Pipe special for manufacturing continuous fiber reinforced thermoplastic pipe fitting, and manufacturing method thereof

A technology of reinforced thermoplastic and continuous fiber, which is applied in the direction of rigid pipes, pipes/pipe joints/fittings, pipes, etc. It can solve the problem that pipe fittings cannot meet high pressure resistance, high pressure resistance, and cannot achieve breakthroughs in non-metallic pipe fittings and interface technology, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

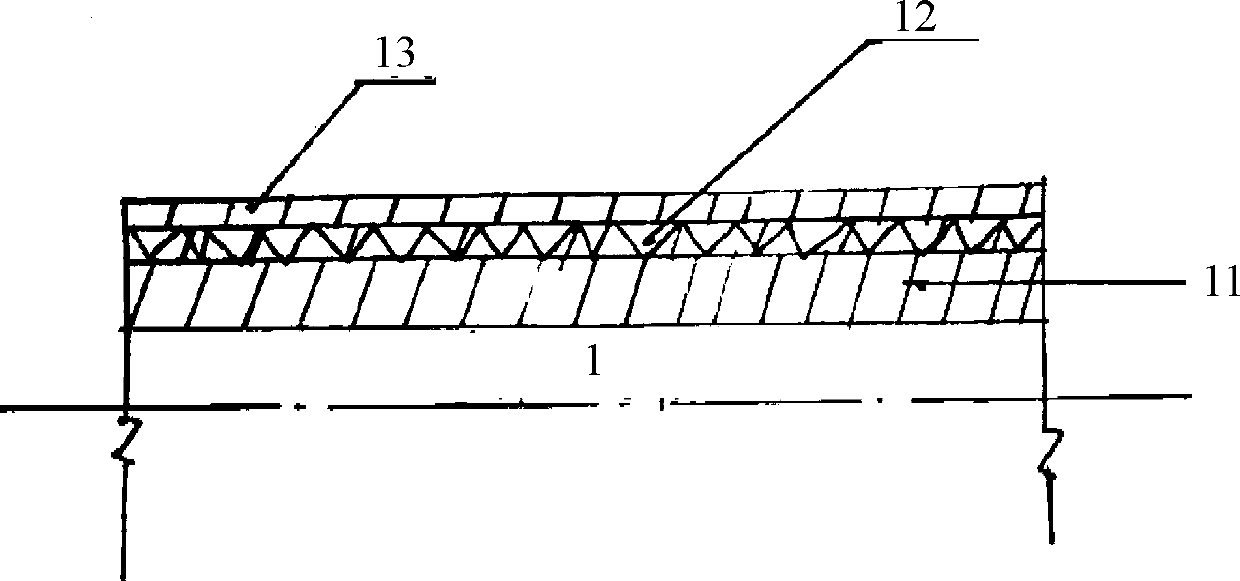

[0023] A special pipe for making continuous fiber reinforced thermoplastic pipe fittings, such as figure 1 As shown, the specific structure is:

[0024] The continuous fiber reinforced thermoplastic pipe fitting tube 1 is composed of a special thickened pure plastic inner layer tube 11, a specially increased continuous fiber prepreg tape winding layer reinforced core layer tube 12 and a pure plastic protective layer outer layer tube 13. Three-layer continuous fiber reinforced composite pipe, referred to as pipe fittings;

[0025] The purpose of the special thickening of the pure plastic inner layer pipe 11 is to process and manufacture the concave three-step hot-melt socket four-sided interface or the concave double-step hot-melt socket double-sided interface;

[0026] The purpose of increasing the number of layers of the continuous fiber prepreg tape-wound reinforced core tube 12 is to increase the working heat-resistant temperature, ring-shaped working pressure and axial wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com