Drawbench

A wire-drawing machine and wire-drawing technology, applied in the field of wire-drawing machines, can solve the problems affecting the wire-drawing accuracy, the length of the remaining tail rod, and the uncontrollable air convection, etc., to achieve the effect of eliminating mechanical disturbance and improving the drawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

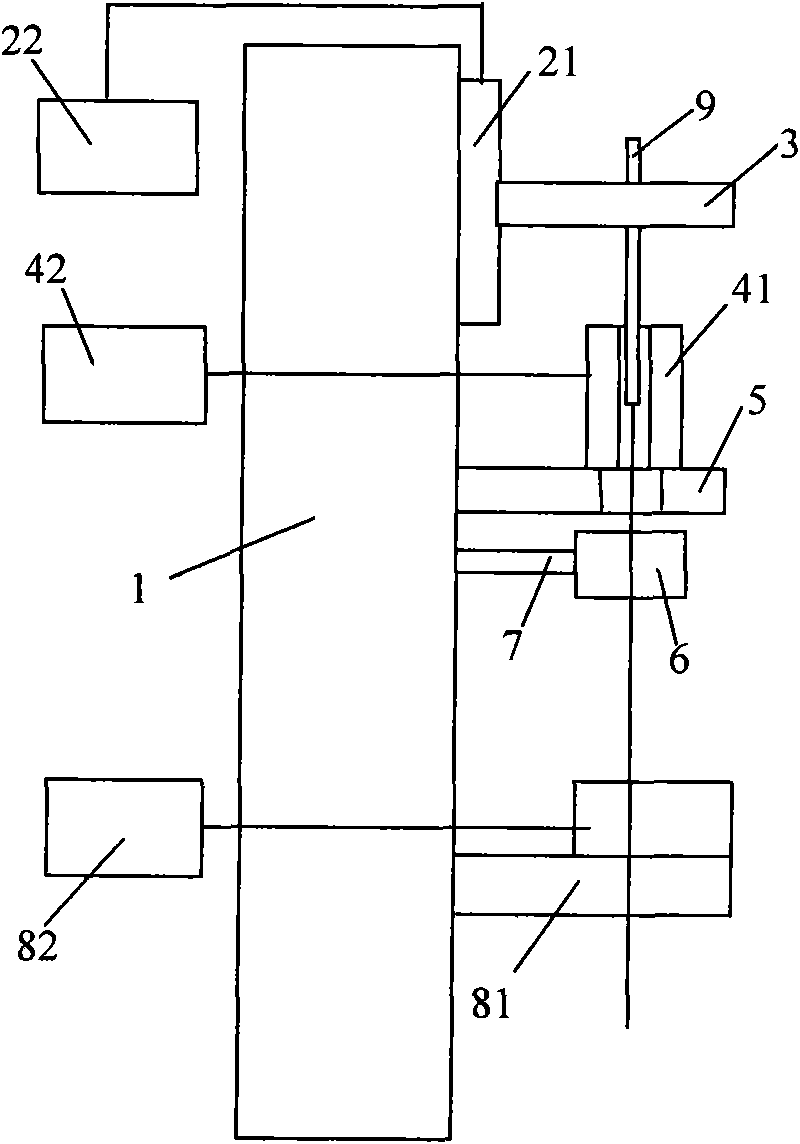

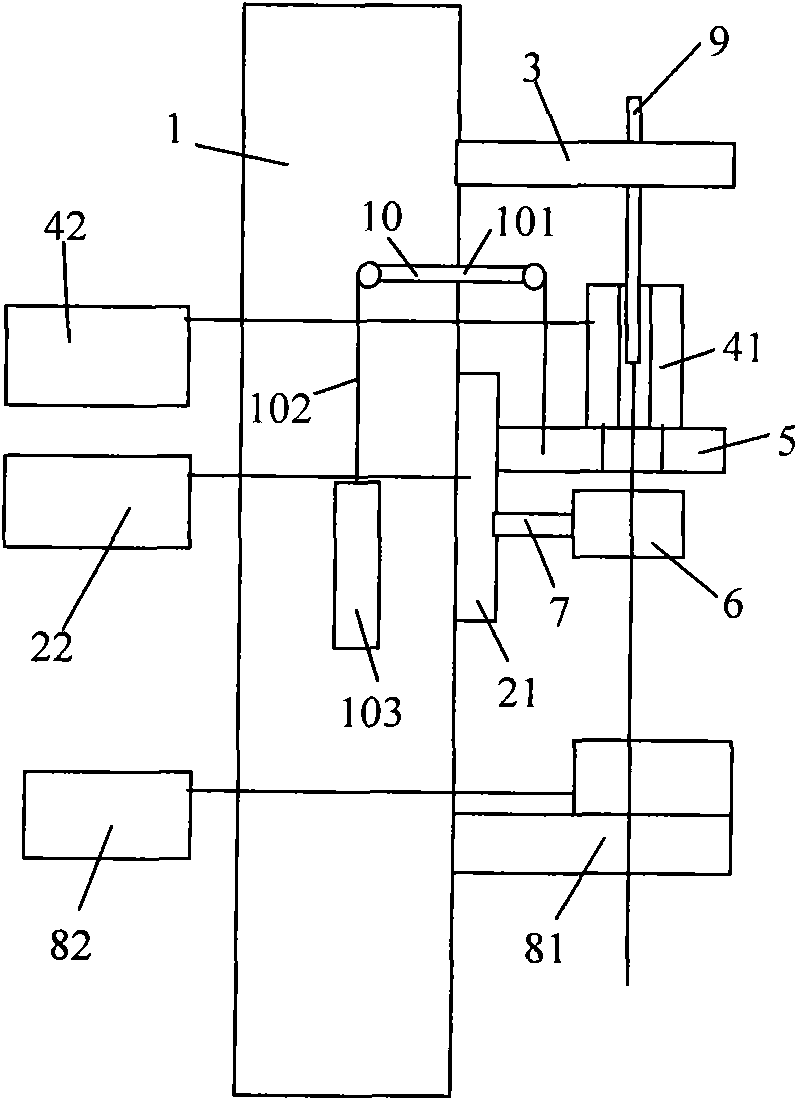

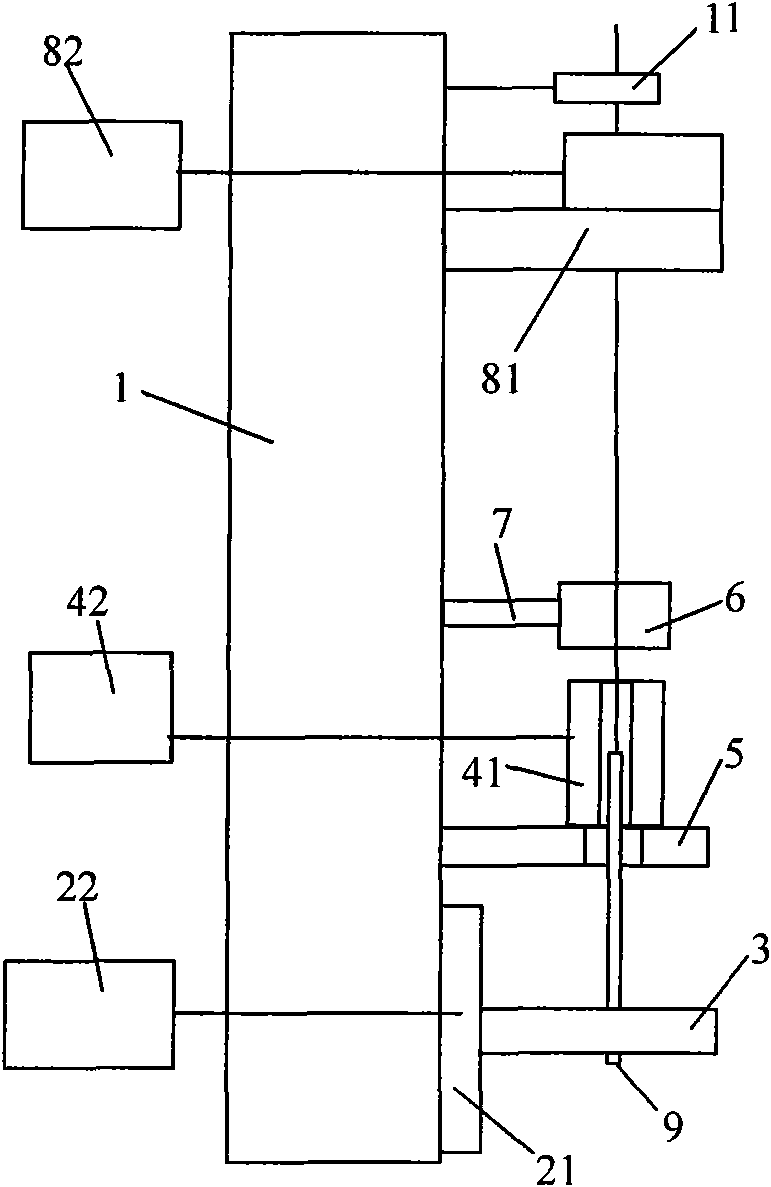

[0018] The three precision glass drawing machines proposed by the present invention will be further described below in conjunction with the accompanying drawings.

[0019] figure 2 It is a structural block diagram of the first wire drawing machine proposed by the present invention. The brushed tower base 1 is a solid and stable base, usually made of cast iron structural parts or steel structural parts. The preform rod clamping device 3 is fixed on the upper part of the tower base 1 for fixing the preform rod 9 . The base of the moving platform 21 is fixed on the tower base 1 and is located below the preform clamping device 3 , the furnace rack 5 is fixed on the bearing platform of the moving platform 21 , and the electric furnace 41 is fixed on the furnace rack 5 . The electric furnace adopts a well-type structure, with upper and lower furnace openings, and the preform is heated in the furnace. Through holes are arranged on the grate 5, and the drawn product is allowed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com