Accurate tire section constraint method

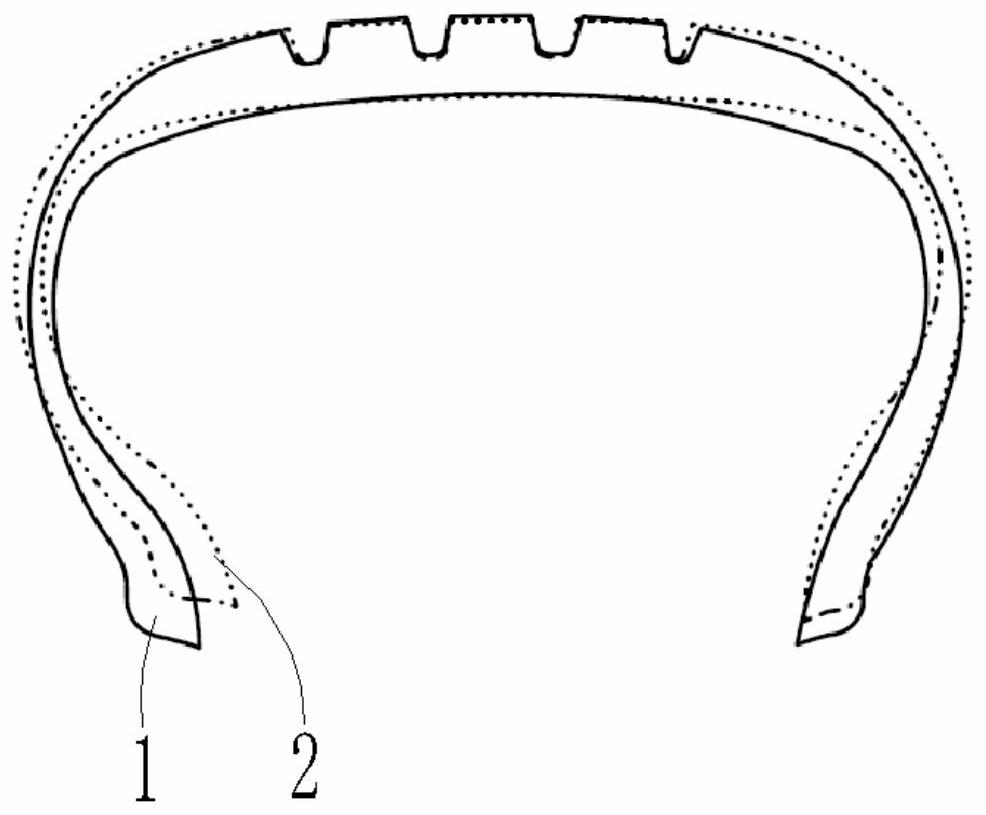

A tire and section technology, applied in the field of precise tire section constraints, can solve problems such as large deformation, inability to accurately represent the shape of the tire section profile, and affect the detection accuracy of the tire section size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] Below in conjunction with accompanying drawing, the present invention will be further described, and this description is only used to explain the specific embodiment of the present invention, and can not be interpreted in any form as limiting the present invention, and specific embodiment is as follows:

