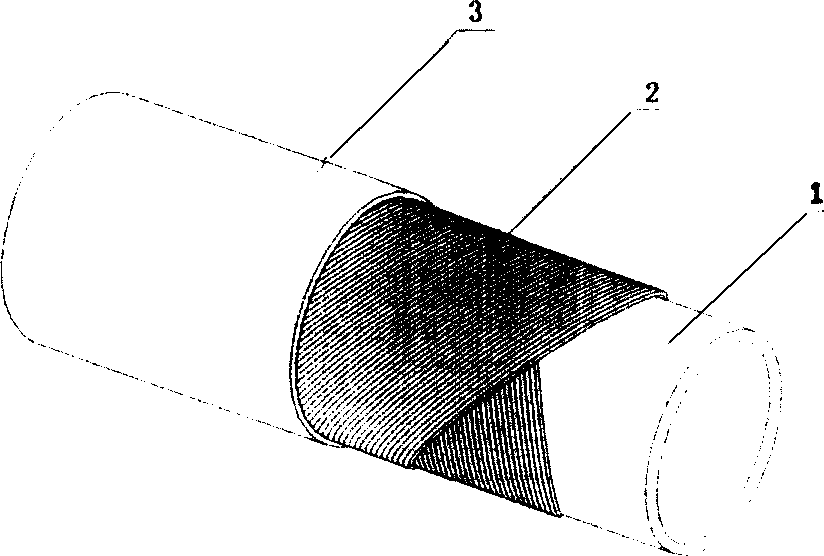

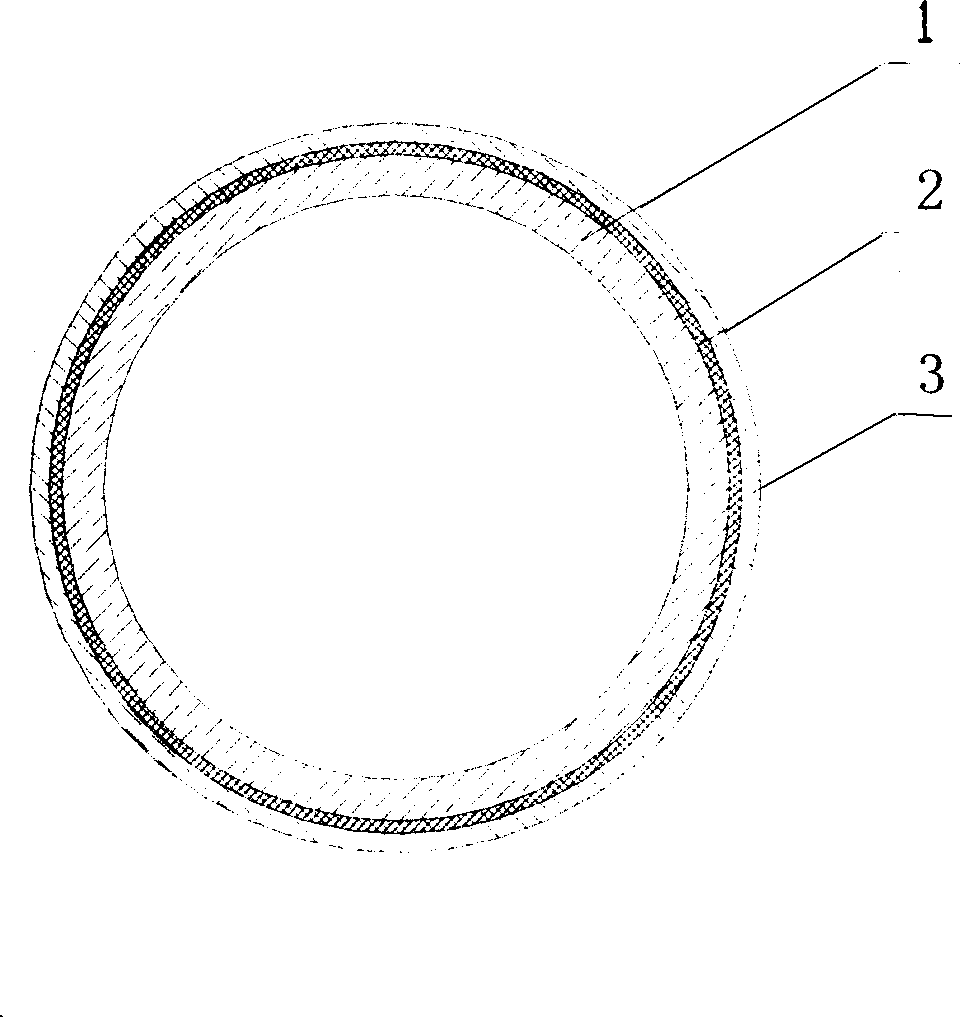

Reinforced thermoplastic plastic pipe and its production method

A technology for enhancing thermoplastic and plastic pipes, applied to rigid pipes, chemical instruments and methods, pipes, etc., can solve problems such as difficult promotion, and achieve the effects of less fouling, reduced conveying resistance, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The steps of the method for producing reinforced thermoplastic pipes are as follows:

[0038]①According to the weight ratio of 20:1.5:5.0:78.5, nanomaterials (calcium carbonate with a particle size of 10-80nm), antioxidants (pentaerythritol esters), paraffin (liquefied paraffin) and high-density polyethylene resin (HDPE100) were processed simultaneously. Equipped with an ultraviolet emitting device (non-metallic material artificial accelerator) and non-stop moving dry channel for dispersion, and then enter the Lantian twin-screw extruder to make masterbatches, at this time the paraffin wax that acts as a lubricant has been completely volatilized;

[0039] ②In the SJ series screw extruder, according to the weight ratio of 6:2:92, the masterbatch, antistatic agent (nano-scale copper oxide) and high-density polyethylene resin (HDPE100) prepared in step ① are extruded together into a pipe, which is the inner layer 1;

[0040] ③The composite polyester monofilament is wound ...

Embodiment 2

[0044] The steps of the method for producing reinforced thermoplastic pipes are as follows:

[0045] It is basically the same as Example 1, and its difference is: the nanometer material of step 1. uses the silicon dioxide of particle diameter 10~80nm instead; Use metal powder; step ③ is carried out as follows: twist the rope made of composite polyester monofilament, use a winding machine to spirally wind three layers on the surface of the inner layer 1 to form the middle layer 2 composite polyester fiber layer.

Embodiment 3

[0047] The steps of the method for producing reinforced thermoplastic pipes are as follows:

[0048] It is basically the same as Example 1, and its difference is: the nanometer material of step 1. uses the zinc oxide of particle size 10~80nm instead; The antistatic agent of step 2. uses graphite instead; The tape that is made uses a winding machine to wind two layers of positive and negative cross-winding on the surface of the inner layer 1 to form a middle layer 2 composite polyester fiber layer; the anti-ultraviolet agent in step 5 is replaced by nano-silica ultraviolet reflective material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com