Multifunctional pressure difference type method for testing compatibility of high-pressure hydrogen and materials

A test method and technology of high-pressure hydrogen, applied in the direction of applying stable tension/pressure to test the strength of materials, using repetitive force/pulse force to test the strength of materials, etc., can solve the problems of difficult measurement, signal drift, hydrogen leakage, etc., Achieve the effect of improving reliability and safety, avoiding servo test mechanisms, and reducing the probability of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

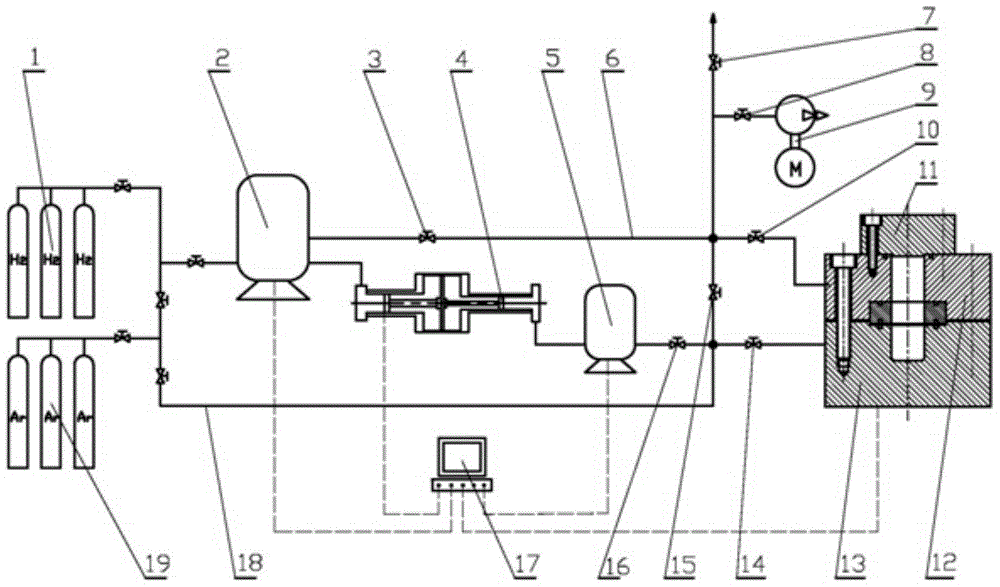

[0055] Such as figure 1 The shown multifunctional differential pressure high-pressure hydrogen and material compatibility test device includes a test chamber, a pneumatic booster pump 4, a low-pressure storage tank 2, a high-pressure storage tank 5, a vacuum pump 9, a hydrogen cylinder set 1, an argon gas Bottle set 19 and control system module 17. The test device uses a disc-shaped thin slice as a sample, and can use the pressure difference between the upper and lower surfaces of the disc sample 23 under a high-pressure hydrogen environment (up to 100 MPa) to apply a load to the disc sample 23 for mechanical performance testing.

