Device for drawing wall surface curves and ceiling curves and use method thereof

A curve and ceiling technology, applied in the field of custom furniture, can solve the problems of long drawing time and low precision, and achieve the effect of shortening drawing time, improving work efficiency and improving drawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

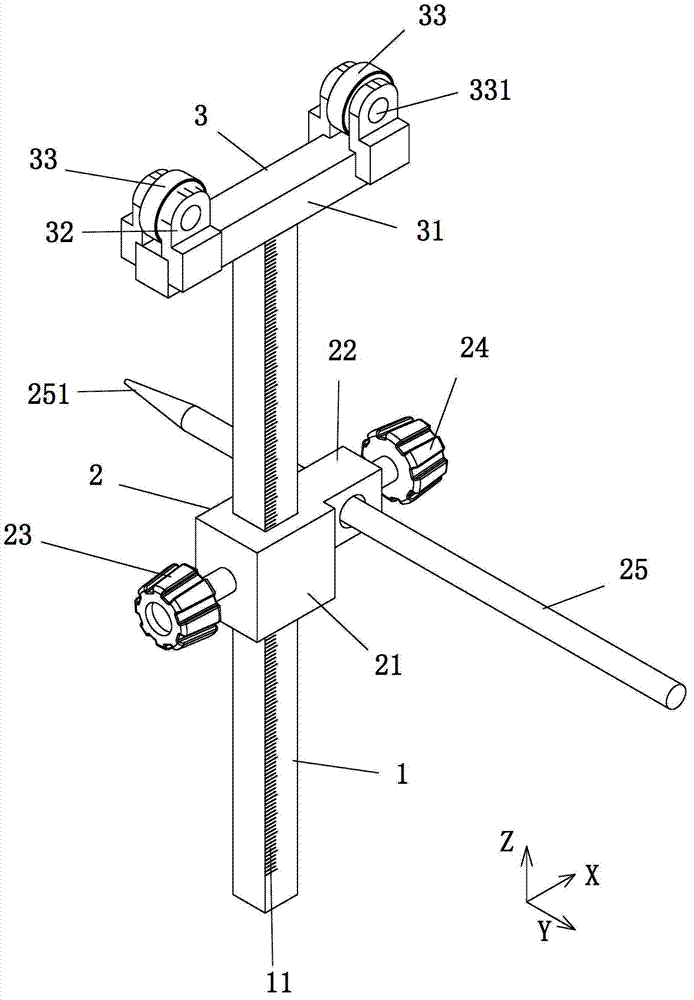

[0039] Such as figure 1 As shown, the device for drawing wall curves and ceiling curves includes a cylinder 1 , a brush fixing mechanism 2 and a rolling mechanism 3 .

[0040] The brush fixing mechanism 2 includes a sleeve body 21 with a first through hole (not shown in the figure), a brush fixing body 22 with a second through hole (not shown in the figure), a paintbrush 25, a first hand Tighten the screw 23 and a second finger screw 24, the sleeve body 21 is socketed with the cylinder body 1 through the first middle through hole, the paintbrush fixed body 22 is fixed on one side of the sleeve body 21, and the paintbrush fixed body 22 passes through the second middle through hole. The hole is socketed with the paintbrush 25; the first thumb screw 23 is screwed to the other side of the sleeve body 21, and the end of the first thumb screw 23 is in contact with the cylinder 1, and the first thumb screw 23 is used to screw the sleeve The body 21 is locked on the cylinder 1, so th...

