Continuous fiber reinforced thermoplastic pipe high-pressure resistant joint pipe fitting group and manufacturing method thereof

A technology of reinforced thermoplastics and continuous fibers, applied in the direction of pipes/pipe joints/fittings, rigid pipes, pipes, etc., can solve the problems of complex manufacturing, restrictions on the popularization and use of fiber-reinforced plastics, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

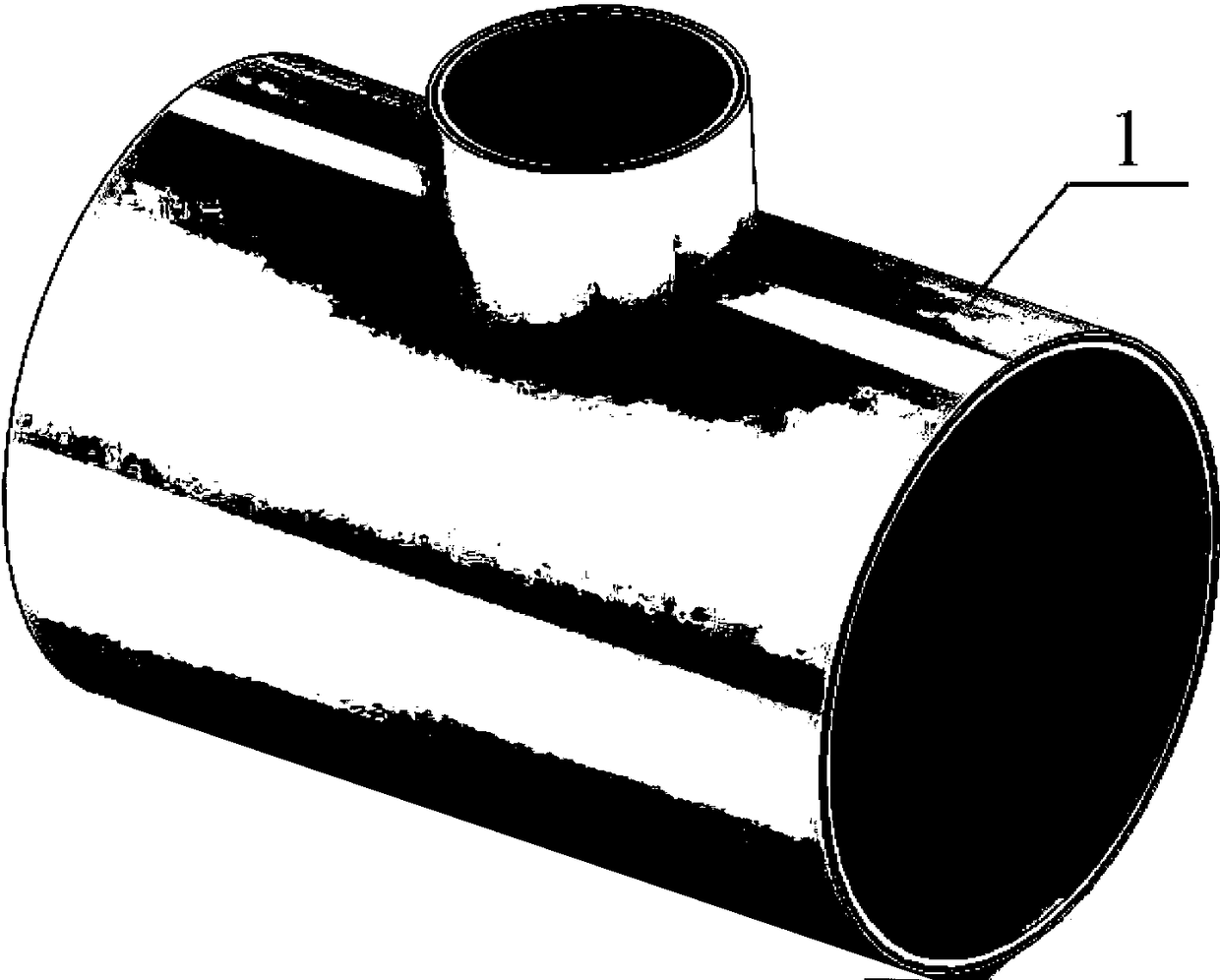

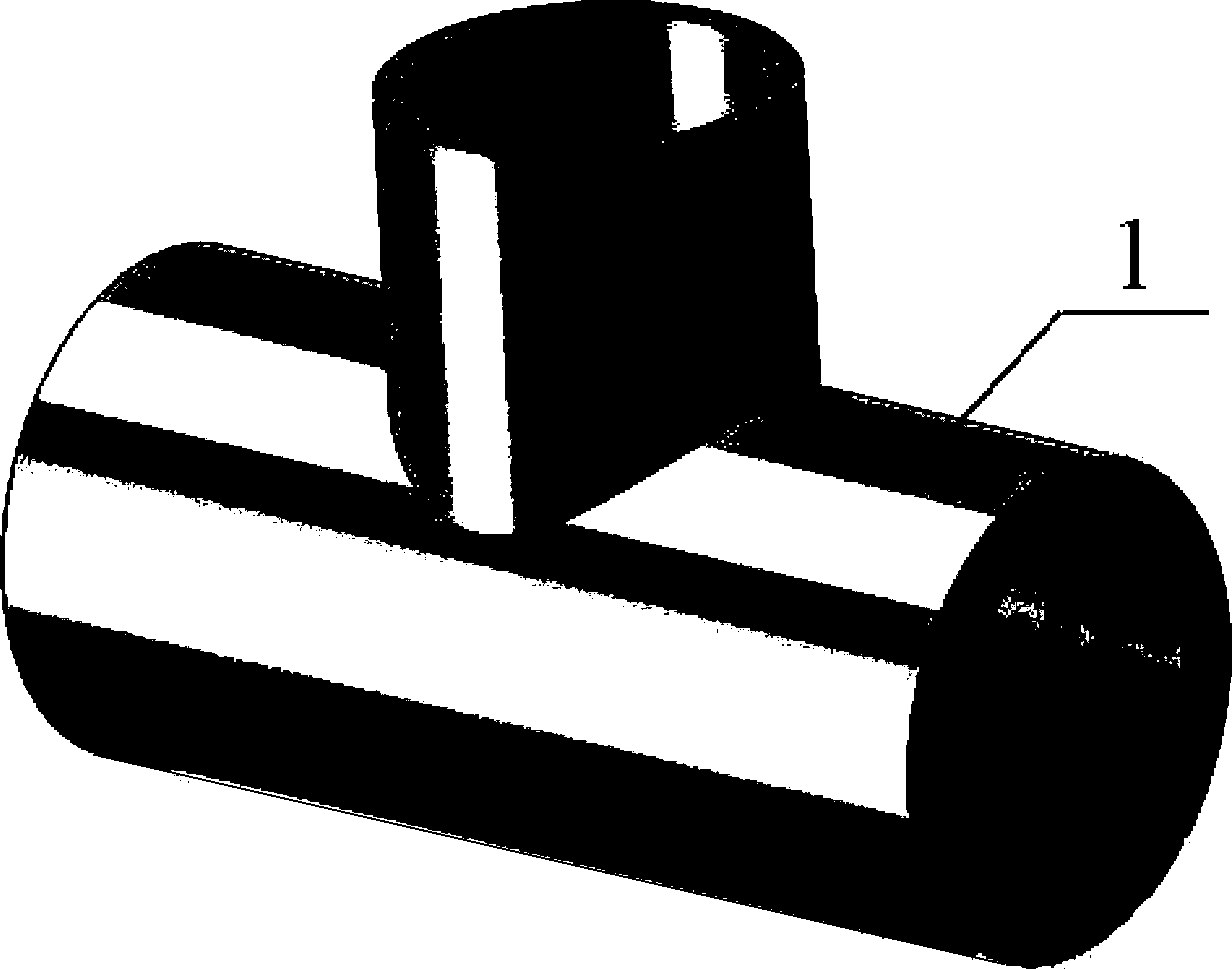

[0067] A continuous fiber-reinforced thermoplastic pipe high-pressure interface pipe fitting set, including pipe fittings and connectors, both of which are composed of a pipe body 1, such as figure 1 As shown, the specific structure is:

[0068] The pipe body 1 includes three layers from the inside to the outside, which are respectively the inner layer pipe 11, the reinforcement layer 12 and the outer layer pipe 13. Both the inner layer pipe 11 and the outer layer pipe 13 are pure plastic layers; the inner diameter of the inner layer pipe 11 determines the The inner diameter of the present invention, the wall thickness of the inner tube 11 is greater than 3 mm and more than 3 mm of the outer tube wall thickness, and the inner tube 11 plays the role of sealing the outer tube fibers in the welding process; the reinforcement layer 12 is pre-impregnated by multi-layer continuous fibers The reinforcement layer 12 is hooped outside the inner layer tube 11; the outer layer tube 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com