Device for tire burst test

A technology for testing and puncture, which is applied in the direction of automobile tire testing, etc. It can solve the problems of limited number of times and repeatability, aggravate test costs, and tires cannot be used again, and achieve the effects of simple structure, avoiding wire entanglement, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The device of the present invention will be further described below in conjunction with the accompanying drawings.

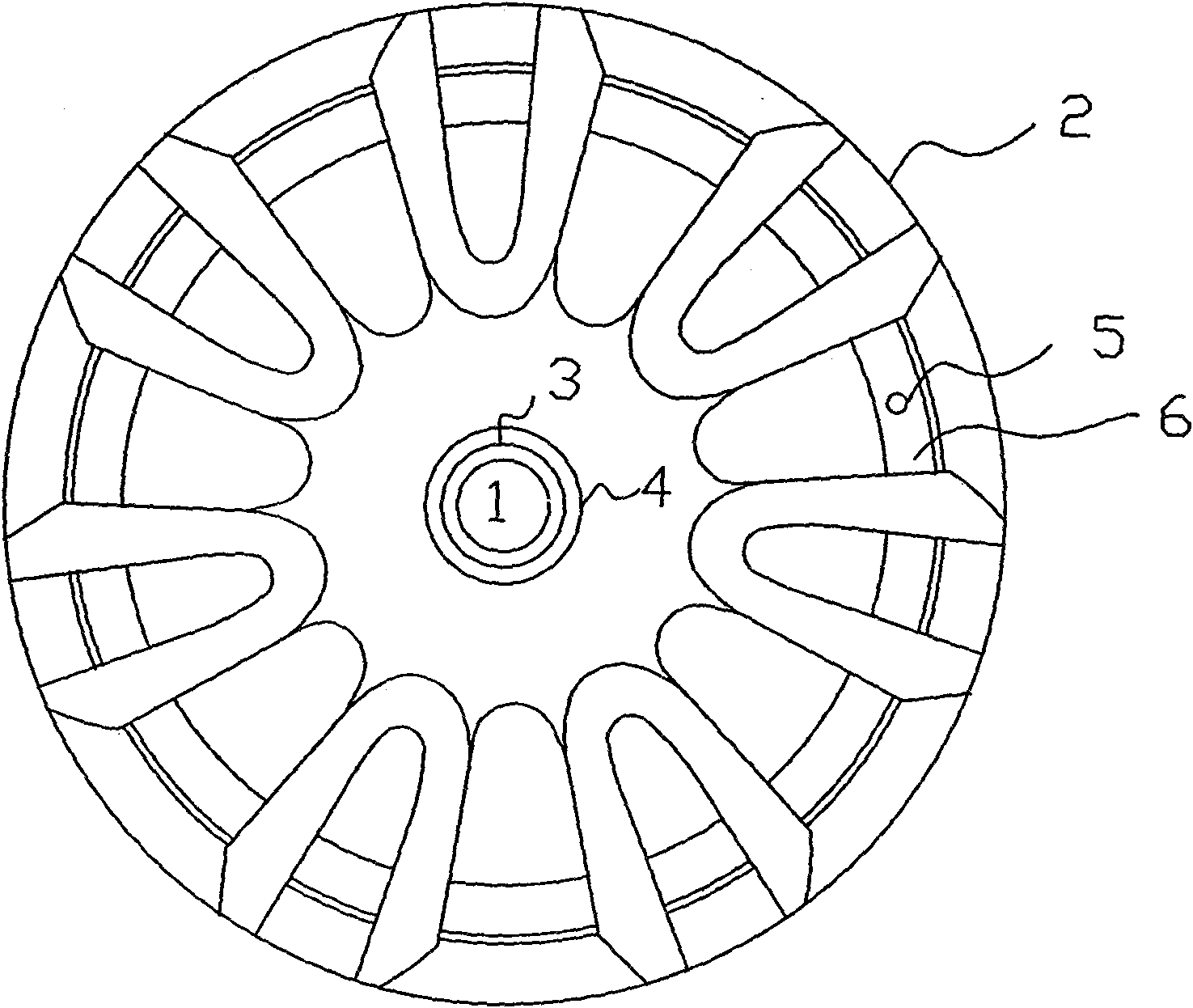

[0015] A kind of tire blowout test device of the present invention comprises wheel, as figure 2 As shown, a rotating bearing 3 is arranged outside the axle 1 of the wheel, and an insulating rubber is arranged outside the rotating bearing 3 as an insulating layer 4; an air release port 5 is provided on the hub 2, and the air release port 5 is provided on the inner steel ring 6, and there are 5 air release ports Weld the deflation pipe, set the solenoid valve on the deflation pipe to control the opening and closing of the deflation pipe, and set the number and diameter of the deflation port according to the deflation speed required for the test.

