Patents

Literature

68results about How to "Improve drawing precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

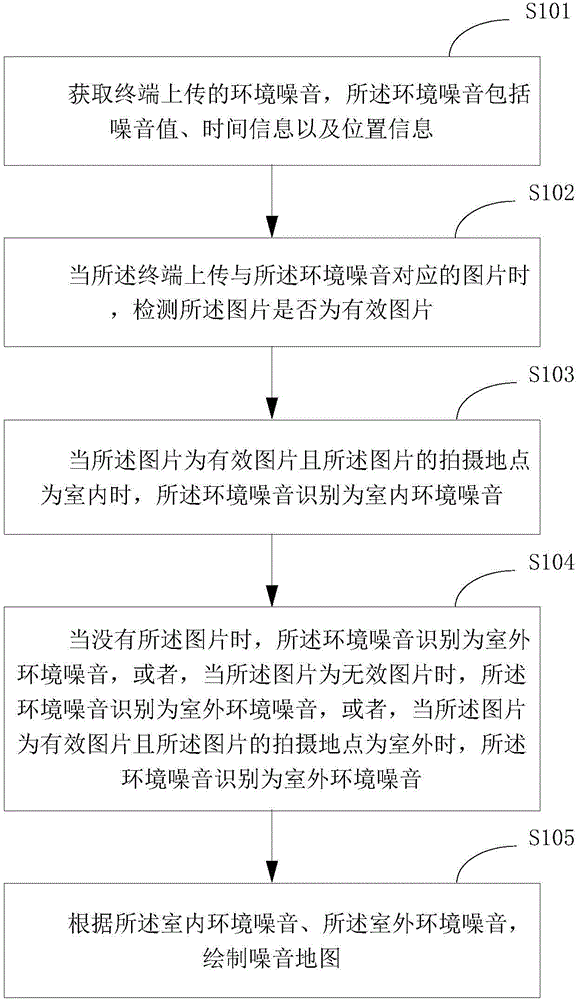

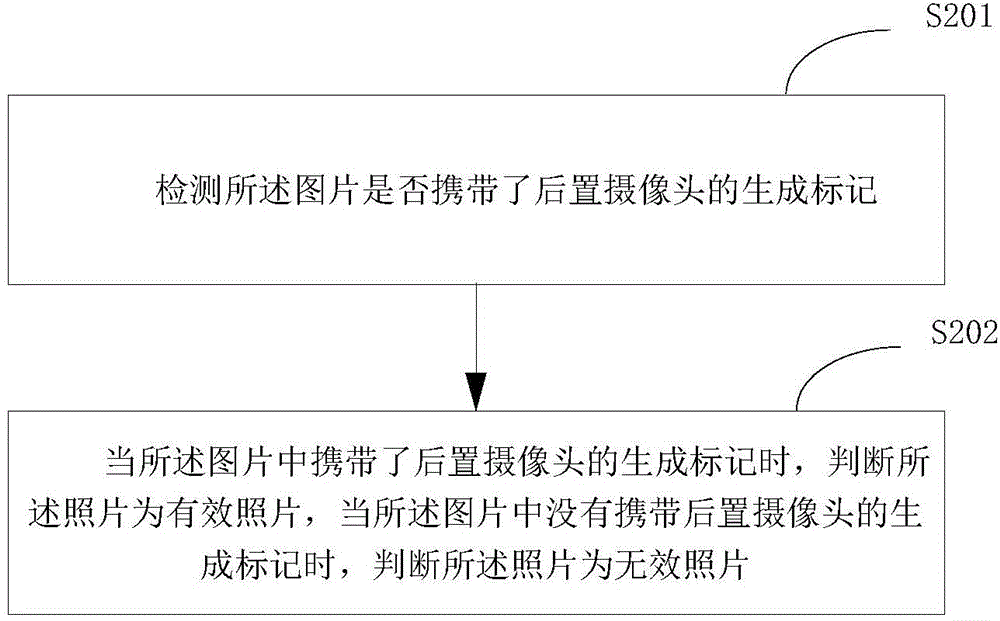

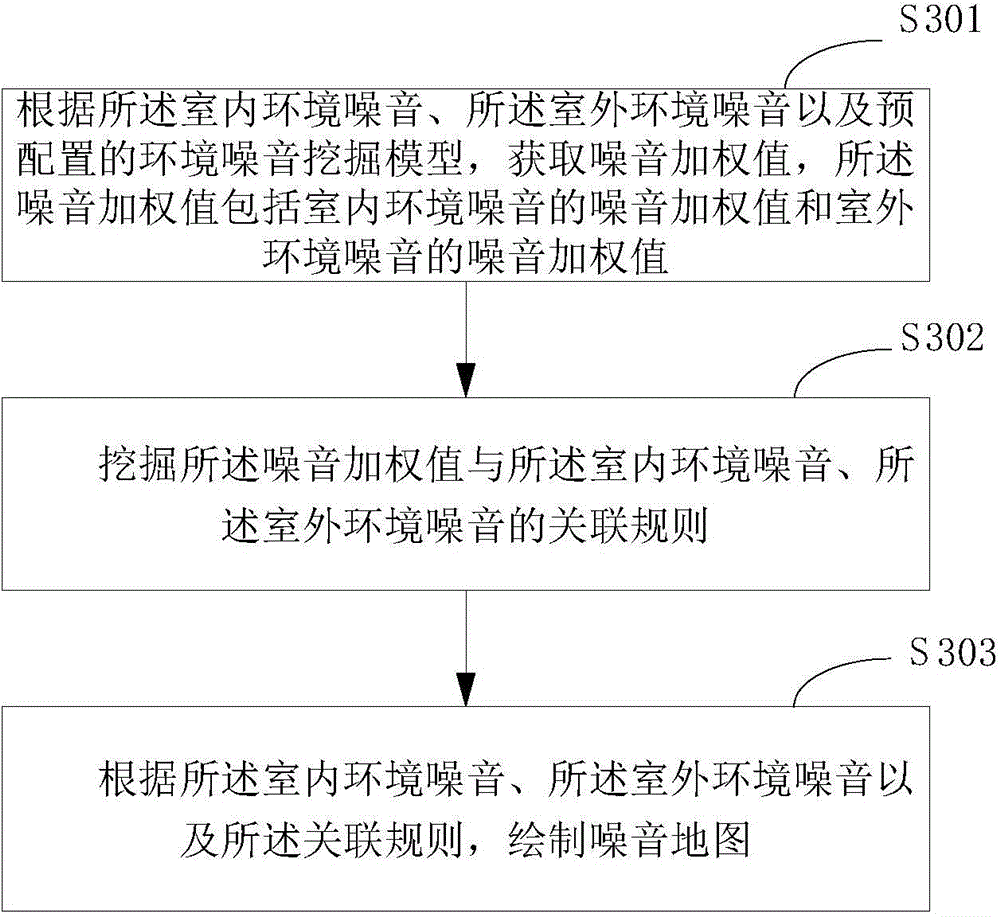

Noise map drawing method and device

ActiveCN104573387AImprove drawing precisionImprove reliabilitySpecial data processing applicationsTime informationEnvironmental noise

The invention belongs to the technical field of noise maps and provides a noise map drawing method and device. The method include acquiring environmental noises, including noise values, time information and location information, uploaded by terminals; when the terminals upload images corresponding to the environmental noises, detecting whether the images are valid or not; when the image is valid and is shot indoors, recognizing the noise as indoor environmental noise; when no image is provided, the image is invalid or the image is valid and is shot outdoors, recognizing the noise as outdoor environmental noise; drawing a noise map according to the indoor environmental noises and outdoor environmental noises. By the aid of the method, the noise map drawing accuracy is improved, and the reliability of the noise map is improved.

Owner:SHENZHEN GRANDSUN ELECTRONICS CO LTD

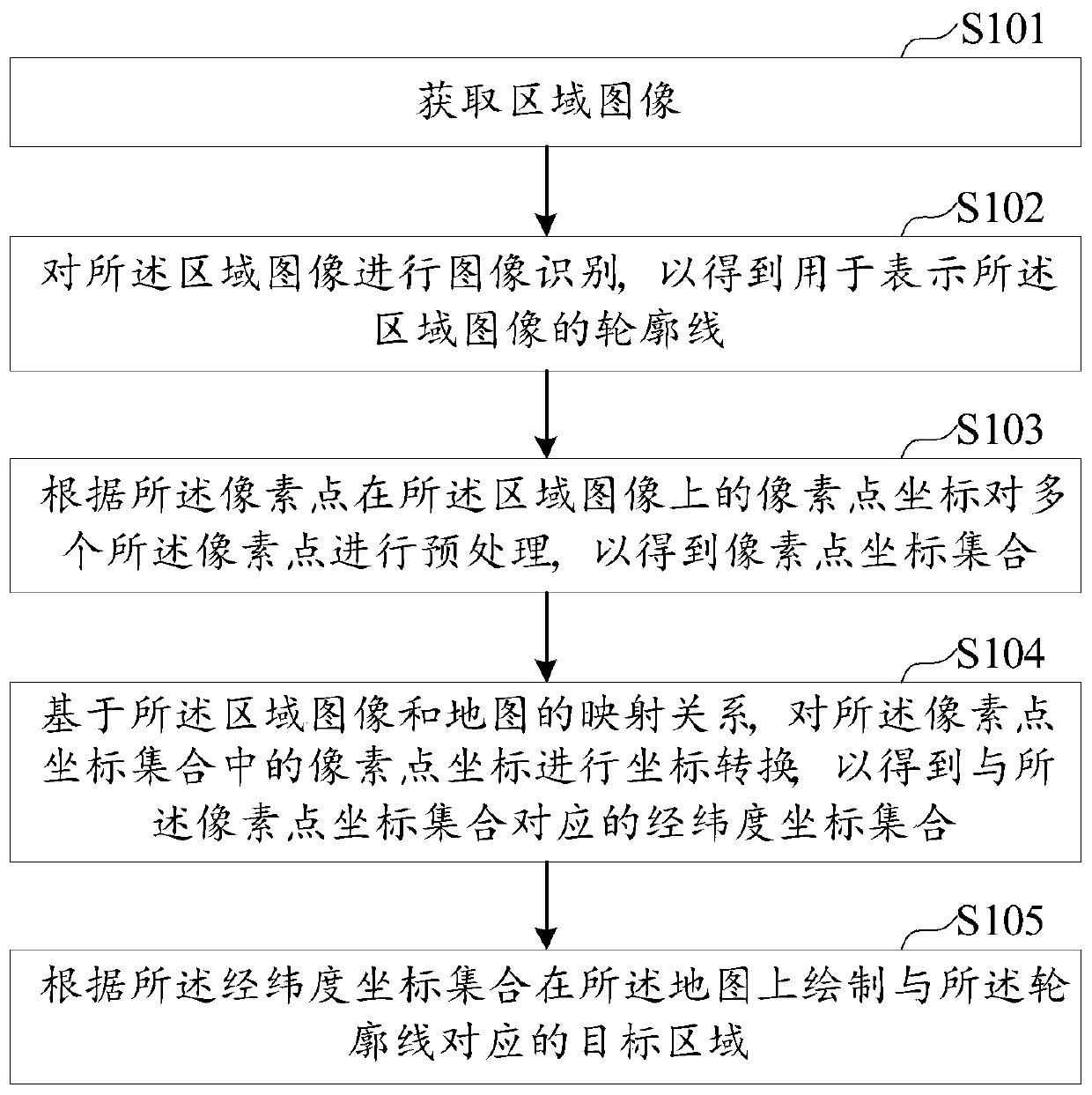

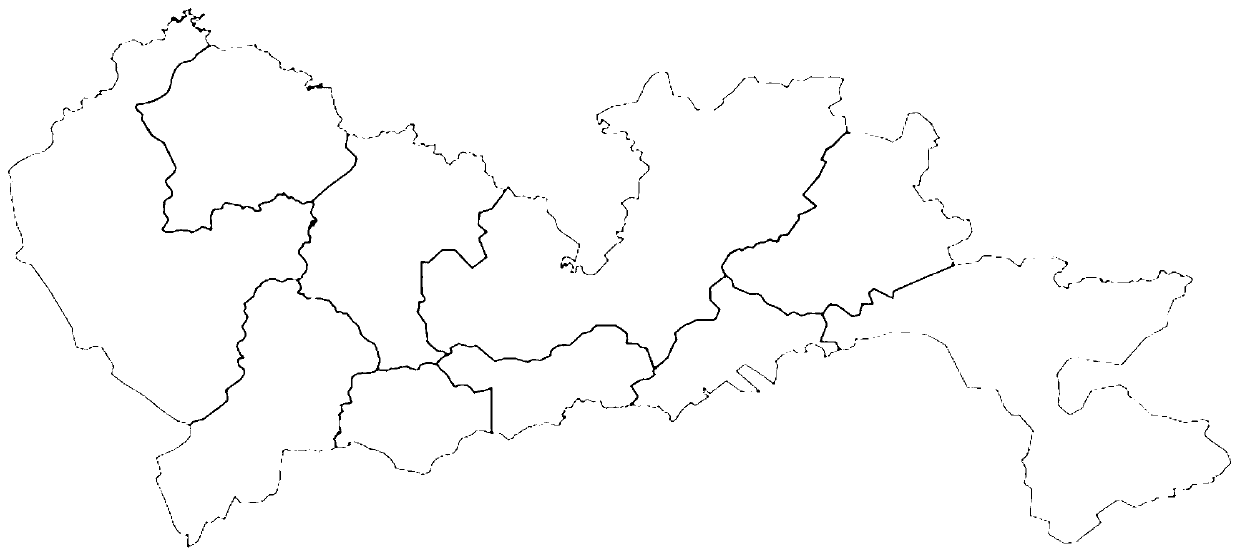

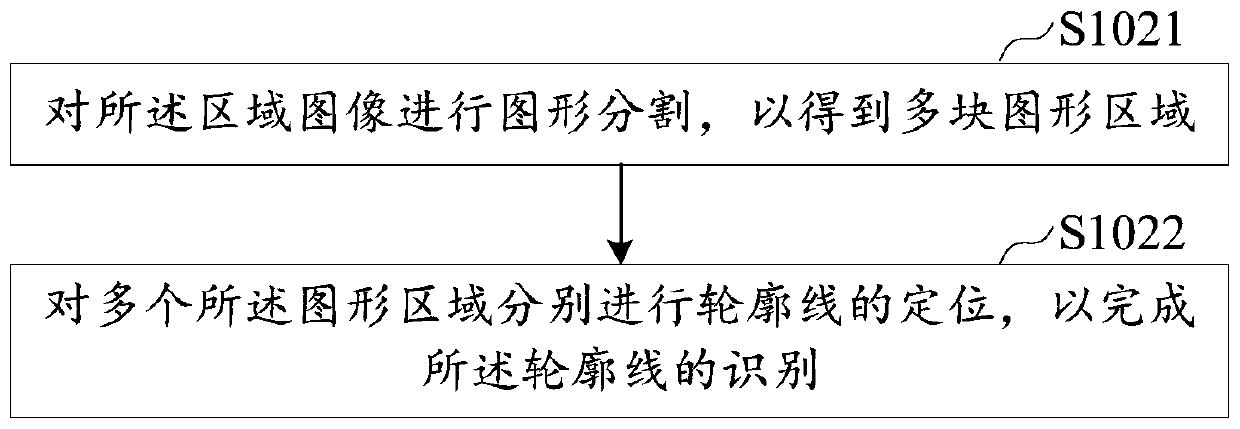

Map area determination method and device, equipment and storage medium

PendingCN111275730AImplement extractionImprove accuracyImage analysisGeographical information databasesImaging processingComputer graphics (images)

The invention relates to the field of image processing, and particularly discloses a map area determination method, device and equipment and a storage medium. The method includes: acquiring a regionalimage; caryring out image recognition on the regional image to obtain a contour line used for representing the regional image, and the contour line comprises a plurality of pixel points; preprocessing the plurality of pixel points according to the pixel point coordinates of the pixel points on the regional image to obtain a pixel point coordinate set; performing coordinate conversion on pixel point coordinates in the pixel point coordinate set based on a mapping relationship between the regional image and a map to obtain a longitude and latitude coordinate set corresponding to the pixel pointcoordinate set; and drawing a target area corresponding to the contour line on the map according to the longitude and latitude coordinate set. And the accuracy of obtaining the longitude and latitudecoordinates of the irregular area is improved.

Owner:PINGAN INT SMART CITY TECH CO LTD

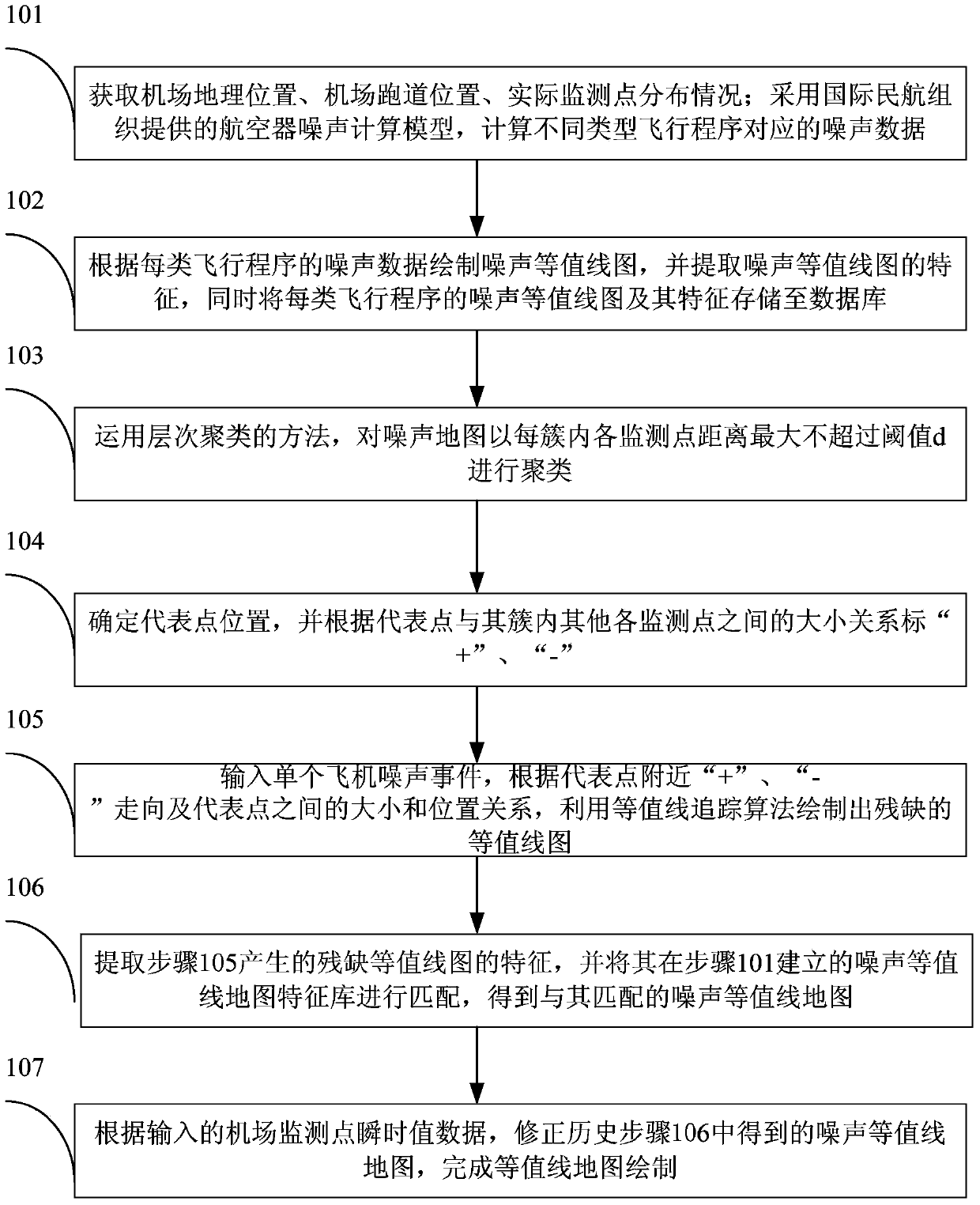

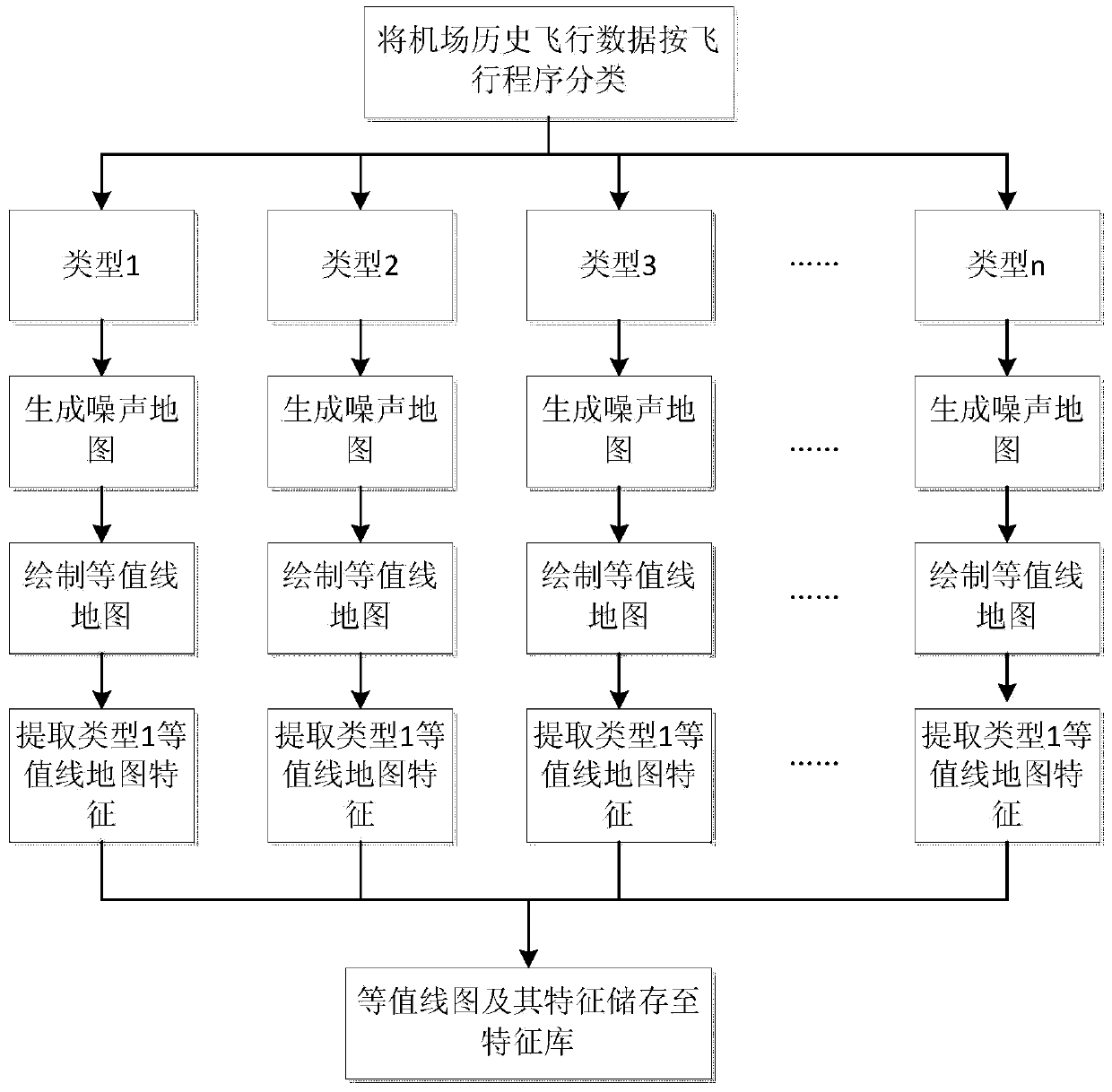

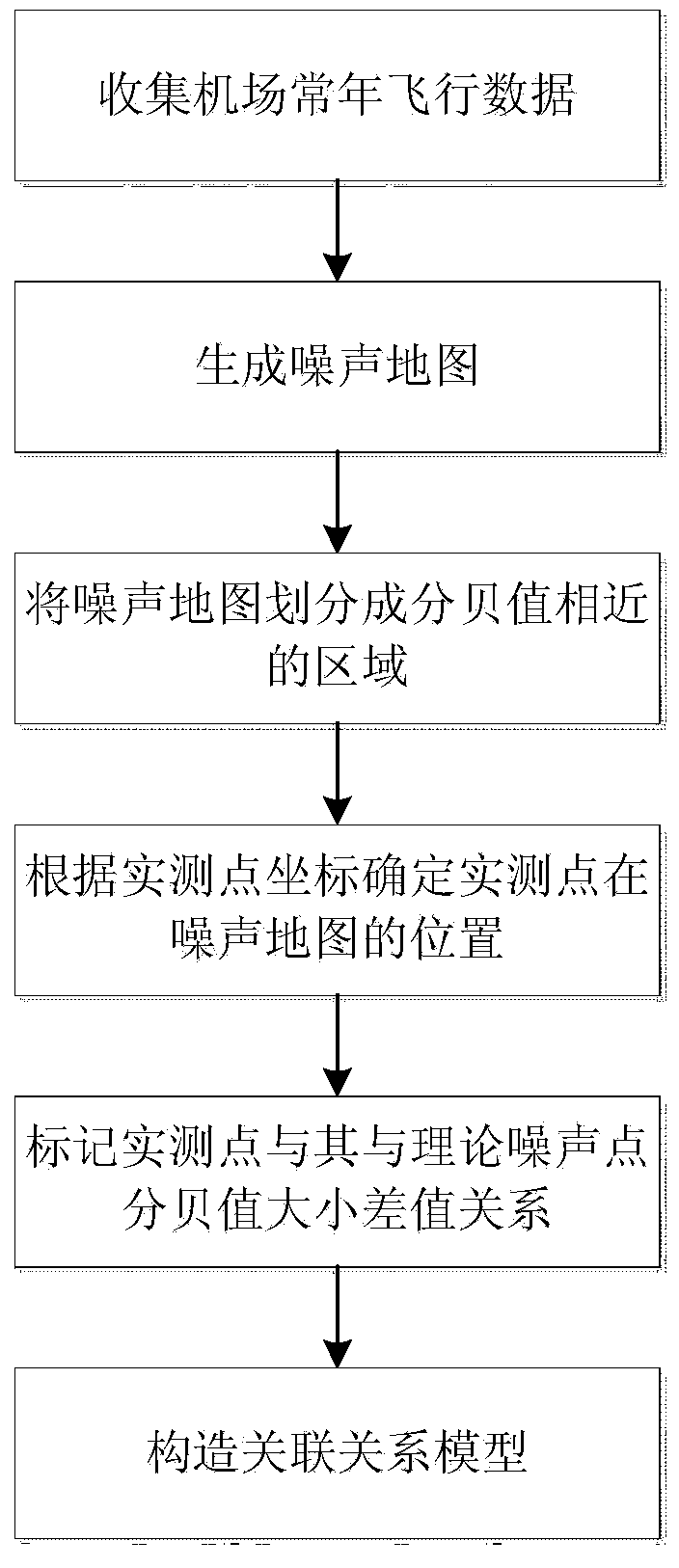

Method for drawing aircraft noise contour map

ActiveCN103617336AImprove drawing precisionReduce dependenceSpecial data processing applicationsNoise monitoringAviation

The invention discloses a method for drawing an aircraft noise contour map. The method comprises the following steps of: 1, establishing a flight program noise contour map feature library; 2, excavating the incidence relation of monitoring points: excavating the historical noise data of an airport by adopting a hierarchical clustering method to discover the incidence relation of noise monitoring points; 3, drawing the noise contour ma: firstly drawing an incomplete contour map according to the incidence relation of actually measured noise data of measuring points and the monitoring points under a single flight incident, then extracting the characteristics of the incomplete contour map, then matching the extracted characteristics of the incomplete contour map in the flight program noise contour map feature library, and finally correcting a matched noise contour map by utilizing instantaneous noise data obtained by being monitored on a small quantity of sparse monitoring points to complete the drawing of the noise contour map. The method disclosed by the invention has higher instantaneity and practicability.

