Multifunctional high voltage apparatus safe property checking device

A technology for high-voltage equipment and safety performance, which is applied in the field of multi-functional high-voltage equipment safety performance detection devices, can solve problems such as single boosting method, single function, and slow boosting rate, and achieve a wide output pressure range, good safety performance, and high boost pressure. The effect of pressing quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

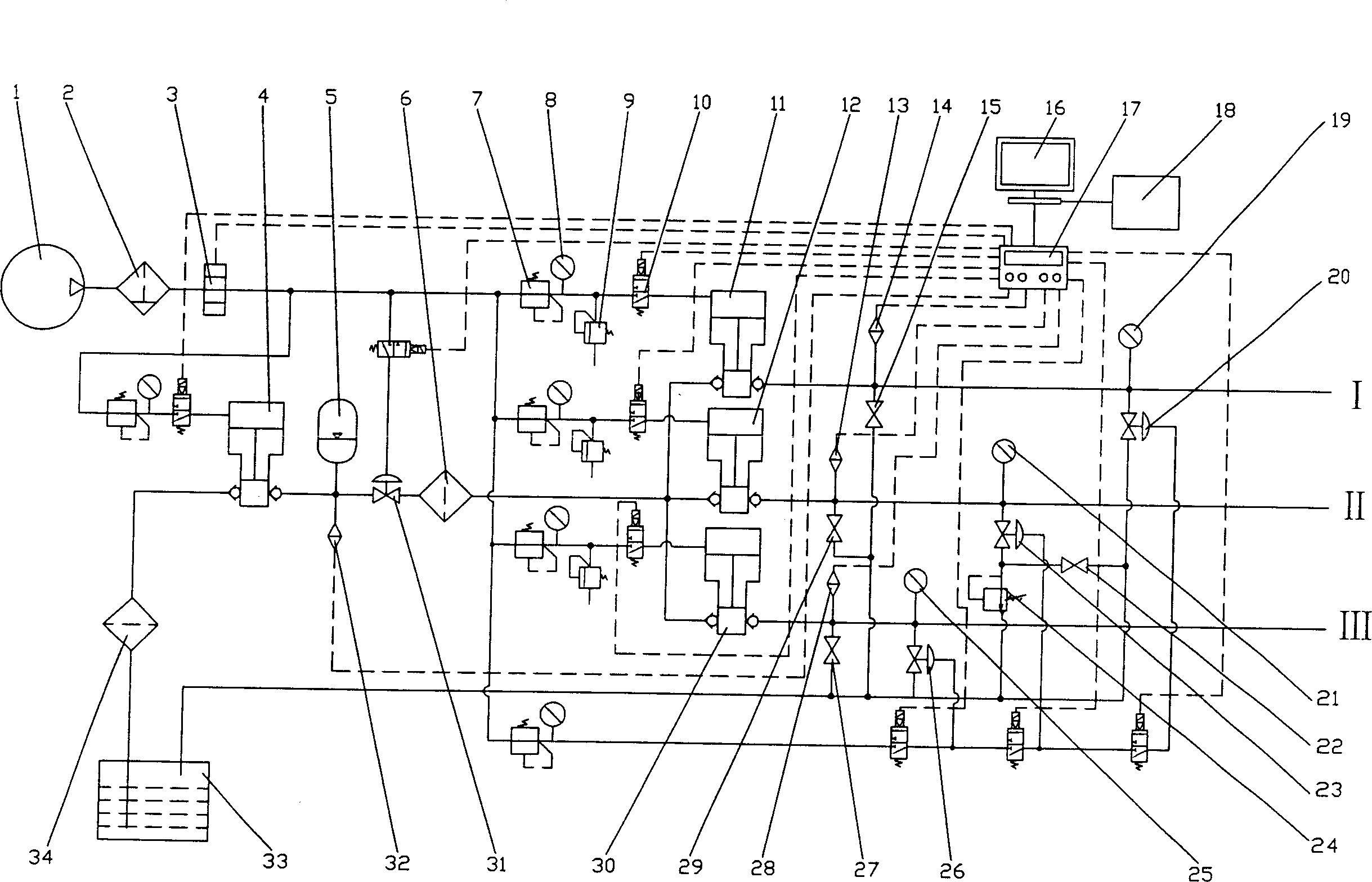

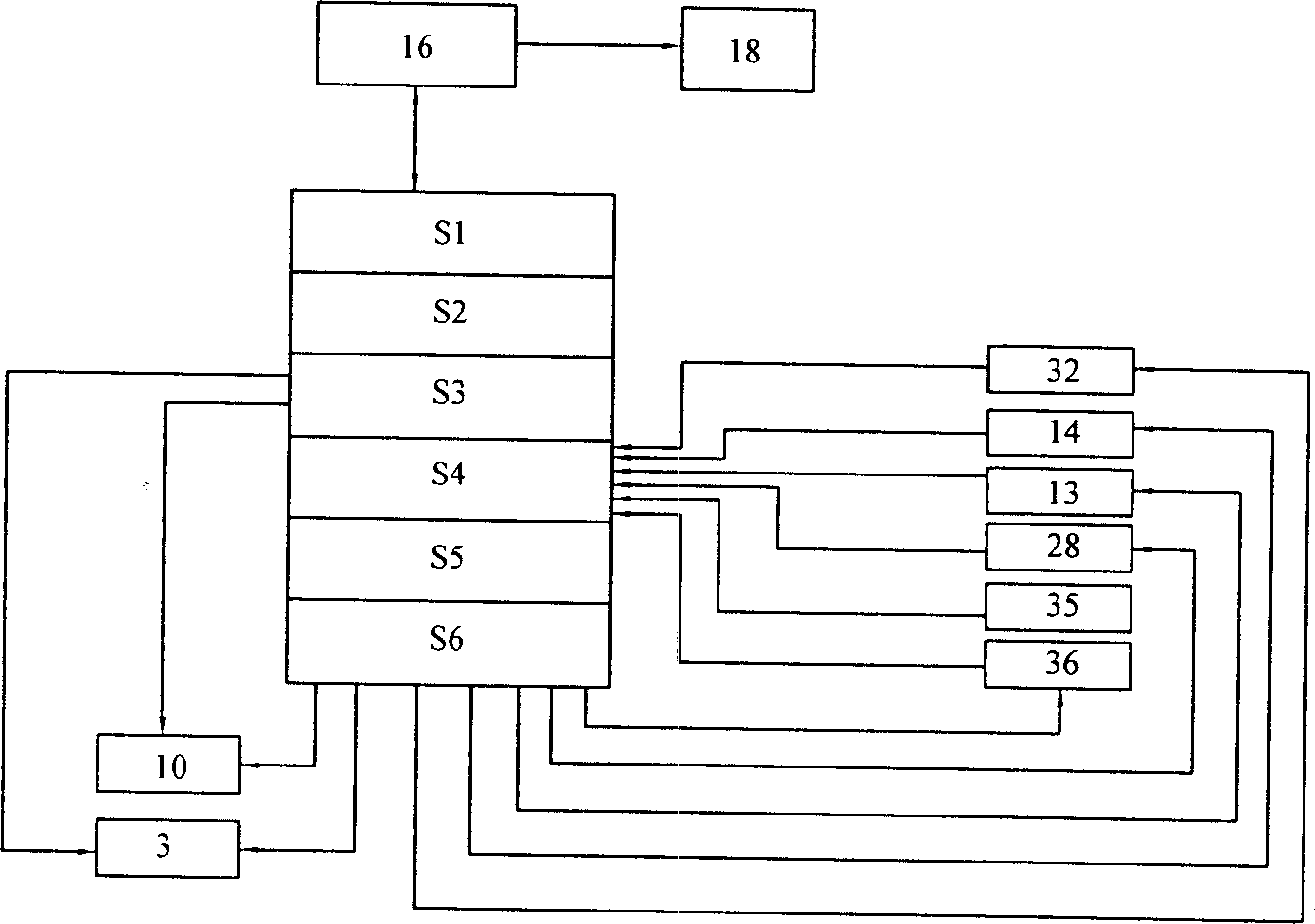

[0011] Such as figure 1 As shown, the multifunctional high-voltage equipment safety performance testing device includes a gas power system, a water injection and exhaust system, a pressure lifting system, a measurement control system, and a safety protection system. The gas power system is connected with an air compressor 1, a filter 2, and a Two-way solenoid valve group 3, pressure reducing valve 7, safety valve 9, two-position three-way solenoid valve 10, and low-pressure pump 4, first high-pressure pump 11, second high-pressure pump 12, third high-pressure pump 30 and low-pressure pneumatic The air inlets of valve 31, first high-pressure pneumatic valve 20, second high-pressure pneumatic valve 23, and third high-pressure pneumatic valve 26 are connected; the water injection and exhaust system is connected with water tank 33, low-pressure filter 34, low-pressure pump 4, and energy storage in sequence. Device 5, low-pressure pneumatic valve 31, high-pressure filter 6, and lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com