Hexagonal screw production process

A production process and screw technology, which is applied in the field of hexagonal screw production process, can solve the problems affecting the wire drawing accuracy, etc., and achieve the effects of reducing the dimensional accuracy of the wire drawing die and the characteristics of the wire itself, improving the accuracy of the wire, and reducing the heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

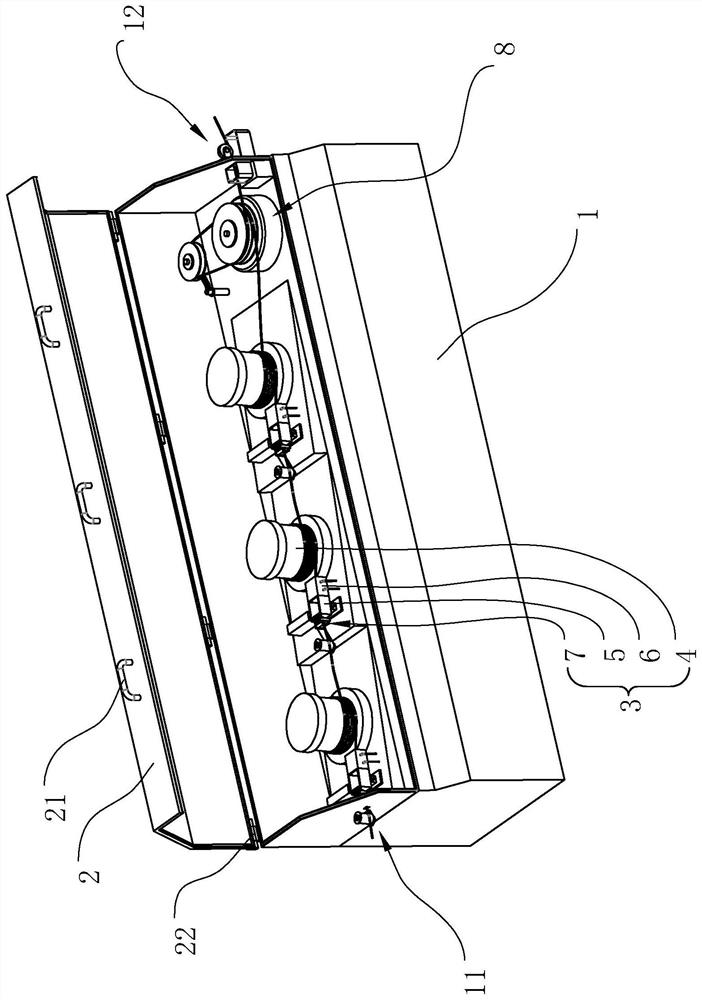

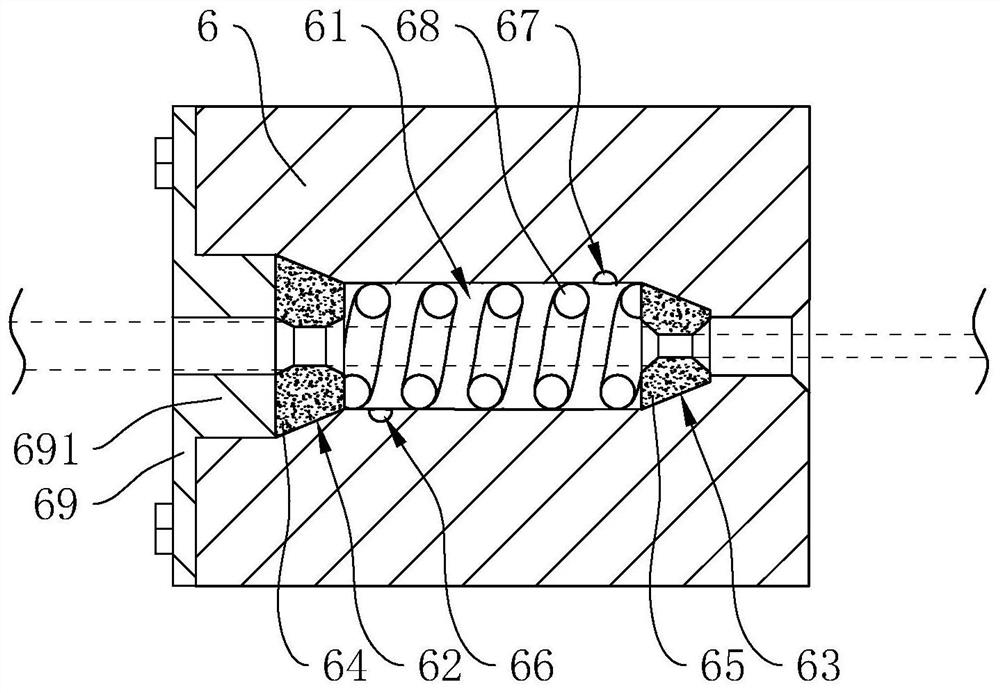

[0046] The following is attached Figure 1-5 The application is described in further detail.

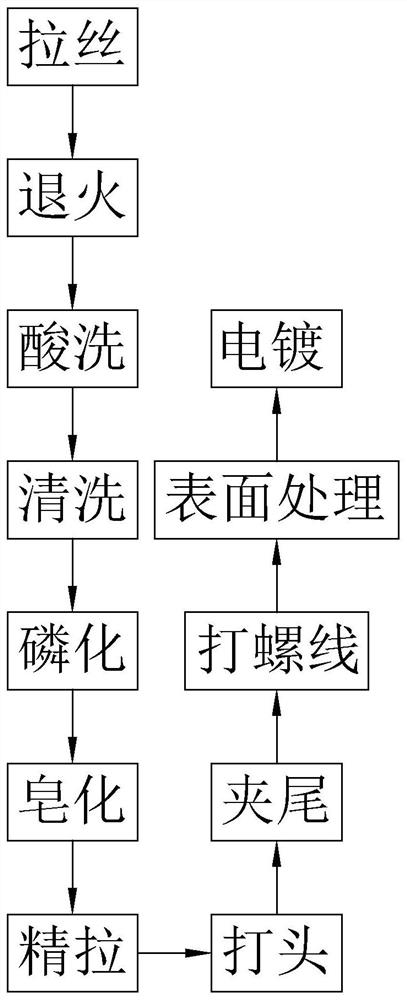

[0047] A hexagonal screw production process, such as figure 1 shown, including the following steps:

[0048] A: Wire drawing, the steel bar is sent to the wire drawing machine for drawing treatment and coiled on the wire frame to obtain a wire rod that is easy to process;

[0049] B: annealing, sending the wire rod obtained in step A into an annealing furnace for annealing treatment;

[0050] C: pickling, put the wire rod annealed in step B into a tank filled with pickling solution, and pickling the pickling solution for 5-15 minutes under the condition of heating to 50°C-60°C;

[0051] D: Cleaning, wash the wire rod and wire pickled in step C, then hang it into the tank with neutralizing solution, and neutralize it at room temperature for 1-3 minutes; then hang the wire rod into the tank with clear water liquid , wash at room temperature for 1 min;

[0052] E: Phosphating: hoist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com