Owner:CIVIL AVIATION UNIV OF CHINA

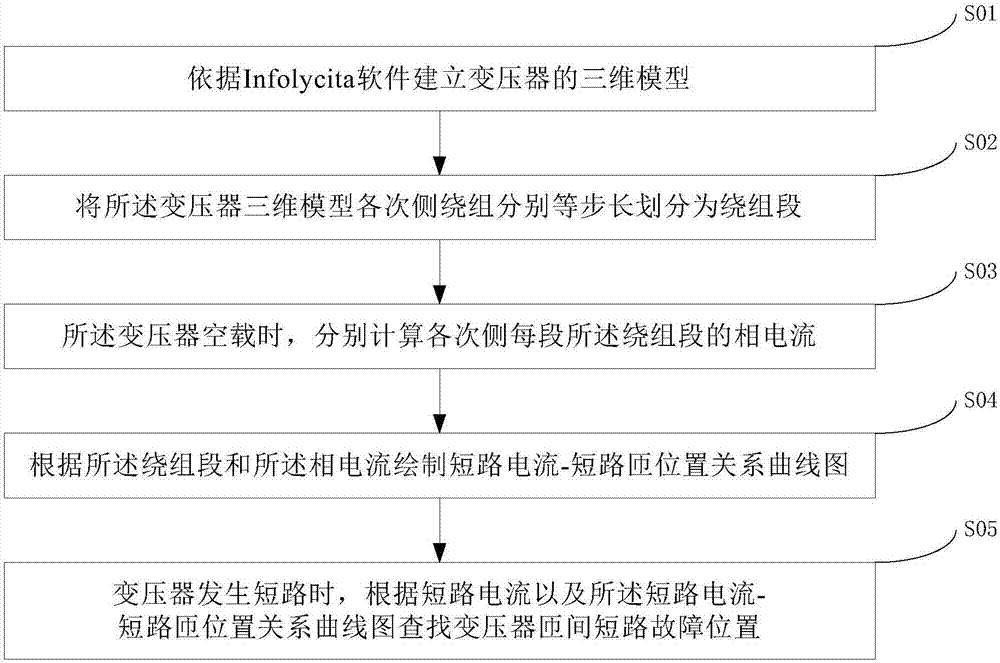

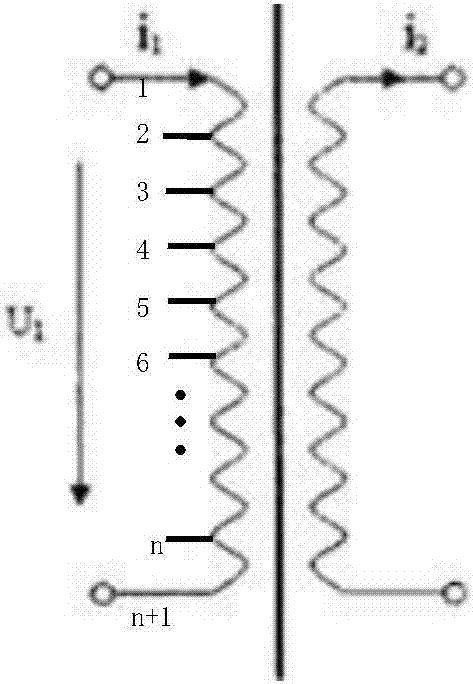

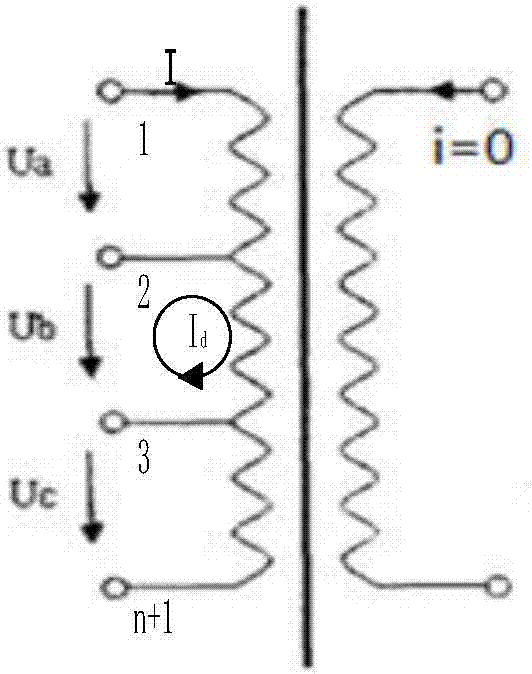

Transformer turn-to-turn short-circuit fault location positioning method

InactiveCN107247208AImprove calculation accuracyImprove drawing precisionTransformers testingPhase currentsEngineering

The invention provides a transformer turn-to-turn short-circuit fault location positioning method. According to the method, a transformer model is established according to Infolycita software; secondary side windings are divided into winding sections in an equal-step length manner; the phase current of each winding section is measured, a short-circuit current-short circuit turn location curve is drawn, so that a change rule of short-circuit current changing with a transformer turn-to-turn short-circuit location is obtained; and when a transformer is short circuited, a turn-to-turn short-circuit location corresponding to measured short-circuit current is searched on the short-circuit current-short circuit turn location curve, so that the specific location of the turn-to-turn short-circuit fault of the transformer can be determined. According to the method, the establishment of the transformer model and the division of the secondary side windings consider a magnetic field and a circuit, and therefore, magnetic flux leakage can be avoided, the calculation accuracy of the phase current can be improved, and therefore, the drawing accuracy of the short-circuit current-short circuit turn location curve can be improved, and the specific location of the turn-to-turn short-circuit fault of the transformer can be determined accurately.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

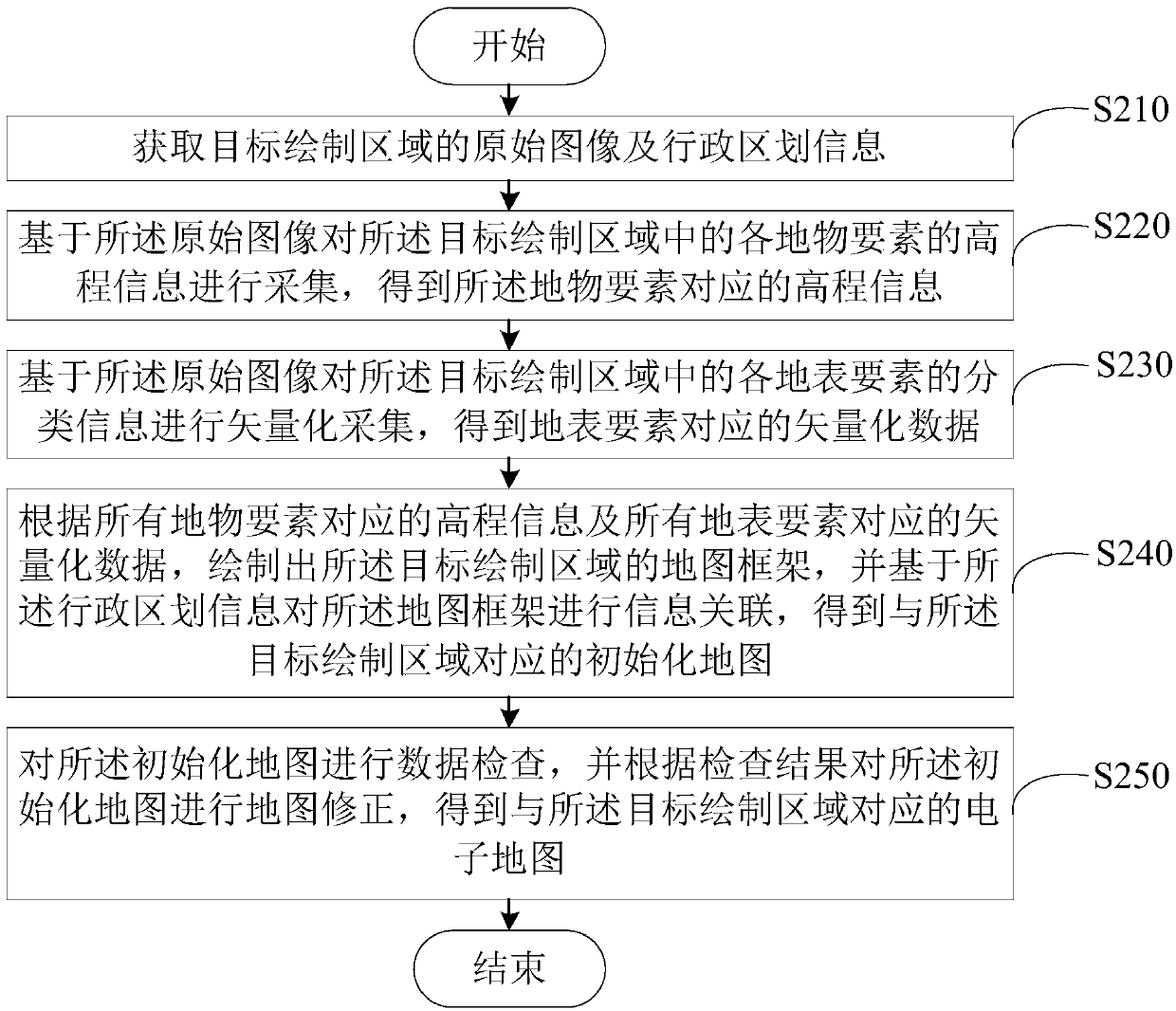

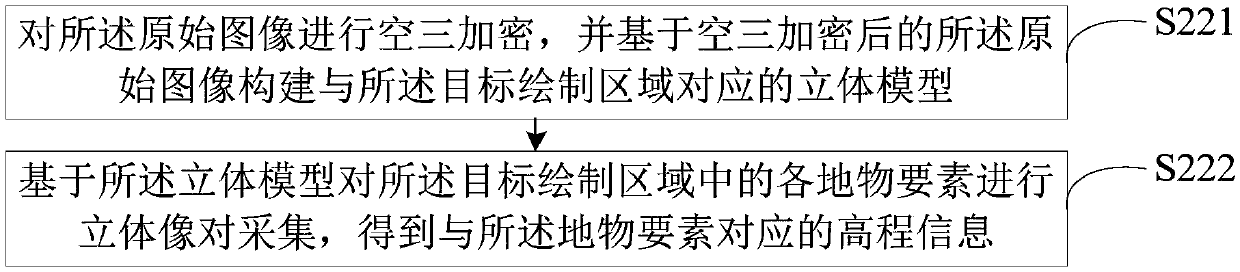

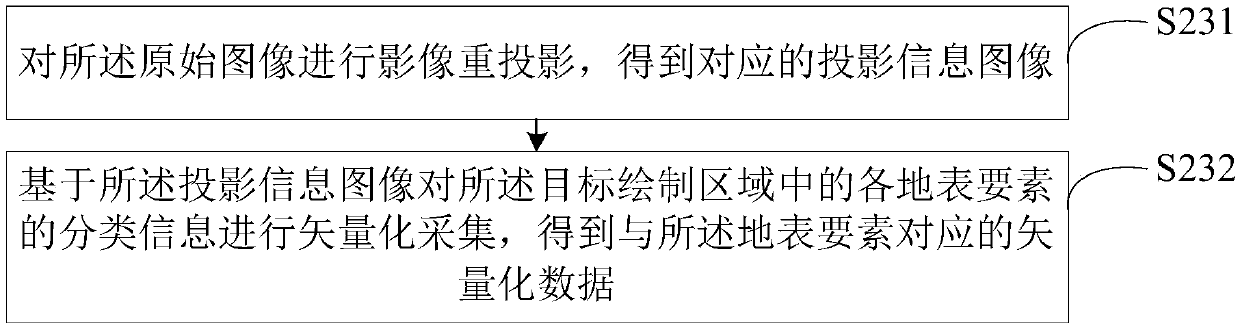

Electronic map drawing method and device

ActiveCN107564402AReduce human resource consumptionImprove user experienceMaps/plans/chartsClassified informationTerrain

The invention provides an electronic map drawing method and device. The electronic map drawing method includes: acquiring an original image and administrative division information of a target drawingarea; based on the original image, collecting elevation information of terrain factors in the target drawing area to acquire corresponding elevation information; based on the original image, performing vectorization collection on classified information of the surface factors in the target drawing area to acquire corresponding vectorization data; according to the elevation information correspondingto the terrain factors and the vectorization data corresponding to the surface factors, drawing a map frame of the target drawing area and performing information association on the map frame on the basis of the administrative division information to acquire an initialized map; performing data check on the initialized map and subjecting the initialized map to map modification according to a checkresult to acquire a corresponding electronic map. The method has the advantages of small resource consumption, low in drawing difficulty and high in drawing efficiency, and the electronic maps with high accuracy can be provided for users.

Owner:AERIAL PHOTOGRAMMETRY & REMOTE SENSING CO LTD

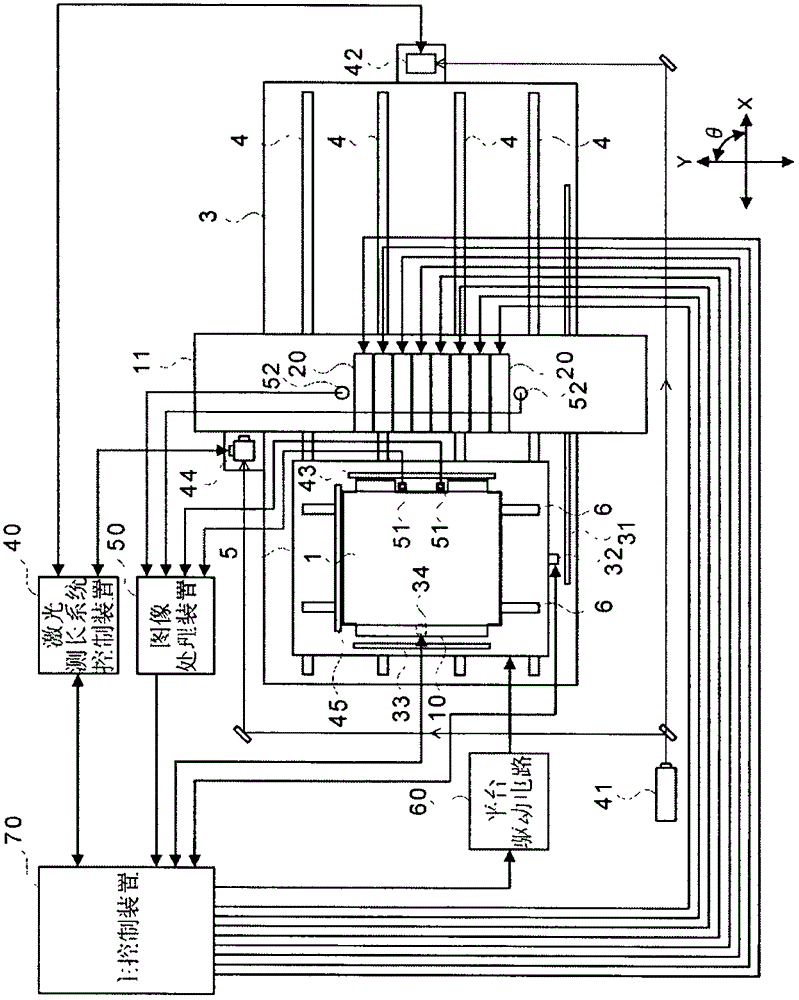

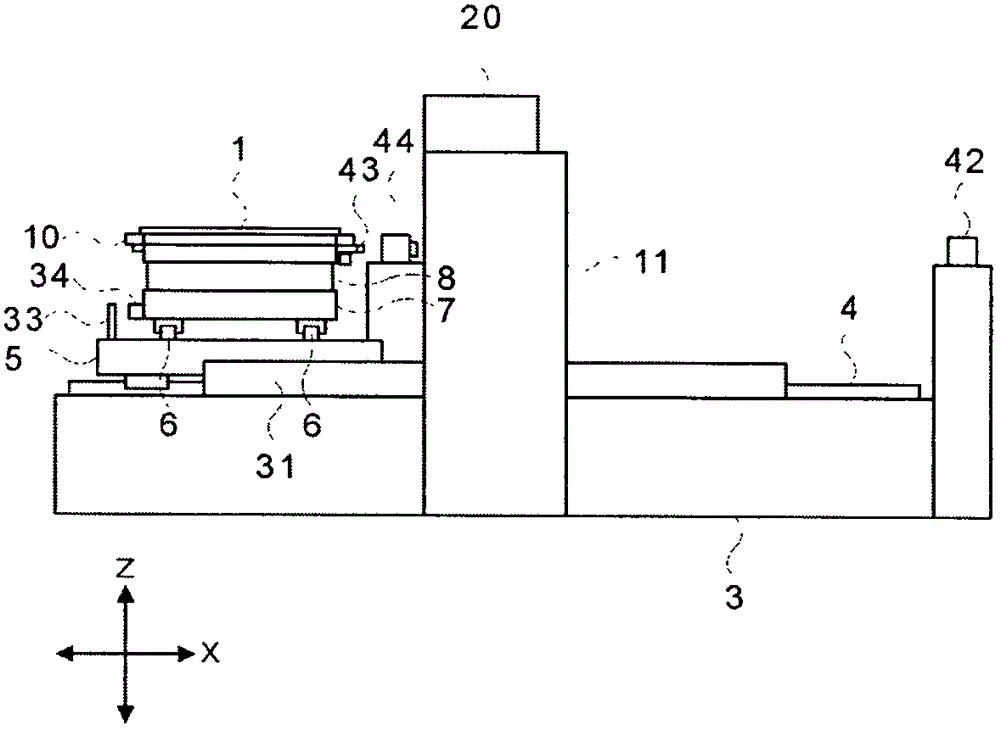

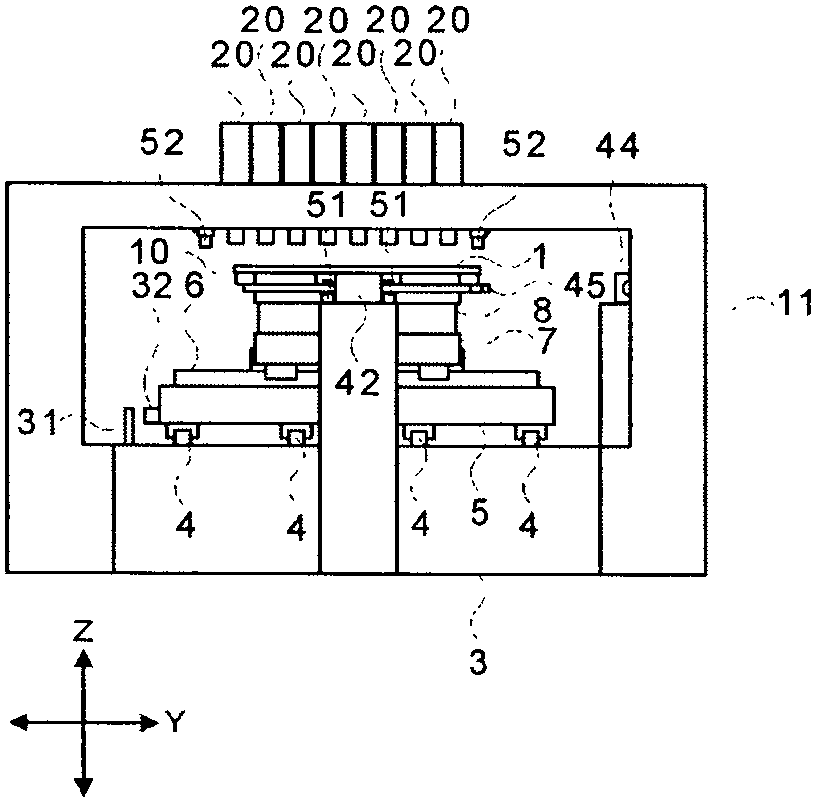

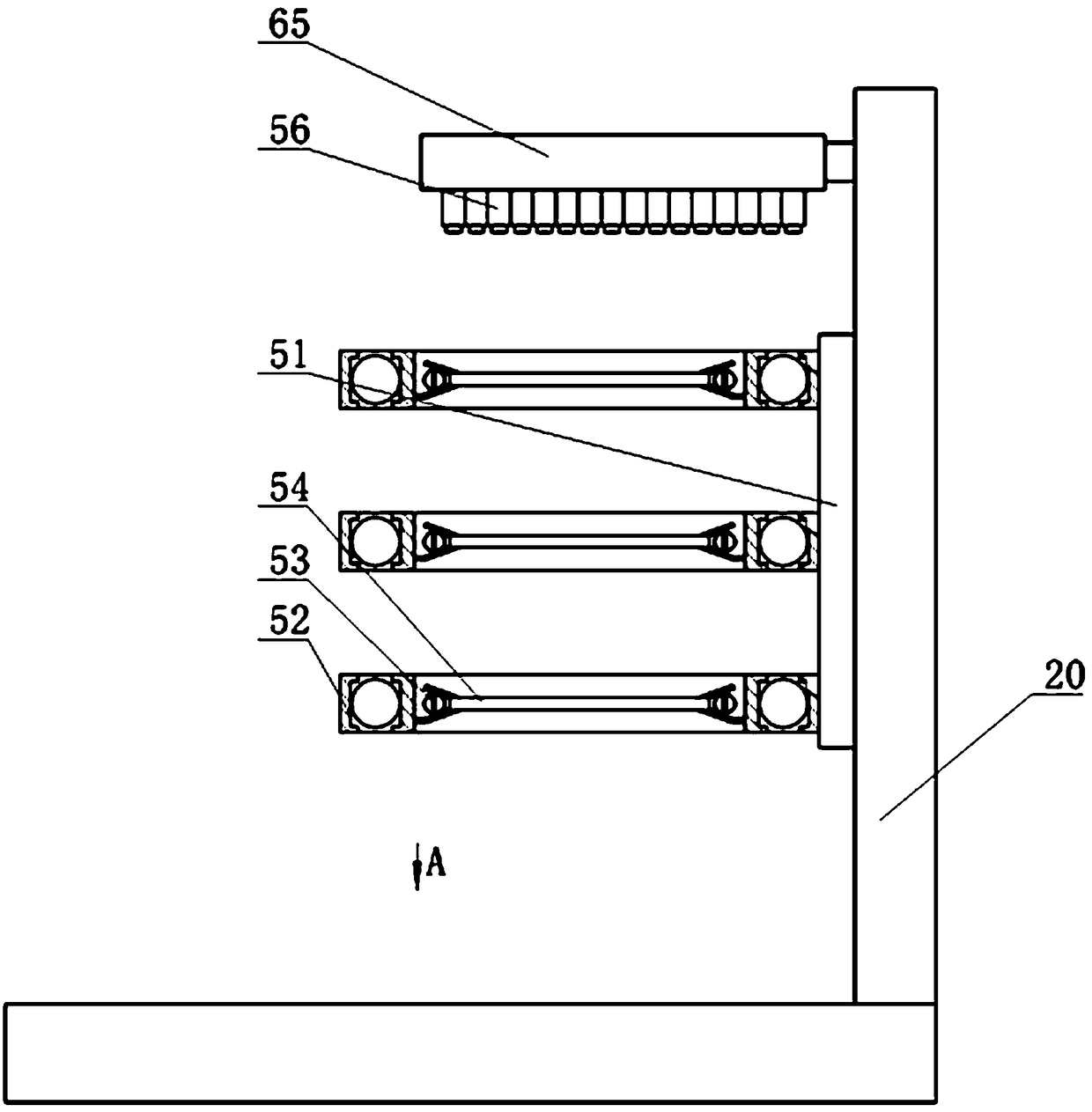

Exposure device, exposure and inspection method, and manufacturing method for substrate of display panel

InactiveCN102799073AImprove deformationAvoid deformationUsing optical meansPhotomechanical exposure apparatusLight beamCcd camera

An exposure device, an exposure and inspection method, and a manufacturing method for a substrate of a display panel. The present invention suppresses deformation of a light beam irradiated from a light beam irradiation device, in order to raise a drawing precision. A first image acquisition device (CCD camera (51)) is arranged on a chuck plate, a reticle piece provided with patterns used for inspection is arranged between a head of the light beam irradiation device and the first image acquisition device. Drawing data used for inspection is supplied to a drive circuit of the light beam irradiation device, images of the patterns (2a) used for inspection of the reticle piece and images (2c) of the light beam irradiated from the light beam irradiation device are obtained through the first image acquisition device. Position offset of the light beam is detected from the images of the patterns (2a) used for inspection of the reticle piece and the images (2c) of the light beam obtained by the first image acquisition device, in order to detect deformation of the light beam. Based on a detection result for the deformation of the light beam, coordinates of the drawing data used for exposure are corrected and supplied to the drive circuit of the light beam irradiation device.

