Multi-station ball-valve bursting test machine

A blasting test, multi-station technology, used in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of inability to formulate the pressure limit of ball valves, no sampling blasting of ball valves, etc. Save space and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

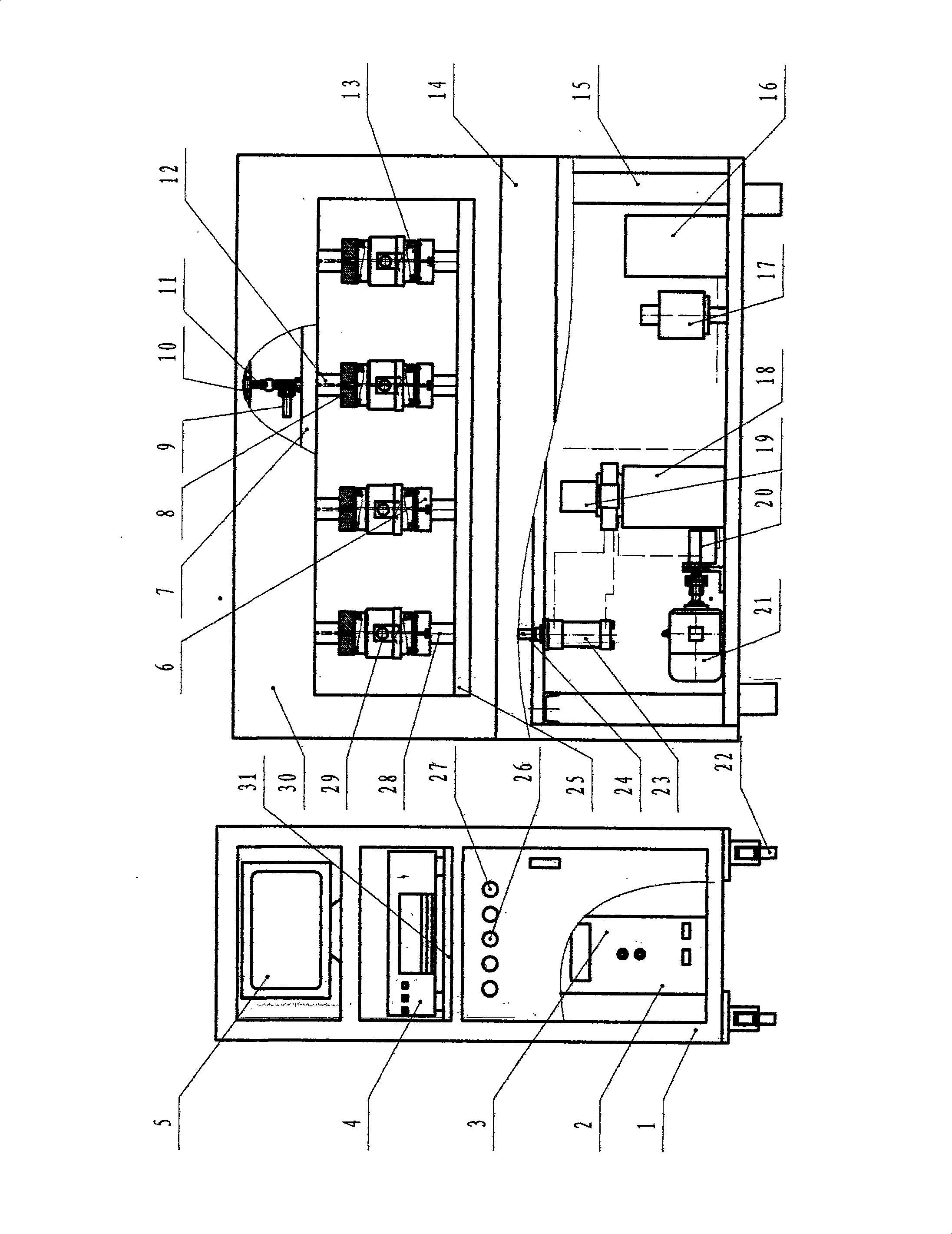

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] As shown in the figure, a multi-station ball valve blasting test machine includes: a test host 30 and a control cabinet 1 . The main engine 30 is divided into upper and lower layers, the upper layer is the test bench 6, the lower floor is the machine base 15, and the main engine 30 is an integral vertical structure. The test bench 6 is composed of a sealing fixture 8, a beam 7, a support plate 25, and a pressure rod 12. On the support plate 25, 3-10 test stations parallel to each other are vertically installed, and 1-10 ball valves can be selected to be tested at the same time. Pressure and burst performance test. Each test station is equipped with two special ball valve test sealing fixtures 8, one is fixed on the beam 7 through the pressure rod 12, the other is fixed on the lower pressure rod 28, and can move up and down along its axis, the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com