Stress and temperature sensing optical cable pre-embedded in RTP

A technology of stress and optical cables, applied in the field of intelligent monitoring of non-metallic flexible pipelines, to achieve the effects of easy pre-embedding, high strength, good transmission performance and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

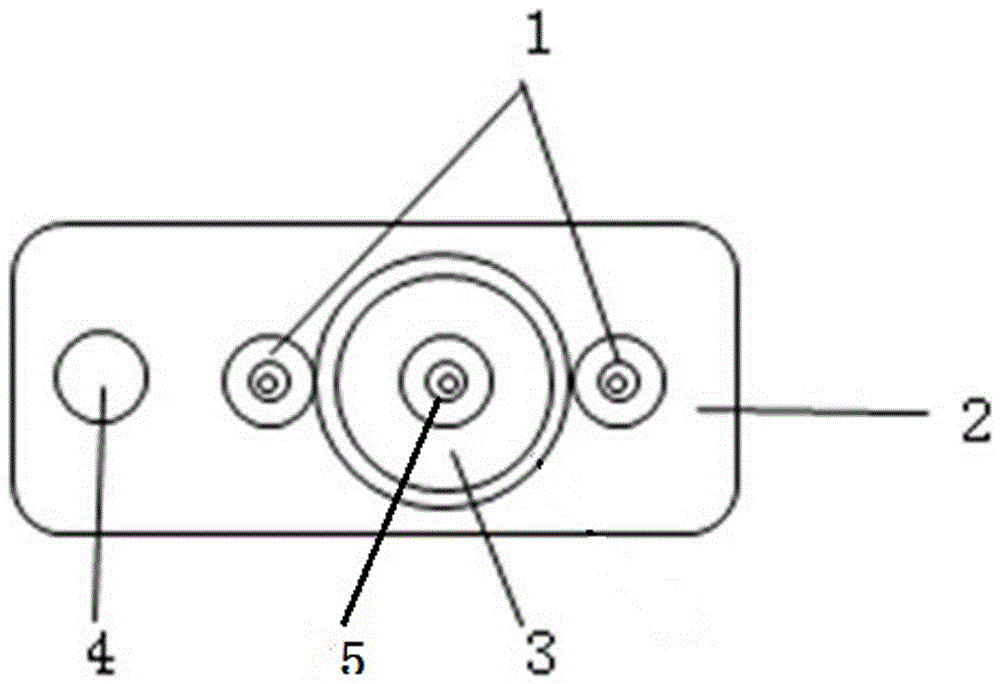

[0023] Such as figure 1 As shown, a pre-embedded stress temperature sensing optical cable in an RTP tube includes two tight-wrapped optical fibers II1, FRP tensile element 4, optical unit and outer sheath 2, and the optical unit includes PBT loose tube 3 and tight-wrapped optical fiber Ⅰ5, the cross section of the outer sheath 2 has a rounded rectangular structure. The optical unit is placed between two tight-packed optical fibers II1, and the FRP tensile element 4 is placed next to one side of one of the tightly-packed optical fibers II1. In order to further improve the sensing accuracy and real-time performance, the FRP tensile element 4, the two tightly wrapped optical fibers II1 and the optical unit are arranged on the same plane. In order to reduce the overall size of the optical cable, the size of the tight-packed optical fiber I is 0.6mm.

Embodiment 2

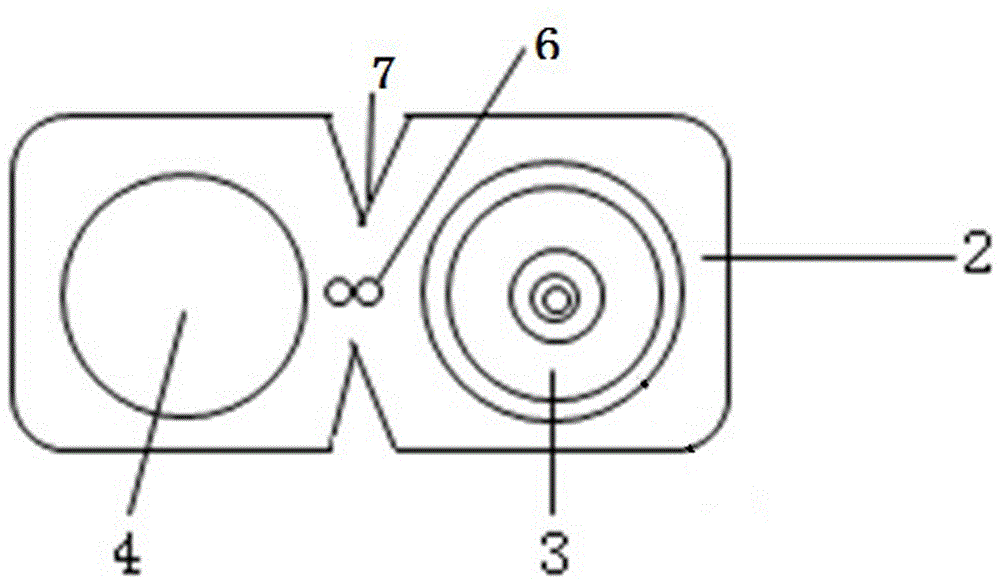

[0025] Such as figure 2 As shown, the optical fiber assembly of this embodiment is composed of two colored optical fibers 6, and the two colored optical fibers 6 are arranged side by side between the FRP tensile element 4 and the optical unit, and the outer sheath 2 is provided with an easy-to-peel tear opening 7 . Other structures are with embodiment 1.

[0026] The sensing optical cable of the present invention can carry out 24-hour uninterrupted full-path detection in the whole process, which brings a technical revolutionary change to the operation and maintenance work. It can be widely used in the detection of reservoir parameters (including temperature and pressure) in oil and gas wells, which greatly enriches oil and gas companies' understanding of reservoirs and facilitates the optimization of oil and gas field production and maintenance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com