Owner:HITACHI HIGH-TECH CORP

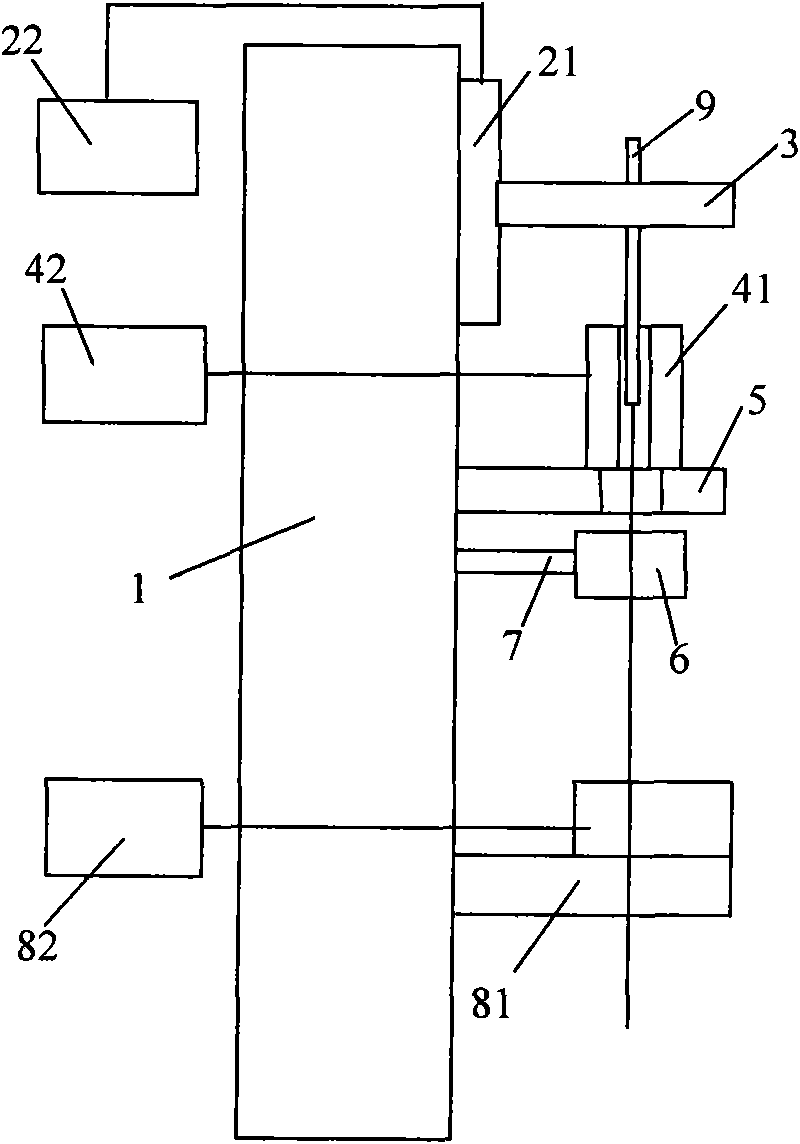

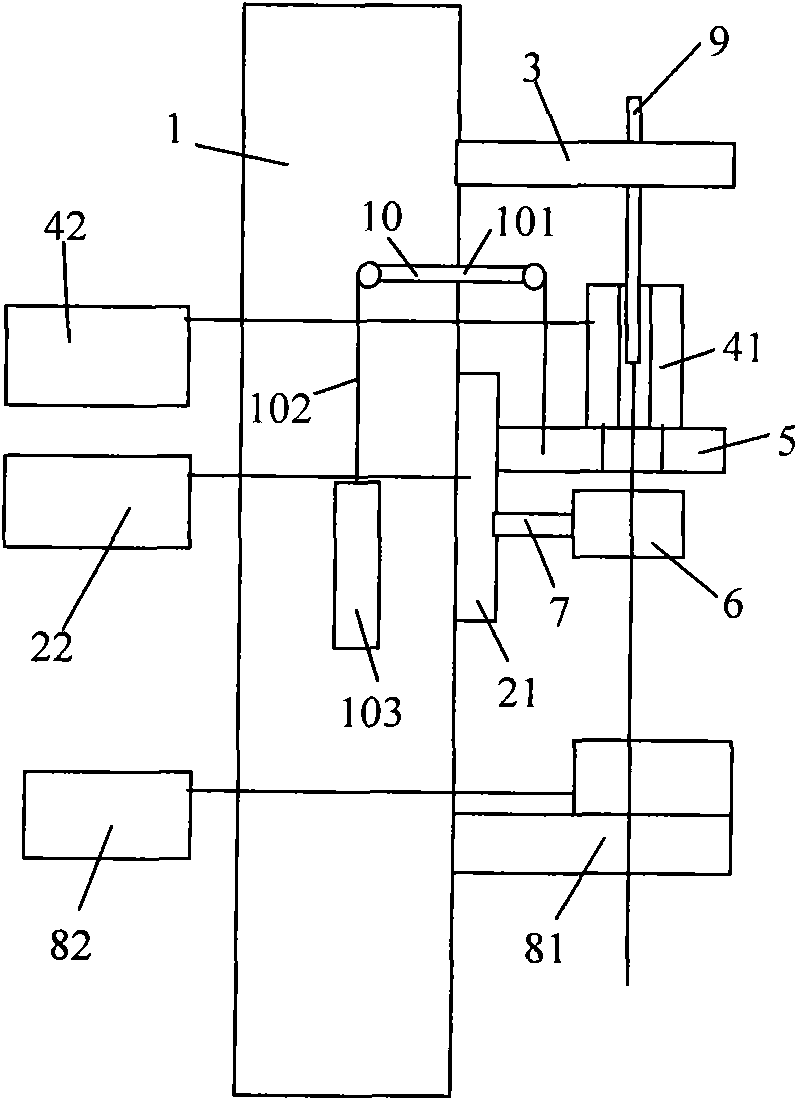

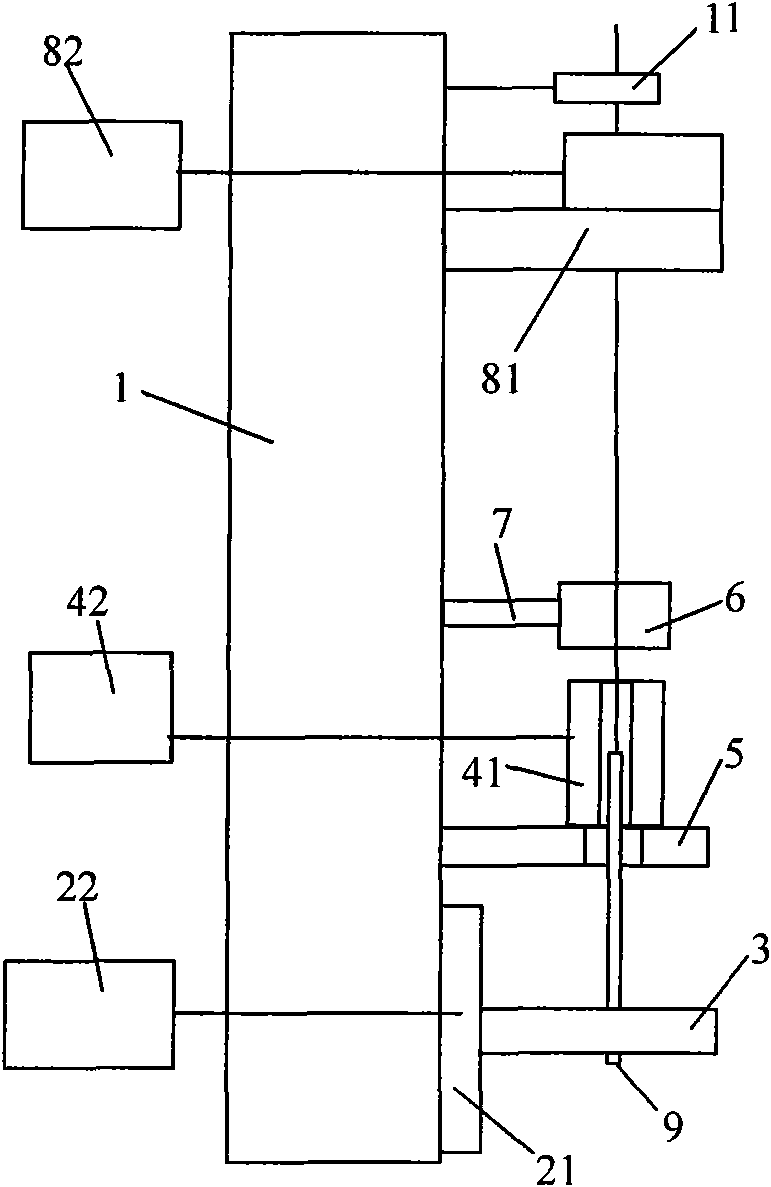

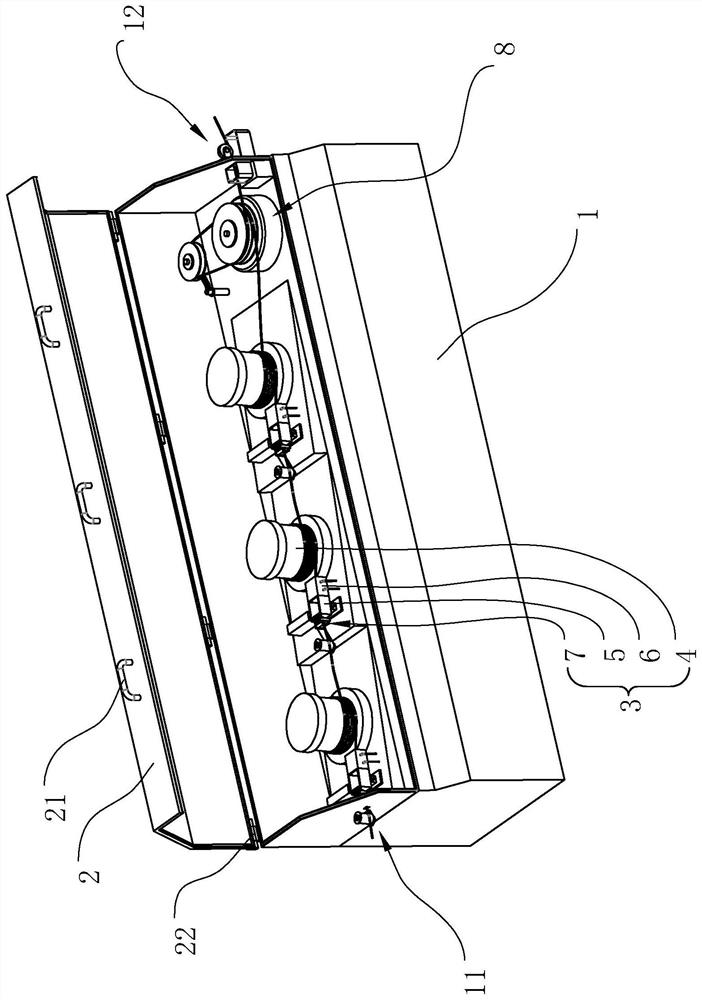

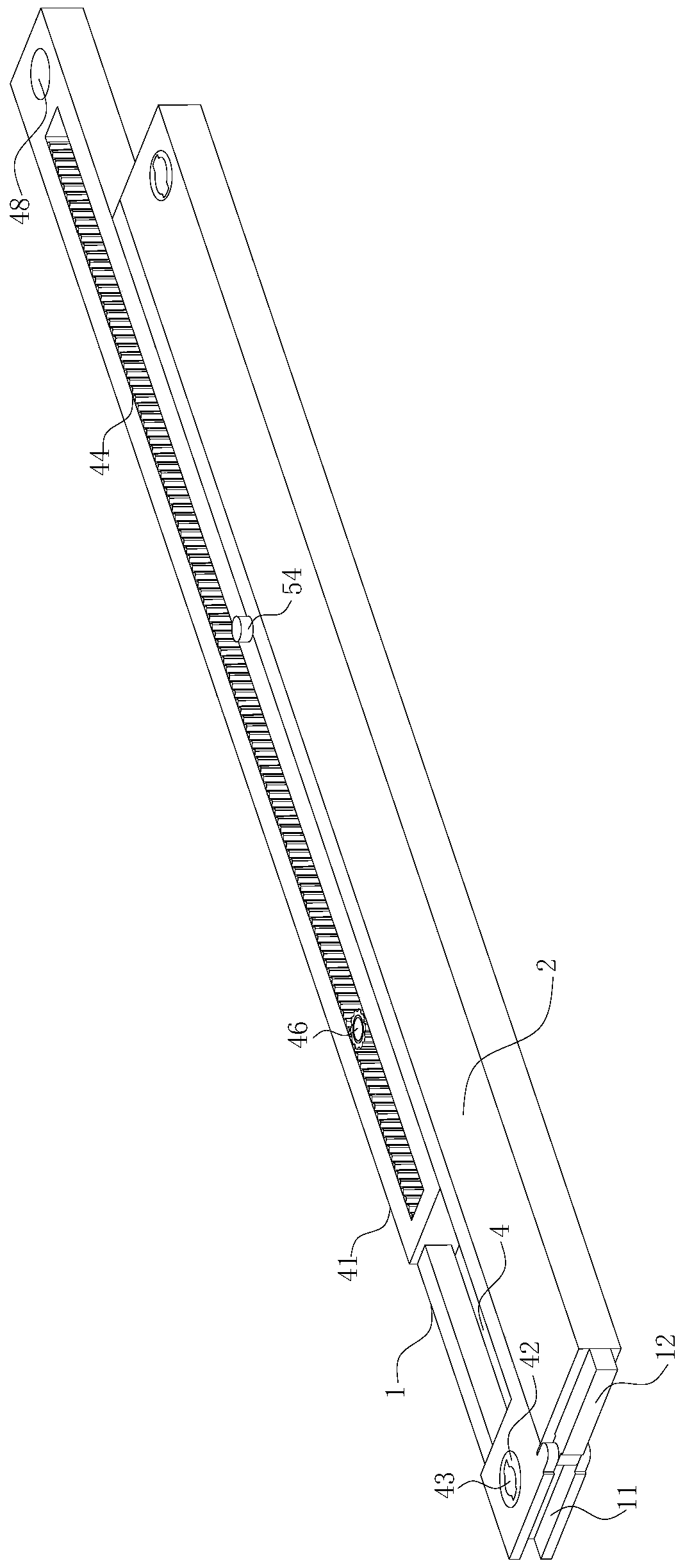

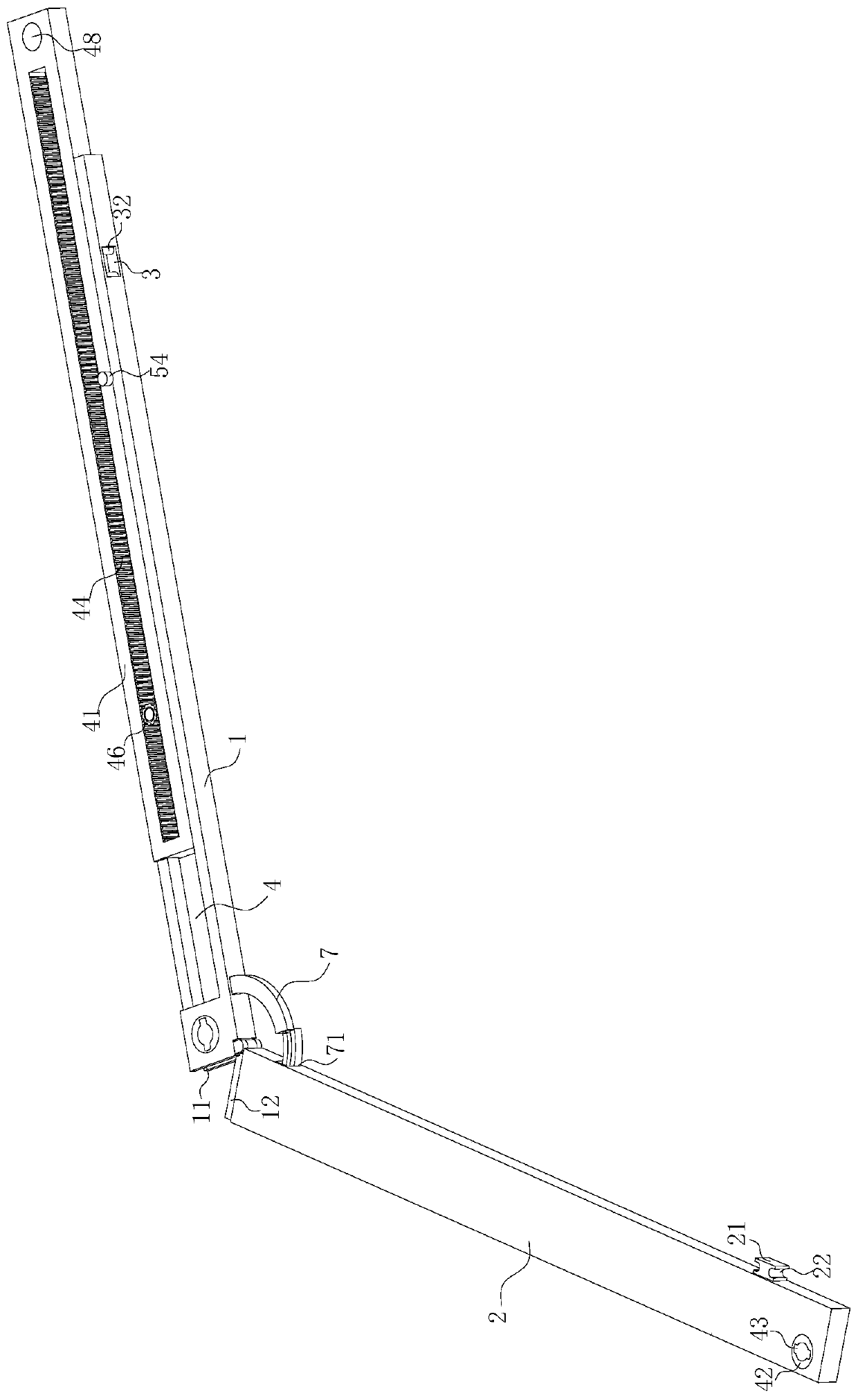

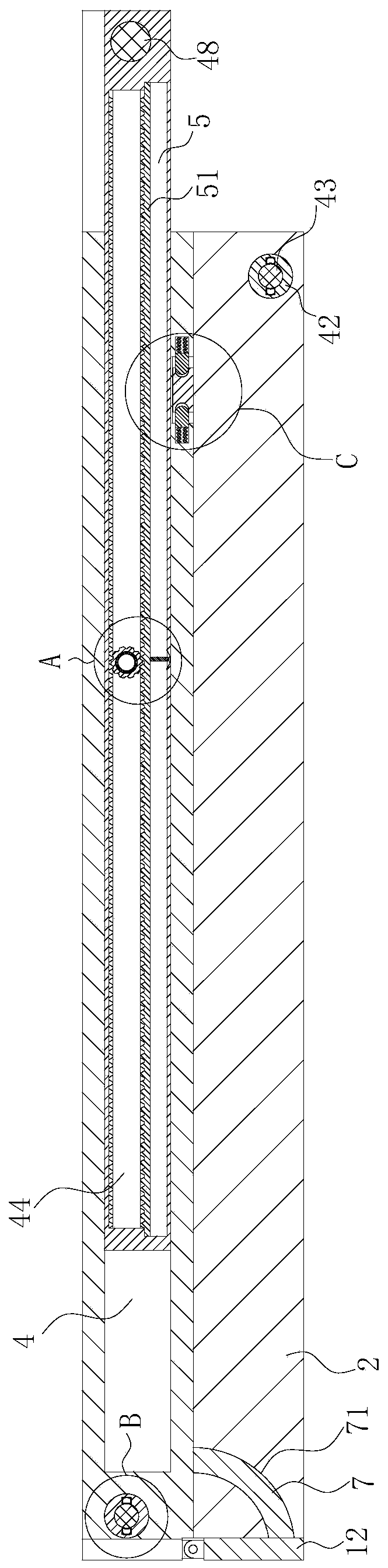

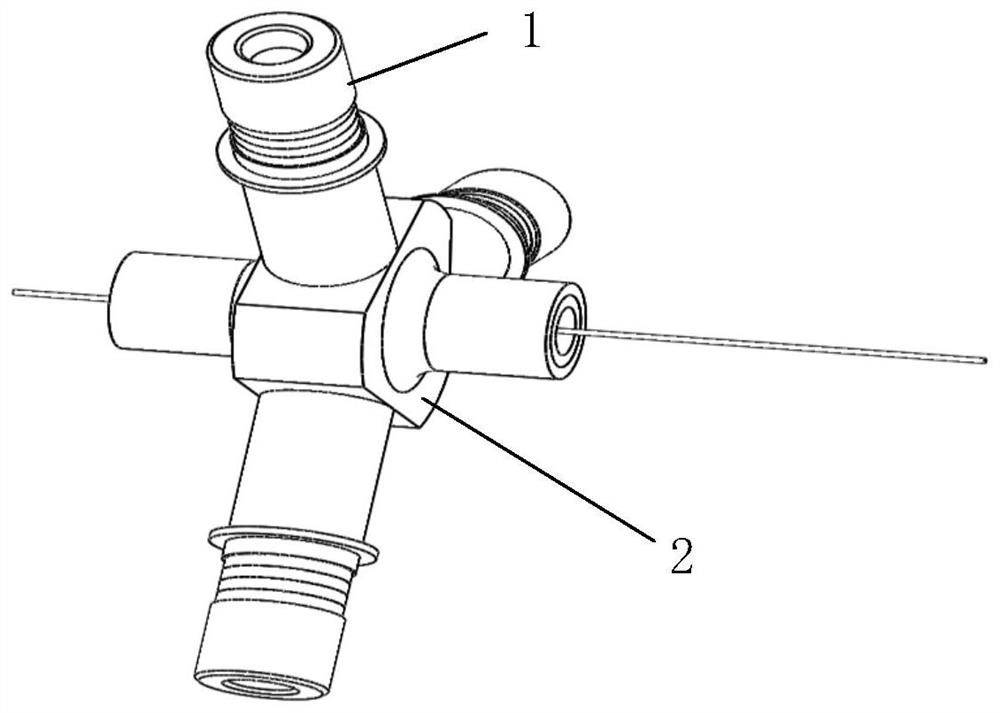

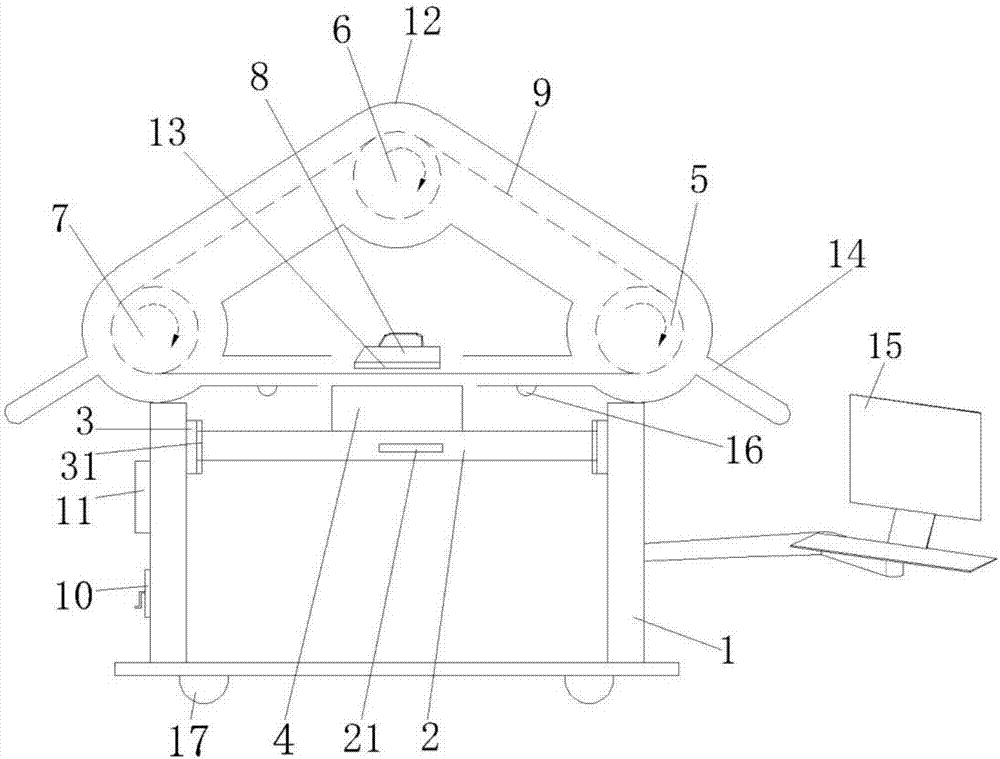

Drawbench

InactiveCN101786789AImprove drawing precisionEliminate mechanical disturbanceGlass reforming apparatusFurnace temperatureEngineering

The invention discloses three drawbenches, which are mainly applied in the fields of precisely drawing glass tubes, glass bars, plastic tubes and plastic bars. The invention provides a drawbench, which consists of a column foot 1, a motion platform 21, a motion platform controller 22, a prefabricated bar holding device 3, an electric furnace 41, an electric furnace temperature controller 42, a grate 5, a wire diameter meter 6, a wire diameter meter frame 7, a drawing device 81, a drawing control device 82 and the like. The drawbench is characterized in that the prefabricated bar holding device 3 is fixed on the upper part of the column foot 1; the motion platform 21 is fixed on the column foot 1 and positioned below the prefabricated bar holding device 3; the grate 5 is fixed on a motion plummer of the motion platform 21; the electric furnace is fixed on the grate 5; the wire diameter meter frame 7 is fixed on the motion plummer of the motion platform 21 and positioned below the grate 5; the wire diameter meter 6 is fixed on the wire diameter meter frame 7; and the drawing device 81 is fixed on the column foot 1 and positioned below the wire diameter meter 6. The precise drawbench can improve drawing precision of a drawing system and improve utilization rate of prefabricated bars.

