Building indoor decorative plate machining production line

A technology for interior decorative panels and production lines, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low wire drawing accuracy, difficulty in affecting the wire drawing accuracy by the body of the wire drawing abrasive belt, and wire drawing processing of the curtain wall aluminum veneer. Achieve the effect of improving the quality of wire drawing, solving the low efficiency of wire drawing, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

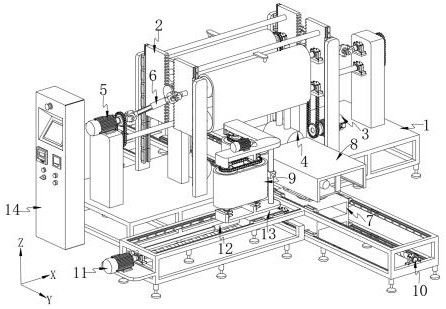

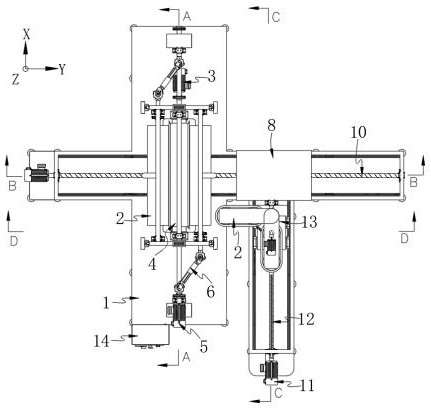

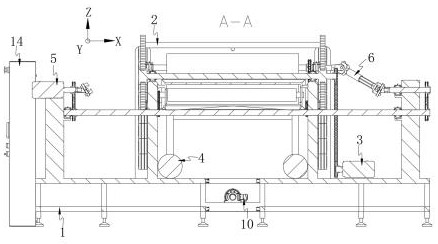

[0049] Such as Figure 7 As shown, a production line for processing interior decorative boards for buildings includes: a workbench 1; the workbench 1 includes a main support frame 101, and the side supports 102 are connected to both sides of the main support frame 101 along the X-axis direction, and the side support platforms 102 are The surface is respectively connected with the first support column 103, the second support column 104 and the third support column 105, and the side support frame 106 is connected to one side of the main support frame 101 along the X-axis direction;

[0050] It should be noted that the second support column 104 is located in the middle of the upper surface of the side support platform 102, the two groups of first support columns 103 are respectively located on both sides of the second support column 104 along the Y-axis direction, and the third support columns 105 are respectively located on the second side. A supporting column 103 is positioned ...

Embodiment 2

[0058] Such as Figure 1-4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0059] A production line for building interior decoration panels, which also includes a main body drawing assembly 2, which is slidably connected to the top of a side support platform 102 for drawing the upper surface of an aluminum curtain wall 8; the first driving part 3 is used for driving the adjacent The two main body wire drawing assemblies 2 reciprocate along the Z-axis direction; there are two main body wire drawing assemblies 2, and the inner surfaces of the two main body wire drawing assemblies 2 are connected by transmission through the first driving part 3;

[0060]It should be noted that the two main ...

Embodiment 3

[0070] Such as figure 1 , 2 , 4, and 6, wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of brevity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0071] A production line for processing interior decorative panels for buildings, which also includes a dust removal assembly 4 connected to the top of the workbench 1, and the dust removal assembly 4 is used to remove dust from the drawing assembly 2 of the main body; it should be noted that most of the existing dust removal devices only It can clean up the scrap attached to the surface of the aluminum curtain wall 8, but the scrap attached to the abrasive belt is difficult to clean, causing the scrap attached to the wire drawing belt to cause secondary damage to the aluminum curtain wall 8, and at the same time, the scrap attached to the wire drawing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com