Safety pilot electromagnetic valve

A pilot valve, solenoid valve technology, applied in safety valve, lift valve, valve details and other directions, can solve the problems of short power-on time, leakage, burning, etc., to achieve the effect of extending service life and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

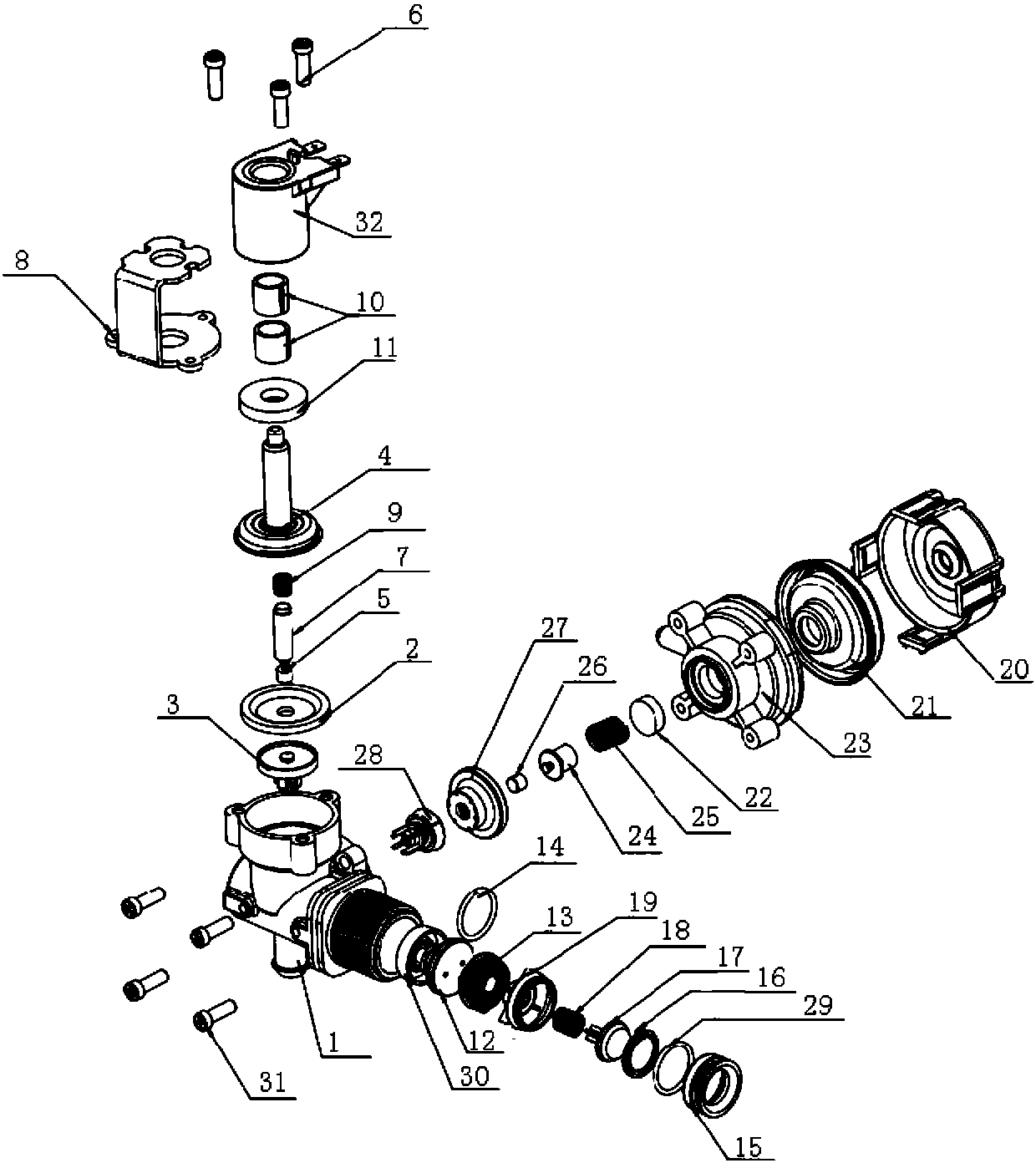

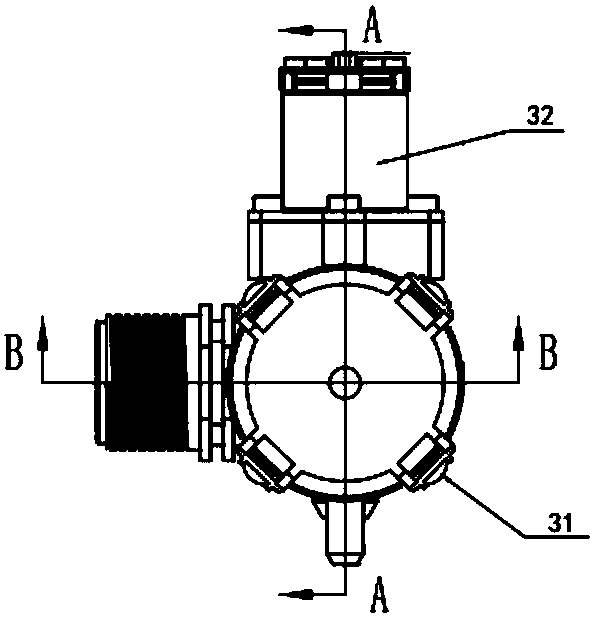

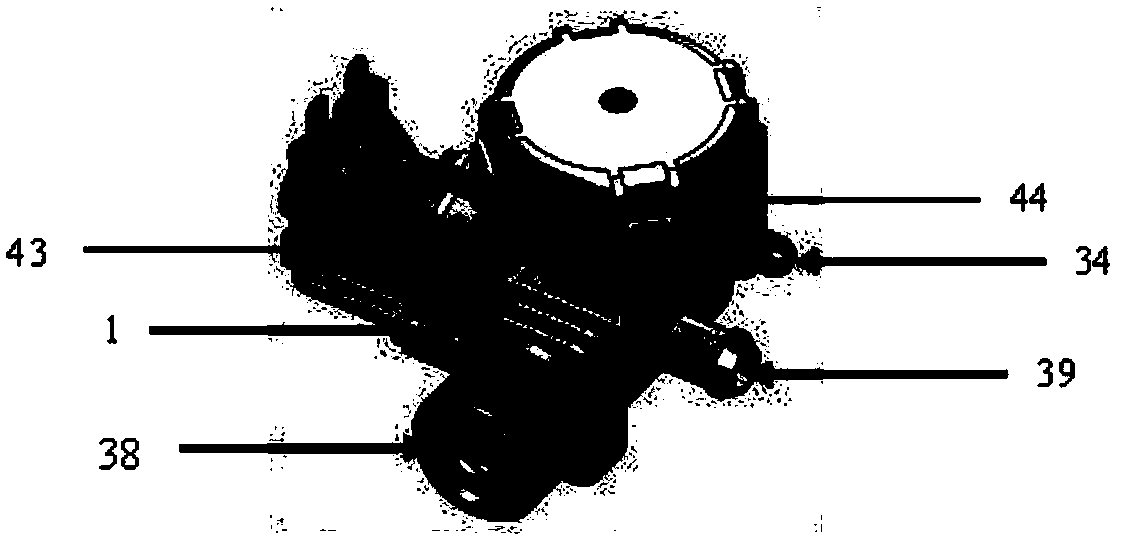

[0043] Embodiment, a safety pilot solenoid valve

[0044] (1) Basic working principle

[0045] The safety pilot solenoid valve provided in this embodiment has two pilot structures, the first pilot structure is an ordinary pilot valve not limited by water pressure; the second pilot structure is a safety valve for safety protection; this implementation The safety pilot solenoid valve provided in the example has an overpressure self-protection function, and can cooperate to realize automatic selection of different protection schemes according to the overpressure level. When inside (medium pressure is low pressure, medium pressure), the medium passes through the water inlet, the first pilot structure, the second pilot structure, and the water outlet in sequence. That is, it is controlled by a common pilot valve, and the second pilot structure and the first pilot structure and the water outlet are in a conduction state; when the system pressure suddenly exceeds the warning value, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com