Owner:方强

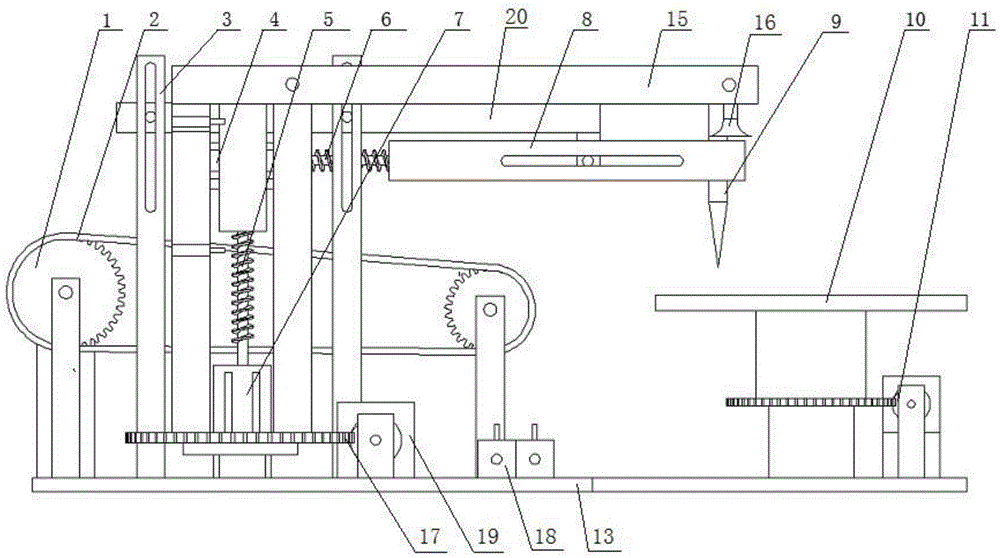

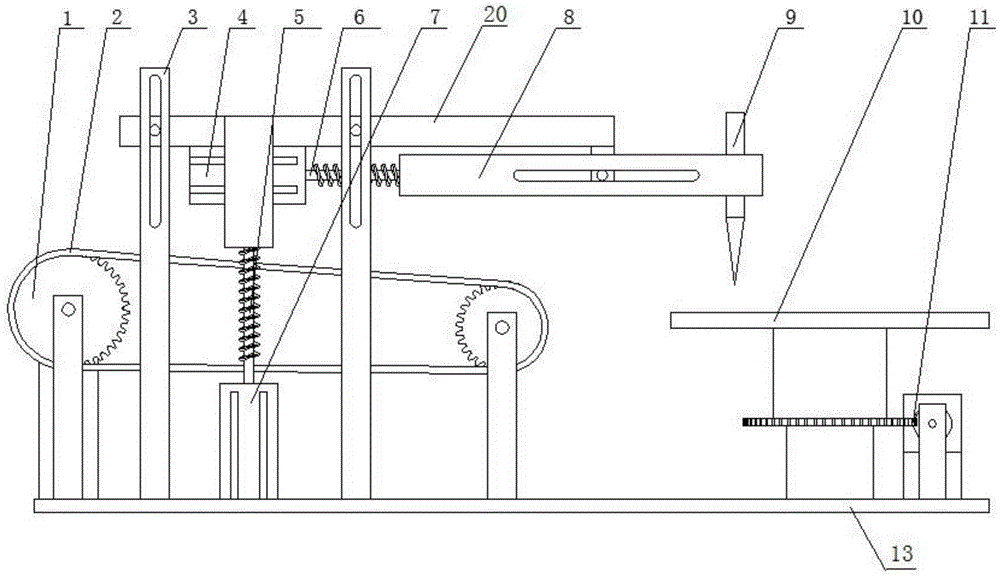

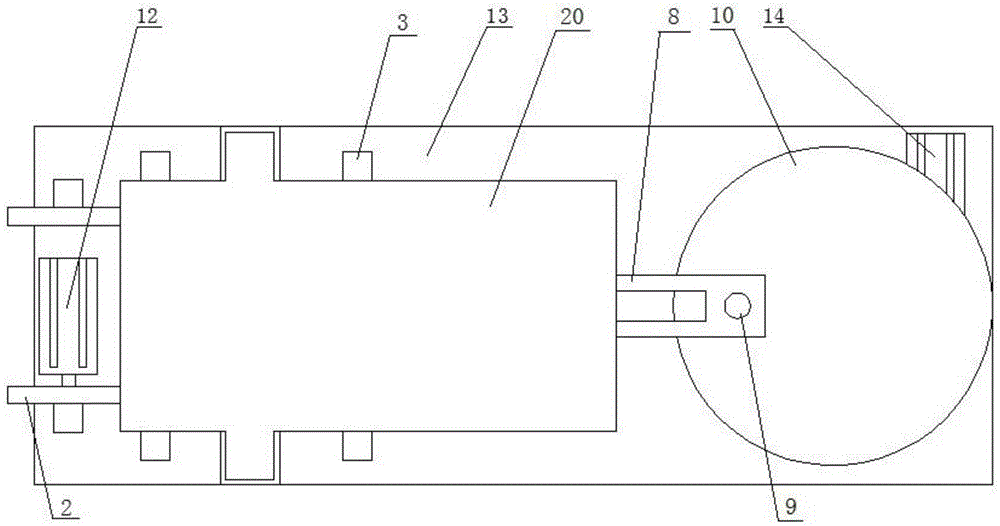

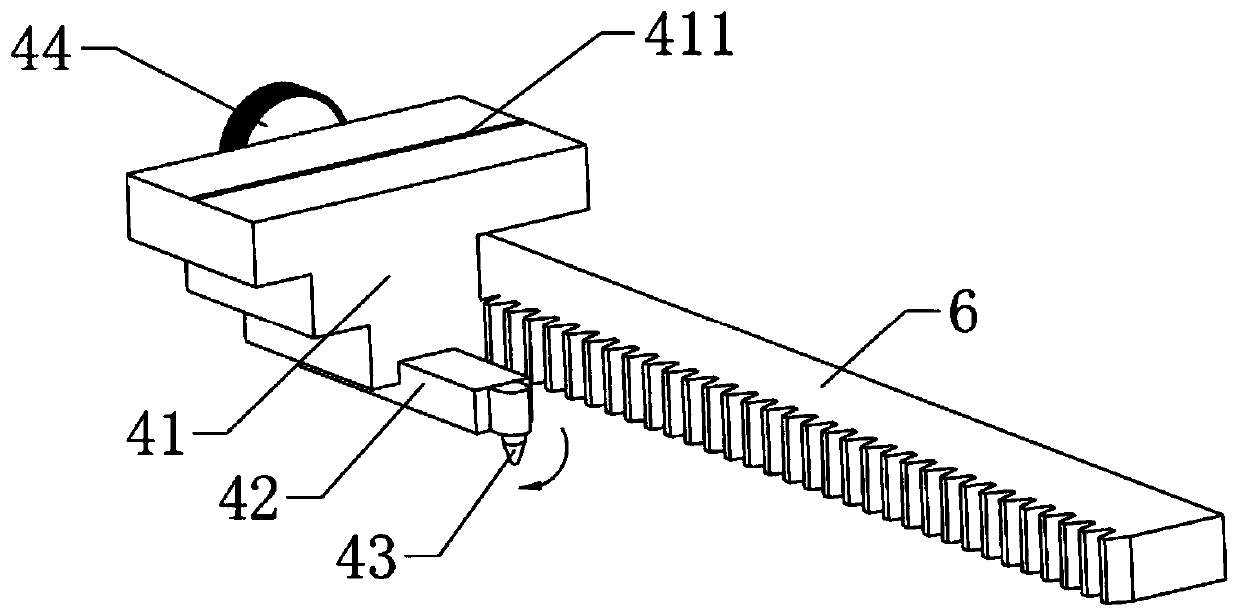

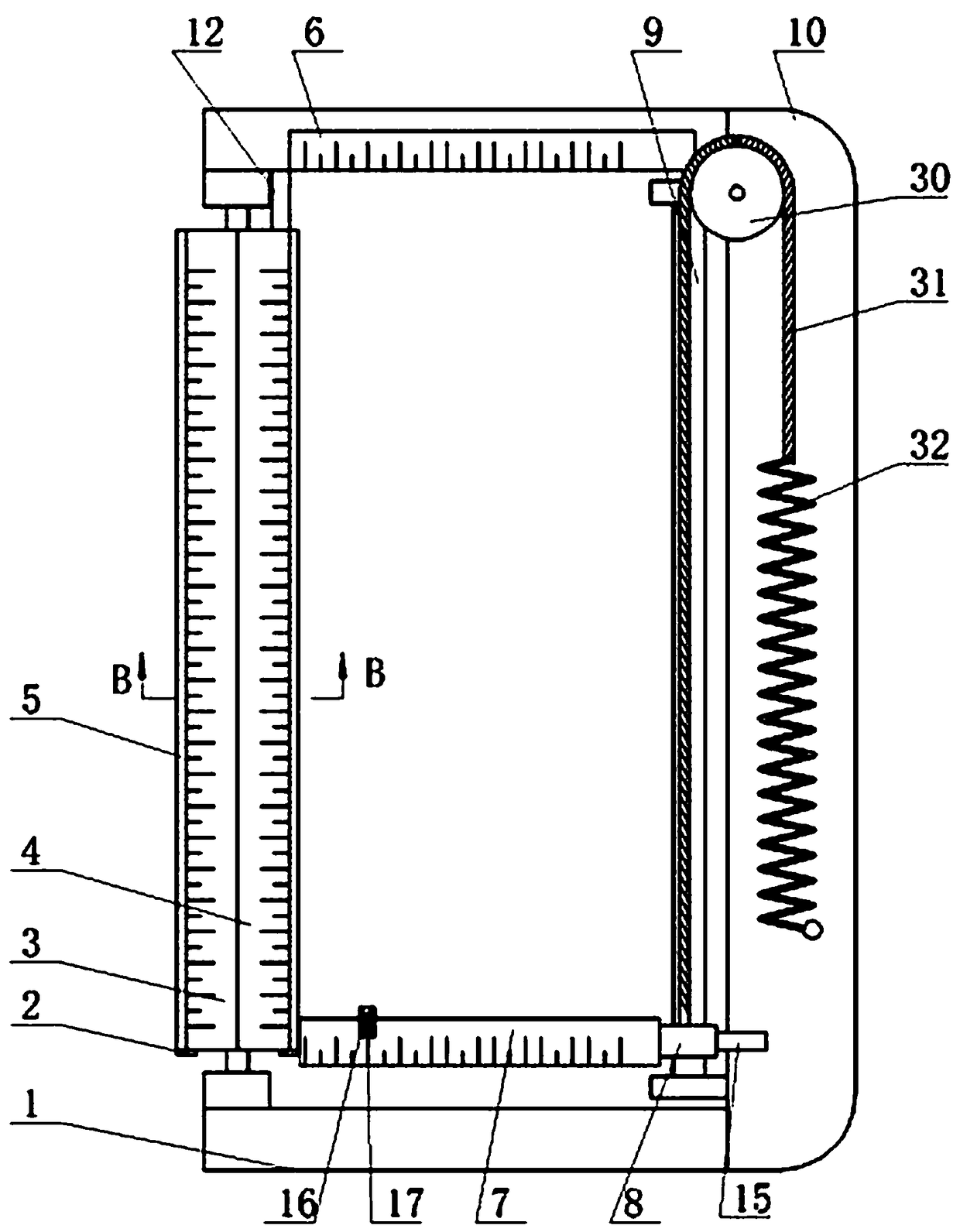

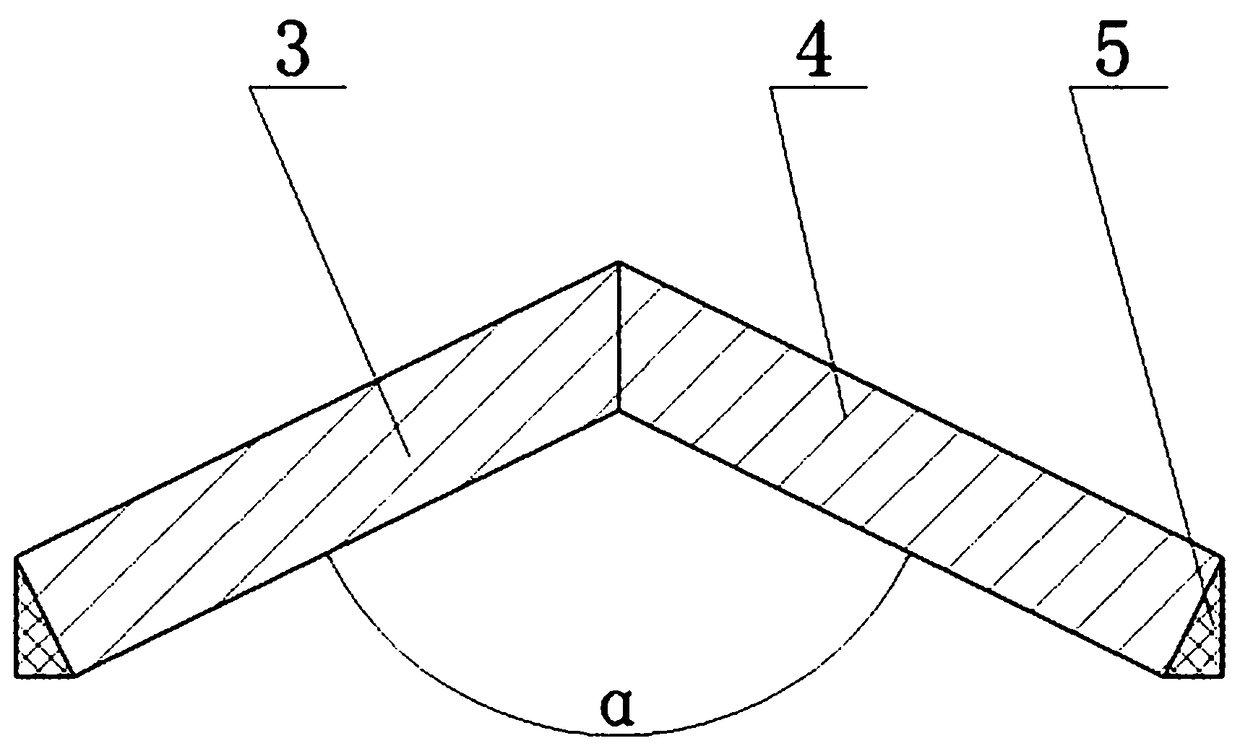

Parameter adjustable cam profile drawing instrument based on relative motion principle

InactiveCN105329029AImprove drawing precisionRealize drawing automatic drawingNon-circular curve drawing instrumentsDisplay deviceEngineering

The invention discloses a parameter adjustable cam profile drawing instrument based on a relative motion principle. The parameter adjustable cam profile drawing instrument comprises a cam profile drawing unit, a belt transmission device and an automatic display device that are arranged on a bottom plate, wherein the cam profile drawing unit comprises a lifting table device; a telescopic arm device is arranged on the lifting table device; a drawing pen is arranged on the telescopic arm device; a drawing panel is arranged below the drawing pen, and is connected with a drawing panel driving device; the belt transmission device and the automatic display device are arranged on the side surface of the drawing panel; the automatic display device comprises a display arm; the display arm is connected with a display arm driving device; a small suction disc is arranged below the display arm, and is connected with an air pump; and the lifting table device, the telescopic arm device, the drawing panel driving device, the belt transmission device and the automatic display device are connected with a control panel. The parameter adjustable cam profile drawing instrument realizes the effect of automatically displaying cam profile drawing, and solves the problem that the conventional cam profile curve design method is low in design accuracy.

Owner:CHINA UNIV OF MINING & TECH

A multi-element Gerber file parsing and rendering method for improving drawing precision

ActiveCN109241555AImprove drawing precisionHigh precisionCAD circuit designSpecial data processing applicationsRounded RectangleArray data structure

The invention provides a multi-element Gerber file analysis and drawing method for improving drawing precision.Aiming at the single problem of Gerber file element analysis and drawing by domestic software at present, the data information of Gerber file is analyzed, and the data is analyzed, extracted and sorted by regular expression, and the analytical drawing of ellipse, arc, sector, regular polygon and rounded rectangle is realized. As you save the Gerber file data, for the data analyzed and sorted out, the storage structure is optimized, the structure and dynamic array are used to solve theproblem of data storage, and the complex data structure such as linked list is abandoned, which ensures the complete extraction and preservation of Gerber file information, and improves the flexibility of image data processing and analysis. Aiming at the problem of data loss after Gerber file data coordinates are converted into pixel coordinates, a solution is proposed to improve the image rendering accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

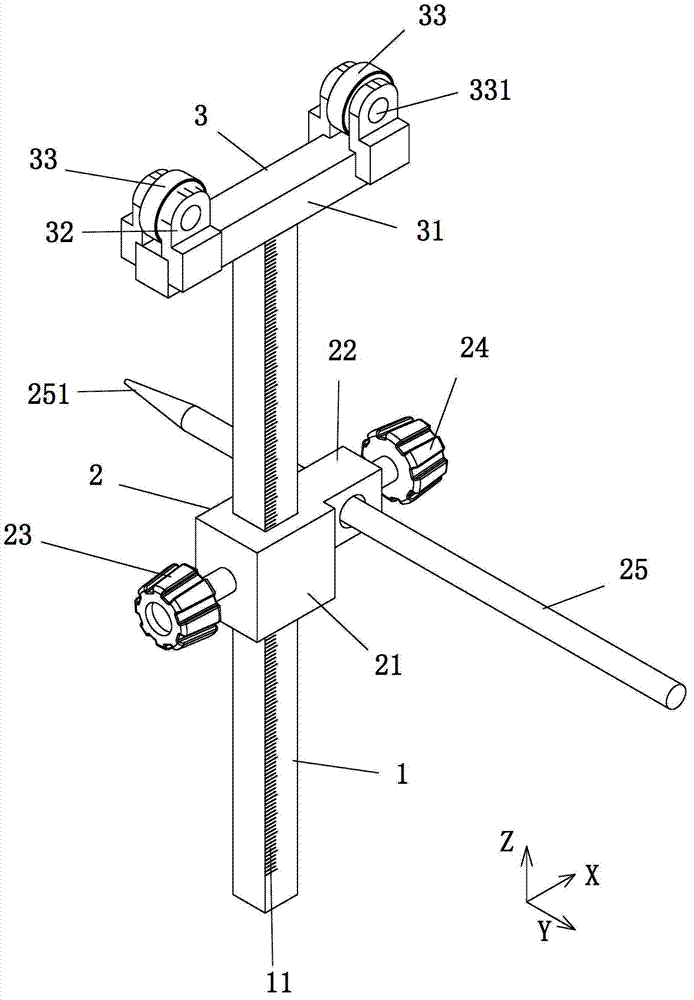

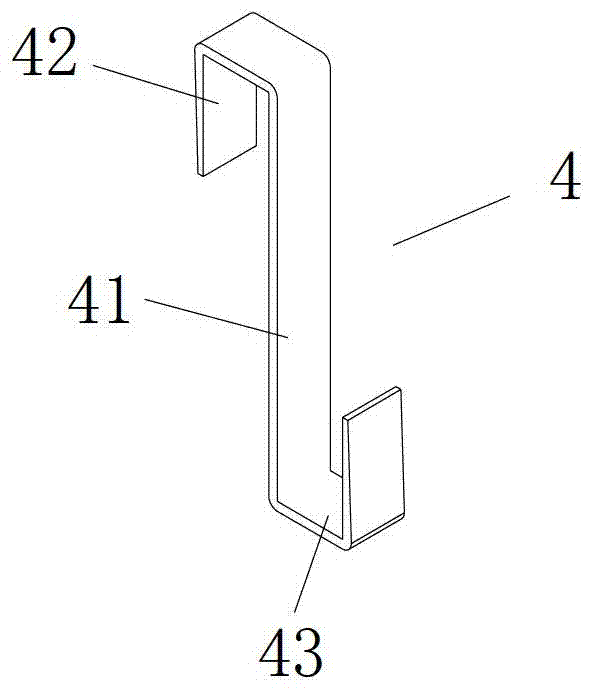

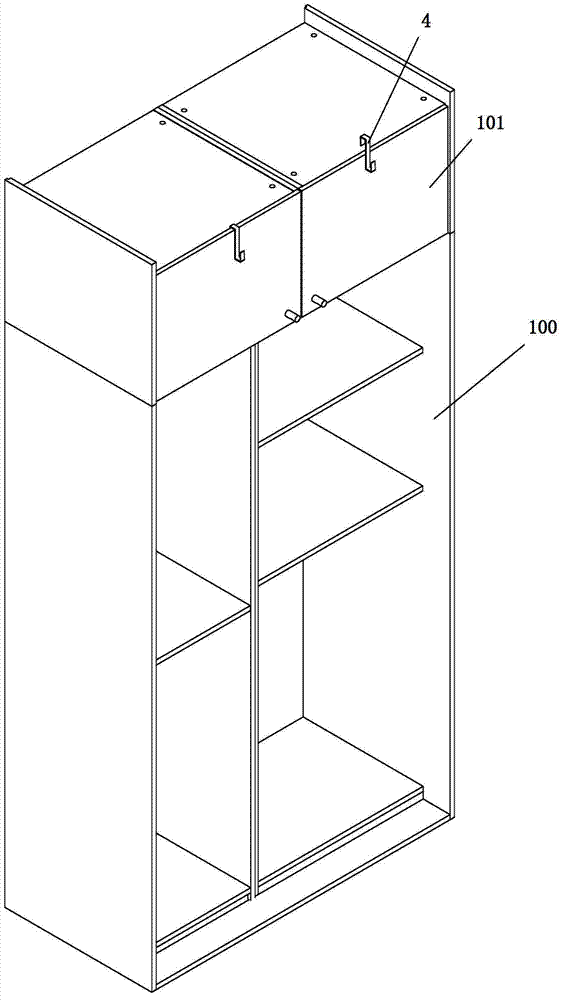

Device for drawing wall surface curves and ceiling curves and use method thereof

ActiveCN102814805AReduce drawing timeImprove drawing precisionOther workshop equipmentEngineeringMechanical engineering

The invention relates to a device for drawing wall surface curves and ceiling curves and a use method thereof. The device comprises a pillar, a painting brush fixing mechanism and a rolling mechanism, wherein the painting brush fixing mechanism comprises a sleeve body provided with a first middle through hole, a painting brush fixing body provided with a second middle through hole, a painting brush, a first manually turning screw and a second manually turning screw, the sleeve body is in cup joint with the pillar through the first middle through hole, the painting brush fixing body is fixed at one side of the sleeve body, the painting brush fixing body is in cup joint with the painting brush through the second middle through hole, the first manually turning screw is connected with the other side of the sleeve body through threads, the end part of the first manually turning screw is contacted with the pillar, the second manually turning screw is connected with one side of the painting brush fixing body through threads, and the end part of the second manually turning screw is contacted with the painting brush; and the rolling mechanism comprises a roller support part and at least two rollers, the roller support part is fixedly arranged on the top of the pillar, and the rollers are arranged on the top of the roller support part and can rotate freely. According to the device for drawing the wall surface curves and the ceiling curves and the use method thereof disclosed by the invention, the drawing time can be greatly shortened, the drawing precision can be improved, and the working efficiency is improved.

Owner:SUOFEIYA HOME COLLECTION

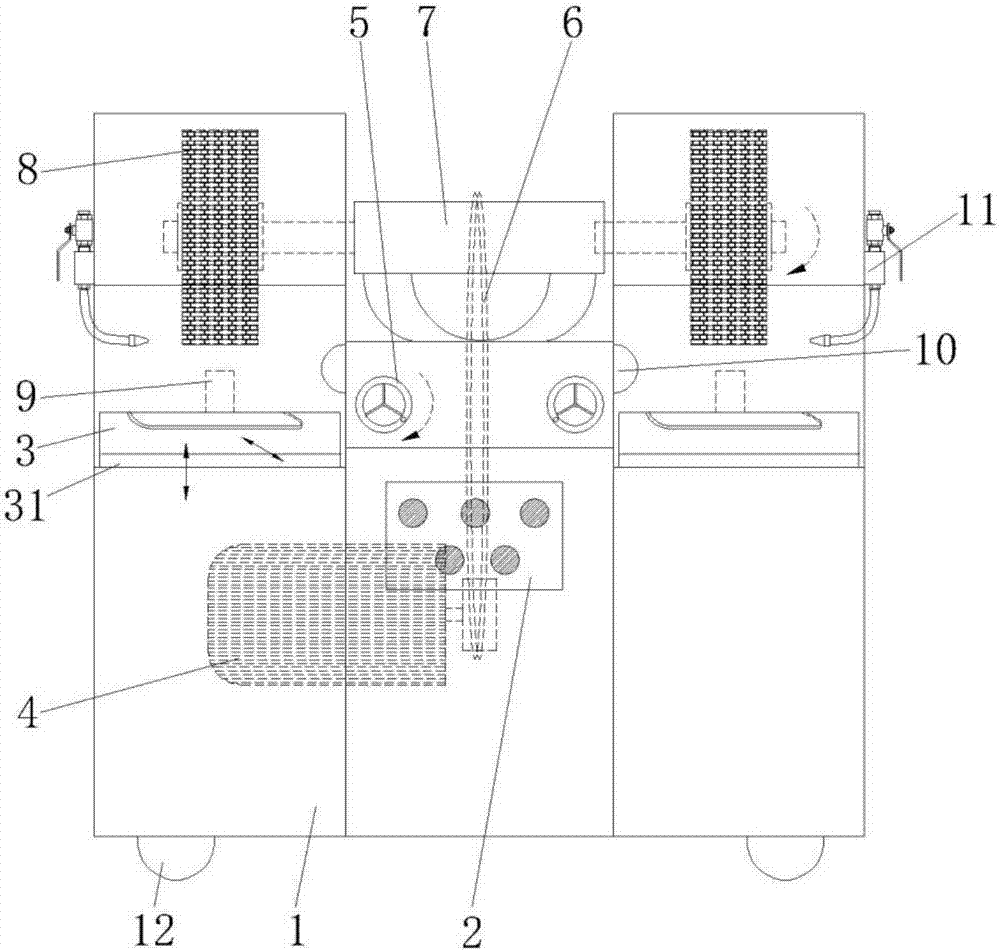

Low-noise nylon wheel wire drawing machine for hardware machining

InactiveCN107263276AAccurate speed controlEasy to operateGrinding carriagesGrinding drivesLow noiseEngineering

The invention discloses a low-noise nylon wheel wire drawing machine for hardware machining, and relates to the technical field of hardware machining. Workbenches are arranged on the two sides of a rack, and workpieces are arranged right in the middles of the workbenches and located under nylon wheels. A set of sliding wheels are arranged at the bottom of the rack. A buffering pad is arranged between the bottom of each workbench and the rack and comprises a foam plate and a damping material layer. Cooling mechanisms are arranged on the two sides of the rack and connected with a cooling liquid box in the rack through plastic pipes and water pumps. The heads of the cooling mechanisms can rotate by 360 degrees. The wire drawing machine is easy to operate, the wire drawing precision and the wire drawing efficiency are greatly improved, the work noise is low, safety and reliability are achieved, carrying, repairing and maintaining are convenient and fast, and long-time and high-quality proceeding of wire drawing work is guaranteed.

