Roll Forming Technology of Fiber Reinforced Thermoplastic Pipes

A thermoplastic and fiber-reinforced technology, which is applied in the field of roll-forming of fiber-reinforced thermoplastic pipes, to reduce equipment investment, facilitate large-scale production, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

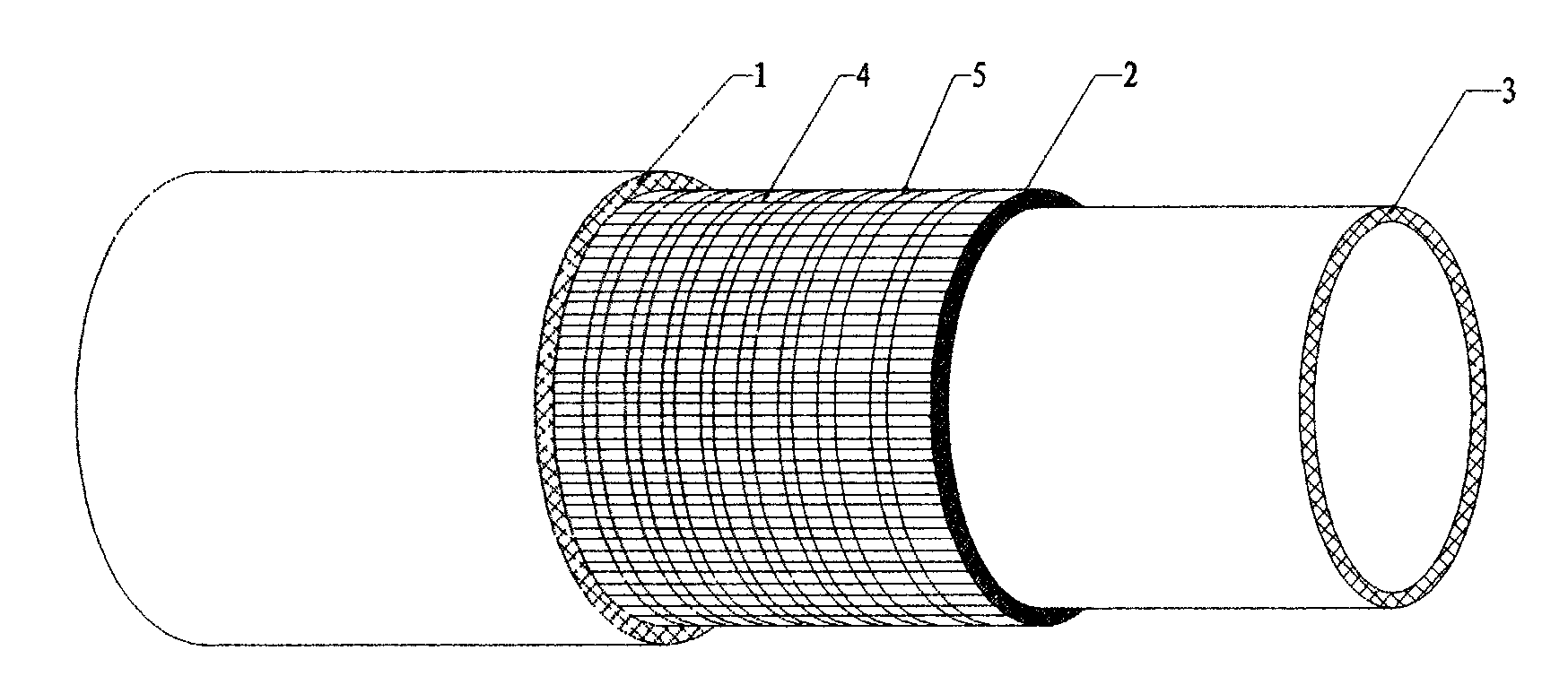

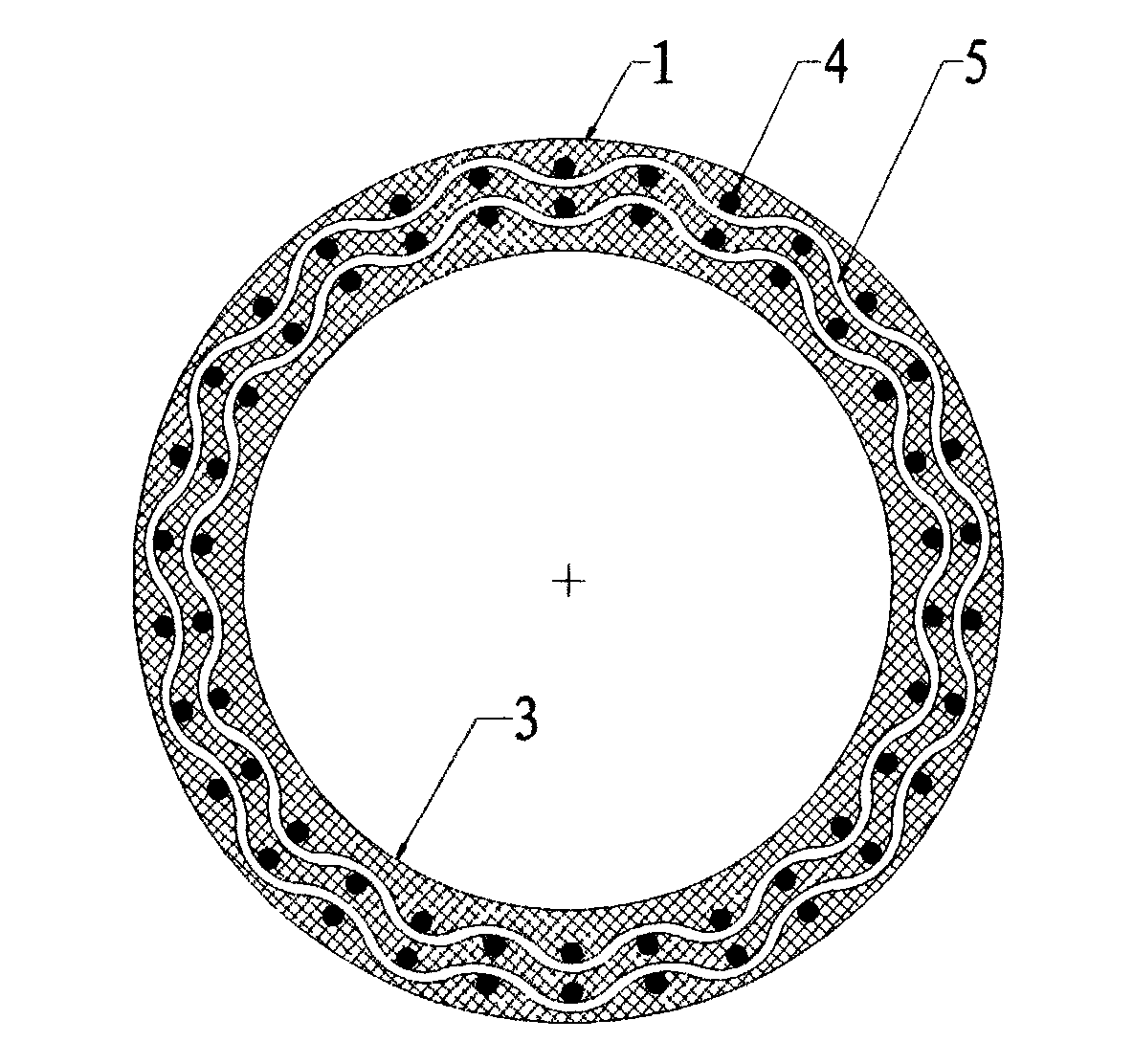

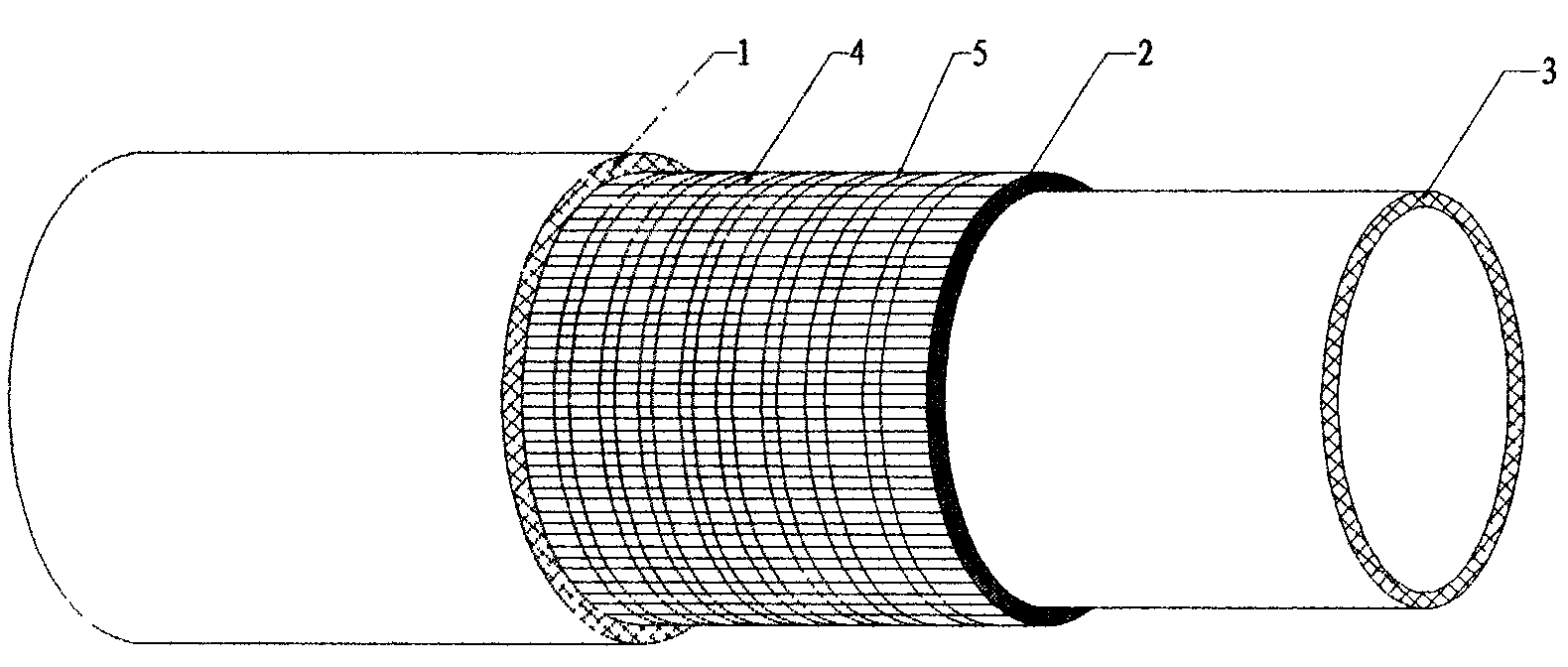

[0027] Combining with the technical route implemented by the present invention, the implementation of the present invention will be described as follows.

[0028] Fiber weaving into a net: use a weaving machine to weave fibers into a net. The diameter and quantity of warp and weft fiber bundles are determined according to the hoop performance and longitudinal performance of the pipe. The width of the fiber web is determined according to the diameter and wall thickness of the pipe. After the fibers are woven into a web, they are cleaned and sent to a drying oven.

[0029] Fiber web coupling treatment: According to the thermoplastics and fibers used, select the corresponding coupling agent and coat it on the surface of the fiber web.

[0030] Prefabricated strip-shaped sheet: After the thermoplastic is heated and plasticized in the extruder, a flat-mouth extruder is used to produce a strip-shaped thermoplastic sheet. The width of the strip-shaped thermoplastic sheet is substant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com