Forming mold and forming method of continuous fiber reinforced thermoplastic pipe

A technology for reinforcing thermoplastic and plastic pipes, which is applied in the field of continuous fiber reinforced thermoplastic pipe preparation, can solve the problems of high viscosity of thermoplastic resin, difficult to achieve uniform fiber arrangement, poor effect, etc., and achieves good impregnation, simple molding method and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the invention will be further described below in conjunction with the accompanying drawings.

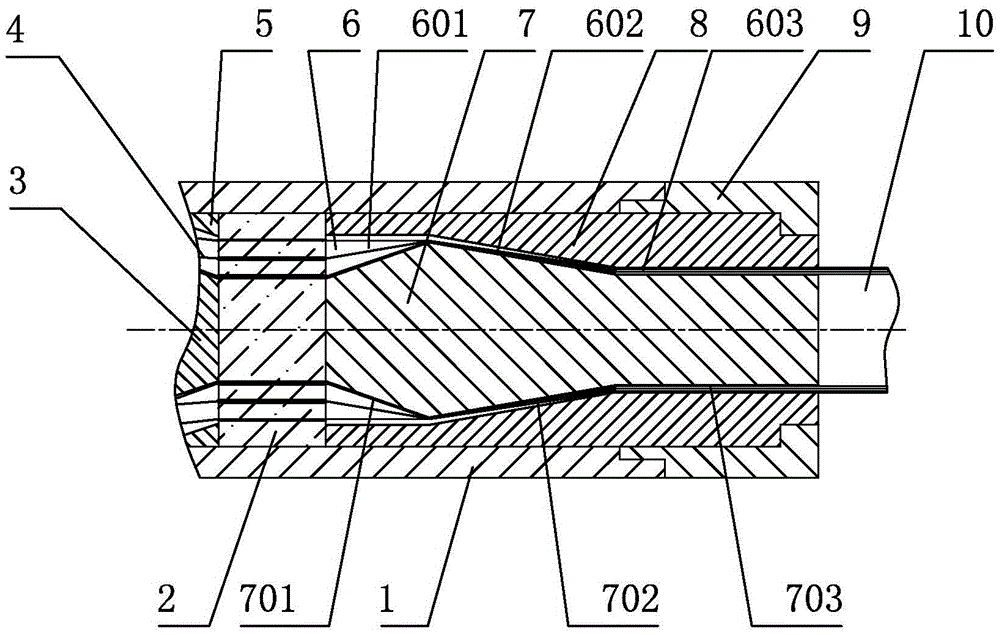

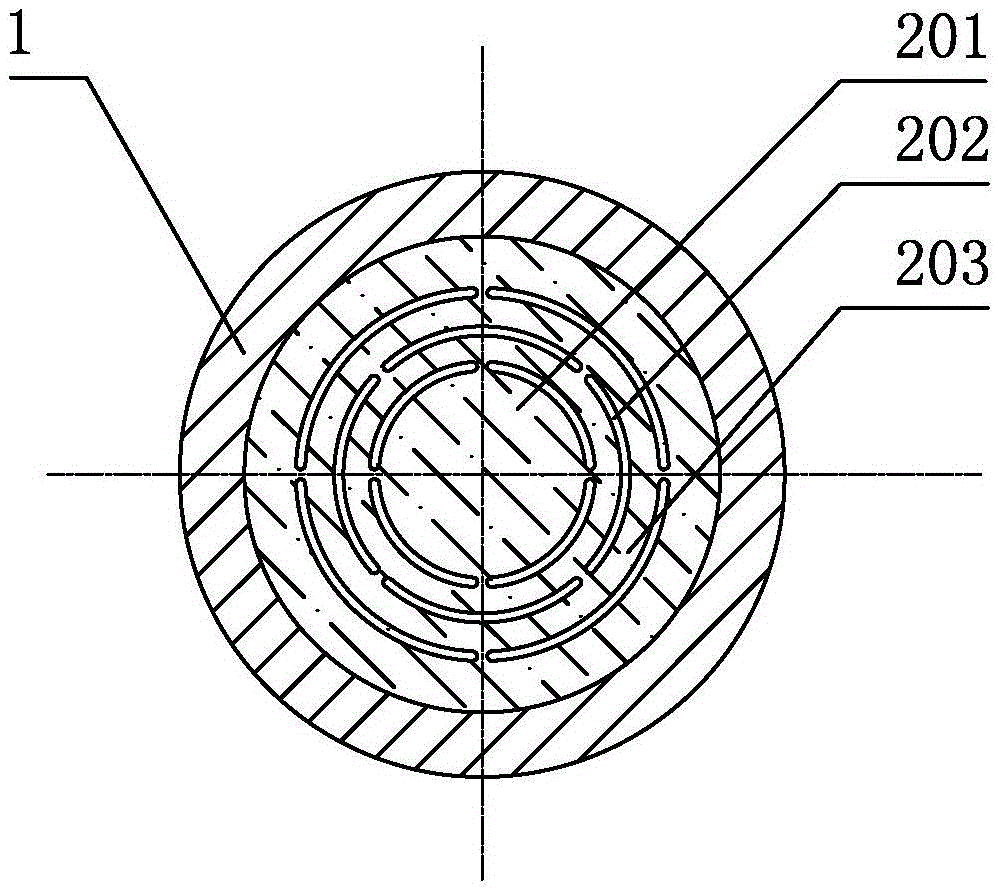

[0037] Such as Figure 1~2 As shown, the forming mold of the continuous fiber reinforced thermoplastic pipe includes a body 1, in which a shaft sleeve 5, a beam splitter 2, and a die 8 are sequentially arranged in the axial direction, and the beam splitter 2 includes a core 201 and a body 203 , the beam splitting slits 202 are distributed in layers along the body part 203 from the inside to the outside, the number of layers is 1 to 10 layers, the same layer of beam splitting slits 202 has the same diameter, and each layer is provided with at least 2 to 100 beam splitting slits The width of the slit 202 and the beam-splitting slit 202 are 0.1-2 mm, and the arc length is 4-100 mm. The specific number of layers of the beam-splitting slit 202 and the number of each layer can be determined according to the performance requirements of the pipe to be produced. The numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com