Embodiment 2

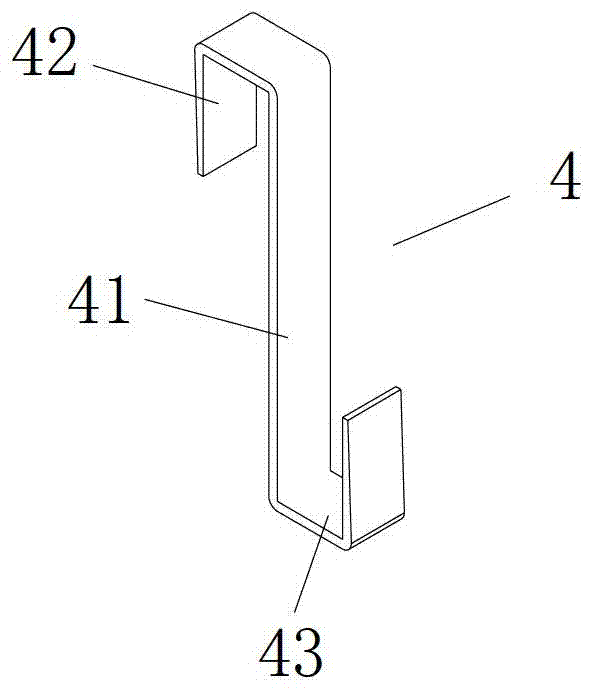

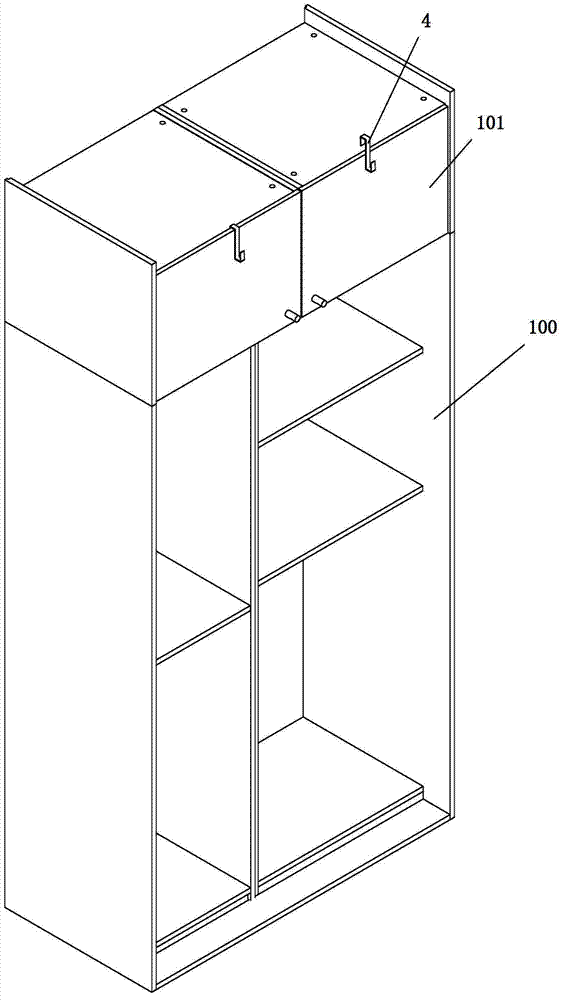

[0052] combine figure 1 , The difference between this embodiment and Embodiment 1 lies in the structure of the board clip. Specifically, such as Figure 9 As shown, the plate clamp 5 includes a connecting rod 51 , a clamping portion 52 and a placing portion 53 , the clamping portion 52 is fixed on the top of the connecting rod 51 , and the placing portion 53 is fixed on the bottom of the connecting rod 51 .

[0053] The usage method of this embodiment is basically the same as that of Embodiment 1, except that the installation method of the board clamp 5 is different. When used, such as Figure 10 As shown, the clamping part 52 is clamped on the top line reinforcement bar 501 of the cabinet body 500, and the bottom of a plate is placed on the placement part 53; the roller 33 of the rolling mechanism 3 is in contact with the ceiling, and the paintbrush 25 of the brush fixing mechanism 2 The nib 251 is in contact with the surface of the board.

Embodiment 3

[0055] This example directly uses figure 1 The device shown, without accessories. Such as Figure 11 As shown, directly place the bottom of a rectangular or square plate 800 on the ground, then make the roller 33 of the rolling mechanism 3 contact the wall 700, and make the nib 251 of the paintbrush 25 of the brush fixing mechanism 2 touch the plate Push the cylinder 1, and keep the roller 33 of the rolling mechanism 3 in contact with the wall 700, the nib 251 of the paintbrush 25 slides along the surface of the plate 800 and leaves a curve 900; saw along the curve 900 Open the panel 800, and install the fabricated panel 800 on the cabinet body 600 so that it is closed with the wall 700.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com