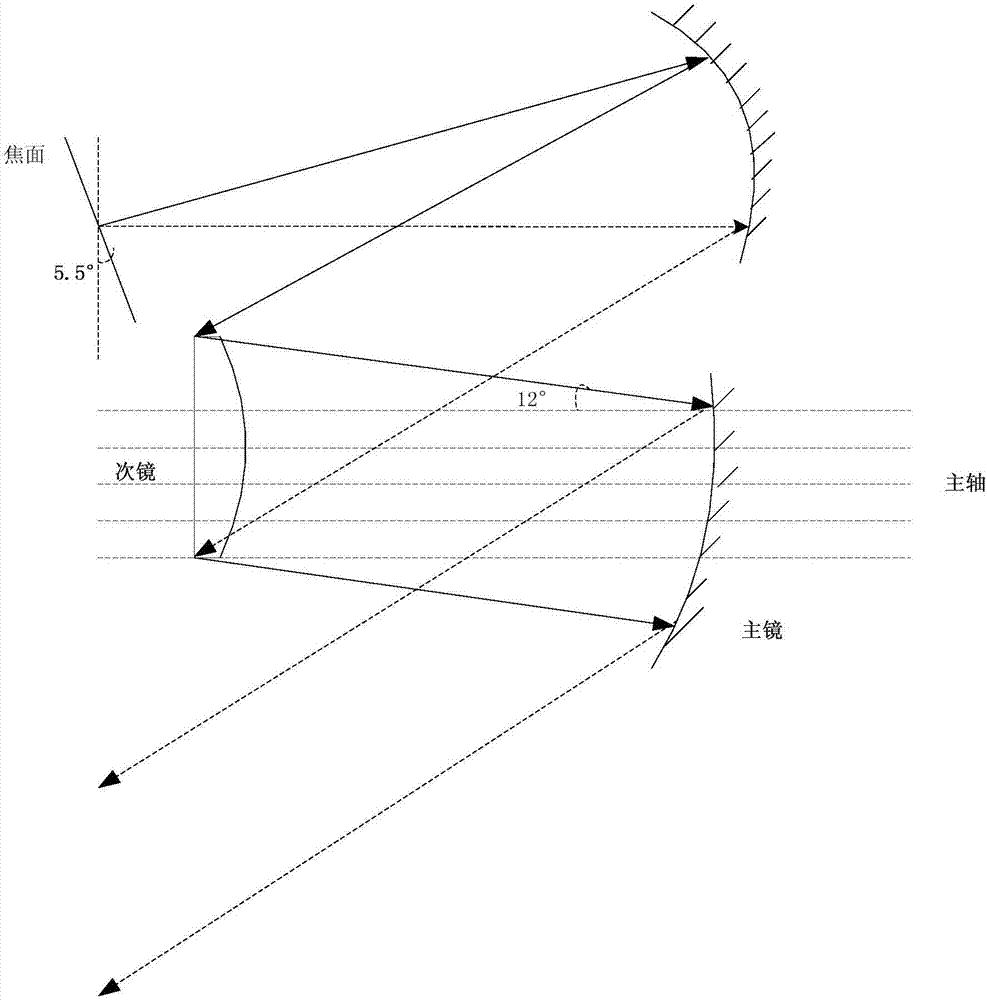

[0039] In order to explain the specific ideas and principles of the present invention more clearly, here we first introduce the main features of the large field of view off-axis three-mirror optical system:

[0040] Feature 1: The light entrance and light exit of the large field of view off-axis three-mirror optical system are in the same plane (the object space and the image space are on the same plane).

[0041] In the general MTF test process, it is necessary to self-adjust the optical path so as to determine the MTF accuracy of the central field of view during the test process.

[0042] The optical path self-alignment adjustment is mainly divided into two parts, one is the optical path self-alignment of the entire test device, that is, by adjusting the azimuth and pitch of the MTF test system, the reflected light path of the detector of the MTF test system is parallel to the optical axis of the MTF test system. The other part is to adjust the optical path of the measured o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com