Owner:太仓市华天冲压五金制品厂

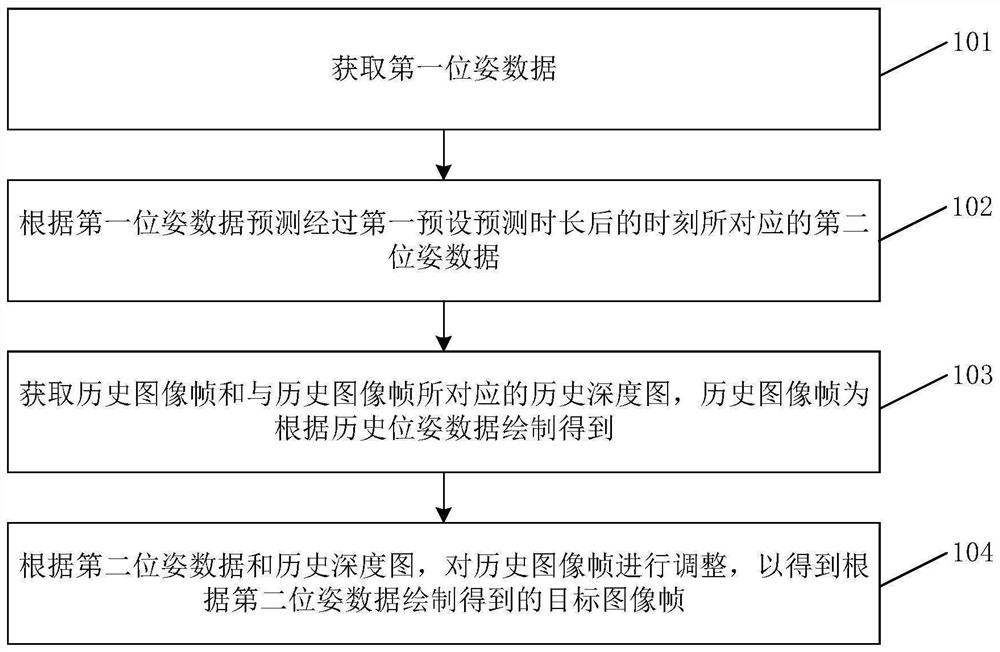

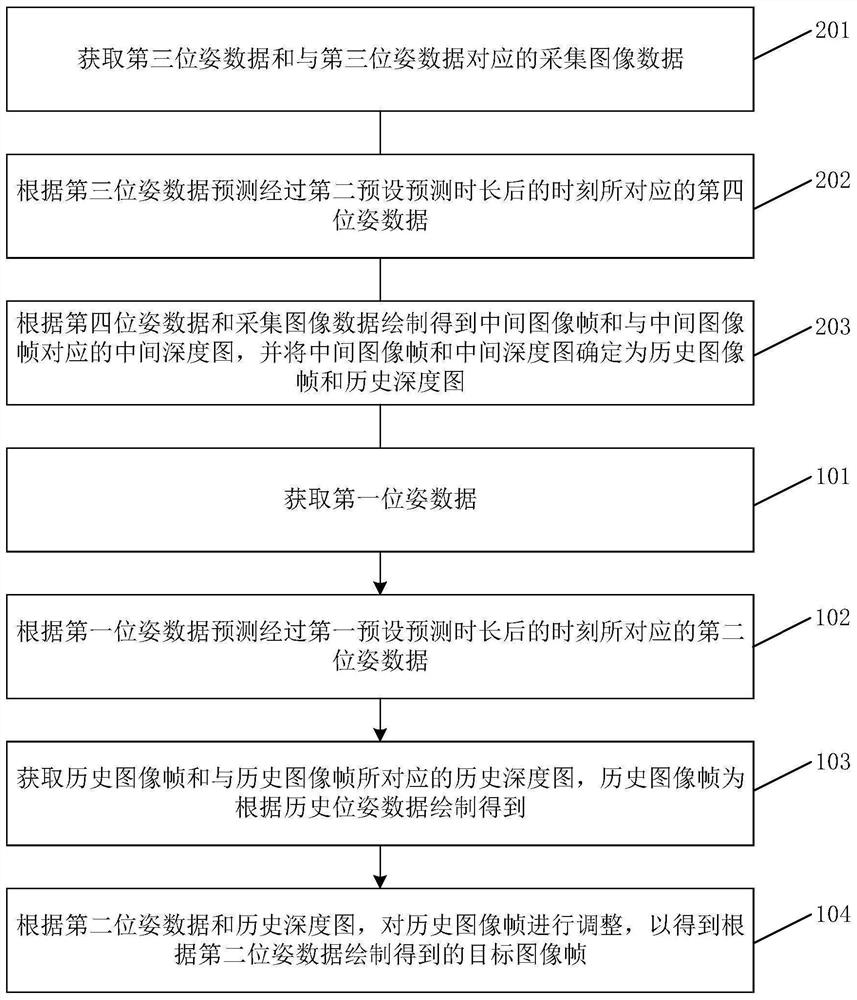

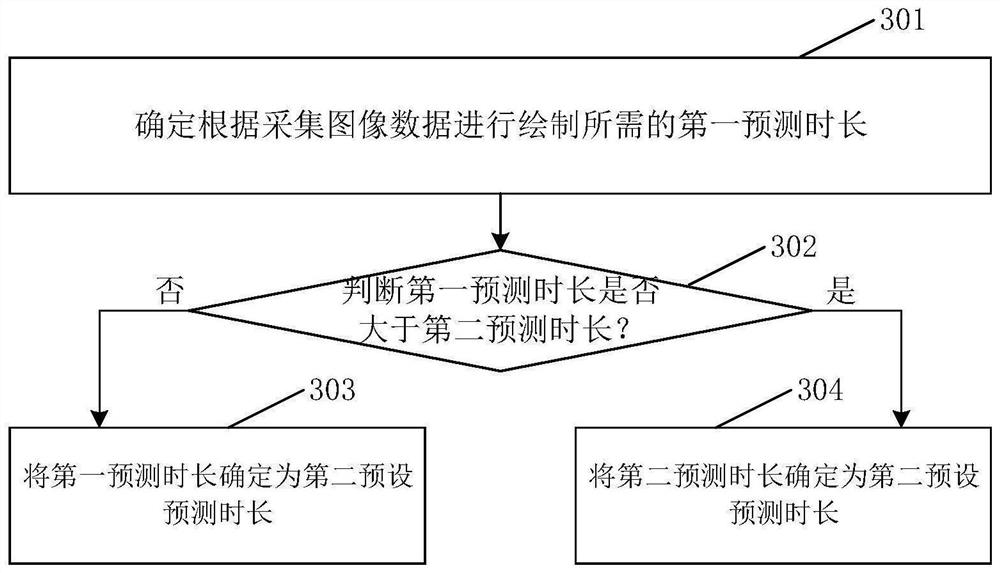

Image drawing method and device, readable medium and electronic equipment

PendingCN112489224AHigh speedImprove drawing precisionImage analysisNavigation by speed/acceleration measurementsMedicineRadiology

The invention relates to an image drawing method and apparatus, a readable medium and an electronic device. The method comprises the steps of obtaining first pose data; predicting second pose data corresponding to the moment after the first preset prediction duration according to the first pose data; acquiring a historical image frame and a historical depth map corresponding to the historical image frame; and adjusting the historical image frame according to the second pose data and the historical depth map to obtain a target image frame drawn according to the second pose data. Thus, by predicting the second pose data, the delay between the target image frame and the image corresponding to the actual pose of the user when the target image frame is displayed in the display area of the AR glasses and other scenes can be reduced, and the user experience is improved. And the target image frame obtained by drawing corresponding to the second pose data can be quickly obtained by adjusting the historical image frame, so that the first preset prediction duration is shortened, and the prediction precision of the target image frame is improved.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

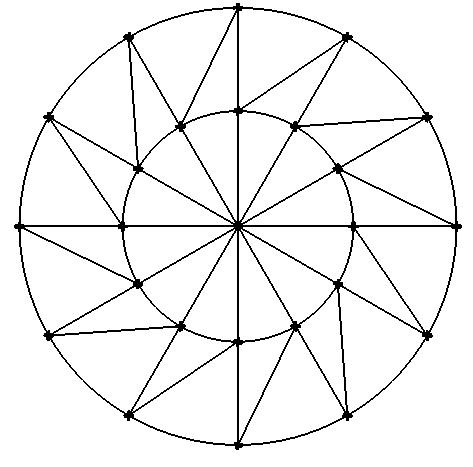

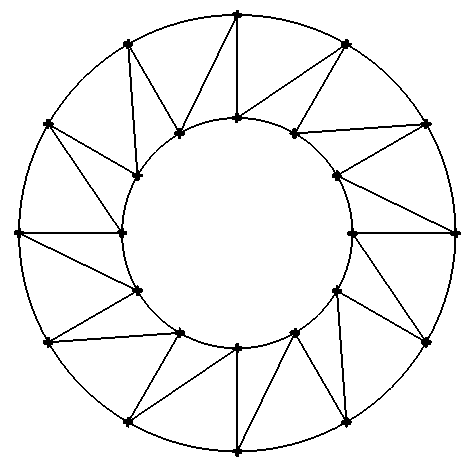

Triangulation algorithm for non-closed graph

InactiveCN103020356ASolving triangulation puzzlesImprove drawing precisionSpecial data processing applicationsGraphicsTriangulation

The invention discloses a triangulation algorithm for a non-closed graph. The triangulation algorithm for the non-closed graph comprises the following steps of: S1, introducing at least one virtual point into a cavity area of the non-closed graph; S2, participating in triangulation by regarding the virtual points as common scatters; and S3, deleting all triangles taking each virtual point as the vertex to form a cavity to realize the triangulation of the non-closed graph. Through adopting the method that the triangulation is performed after the proper virtual points are introduced into the cavity area of the non-closed graph, and then all triangles respectively taking the virtual points as the vertexes are deleted to form the cavity, the triangulation problem of the non-closed graph is effectively solved. Through introducing the virtual points into the cavity area, a traditional logical judgment idea is simplified, and the program execution efficiency and the graphic drawing precision are improved. The triangulation algorithm for the non-closed graph can be easily realized, and meanwhile, the triangulation algorithm is high in graphic drawing precision and can achieve a good display effect.

Owner:CHONGQING UNIV

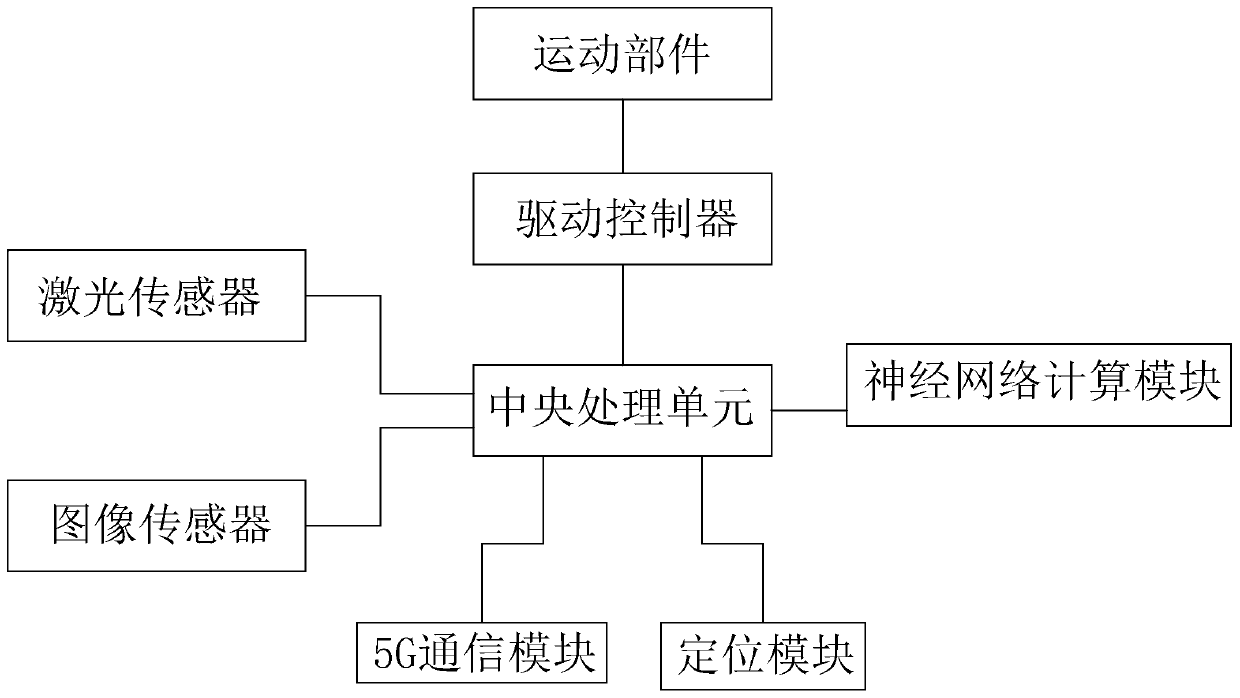

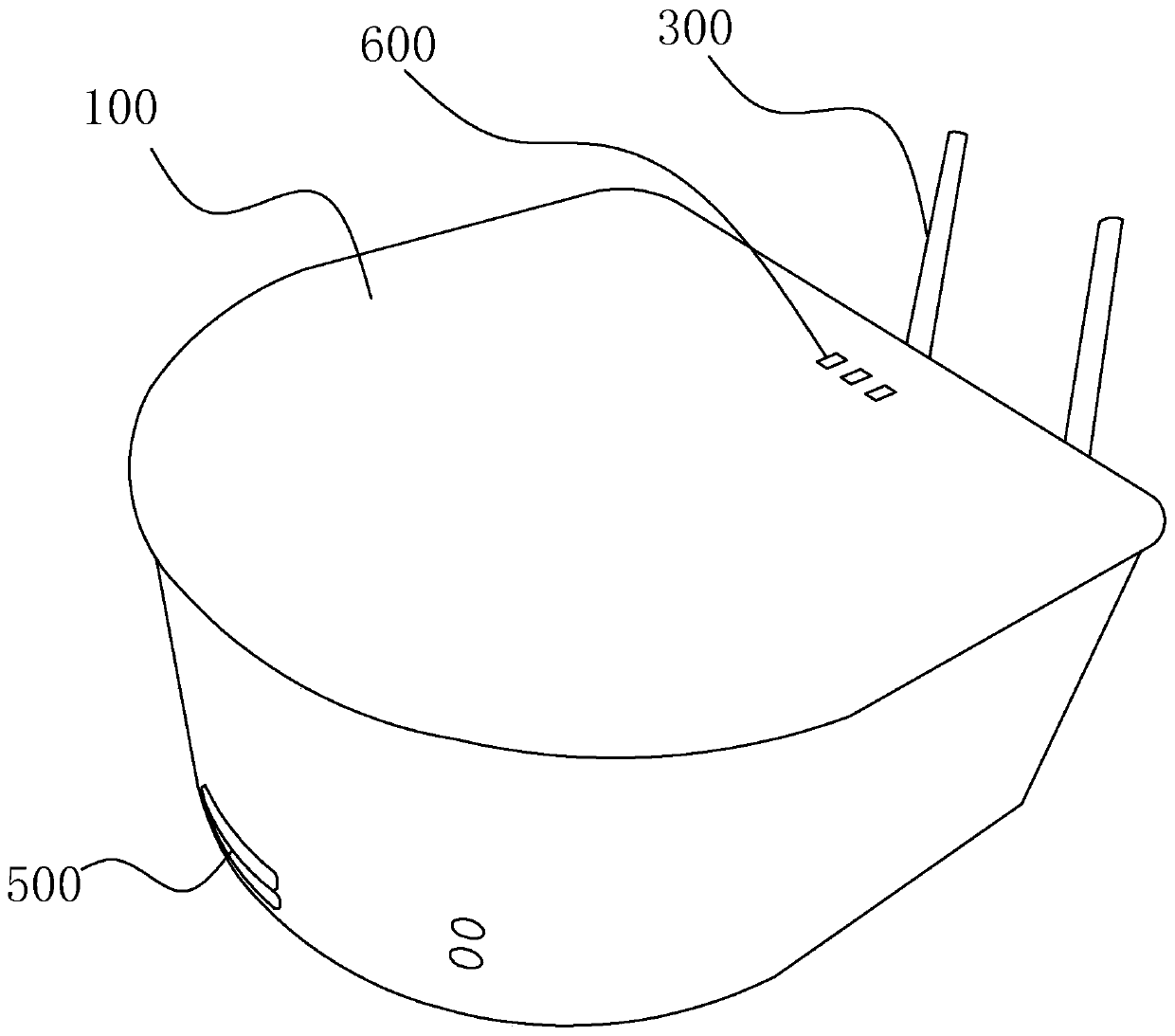

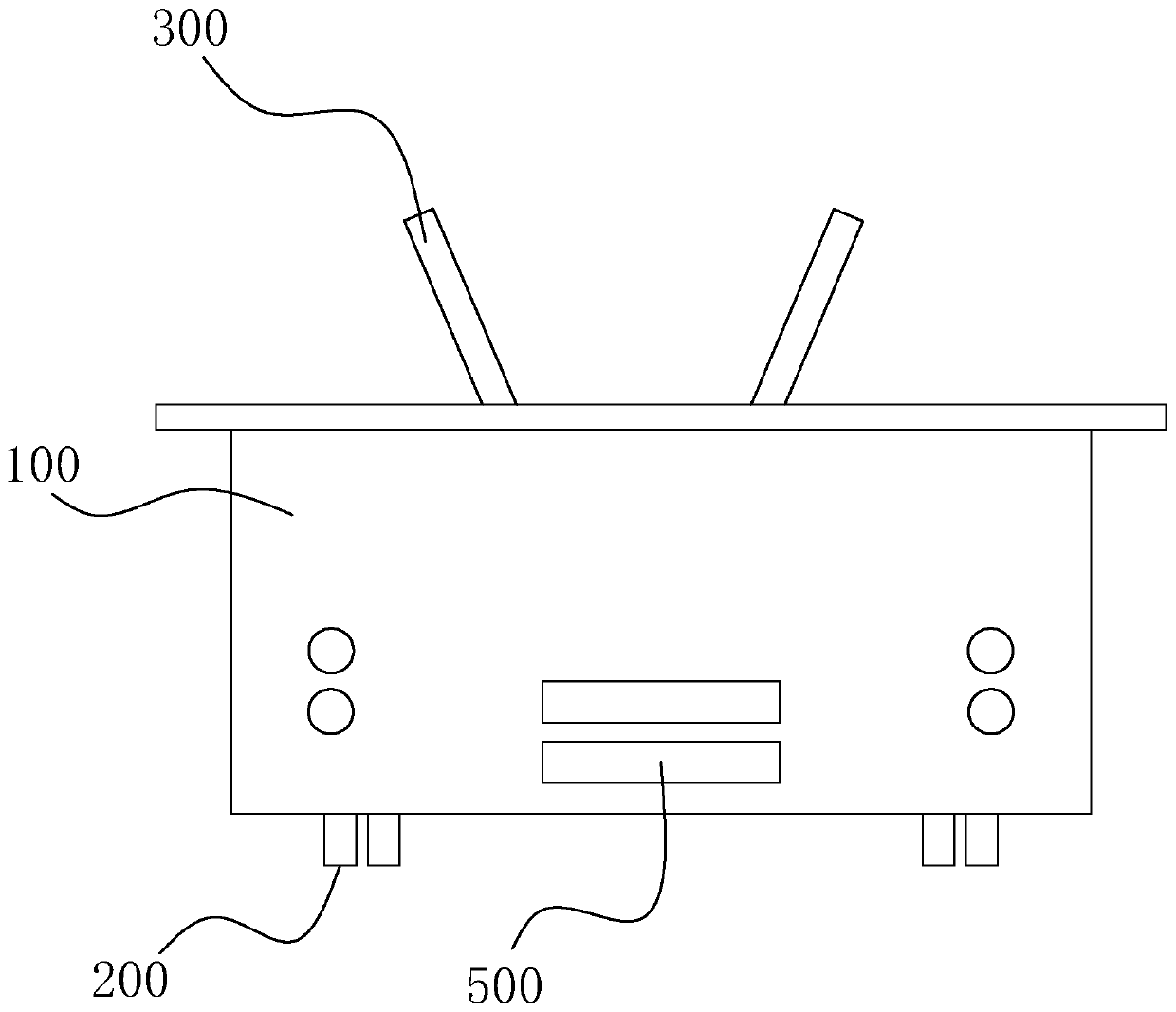

Intelligent walking robot based on integration of multi-sensor technologies

PendingCN110712187AImprove drawing precisionOvercome costsProgramme-controlled manipulatorNavigational calculation instrumentsEngineeringLaser sensor

The invention discloses an intelligent walking robot based on integration of multi-sensor technologies. The intelligent walking robot includes a moving part, a laser sensor, an image sensor, a 5G communication module, a positioning module, a neural network calculation module, a central processing unit and a drive controller. The image sensor obtains a flat image of the external environment, the laser sensor performs deep recognition on a current image, and the neural network calculation module and the 5G communication module capable of achieving high-precision positioning are combined to automatically build an indoor 3D map. On one hand, the 5G dense networking characteristic is utilized to achieve indoor high-precision positioning, and the problems of high cost and low accuracy of a traditional positioning method are solved; on the other hand, the laser sensor and the image sensor are combined to achieve quick indoor map drawing, and the map drawing accuracy is higher; and finally, the neural network calculation module is used for quickly identifying various obstacles and paths in the current environment, and the function of quickly adapting to the new environment is realized.

Owner:珠海市众创芯慧科技有限公司 +1

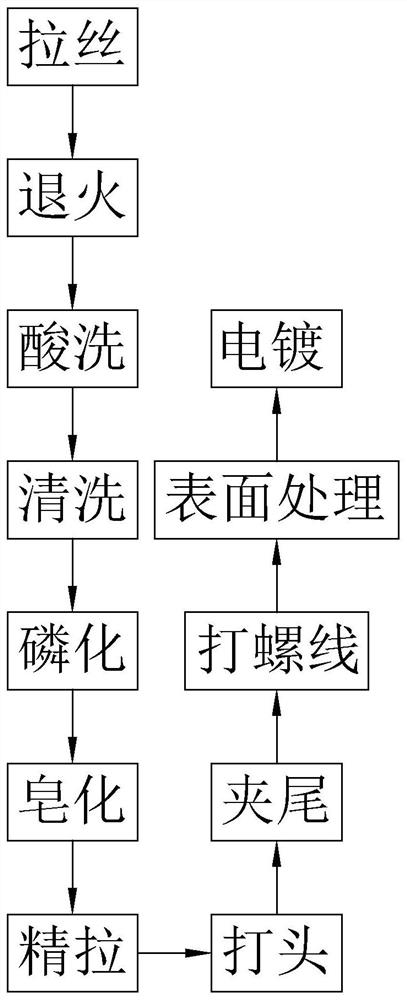

Hexagonal screw production process

The invention relates to a hexagonal screw production process, and relates to the technical field of screw manufacturing. The hexagonal screw production process comprises the following steps of A, wire drawing, specifically, drawing a reinforcing steel bar to obtain a wire rod convenient to process; B, annealing, specifically, annealing the wire rod; C, pickling, specifically, pickling the wire rod; D, cleaning; E, phosphatizing, specifically, phosphatizing the wire rod; F, saponification, specifically, washing the wire rod with water, hanging the wire rod into saponification liquid, and performing saponification for 3-7 minutes at the temperature of 75-80 DEG C; G, finish drawing, specifically, sending the wire rod into a finish drawing machine to be subjected to multi-stage wire drawingtreatment; H, heading; I, tail clamping; J, spiral line making; K, surface treatment; and L, electroplating. In order to solve the problem that in an existing hexagonal screw machining process, the wire rod is greatly influenced by temperature, the production process has the effects that the wire rod is cooled in the wire drawing process, and the wire drawing precision is improved.

Owner:SHANGHAI HONGTING FASTENER MFG CO LTD

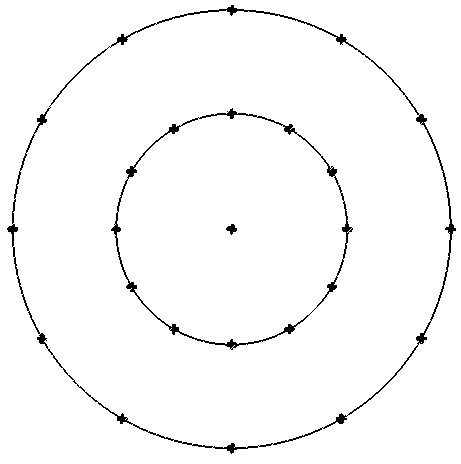

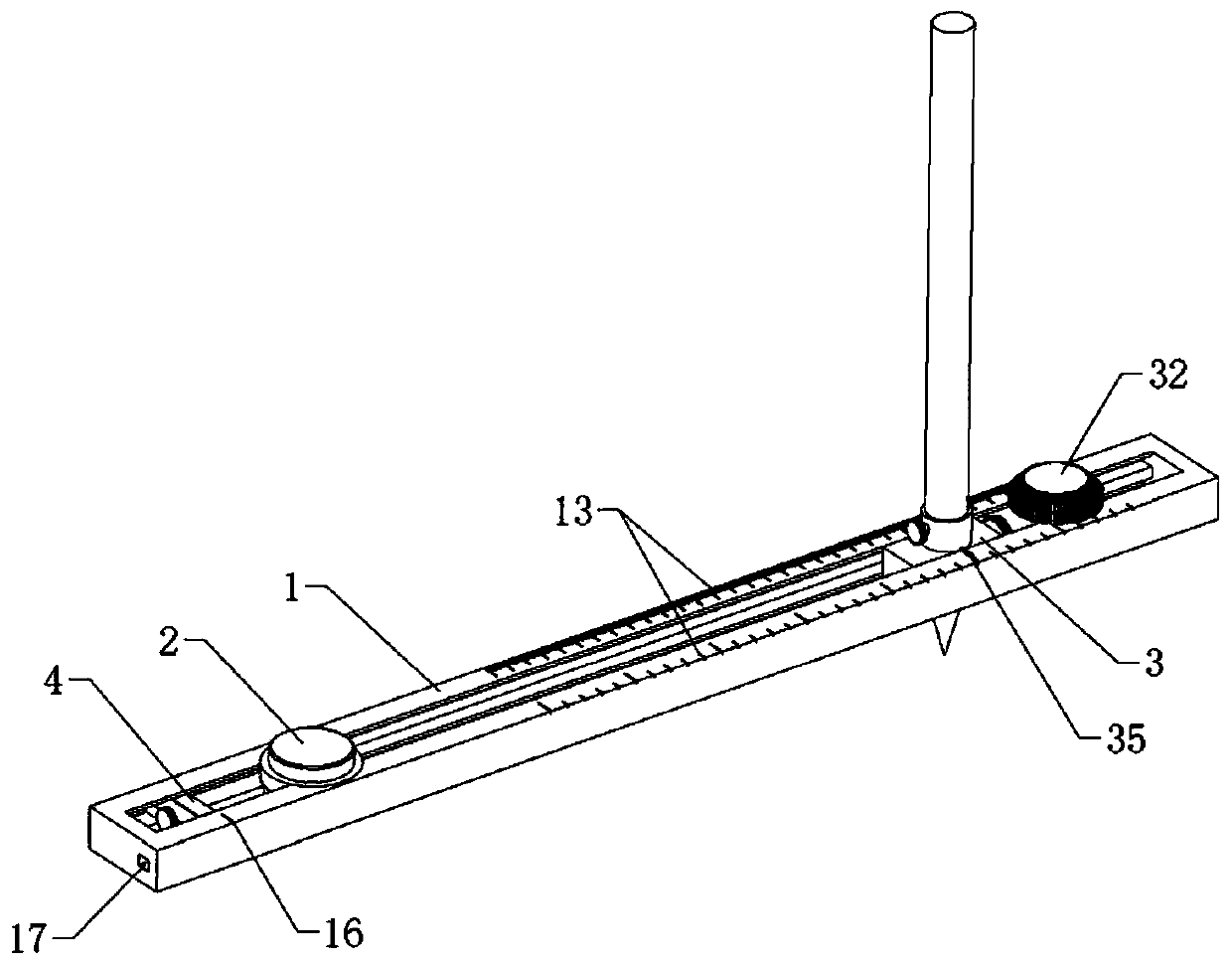

Multipurpose compass ruler and drawing method thereof

InactiveCN109895546AEasy to carryImprove securityCircular curve drawing instrumentsCircular discGreat circle

The invention relates to the field of stationeries, in particular to a multipurpose compass ruler and a drawing method thereof. The multipurpose compass ruler comprises a guide rail ruler body, a circle-center rotary shaft, a great-circle-arc ruling block, a small-circle-arc ruling block, a great-circle rack and a small-circle rack, wherein a circular disc groove and a slide rail are arranged on the inner side of the guide rail ruler body; the circle-center rotary shaft is rotatably connected with the guide rail ruler body through the circular disc groove; two lines of graduated bars are arranged on the upper surface of the guide rail ruler body; the great-circle-arc ruling block and the small-circle-arc ruling block are arranged on two sides of the circle-center rotary shaft; the great-circle rack and the small-circle rack are arranged in the opposite direction; the slide rail is slidably fixed into the guide rail ruler body; and the graduated bars are arranged on the side of the great-circle-arc ruling block.

