System and method for tunnel water-bursting test under high crustal stress-osmotic pressure

A high ground stress and model test technology, applied in the direction of applying stable tension/pressure to test material strength, instruments, measuring devices, etc., can solve the test requirements, test device assembly and disassembly that cannot realize high ground stress-high osmotic pressure simulation The process is cumbersome, and it is not conducive to the uniform arrangement of hydraulic jacks, etc., so as to avoid excessive manpower and test site conditions, provide space utilization, and improve rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

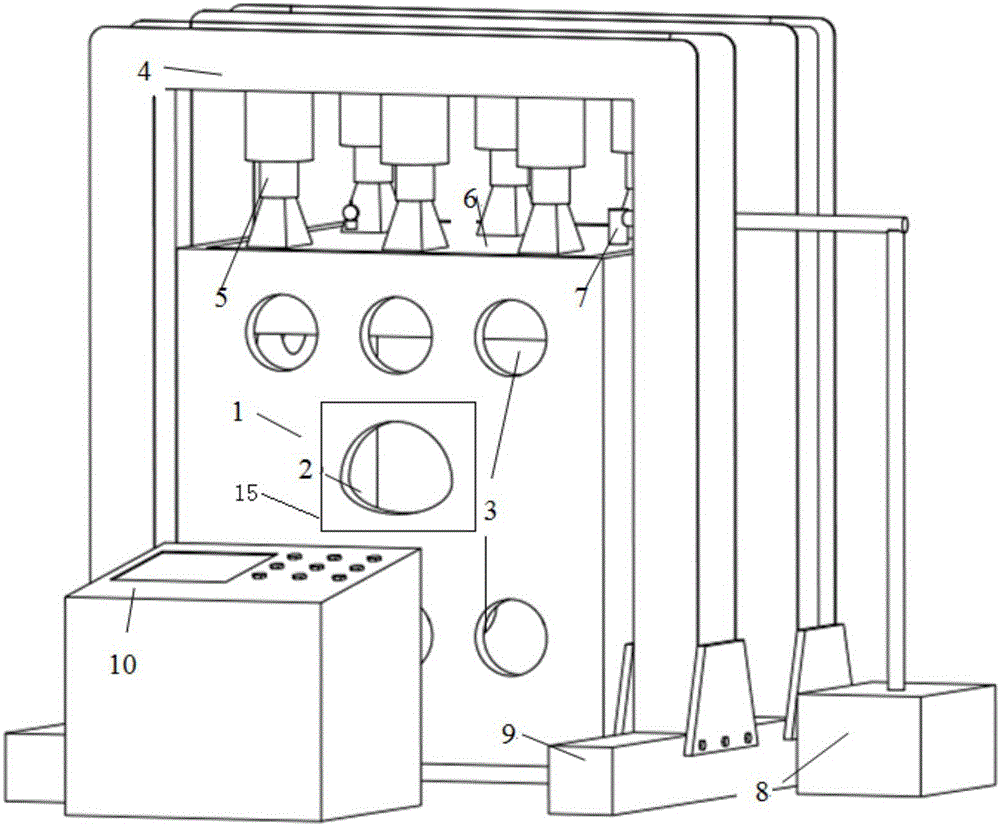

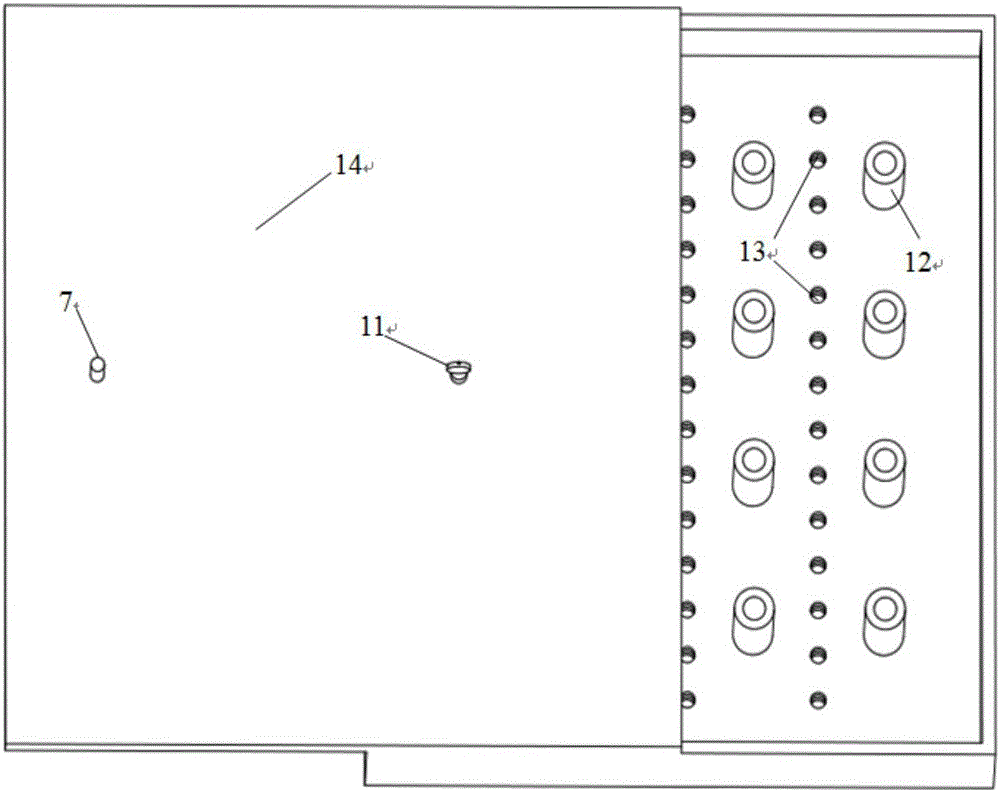

[0043]A model test system for tunnel water inrush under high ground stress-high seepage pressure-engineering excavation disturbance, characterized in that the system mainly includes a main box 1, a ground stress loading system, a seepage pressure loading system, control and monitoring integration Four parts of chemical system 10, in which the main box 1 is a box with an upper opening welded by steel plates, which is an integral structure, which improves the strength and water sealing performance of the box. The glass window 3 enables the visualization of the test device. The front and rear two steel plates have tunnel openings to facilitate the simulation of tunnel excavation; the hydraulic jack 5 is installed on the reaction frame 4 and is controlled by an intelligent hydraulic control device. In the integrated monitoring system 10, the vertical loading of the model body can be realized, and the reaction force frame 4 is installed on the slide rail 9, and can slide on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com