Motor vehicle collision energy dissipator and motor vehicle collision device provided with energy dissipator

A technology of energy consumers and motor vehicles, which is applied in the direction of bumpers, etc., can solve the problems of improving the collision ability of motor vehicles, the volume of energy consumers is large, and the pressure level is reduced, so as to reduce the deformation of the car body, quickly absorb energy, and improve Effects of Acceleration and Collision Force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

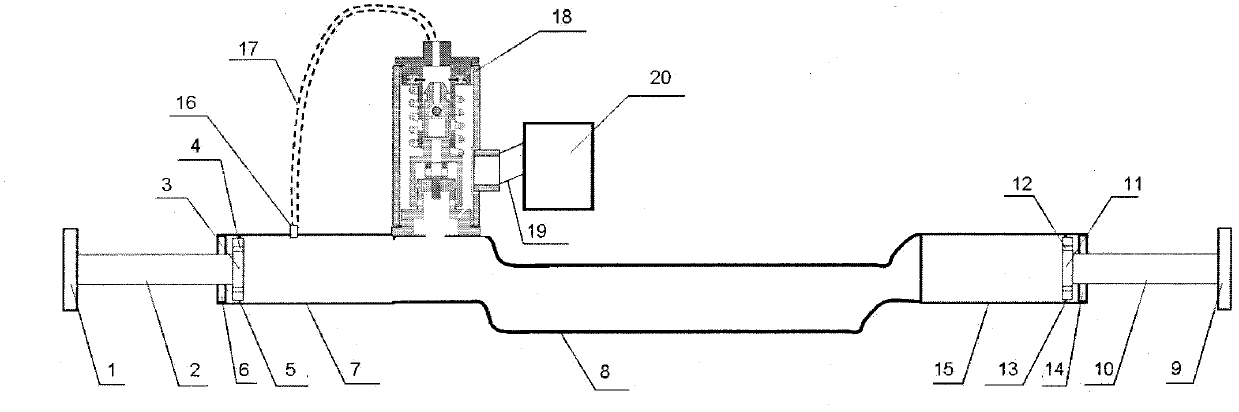

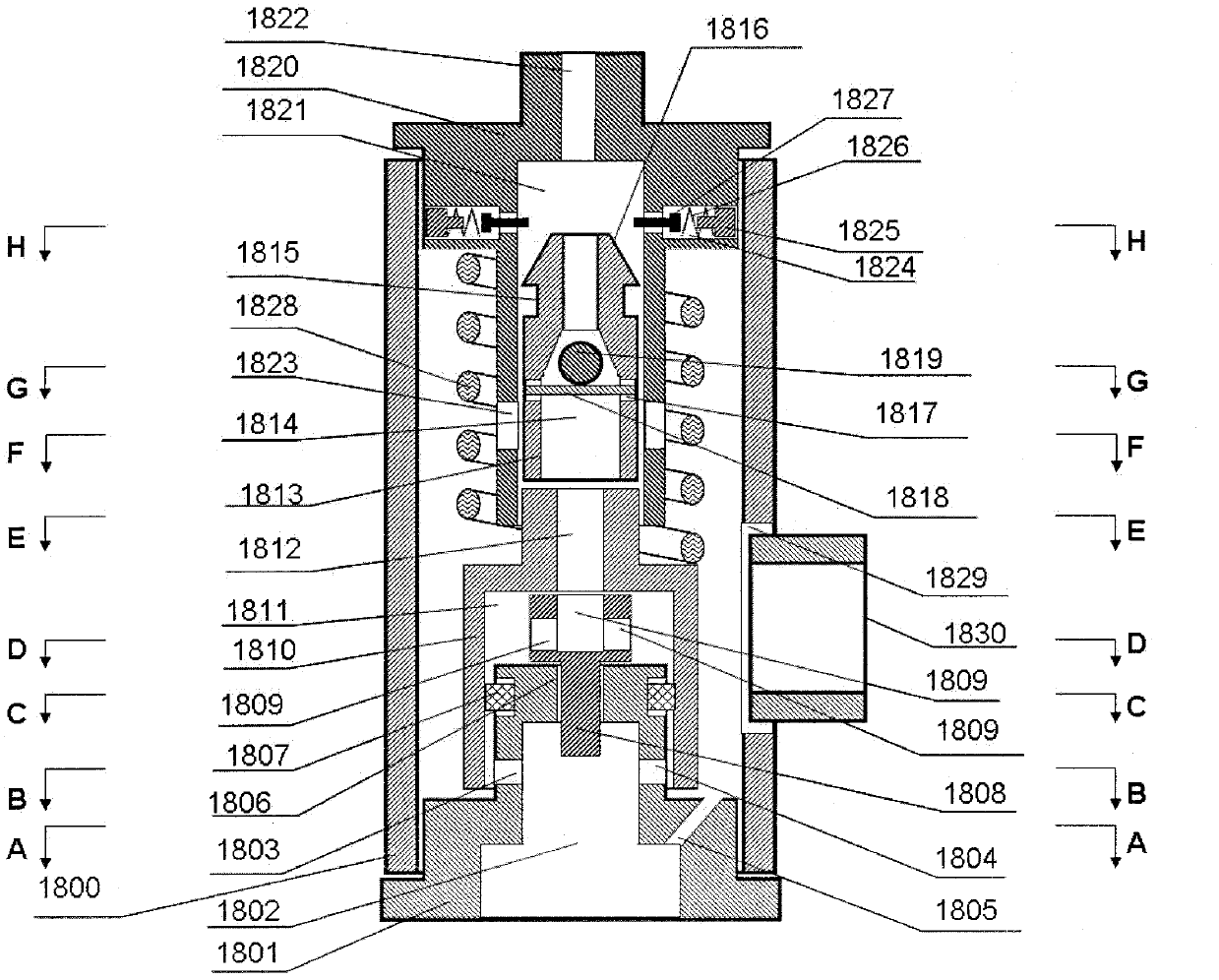

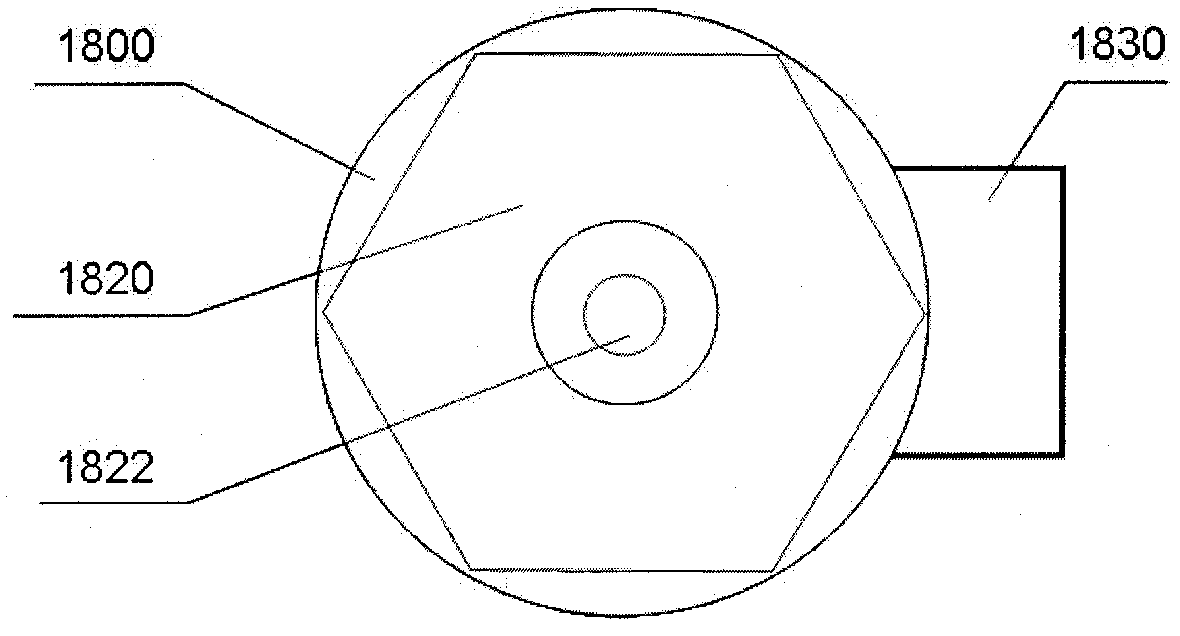

[0053] figure 1 It is a schematic cross-sectional view of a motor vehicle collision device with a motor vehicle collision energy consumer of the present invention; figure 2 It is a schematic cross-sectional view of the motor vehicle collision energy consumer of the present invention; image 3 It is a top view schematic diagram of the motor vehicle collision energy consumer of the present invention; Figure 4 It is a schematic sectional view of the A-A plane of the motor vehicle collision energy consumer of the present invention; Figure 5 It is a schematic sectional view of the B-B plane of the motor vehicle collision energy consumer of the present invention; Figure 6 It is a schematic sectional view of the C-C plane of the motor vehicle collision energy consumer of the present invention; Figure 7 It is a schematic diagram of the D-D plane sectional view of the motor vehicle collision energy consumer of the present invention; Figure 8 It is a schematic sectional view ...

no. 2 approach

[0072] Figure 19 It is a schematic cross-sectional view of the second embodiment of the motor vehicle collision energy consumer; the second embodiment is basically the same as the first embodiment, the only difference is that the upper section of the T-shaped valve stem has changed, that is, the original T-shaped valve stem has been removed. The valve stem communicates with a hole 1809, and a T-shaped valve stem communicates with a groove 1831 on the top surface of the T-shaped valve stem.

Embodiment approach

[0074] The at least one pipe wall injection hole described in the present invention should be understood as greater than or equal to 1, less than or equal to n, and the value range of n is determined by the size of the product and the technical knowledge in the art, which can be 1 or 200. It can also be any number from 1 to 200, so that many different implementations can be formed; the motor vehicle collision energy consumer can be installed on the pressure guide tube or on the piston cylinder, thereby forming different implementations; it should be understood The present invention is not limited to the above-mentioned embodiments, the above-mentioned preferred embodiments are only exemplary, and those skilled in the art can make various equivalent modifications and replacements and different combinations according to the spirit of the present invention to obtain different implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com