Owner:朱元铭

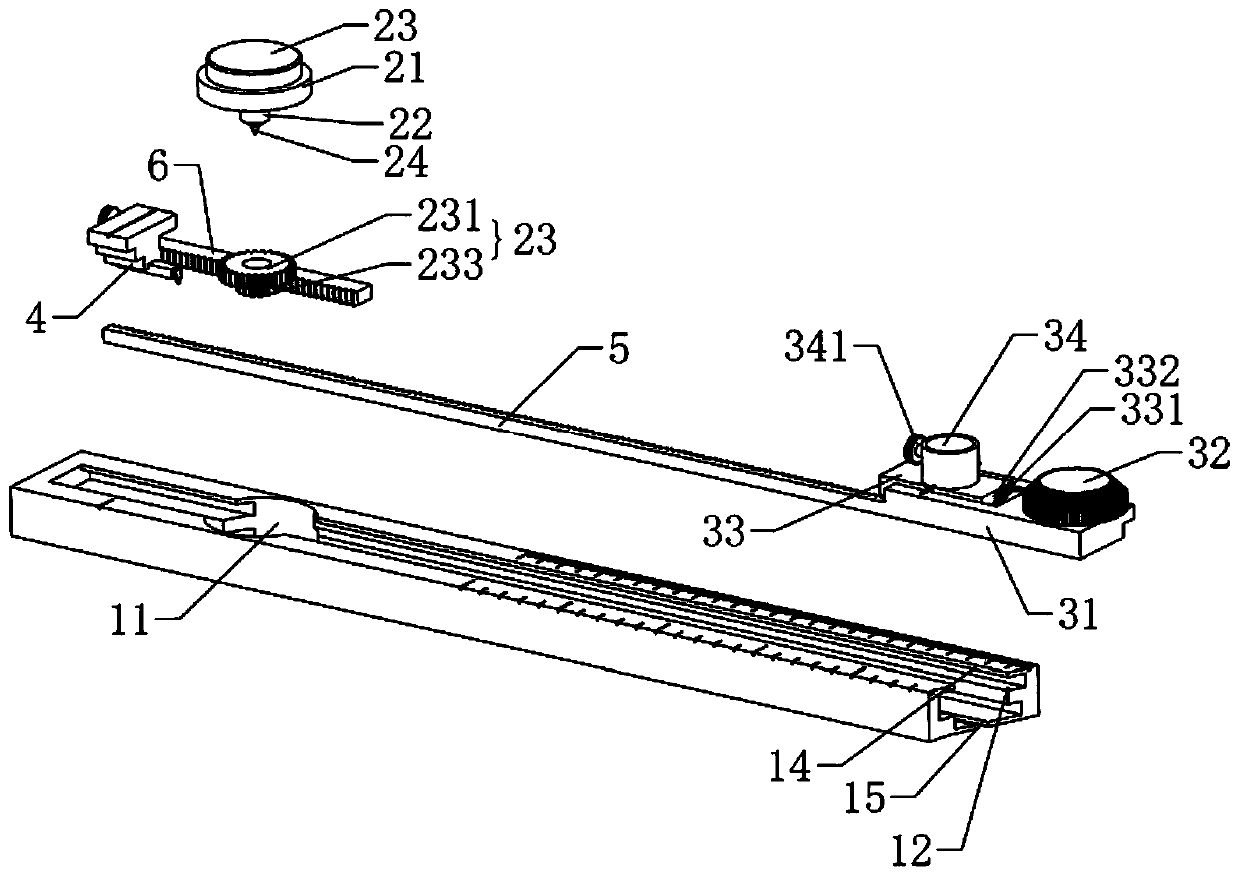

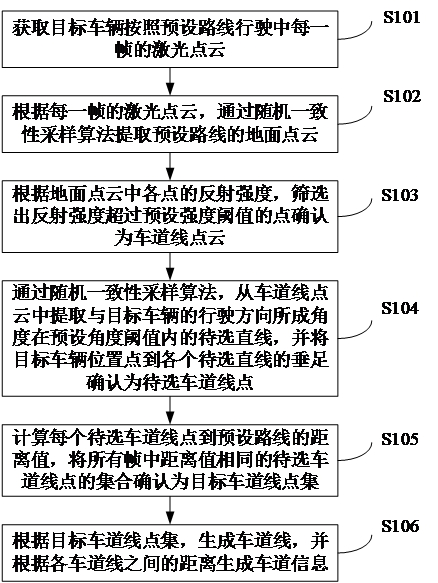

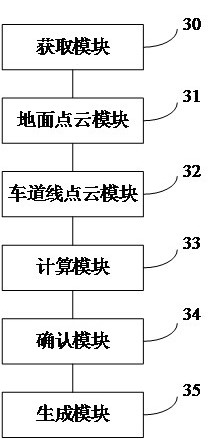

Lane line generation method and device

ActiveCN112240772AImprove production efficiencyImprove drawing precisionInstruments for road network navigationReal-time computingPoint cloud

The invention provides a lane line generation method and device. The method comprises the steps of obtaining laser point cloud of each frame of a target vehicle in driving according to a preset route;extracting ground point cloud of a preset route through a random consistency sampling algorithm according to the laser point cloud of each frame; according to the reflection intensity of each point in the ground point cloud, screening out points with the reflection intensity exceeding a preset intensity threshold value, and determining the points as lane line point cloud; through a random consistency sampling algorithm, extracting to-be-selected straight lines forming angles within a preset angle threshold with the driving direction of the target vehicle from the lane line point cloud, and determining the vertical feet from the position point of the target vehicle to all the to-be-selected straight lines as to-be-selected lane line points; calculating a distance value from each to-be-selected lane line point to a preset route, and determining a set of the to-be-selected lane line points with the same distance value in all frames as a target lane line point set; and generating lane lines according to the target lane line point set, and generating lane information according to the distances between the lane lines.

Owner:北京赛目科技有限公司 +1

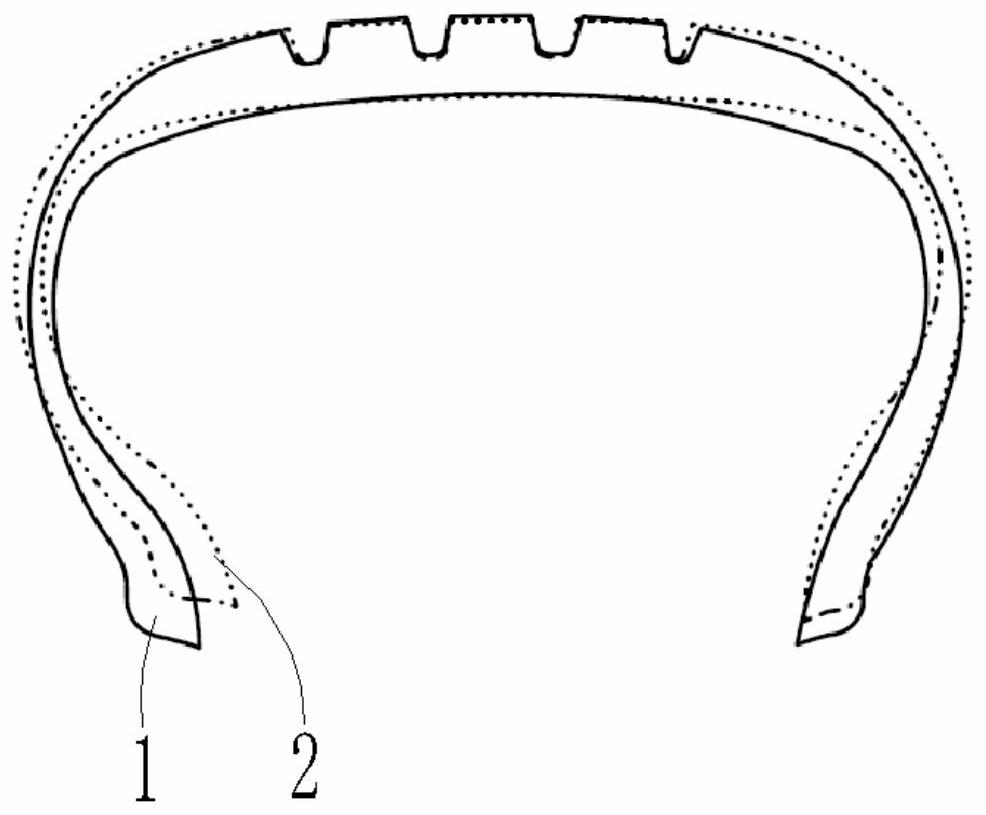

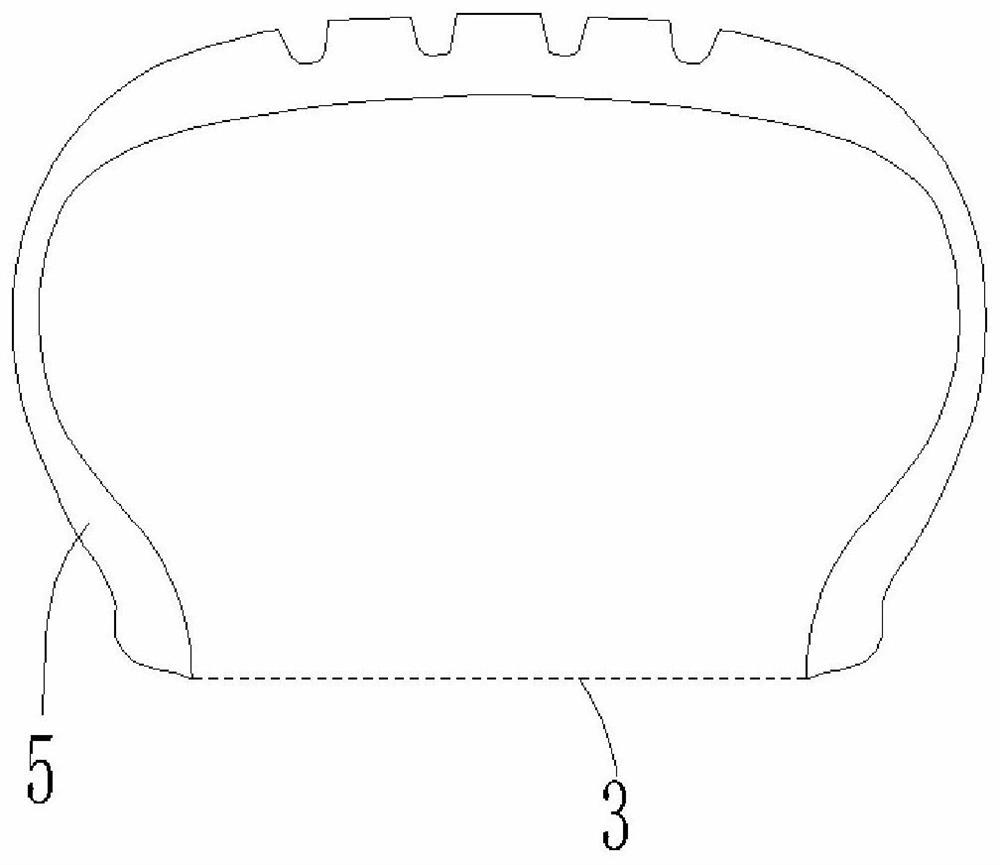

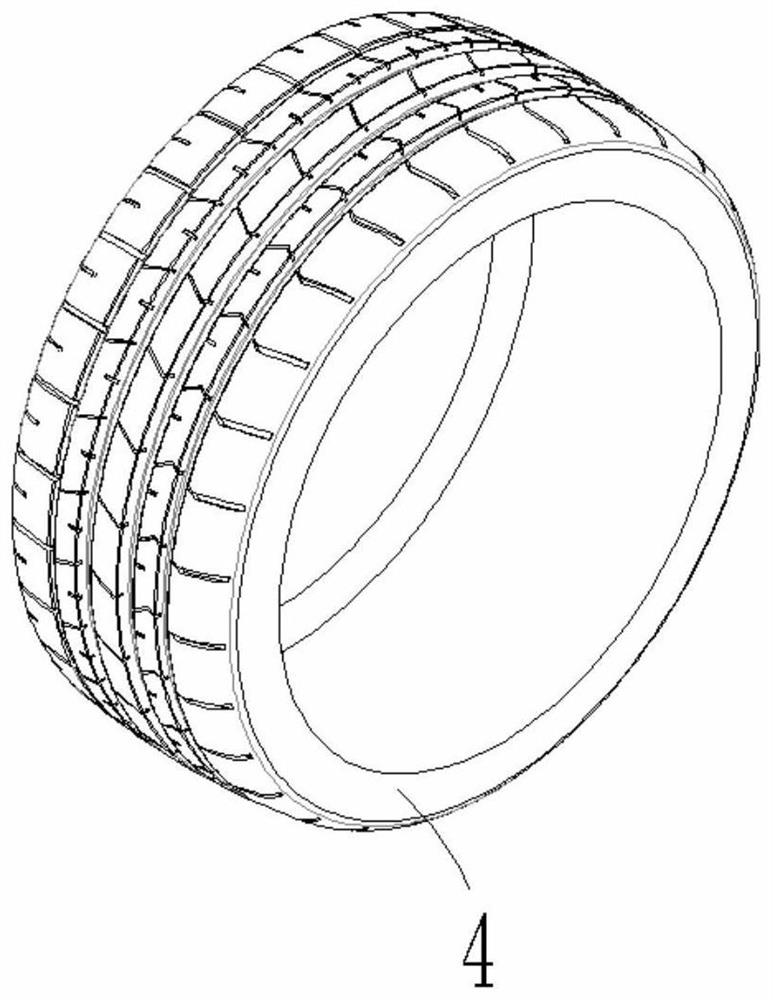

Accurate tire section constraint method

InactiveCN111795645AMeet the needs of section analysisEliminate cross-sectional shape distortionUsing optical meansClassical mechanicsStructural engineering

The invention relates to an accurate tire section constraint method, which comprises the following steps of: scanning by using scanning equipment, establishing a three-dimensional geometric model of afinished tire in a non-assembled state, and generating a tire section model in the non-assembled state by virtue of the three-dimensional geometric model. A constraint plate with a clamping groove ismanufactured according to parameters of a tire section model, the cut tire section is placed in the clamping groove of the constraint plate, and the clamping groove is used for completely constraining the tire section. The constraint plate is used for completely constraining the section of the tire, section shape distortion of the section of the tire due to internal stress release can be eliminated, consistency of the section contour shape of the tire and the section contour of a finished tire during detection is guaranteed, and the section detection precision of the internal structure of thetire is improved.

Owner:SHANDONG LINGLONG TIRE

Drawing ruler for applied mathematics teaching

PendingCN111516416AIncrease the lengthExtend drawing lengthSlippage preventionCircular curve drawing instrumentsStructural engineeringMechanical engineering

The invention belongs to the technical field of drawing tools, and particularly relates to a drawing ruler for applied mathematics teaching. The drawing ruler comprises a first straight ruler and a second straight ruler; a first groove is formed in one end of the first ruler, one end in the first groove is rotationally connected with a rotating block, the side, adjacent to the first ruler, of therotating block is fixedly connected with the second ruler, and the first ruler and the second ruler are arranged in parallel; the end, far away from the rotating block, of the second ruler is fixedlyconnected with a fixing block, and fixing grooves are formed in the two side walls, adjacent to the second ruler, of the fixing block; and a second groove is formed in the position, right opposite tothe fixing block, of the first ruler, symmetrically-arranged first sliding grooves are formed in the side wall of the second groove, and sliding blocks are connected into the first sliding grooves ina sliding mode. According to the drawing ruler for applied mathematics teaching, by arranging the first straight ruler, the second straight ruler and a sliding ruler, the drawing ruler can be freely combined, by arranging first magnet blocks and a telescopic plate, the drawing ruler has the functions of compasses and a protractor, and the auxiliary effect on teaching is effectively achieved.

Owner:ANHUI UNIV OF SCI & TECH

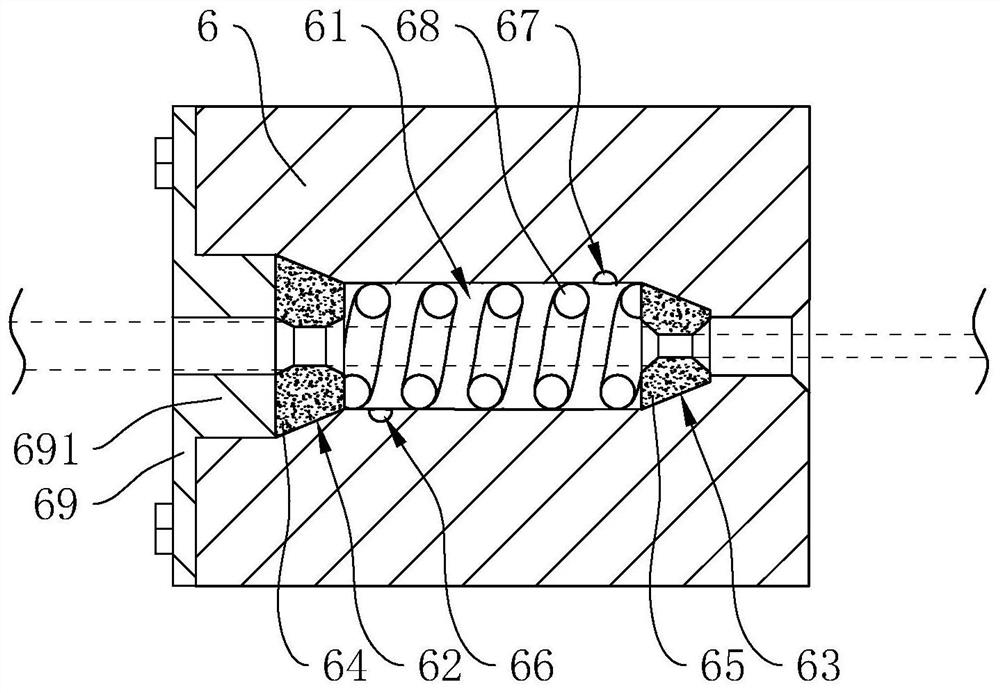

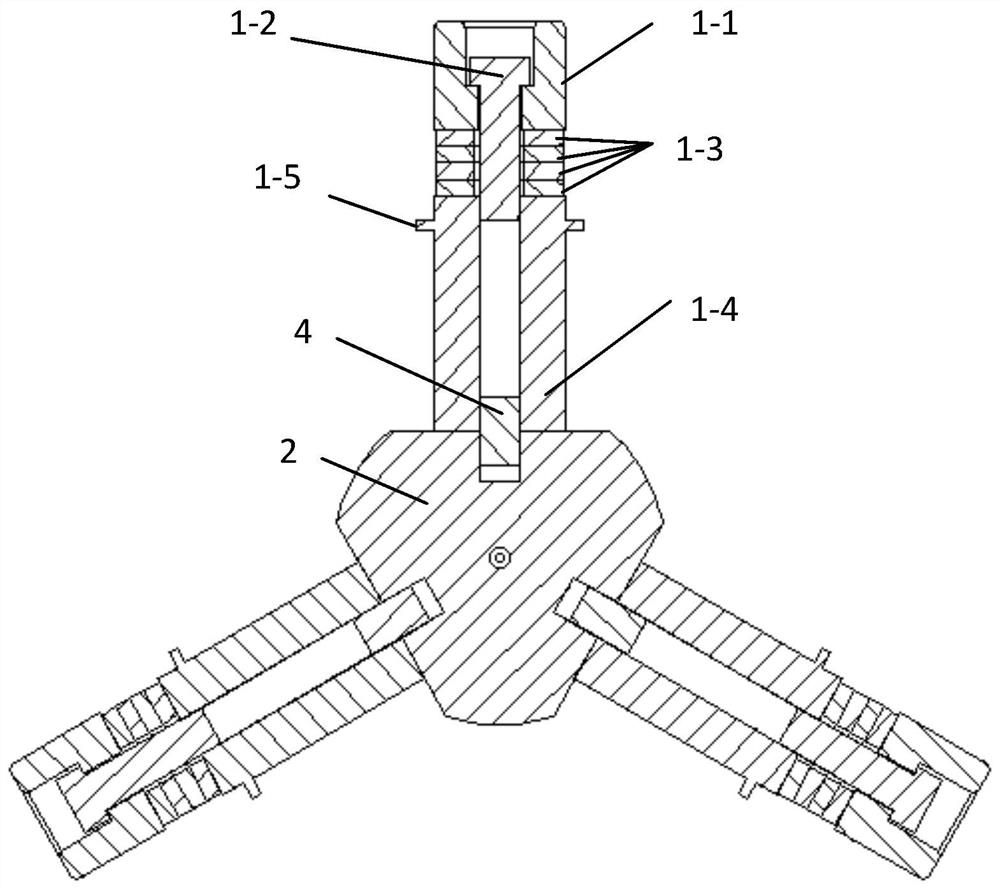

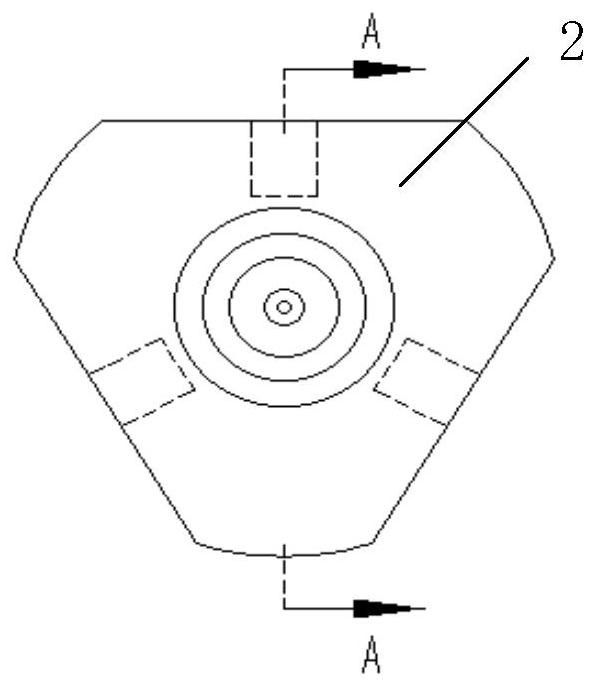

Dual-mode ultrasonic vibrator for drawing metal wire

PendingCN112170149AIncrease productivityImprove processing efficiencyDrawing diesMechanical vibrations separationEngineeringCeramic

The invention discloses a dual-mode ultrasonic vibrator for drawing a metal wire, and belongs to the technical field of ultrasonic vibrators, which solves the problems of complexity in installation and manufacturing of an ultrasonic wire drawing vibrator, fragility of a ceramic chip, difficulty in industrial scene application and the like. The dual-mode ultrasonic vibrator comprises an amplitude-change pole, transducers and wire drawing dies, wherein the transducers and the wire drawing dies are arranged on the amplitude-change pole; the transducers comprise front end covers, back end covers,an even number of piezoelectric ceramics arranged between the front end covers and the back end covers and electrode plates which are arranged between the piezoelectric ceramics as well as between thepiezoelectric ceramics and the front end covers and the back end covers respectively, and the front end covers are connected with the amplitude-change pole; a wire through hole is formed in the center of the amplitude-change pole, and the amplitude-change pole comprises a transition area and wire drawing die mounting areas which are arranged on both ends of the transition area in the length direction of the wire through hole; two wire drawing dies are respectively arranged in the two wire drawing die mounting areas on both ends of the wire through hole, and the two wire drawing dies are installed in the same direction; and more than two transducers are arranged on the outer side wall of the transition area. The dual-mode ultrasonic vibrator is used for drawing the metal wire.