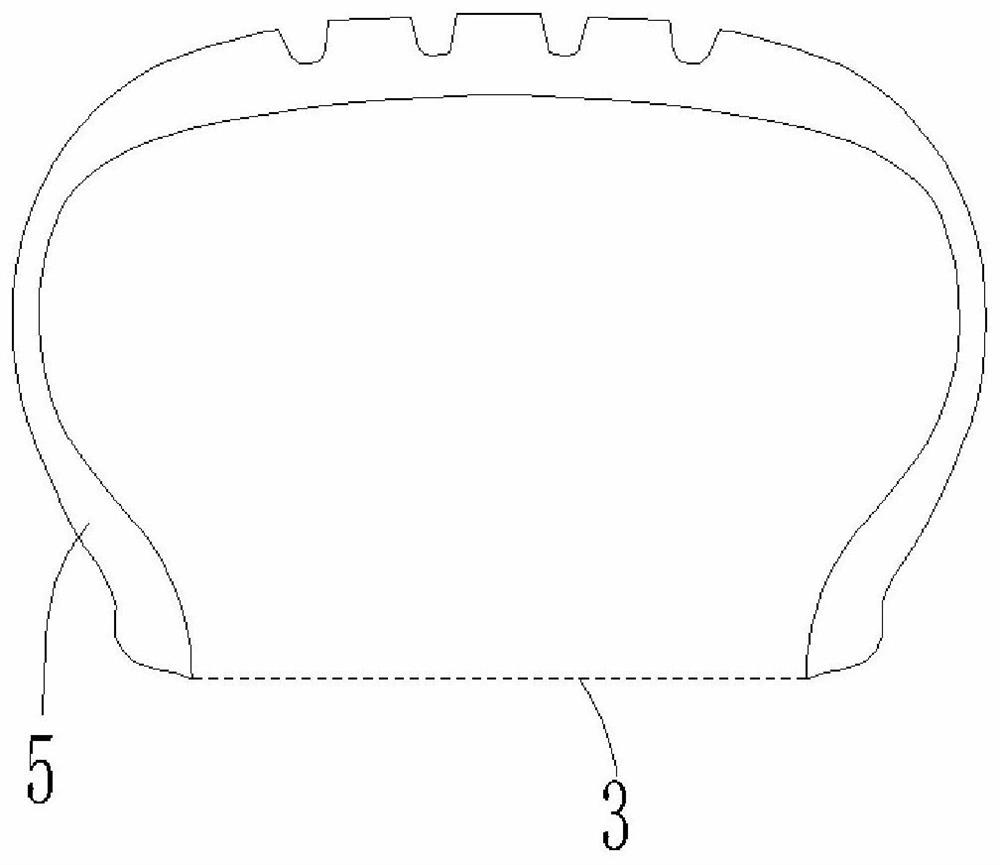

[0030] A precise method for constraining tire sections, the constraining method comprising:

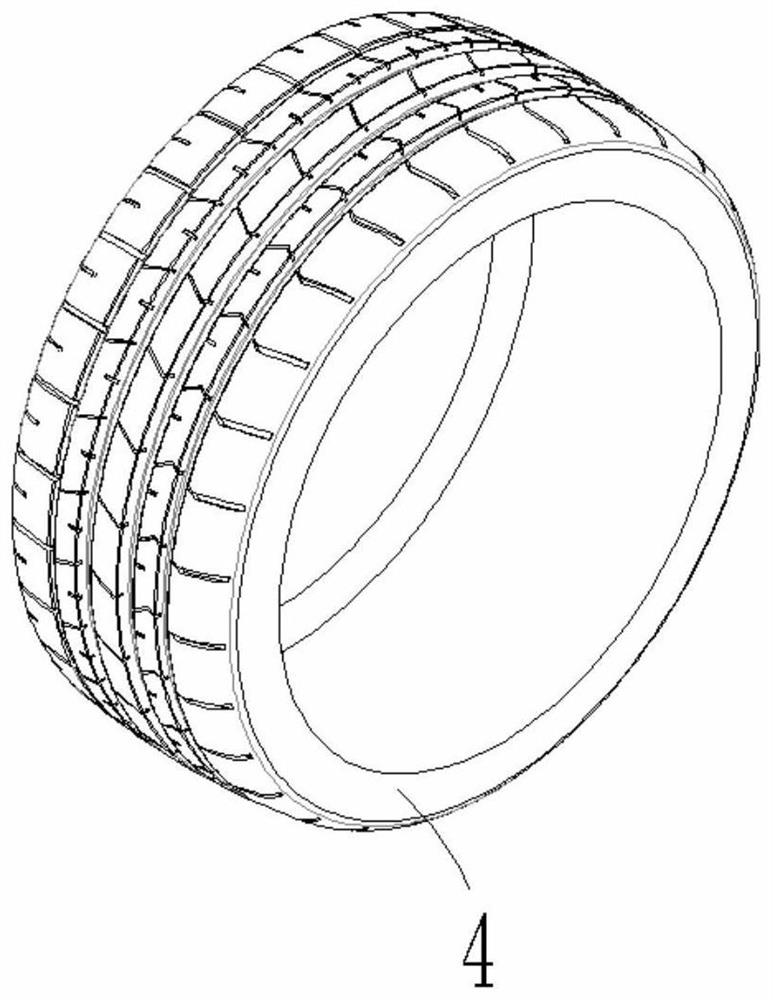

[0031] Step 1: Scanning the finished tire in a non-assembled state by scanning equipment, and establishing a three-dimensional geometric model of the finished tire 4;

[0032] The scanning device is a hand-held three-dimensional laser scanner, and the target positioning points of the hand-held 3D laser scanner are pasted on the inner and outer surfaces of the finished tire in the non-assembled state. More than one target positioning point, start the marking point scanning function of the handheld 3D laser scanner to obtain the position information of all marking points, use 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com