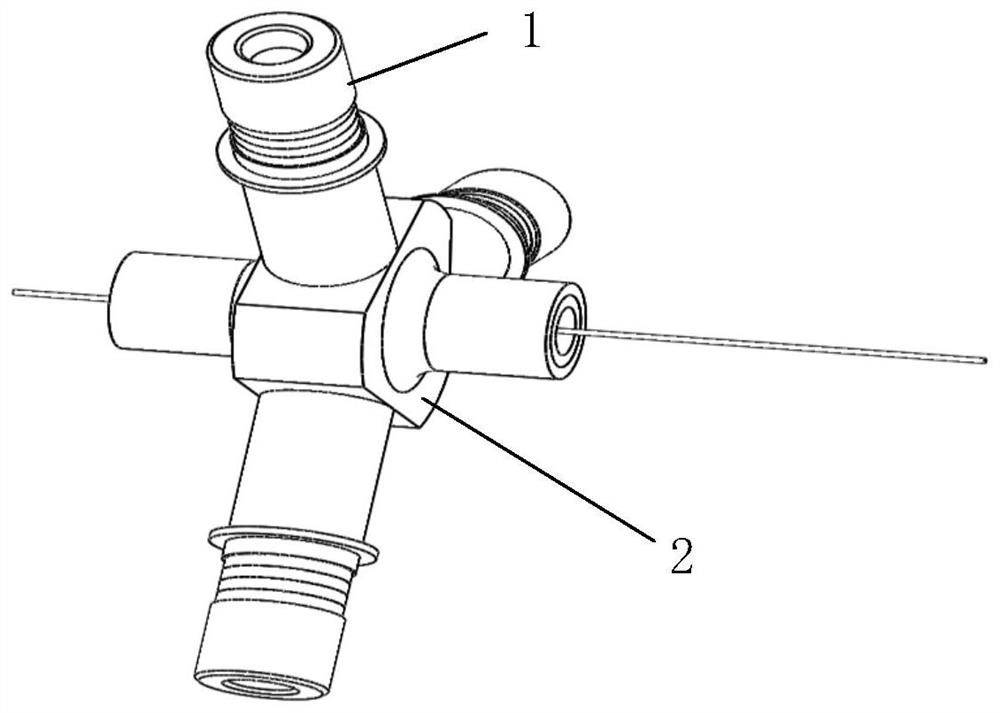

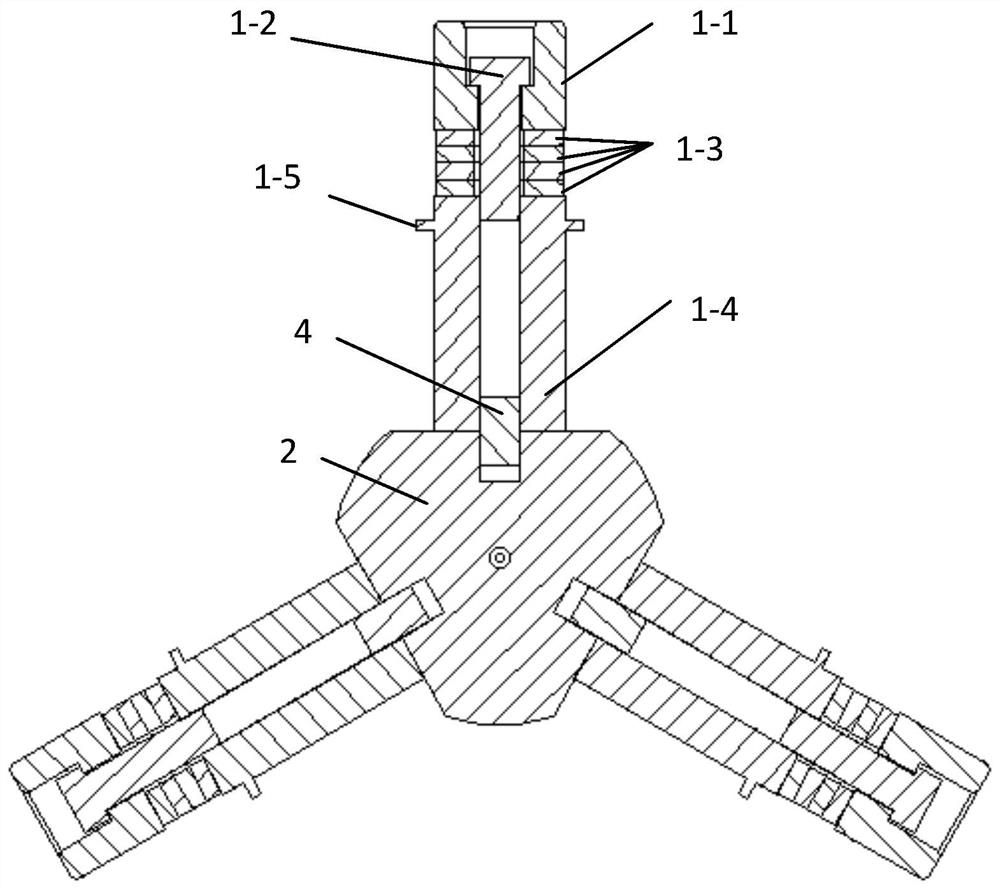

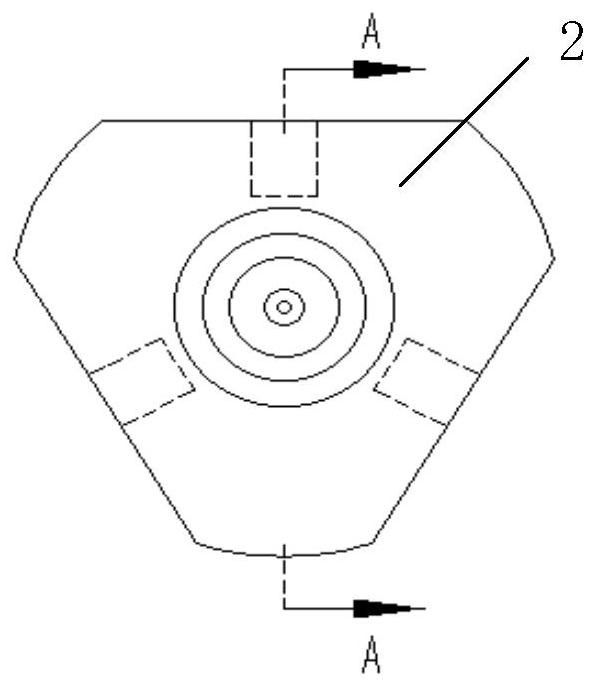

Dual-mode ultrasonic vibrator for drawing metal wire

An ultrasonic and metal wire technology, applied in the direction of wire drawing dies, fluids using vibration, etc., can solve the problems of complicated installation and manufacture of ultrasonic wire drawing vibrators, difficult application in industrial scenarios, low ultrasonic energy, etc. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] During the wire drawing process, the dual-mode ultrasonic vibrator drawn from the wire is installed on the abutment through the fixture and the flange. After installation, the wire passes through the two wire drawing dies through the wire hole in turn. After passing through, the dual-mode ultrasonic vibrator is started, and the metal wire is processed by the dual-mode ultrasonic vibrator. During the processing, the longitudinal vibration of the two drawing dies of the dual-mode ultrasonic vibrator always maintains a phase difference of 180°, that is, two consecutive modes of ultrasonic vibration are realized. Drawing processing, and finally high-quality drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com