Owner:泽川精密科技(宁波)有限公司

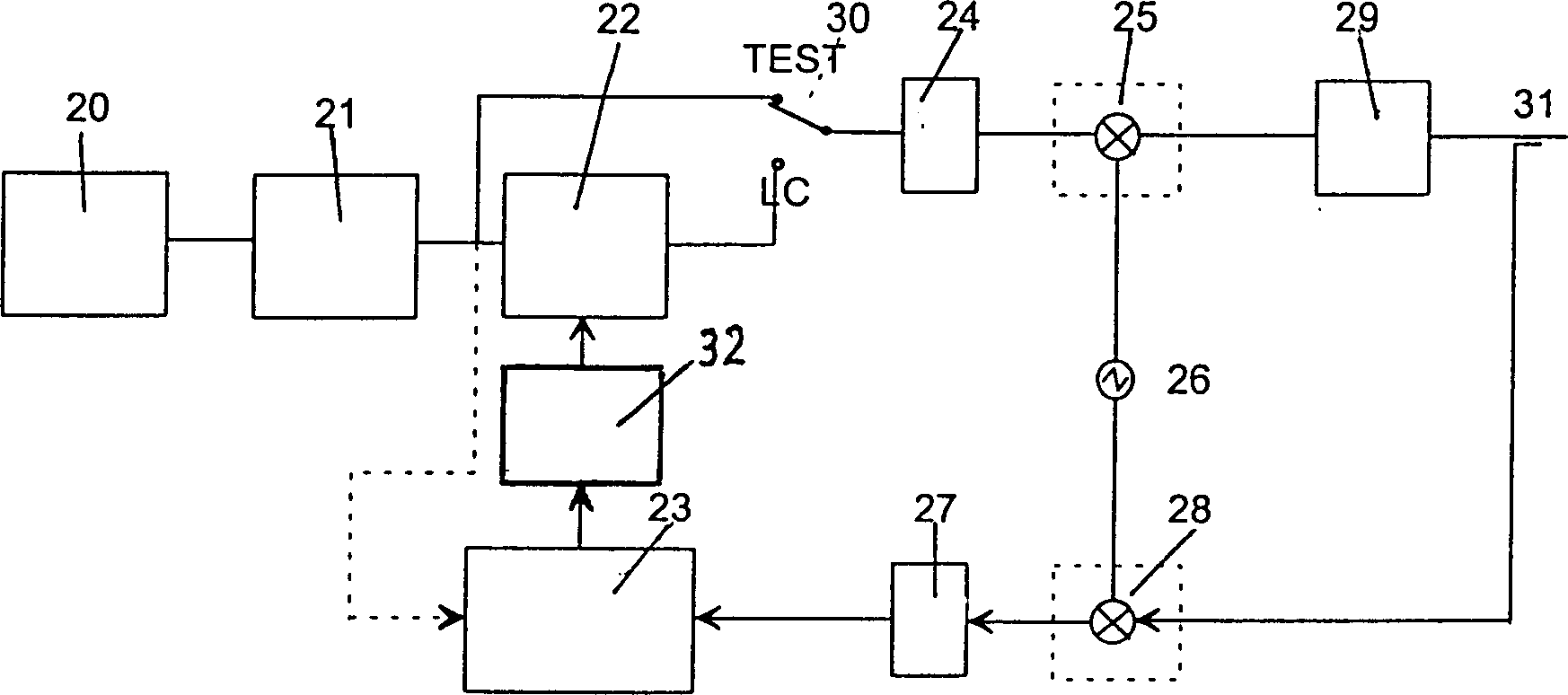

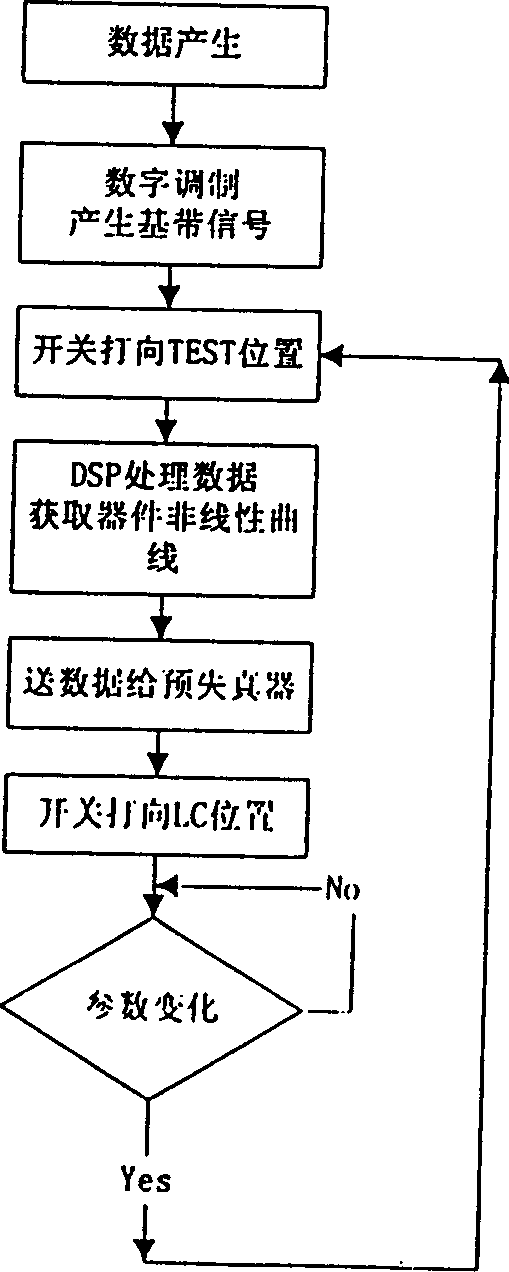

Method and device for testing and correcting the non-linear characteristics of channel

InactiveCN1185813CImprove drawing precisionFast trackingTransmission monitoringBandpass filteringIt equipment

The present invention relates to a method for measuring and correcting non-linear characteristics of channel and its equipment. It is characterized by that under the condition of test state it transmits dual-tone test signal, and utilizes transmission channel, receiving circuit feedback FFT and IFFT treatment to obtain required signal component, and obtain the non-linear characteristics of transmission channel and predistortion correction. The invented equipment includes the devices of testing signal generation, predistortion, D / A and A / D conversion, upper and lower frequency change power amplification, directional coupling, bandpass filter and non-linear detection, and its advantages are: can measure nonlinearity of transmission channel and system, and can raise non-linear measurement accuracy and correct tracking speed of system.

Owner:HUAWEI TECH CO LTD

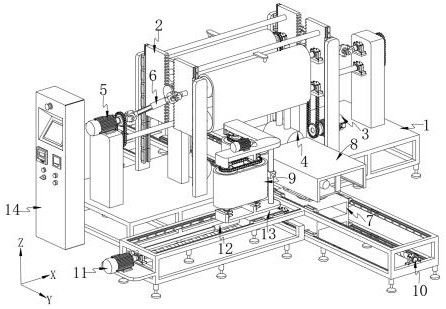

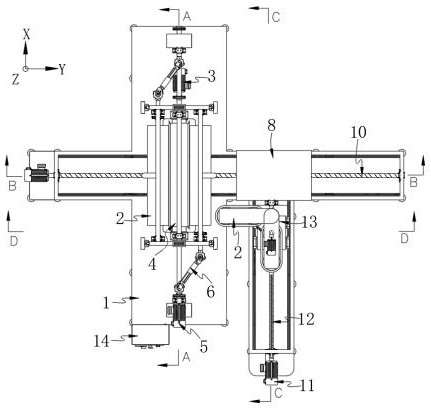

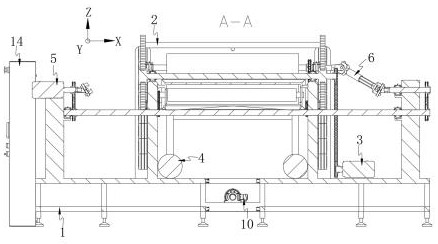

Building indoor decorative plate machining production line

ActiveCN113561014AHigh precisionImprove work efficiencyBelt grinding machinesGrinding feed controlDust controlSingle plate

The invention discloses a building indoor decorative plate machining production line, and belongs to the technical field of aluminum plate curtain wall production equipment. The building indoor decorative plate machining production line comprises a workbench, a clamping assembly, a main wire drawing assembly, a first driving part, a dust removal assembly and an auxiliary wire drawing assembly. The clamping assembly is slidably connected to the top of a main supporting frame and used for positioning and clamping a curtain wall aluminum plate. The main wire drawing assembly is connected to the top of a side supporting table in a sliding manner. The dust removal assembly is used for carrying out dust removal treatment on the main wire drawing assembly. The auxiliary wire drawing assembly is connected to the top of the side supporting frame in a sliding manner and used for conducting wire drawing treatment on the two side faces, in the X-axis direction, of the curtain wall aluminum plate. Through use of the main wire drawing assembly, the clamping assembly, the auxiliary wire drawing assembly and the dust removal assembly, the problems that an existing curtain wall wire drawing machine is low in wire drawing precision, a wire drawing abrasive belt is difficult to clean, and wire drawing treatment to an assembled curtain wall aluminum veneer is difficult are solved.

Owner:南通欧本建筑科技有限公司

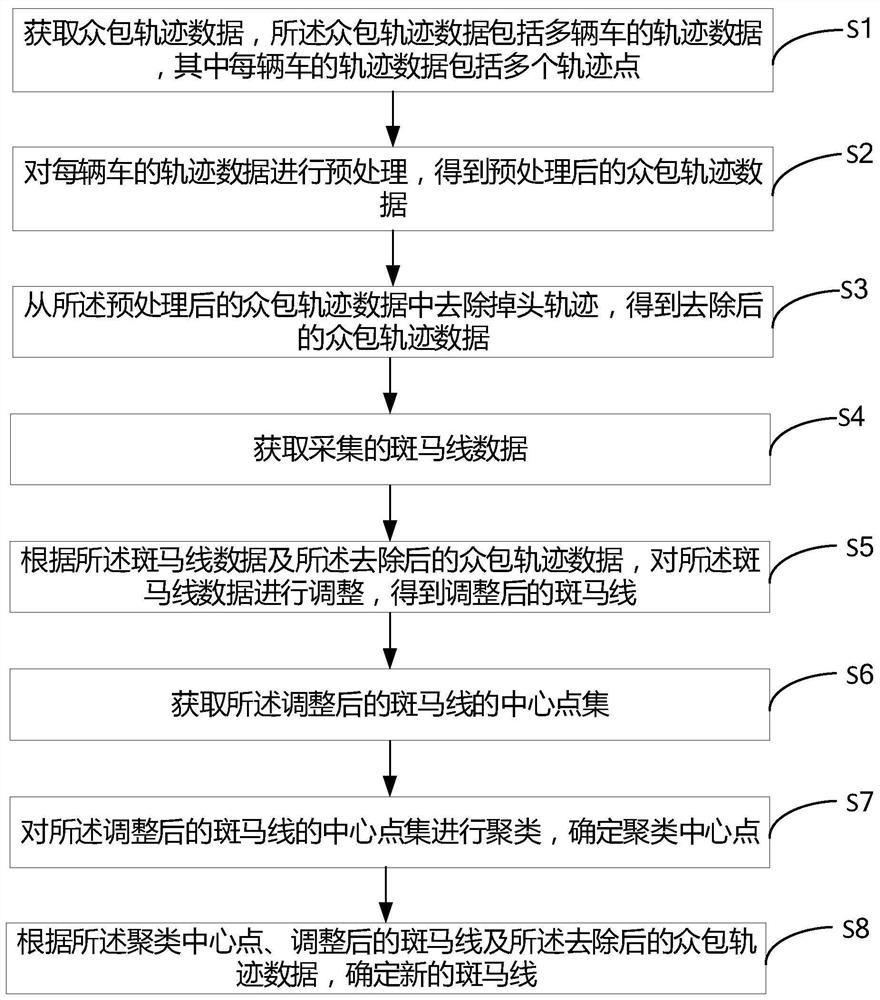

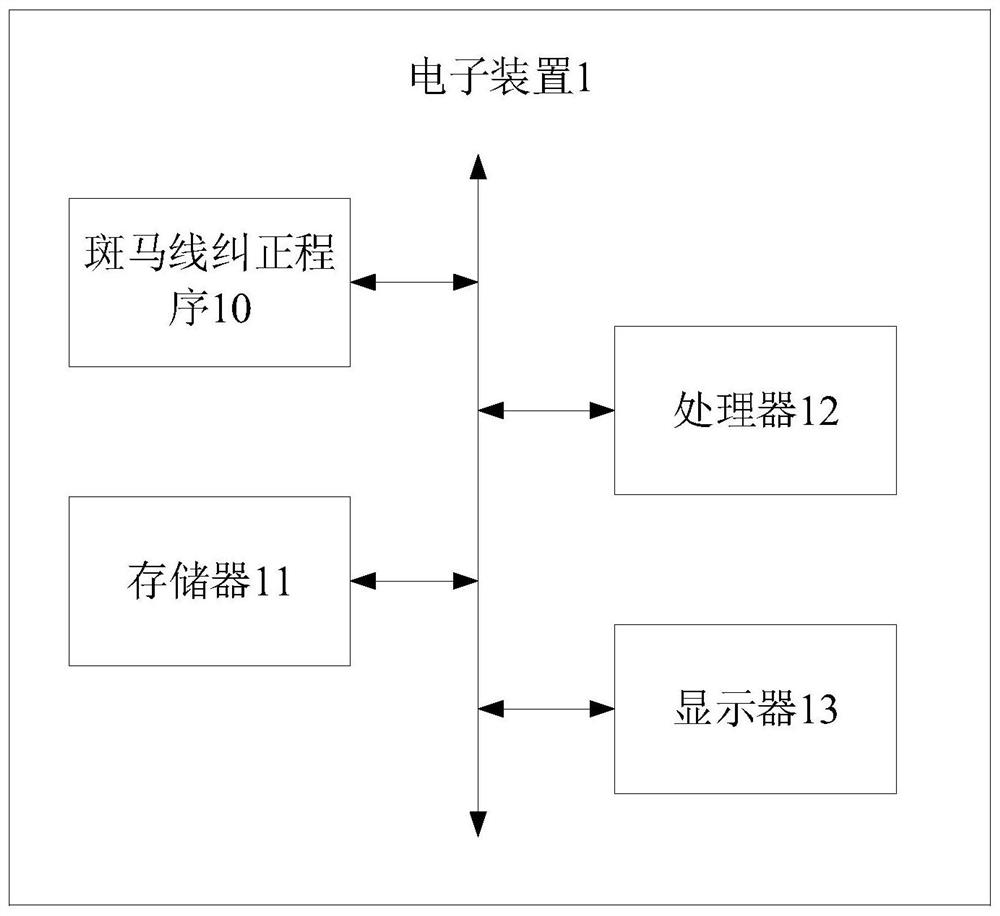

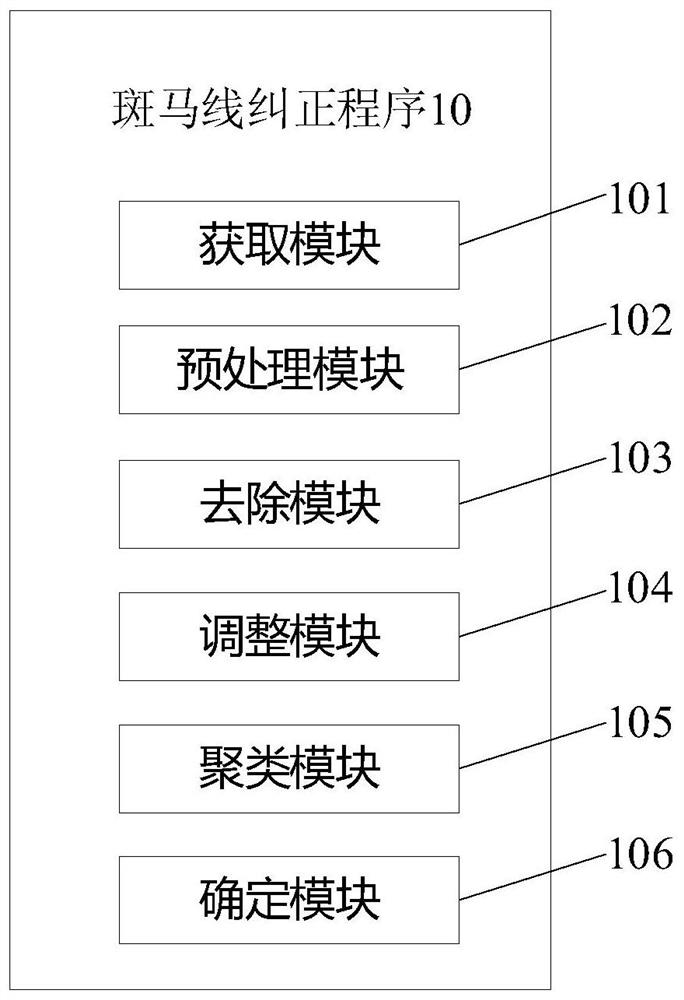

Zebra crossing correction method, electronic device and storage medium

ActiveCN112488217AImprove drawing precisionDrawing from basic elementsParticular environment based servicesData packEngineering

The invention discloses an electronic device, a zebra crossing correction method and a storage medium, and the method comprises the steps: obtaining crowdsourcing track data which comprises the trackdata of a plurality of vehicles, wherein the track data of each vehicle comprise a plurality of track points; preprocessing the trajectory data of each vehicle to obtain preprocessed crowdsourcing trajectory data; removing a U-turn track from the preprocessed crowdsourcing track data to obtain removed crowdsourcing track data; acquiring acquired zebra crossing data; according to the zebra crossingdata and the removed crowdsourcing trajectory data, adjusting the zebra crossing data to obtain an adjusted zebra crossing; obtaining a central point set of the adjusted zebra crossing; clustering the adjusted center point set of the zebra crossing, and determining a clustering center point; and determining a new zebra crossing according to the clustering center point, the adjusted zebra crossingand the removed crowdsourcing trajectory data. The zebra crossing drawing method can improve zebra crossing drawing precision.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

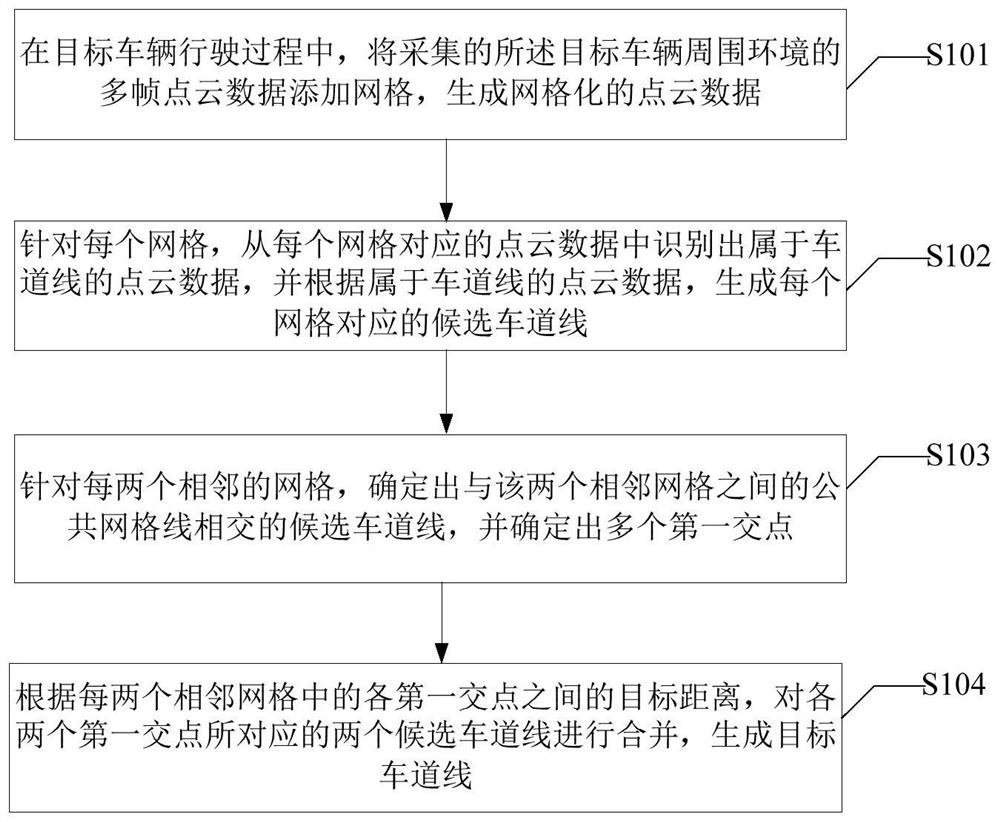

Lane line generation method and device, electronic equipment and storage medium

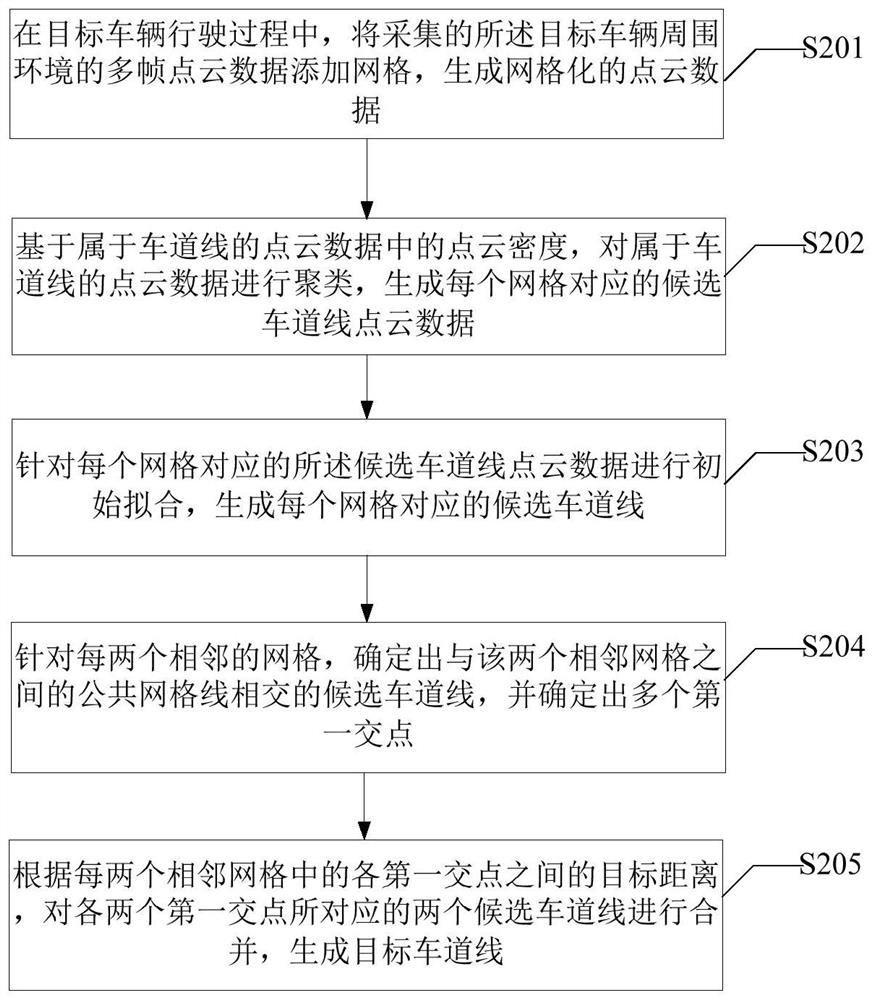

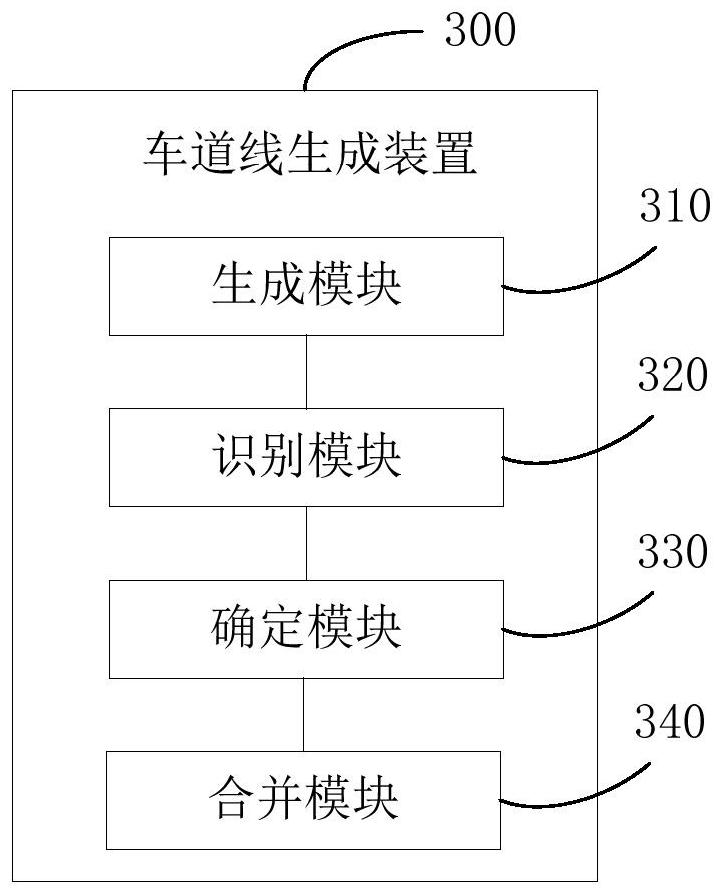

PendingCN114241083AImprove drawing precisionReduce economic costsDrawing from basic elementsPoint cloudSimulation

The invention provides a lane line generation method and device, electronic equipment and a storage medium. The lane line generation method comprises the following steps: generating gridded point cloud data; for each grid, identifying the point cloud data belonging to the lane line from the point cloud data corresponding to each grid, and generating a candidate lane line corresponding to each grid according to the point cloud data belonging to the lane line; determining a plurality of first intersection points based on the candidate lane lines; and generating a target lane line according to the distance between the first intersection points. According to the method and the device, the point cloud data of the lane line of each grid in the gridding point cloud data is identified, the candidate lane lines are generated, the candidate lane lines are combined, and the target lane line is generated, so that on the basis of reducing the repetition rate of the target lane line, the drawing precision of the lane lines is improved, and the economic cost of drawing the lane lines is reduced.

Owner:北京赛目科技股份有限公司

Movable triangular drawing machine for processing of radiating fins

InactiveCN107378702AEasy to adjust and save effortImprove drawing precisionBelt grinding machinesLong lastingScrap

The invention discloses a movable triangular wire drawing machine for heat sink processing, and relates to the technical field of heat sink production and processing; one side of the frame is sequentially provided with a crank handle and a control panel; the machine cover is arranged on the machine Above the frame, there is a sandpaper belt inside, and the sandpaper belt goes around the first drum, the second drum and the third drum in turn; both ends of the machine cover are equipped with scrap outlets; The opening below the hood is located directly above the workpiece; the bottom of the frame is provided with a set of pulleys, and the bottom of the hood is provided with a visual sensor connected to an external display; the surfaces of the control panel, hand press plate and workbench are all Coated with a self-luminous layer, the self-luminous layer is made of long afterglow luminescent material; the wire drawing machine of the present invention is easy to operate, the drawing accuracy and drawing efficiency have been greatly improved, the application range is wide, the safety is good, and the handling and maintenance The maintenance is convenient and fast, which ensures that the drawing work can be carried out efficiently and stably for a long time.

Owner:TAICANG DOW ELECTRIC

Multifunctional mathematics teaching ruler

The invention discloses a multifunctional mathematics teaching ruler which comprises a positioning bracket. A laser bracket is mounted on the upper portion of the positioning bracket; a plurality of laser emission modules are mounted at the bottom of the laser bracket; a stable rotating geometric superposition device is mounted in the middle of the positioning bracket and comprises fixed frames; and the lower portions of the fixed frames are connected with adjusting nuts. The stable rotating geometric superposition device and an angle rotating positioning plotter are combined, a reference linecan be formed on a drawing, and the graphic plotting precision can also be greatly improved; and light-transmitting plates with light-proof geometry graphic rods are combined with lasers emitted by the laser modules, the light-proof geometry graphic rods can block light rays, penetrating through the light-transmitting plates, of the lasers emitted by the laser modules, thus the light rays are projected to the drawing, and geometry graphics corresponding to the light-proof geometry graphic rods are formed, so that a teacher does not need to manually plot the drawing, the standard geometry graphics can be formed on the drawing, and plotting reference is facilitated. The multifunctional mathematics teaching ruler is suitable for teaching plotting.