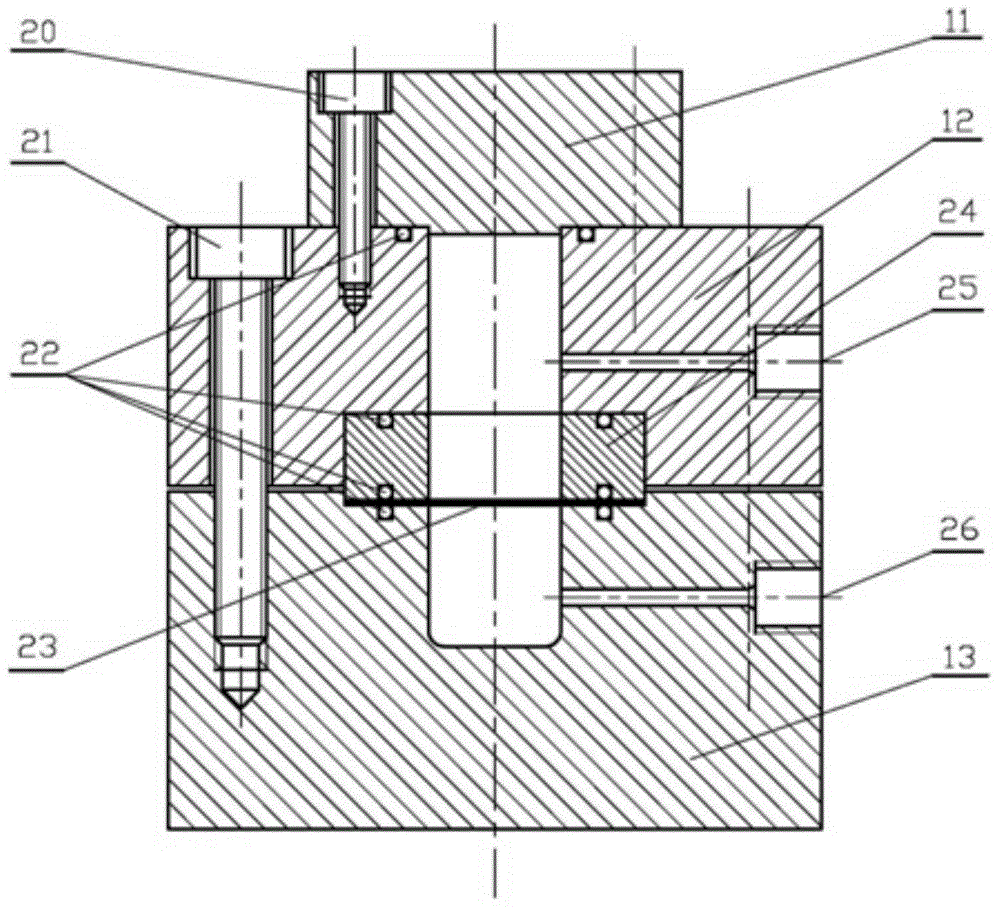

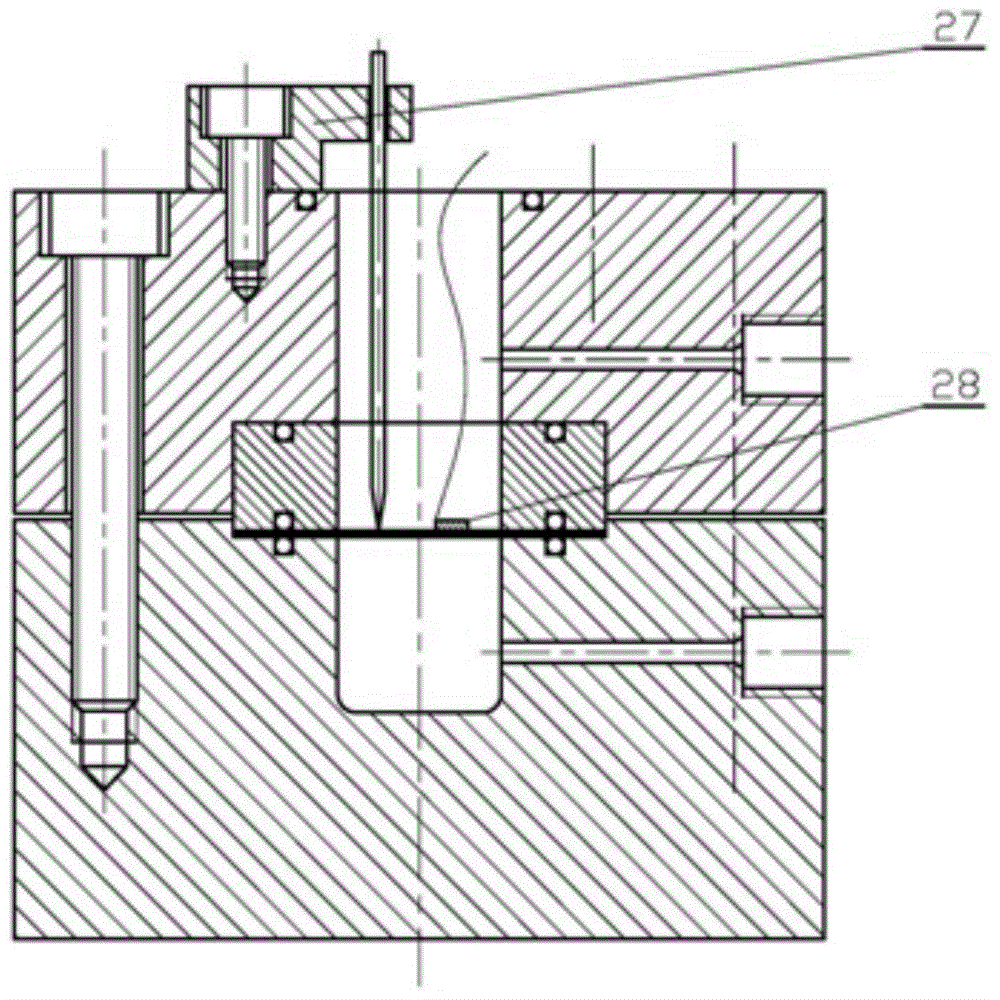

[0056] Such as figure 2 As shown, the test chamber includes an end cover 11, an upper chamber 12, a lower chamber 13, and a pressure ring 24. The design pressure of the test chamber is 35-100 MPa; the upper chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com