A method for forming a multi-layer cable truss curtain wall structure

A forming method and cable truss technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex stress, single structure, small application range, etc., and achieve the effect of reducing potential safety hazards and simplifying stress conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described below in conjunction with the accompanying drawings.

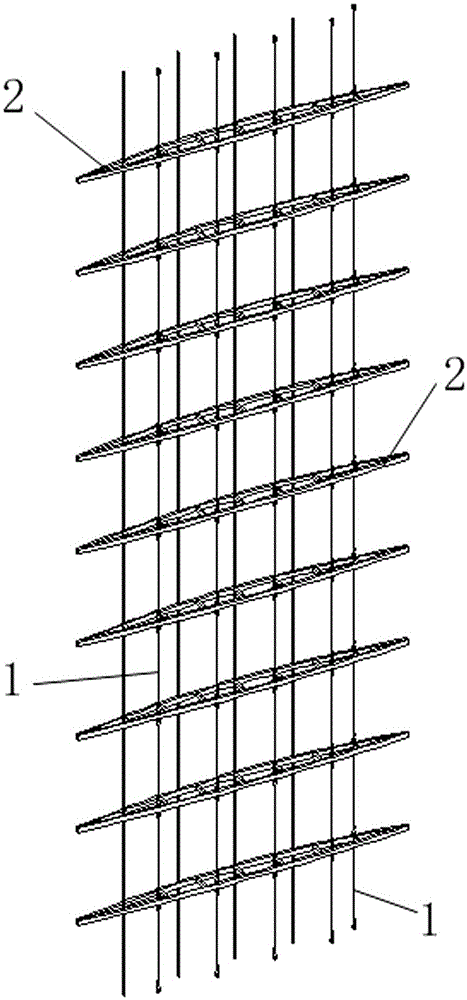

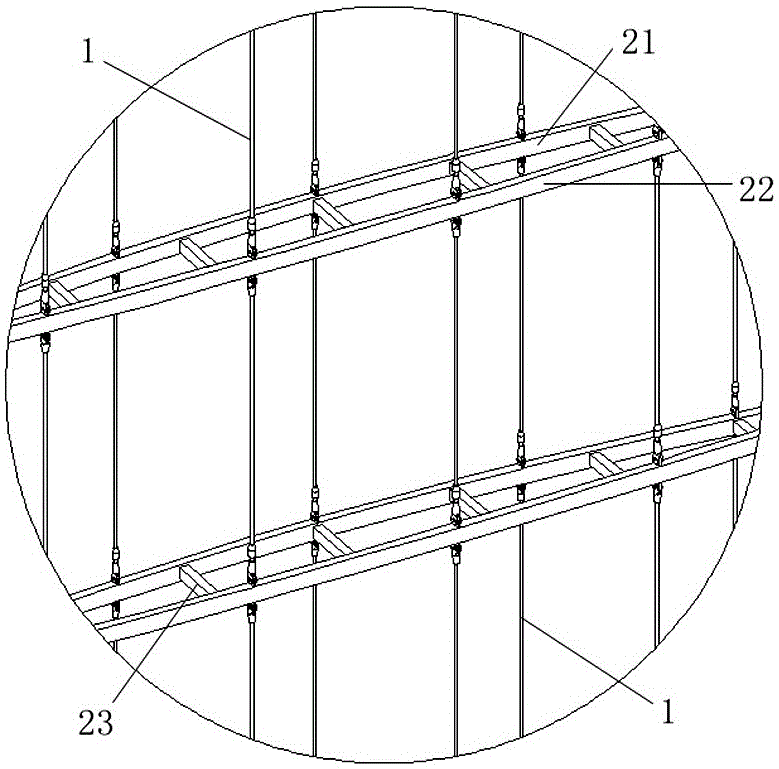

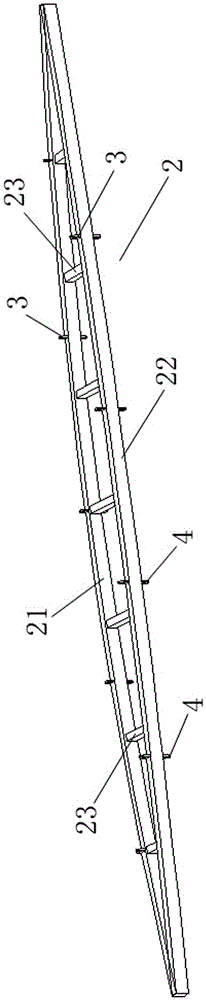

[0031] Such as figure 1 and figure 2 As shown, a multi-layer cable truss curtain wall structure according to the present invention includes multi-layer vertical stay cables 1, and also includes a plurality of horizontal trusses 2 parallel to each other, and the horizontal trusses 2 are horizontal fish-belly trusses. The horizontal truss 2 is composed of an inner chord 21 , an outer chord 22 and a web 23 , and the inner chord 21 and the outer chord 22 of the horizontal truss 2 are in the same horizontal plane. Among them, the vertical stay cables 1 are vertically arranged, the horizontal trusses 2 are arranged horizontally, and a plurality of horizontal trusses 2 are parallel to each other, so that the weight of the glass panels (not shown) installed on each layer can be transmitted in the form of node load To the horizontal truss 2, the horizontal tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com