Owner:张天济

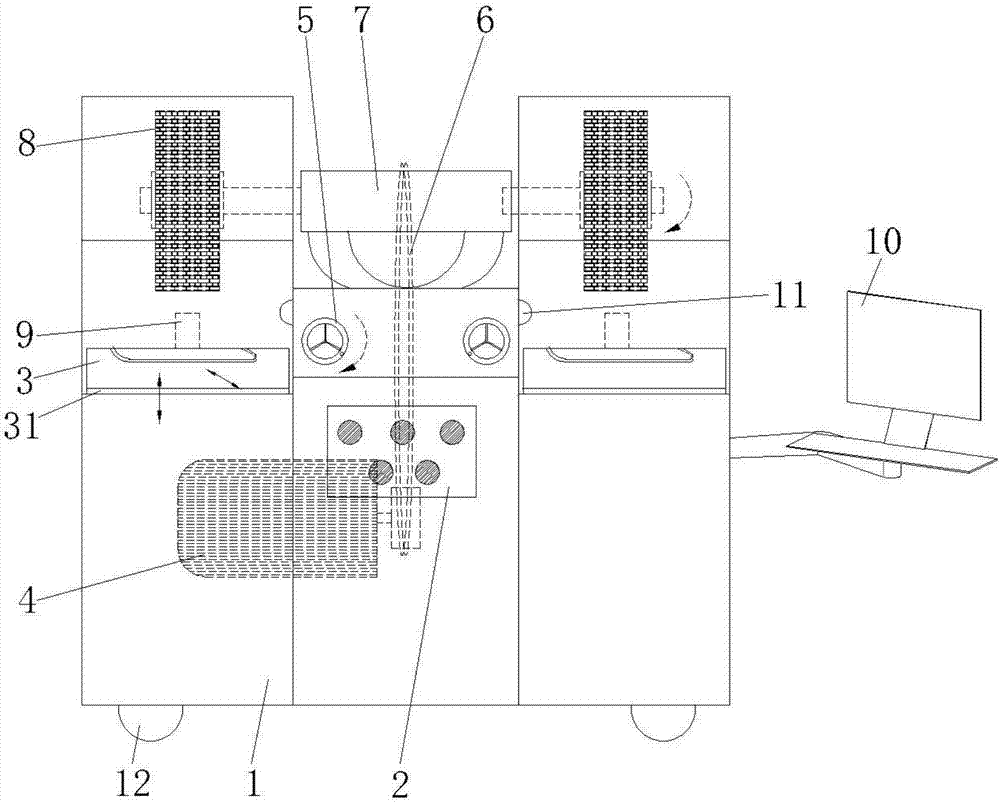

Movable type nylon wheel wire drawing machine used for hardware processing

InactiveCN107263273AAccurate speed controlEasy to operateGrinding carriagesGrinding drivesEngineeringMotor drive

The invention discloses a movable nylon wheel wire drawing machine for metal processing, and relates to the technical field of hardware processing; a motor is provided inside the frame, and the motor is connected with a control panel on the surface of the frame; The motor drives the connecting bridge to rotate through the V-belt, and the two ends of the connecting bridge are respectively connected with two nylon wheels; the two sides of the frame are provided with a workbench, and the workpiece is located in the middle of the workbench, and It is located directly below the nylon wheel; a set of pulleys is provided at the bottom of the frame, and visual sensors connected to external displays are respectively provided on both sides of the frame; the surfaces of the control panel and the workbench are coated with a self-luminous layer; The wire drawing machine of the present invention is easy to operate, has greatly improved wire drawing precision and wire drawing efficiency, is safe and reliable, and is convenient and fast in transportation and maintenance, thereby ensuring efficient and stable wire drawing work for a long time.

Owner:SUZHOU CONYET AUTOMATION TECH

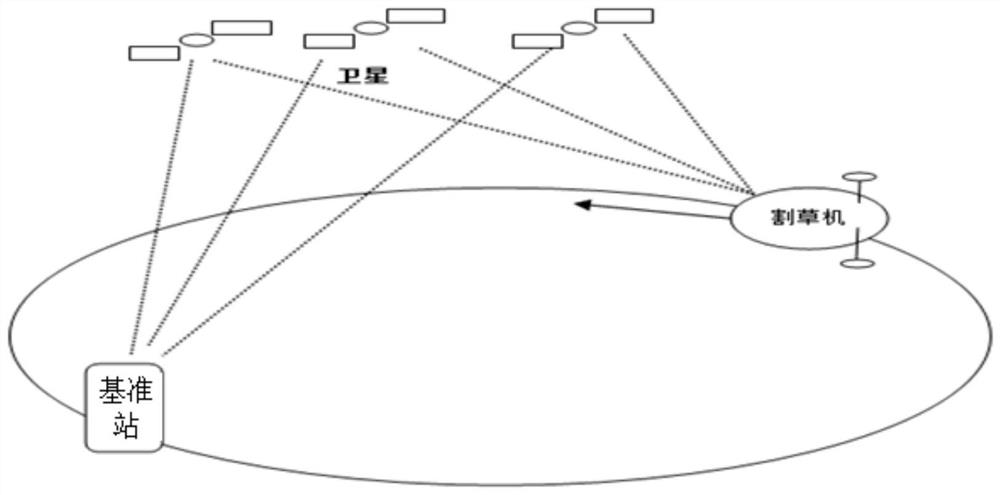

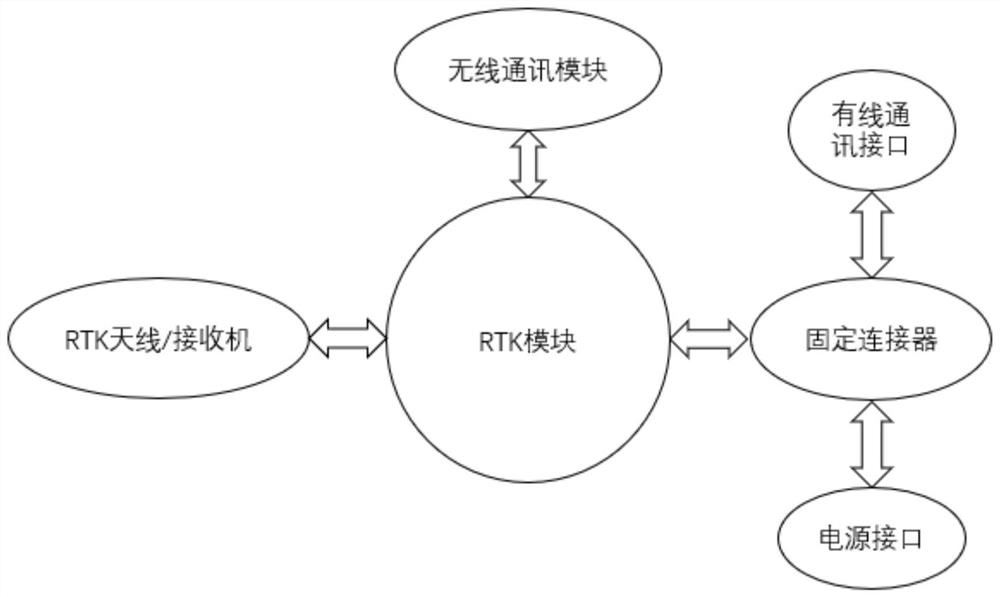

Automatic working system and navigation control device

PendingCN112925303AImprove practicalityRealize automatic charging and dockingPosition/course control in two dimensionsVehiclesControl engineeringWorkspace

The invention provides an automatic working system and a navigation control device. The automatic working system comprises an automatic working device and the navigation control device. The navigation control device comprises a navigation assembly, a planning assembly and a communication assembly. The navigation assembly is configured to receive position signals and environment image signals of the automatic working device and / or the navigation control device, the planning assembly is configured to receive the position signals and the environment image signals transmitted by the navigation assembly and obtain a control map of a working area in a fitting mode, the planning assembly is in communication connection with the automatic working device through the communication assembly, and transmitting the control map to the automatic working device, and the automatic working device is controlled to operate in the working area according to the control map and execute corresponding garden work tasks or return to the charging station to realize automatic charging docking. The automatic working system has a map establishing function, a high-precision control map of a working area can be conveniently and quickly obtained, and the practicability of the automatic working system for realizing garden work is effectively improved.

Owner:CHANGZHOU GLOBE CO LTD

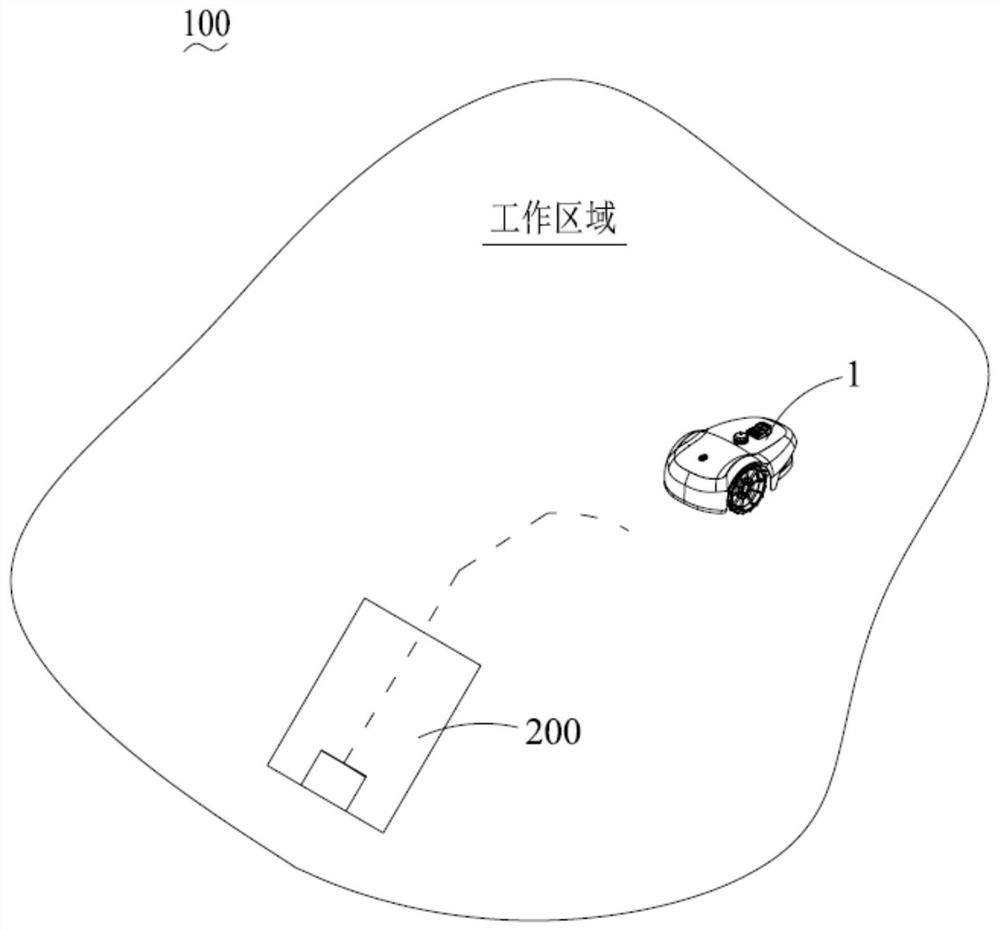

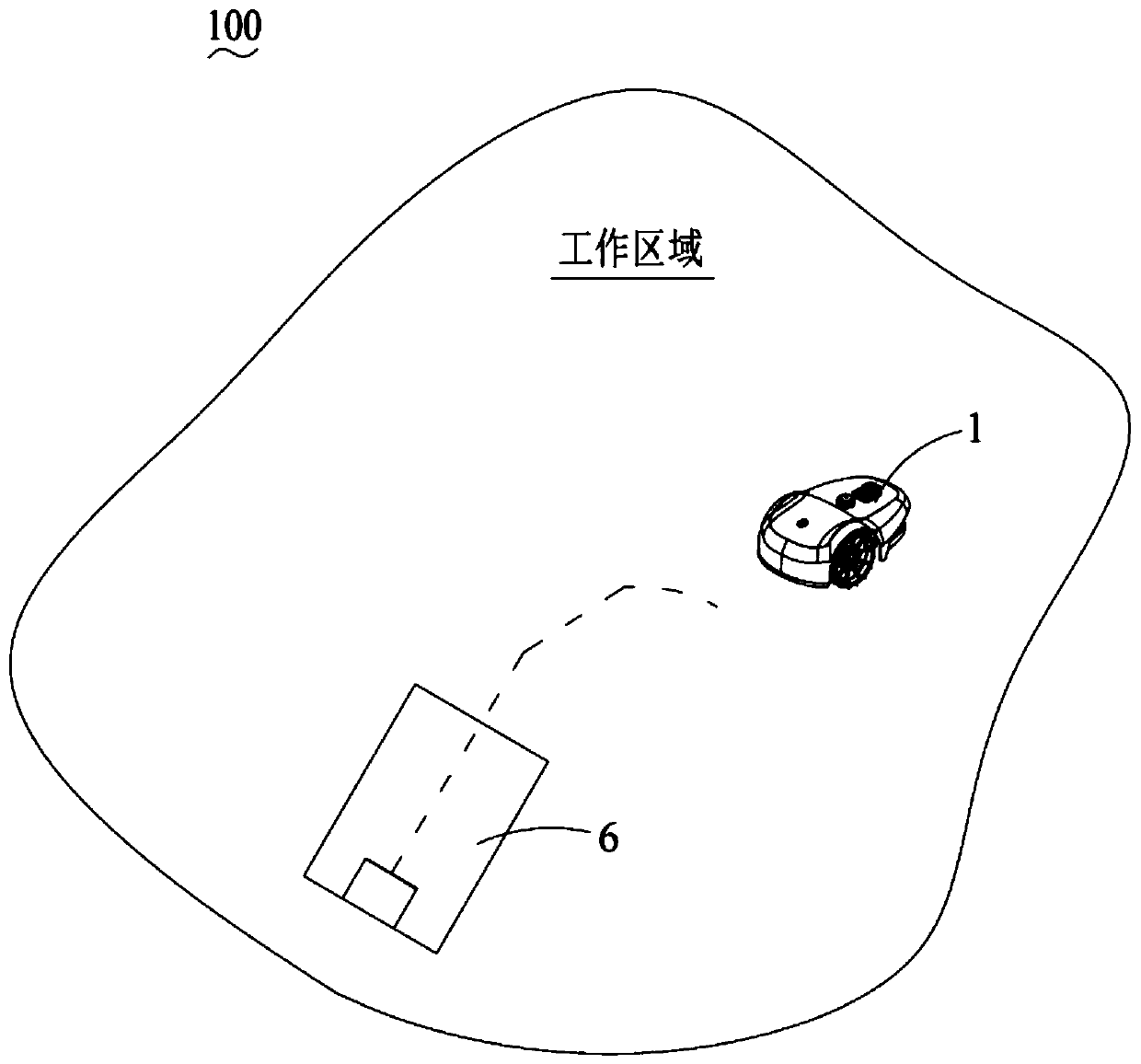

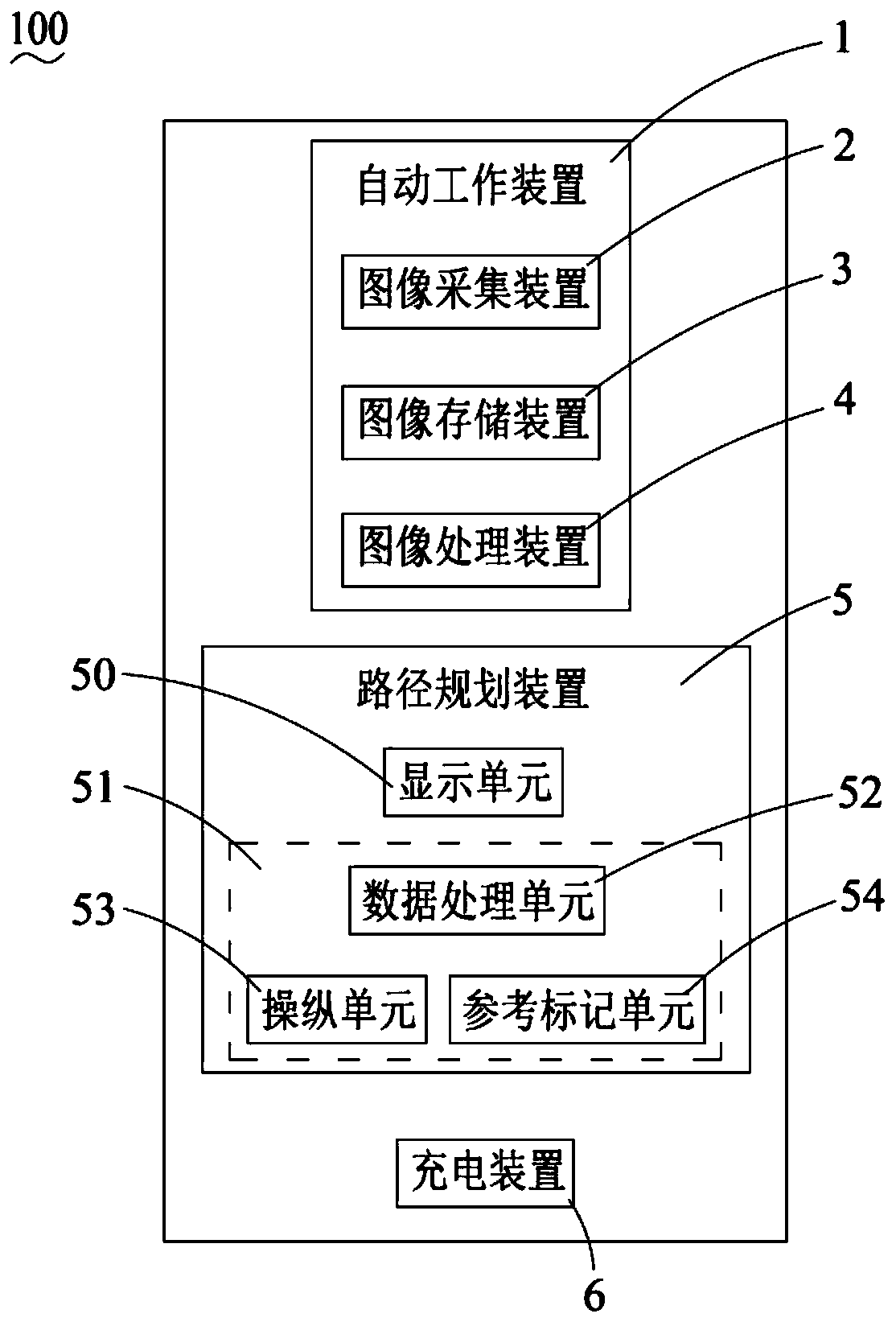

Automatic work system and establishment method of control map of work area of automatic work system

PendingCN110727270AImprove practicalityImprove drawing precisionPosition/course control in two dimensionsVehiclesImaging processingComputer graphics (images)

The invention provides an automatic work system and an establishment method of a control map of a work area of the automatic work system. The automatic work system comprises an automatic work device and a path planning device, and the automatic work system further comprises an image acquisition device connected and mounted onto the automatic work device, an image processing device in communicationconnection with the image acquisition device, and an image storage device, wherein the image acquisition device is connected onto the automatic work device, and is used for obtaining a terrain feature image in the work area and transmitting to the image storage device for storage, and the image processing device is used for fitting to form a three-dimensional control map of the work area according to the terrain feature image. The automatic work system of the invention has a map establishment function, and can conveniently and quickly obtain the high-precision three-dimensional control map ofthe work area, and then plan movement, work and charging paths according to position and environment information in the three-dimensional control map, thereby effectively improving the practicality of the automatic work system implementing garden work.

Owner:CHANGZHOU GLOBE CO LTD

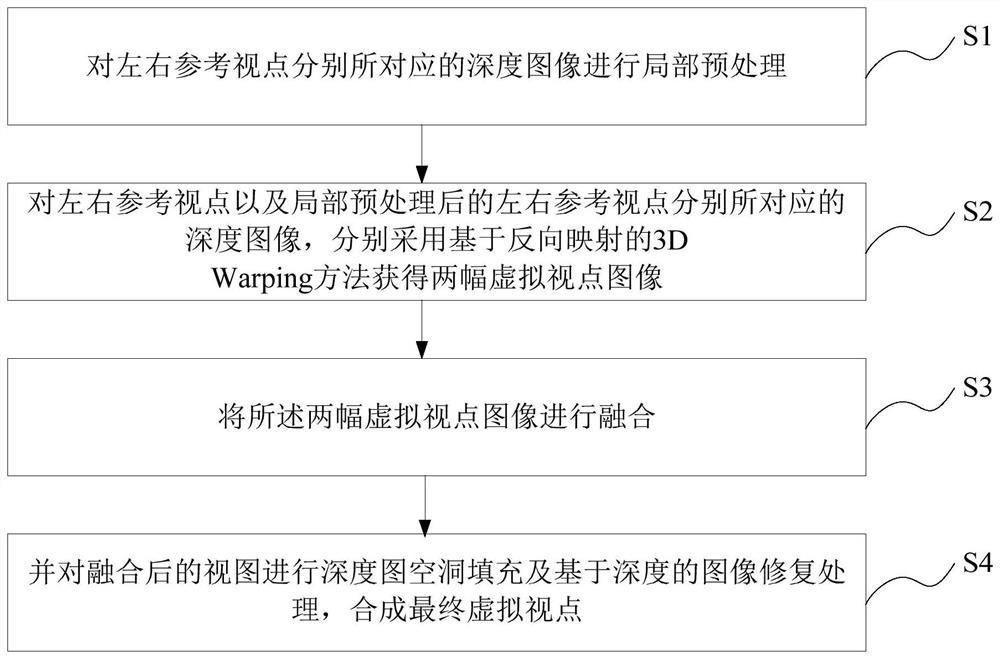

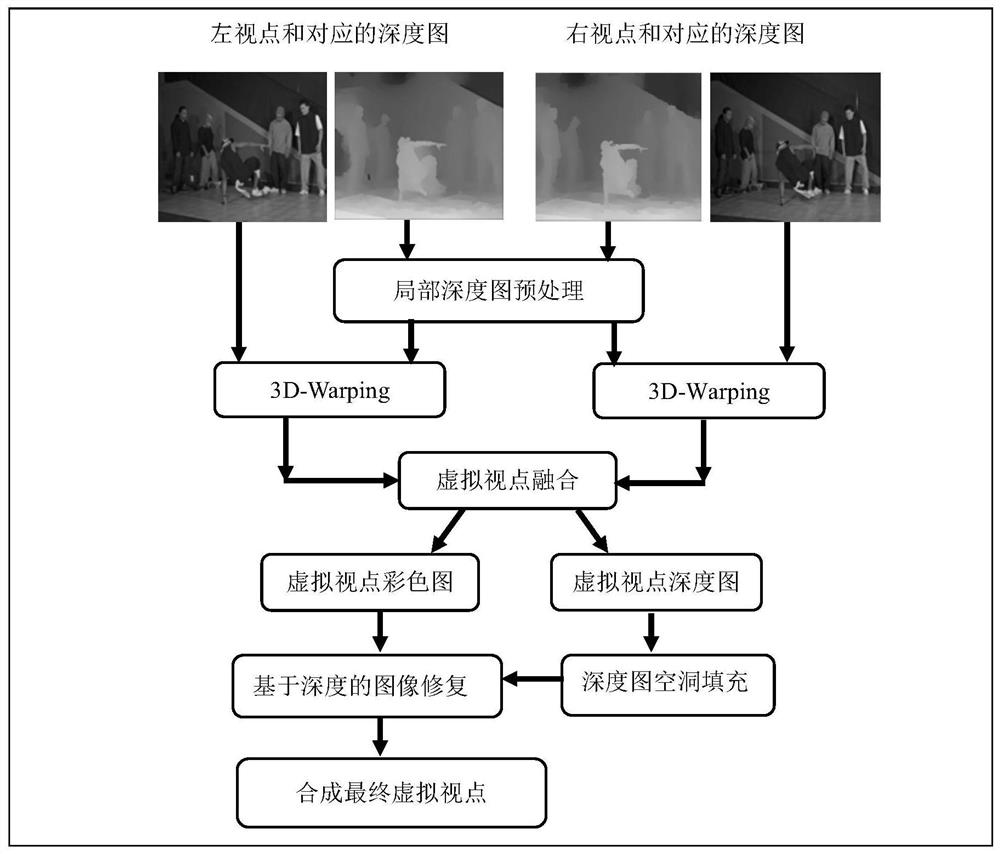

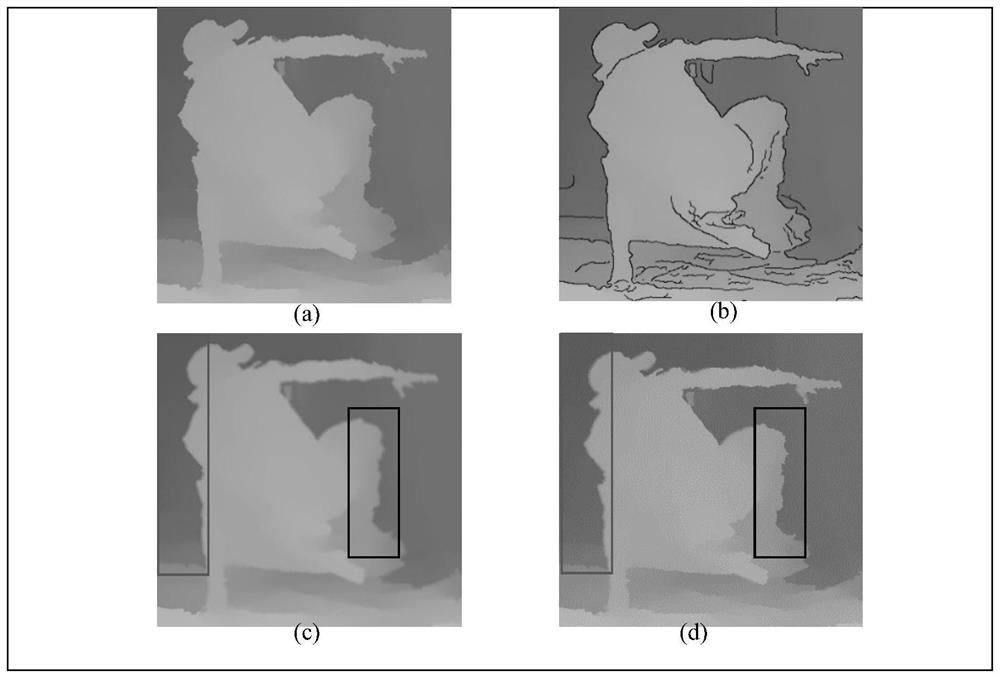

A Virtual Viewpoint Rendering Method Based on Depth Image

ActiveCN109712067BQuality improvementAvoid distortionImage enhancementImage analysisDepth mapVirtual image

The invention relates to a virtual viewpoint rendering method based on a depth image. First, local preprocessing is performed on the depth image corresponding to the reference viewpoint to reduce the holes while avoiding distortion caused by filtering; The 3D Warping method of the proposed method obtains two virtual views. There are large cracks and holes in the image after 3D transformation. First, the median filter is used to remove the small cracks in the virtual image. Afterwards, the bidirectional expansion method is used to expand the hollow area to eliminate the pixels that may produce artifacts. Then the left and right viewpoints are fused to remove most of the semi-occluded void areas. Finally, an image inpainting algorithm based on a depth map is used to fill in a small number of holes that still exist to ensure the depth consistency between the area to be filled and the target block. The invention can reduce the phenomenon of holes and artifacts in the synthesis technology of the virtual pilot point, improve the drawing precision, and can draw a high-quality virtual viewpoint image.

Owner:南通图加智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com