Small sample hydraulic burst test method and device for material property test

A test method and hydraulic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of complex stress state, difficult control, and difficult theoretical analysis of small wafer samples, and achieve simplified loading uncertainty. the effect of simplifying the stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] The sample hydraulic bursting test method proposed in the embodiment of the present invention comprises the steps of:

[0035] A. Provide a base 1. The upper end of the base 1 is provided with a sample holding groove 11. The base 1 has a liquid chamber 12. One end of the liquid chamber 12 is connected to the bottom of the sample holding groove 11, and the other end is a liquid inlet. End 13, the liquid inlet end 13 is located at the bottom of the base 1.

[0036] B. Fill the liquid chamber 12 with liquid to discharge the air in the liquid chamber 12; specifically, input liquid from the liquid inlet 13, such as hydraulic oil, when the liquid chamber 12 is filled with liquid, the air in the liquid chamber 12 can be released All out.

[0037] C. Place the sample 2 in the sample holding groove 11, and place an O-ring between the sample 2 and the base 1; the sample 2 matches the sample holding groove 11.

[0038] D. Set and fasten the clamping part 3 on the upper part of t...

Embodiment approach 2

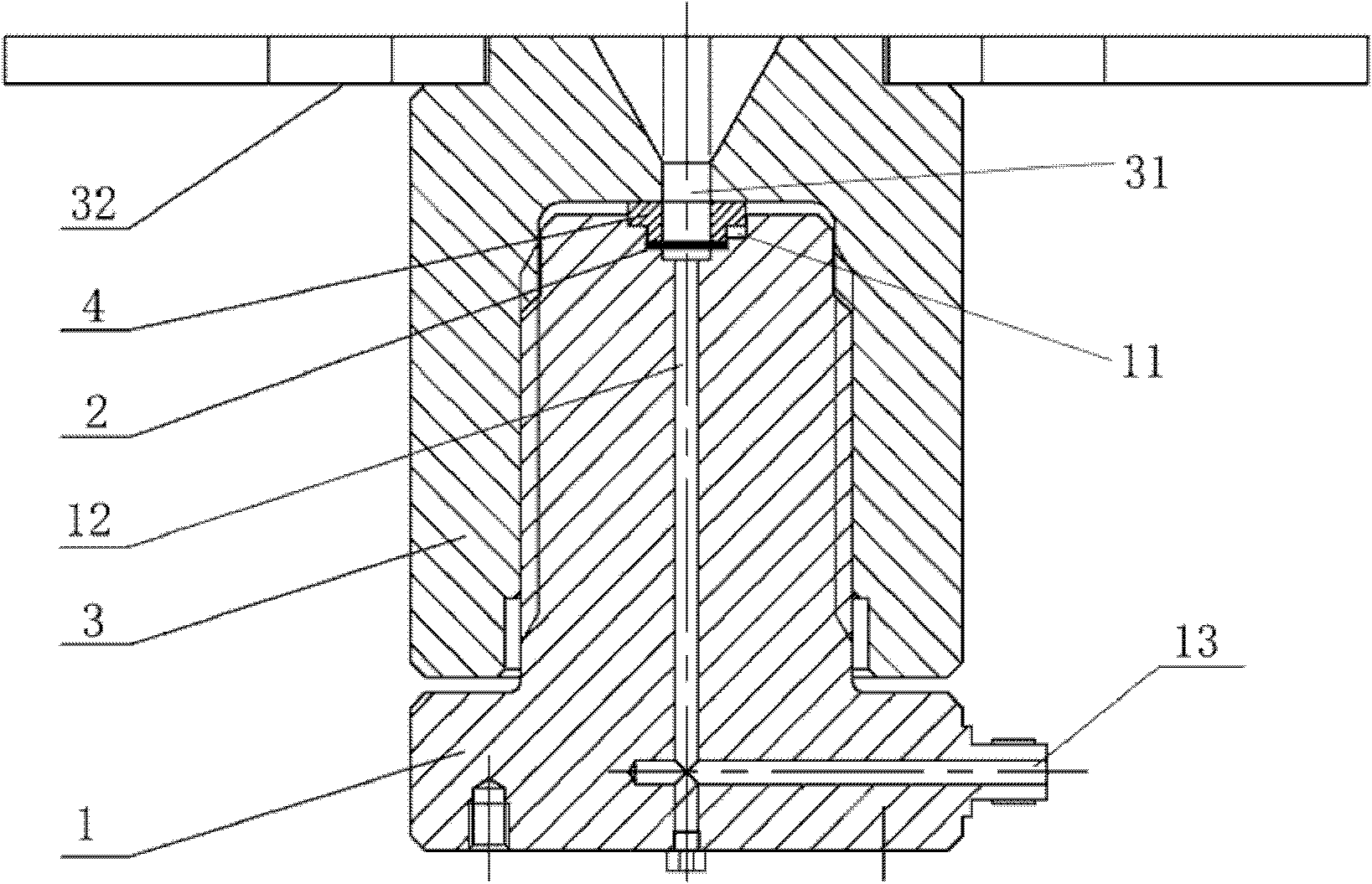

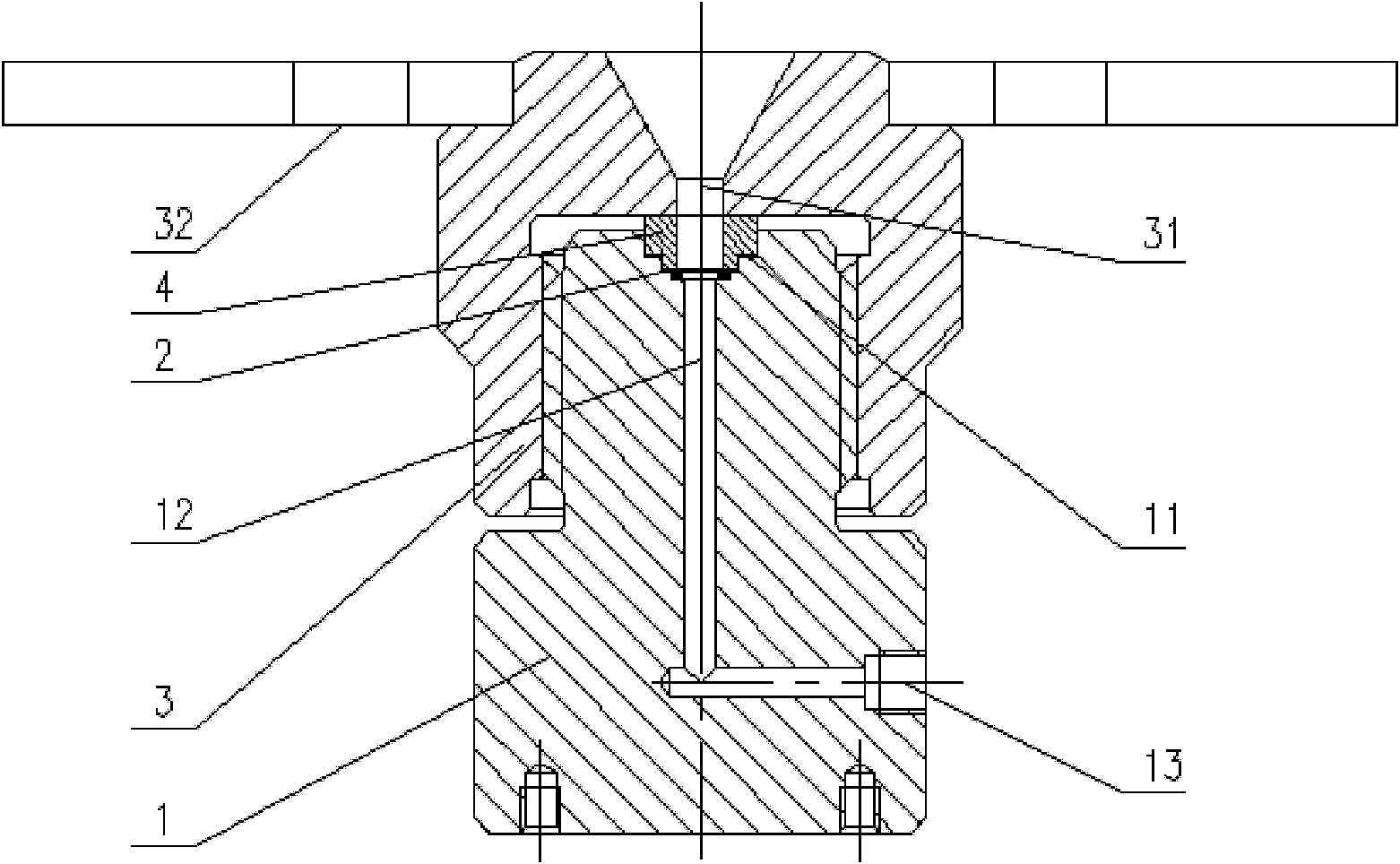

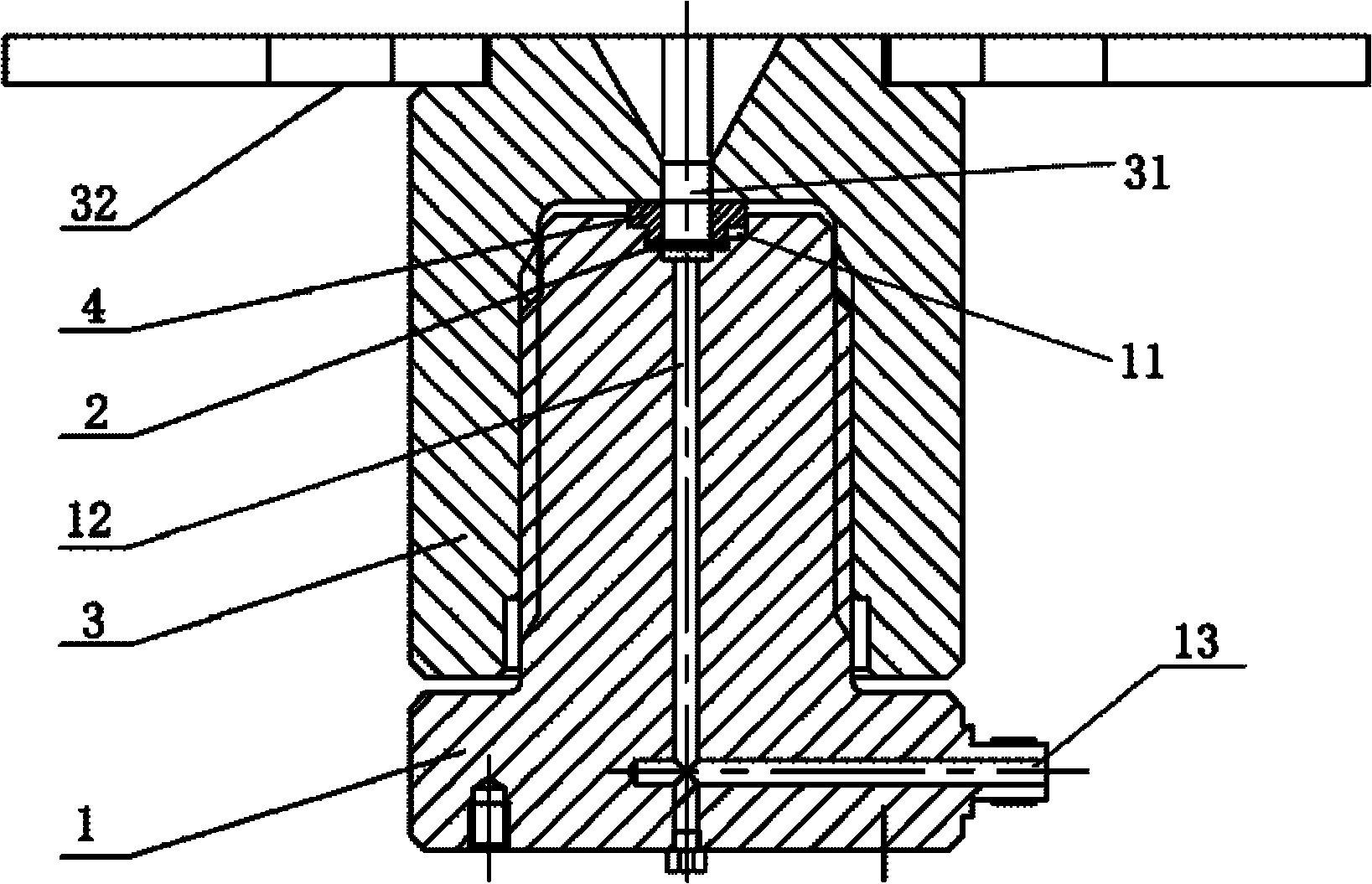

[0049] see figure 1 , 2 As shown, the embodiment of the present invention proposes a sample loading and clamping device, which includes a base 1 and a clamping member 3 . The upper end of the base 1 is provided with a sample accommodating groove 11, and the base 1 has a liquid chamber 12, one end of the liquid chamber 12 is connected to the bottom of the sample accommodating groove 11, and the other end is a liquid inlet 13, and the liquid inlet 13 is located at the lower part of the base; the clip 3 is sleeved on the upper part of the base 1 .

[0050] As an embodiment of the present invention, the clamping member 3 includes a gland 4 , the lower edge of the gland 4 protrudes outward, and the gland 4 is disposed in the sample accommodating groove 11 .

[0051] The clamping part 3 can be a clamping nut, the upper part of the base 1 has an external thread, and the clamping nut is screwed on the base 1 . In addition, the upper end of the clamping nut can also be provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com