Related to continuous fiber reinforced thermoplastic pipe and production method

A technology of reinforcing thermoplastic and continuous fibers, applied in rigid pipes, hoses, pipes, etc., can solve the problems of efficient production hindering the application of RTP pipes, difficulty in infiltrating fibers in-line dipping, and inability to resist the use of high-pressure products. Small footprint and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

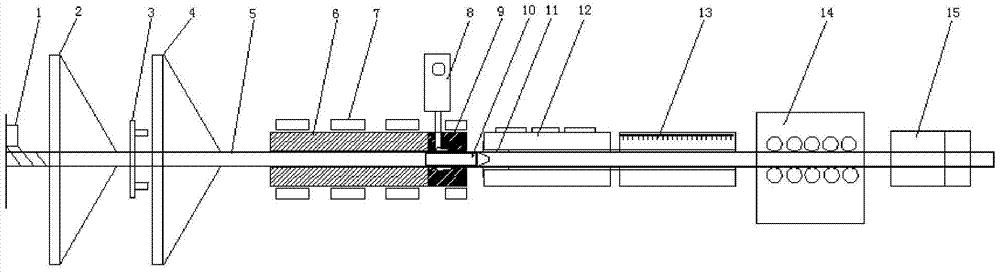

[0027] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

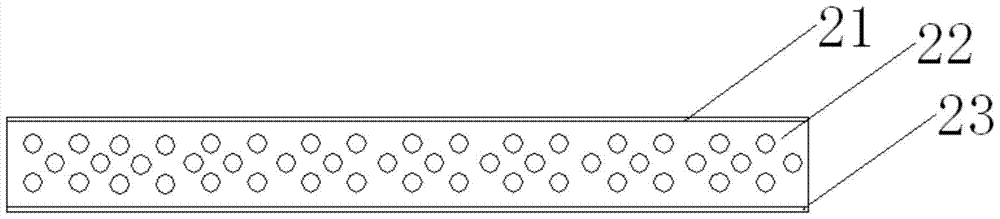

[0028] Such as figure 2 As shown, the pipeline in the present invention is composed of an inner layer and a braided reinforcing layer structure on the inner layer, an outer layer is arranged on the reinforced layer structure, and the three-layer structure is formed at one time, wherein the inner layer is made of a thermoplastic film or sheet to be wound or Portrait mode composition. The reinforcement layer weaves, wraps, and longitudinally arranges the fibers pre-impregnated with thermoplastic materials on the inner layer according to the design requirements. When the thermoplastic material of the inner tube and the reinforcing lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com