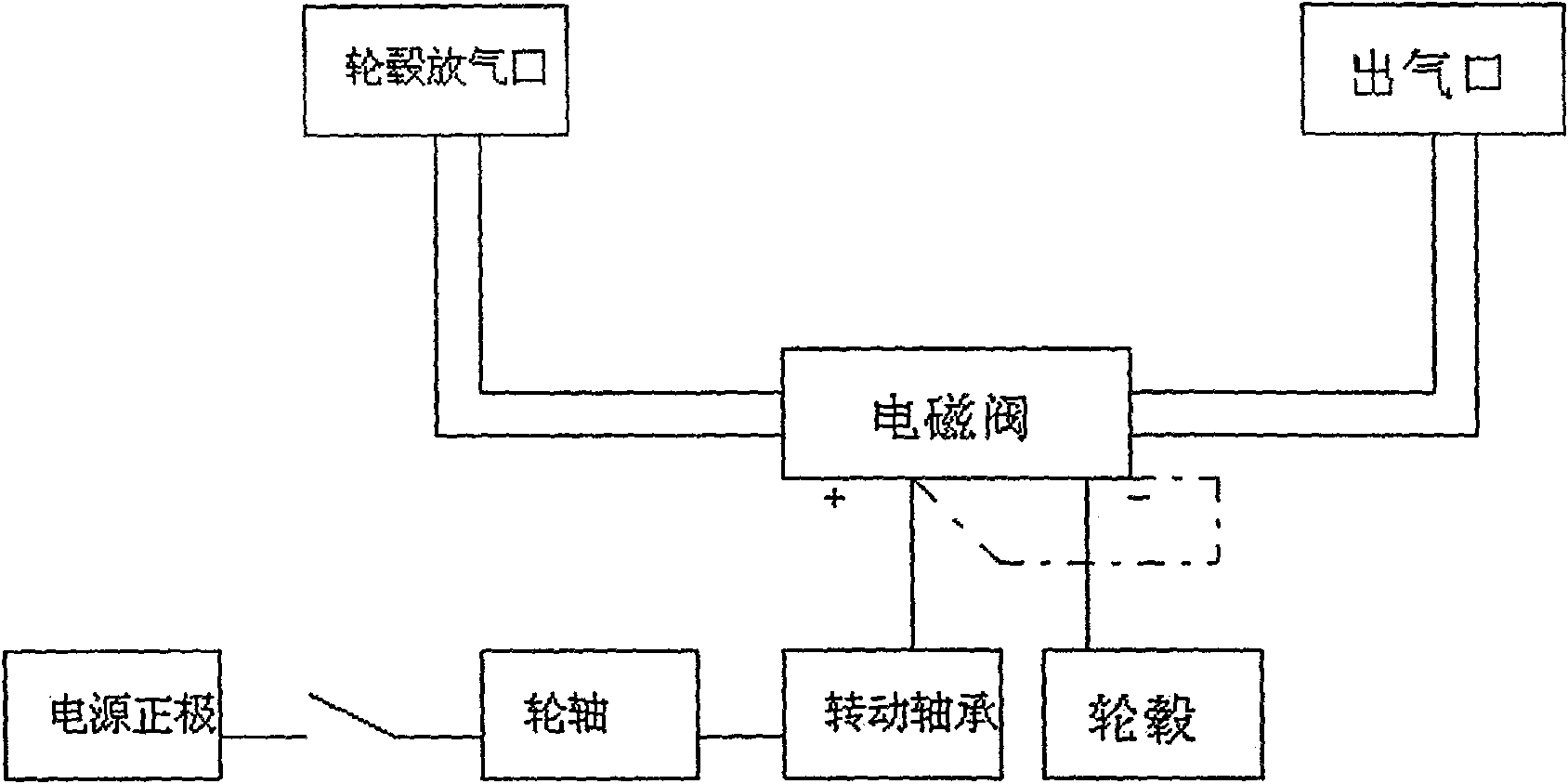

[0016] The device of the present invention uses the vehicle's own power supply to supply power to the solenoid valve, and the working principle is as follows: figure 1 As shown, the axle is connected to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com