Measurement and control system for hydraulic test

A measurement and control system, hydraulic test technology, applied in the direction of control/regulation system, using stable tension/pressure to test material strength, non-electric variable control, etc., can solve the problem that the boost rate cannot be automatically adjusted, automatic control cannot be realized, noise Large and other problems, to achieve the effect of light weight, low noise, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to understand the present invention more clearly, describe in detail in conjunction with accompanying drawing and embodiment:

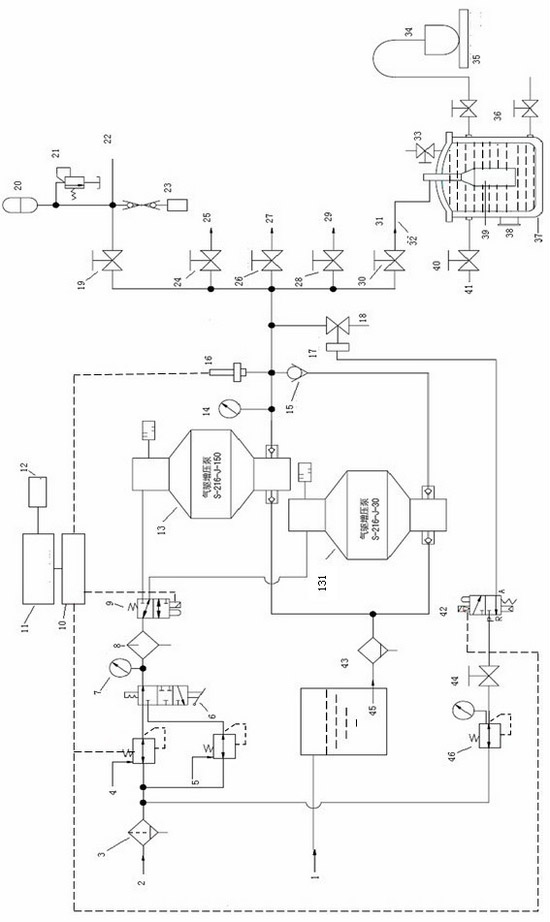

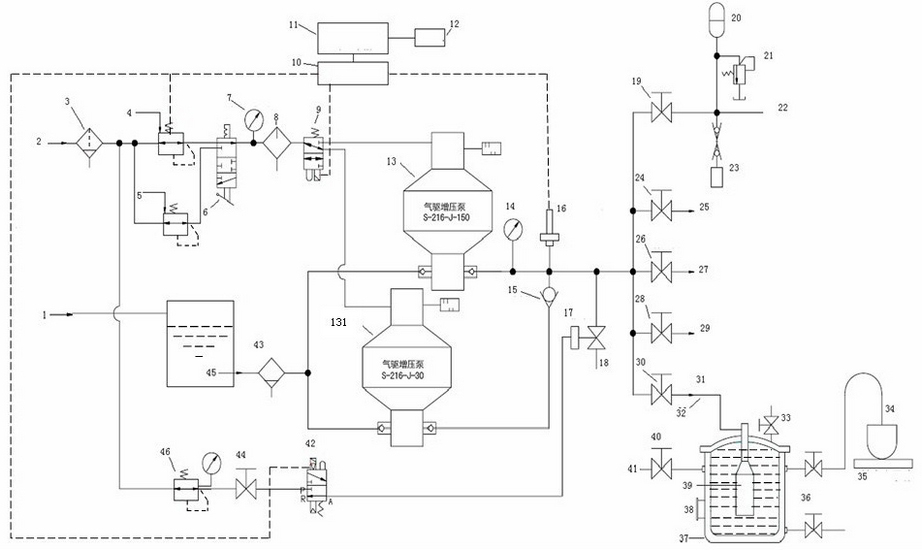

[0045] Such as figure 1 As shown, a hydraulic test measurement and control system includes a system control part and a measurement and control pipeline part; the system control part is composed of a PLC control cabinet 10, an industrial computer 11 and a printer 12, the PLC control cabinet 10 includes a PLC, and the industrial computer 11 is used as a PLC The host computer is connected by a communication cable;

[0046] Electric proportional valve 4, electromagnetic reversing valve A9, electromagnetic reversing valve B42 and pressure sensor 16 are respectively installed on the measurement and control pipeline;

[0047] The PLC is connected to the pressure sensor 16 through its analog input port to collect pipeline pressure signals;

[0048] The PLC is connected to the control terminal of the electric proportional valve 4 through its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com