Threading mold for producing reinforcing band for strengthening thermoplastic plastic pipe

A technology for enhancing thermoplasticity and threading molds, which is applied in home appliances, other home appliances, applications, etc. It can solve the problems of easy wear and tear of silk ropes/cords, and achieve the effects of saving costs, reducing force, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

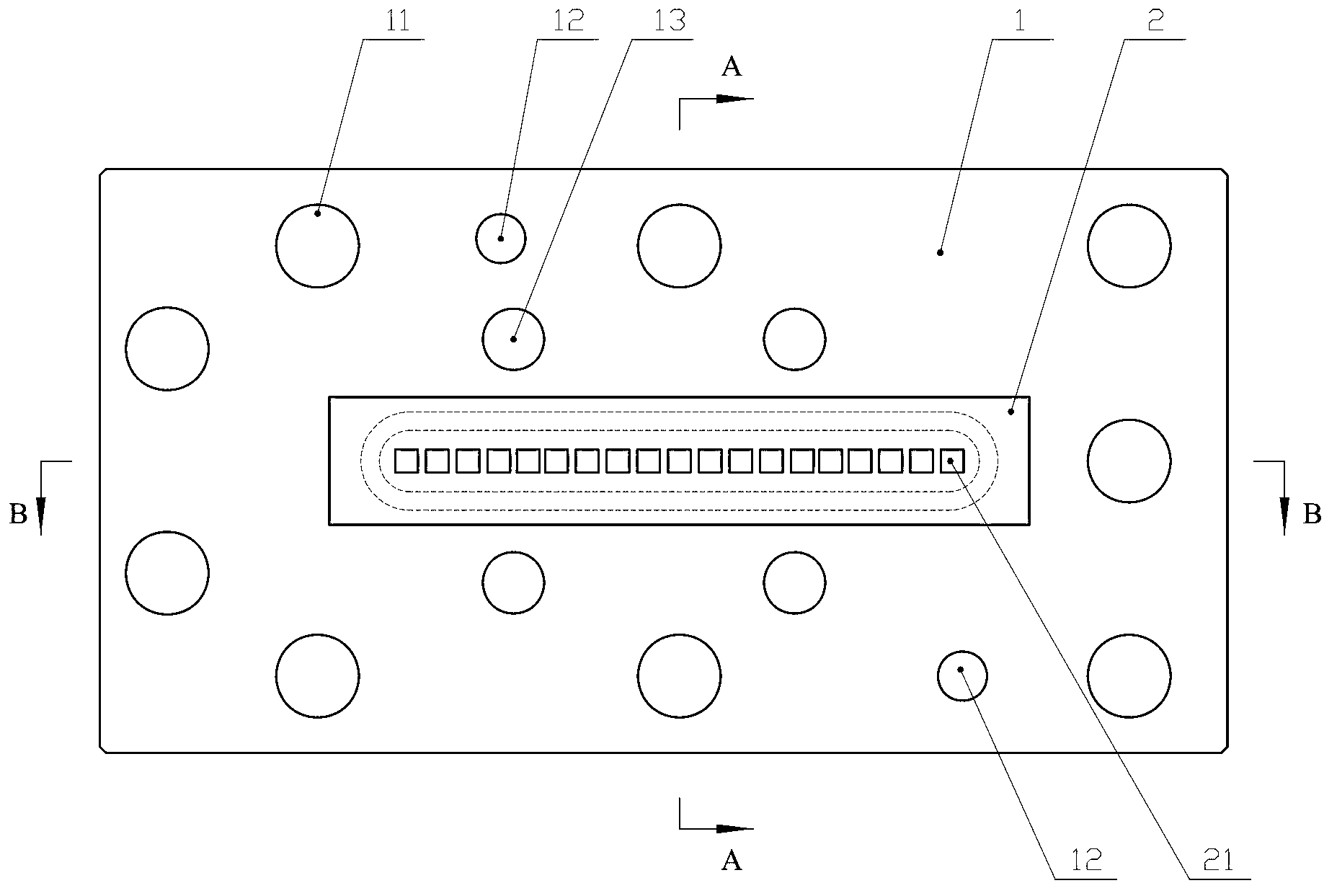

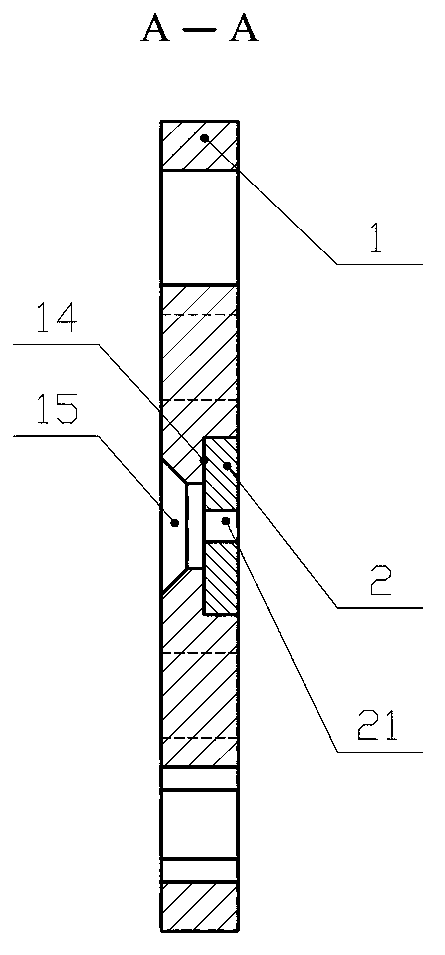

[0027] Figure 1 ~ Figure 4 Shown is the embodiment of a threading mold for the production of a reinforced thermoplastic pipe reinforcing tape of the present invention, as figure 1 As shown, it includes a base body 1 and a threading orifice plate 2, and the base body 1 and the threading orifice plate 2 are detachable mosaic structures. The base body 1 is provided with several fixing holes 11 , two positioning pin holes 12 and two flow channel holes 13 . The perforated plate 2 is made of die steel, alloy material or wear-resistant material treated with surface coating.

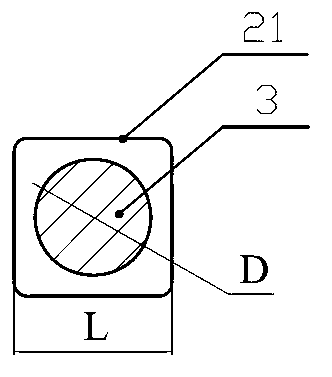

[0028] like figure 1 As shown, square threading holes 21 are horizontally arranged on the threading hole plate 2 . like figure 2 As shown, the four corners of the threading hole 21 are rounded, and the side length L of the threading hole 21 is 0.2-0.6 mm larger than the diameter D of the silk rope / string 3 .

[0029] like image 3 and Figure 4 As shown, the middle part of the substrate 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com