Vertical bow and front edge drainage combined damping structure used for low speed full formed ship

A vertical bow and hypertrophy technology, which is applied in the field of combined drag reduction structure of vertical bow and leading edge drainage, can solve the problems of vortex generation, increase of frictional resistance of the whole ship, delay, etc., to reduce total resistance and reduce wave-making resistance. , the effect of reducing the viscous pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

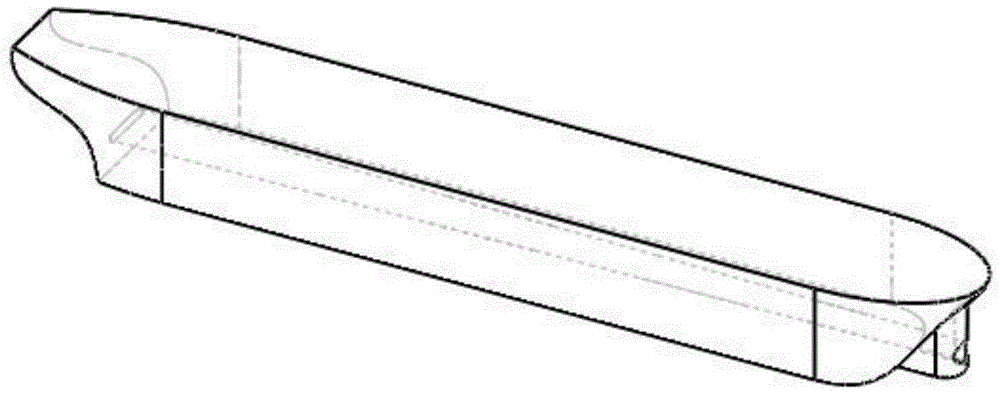

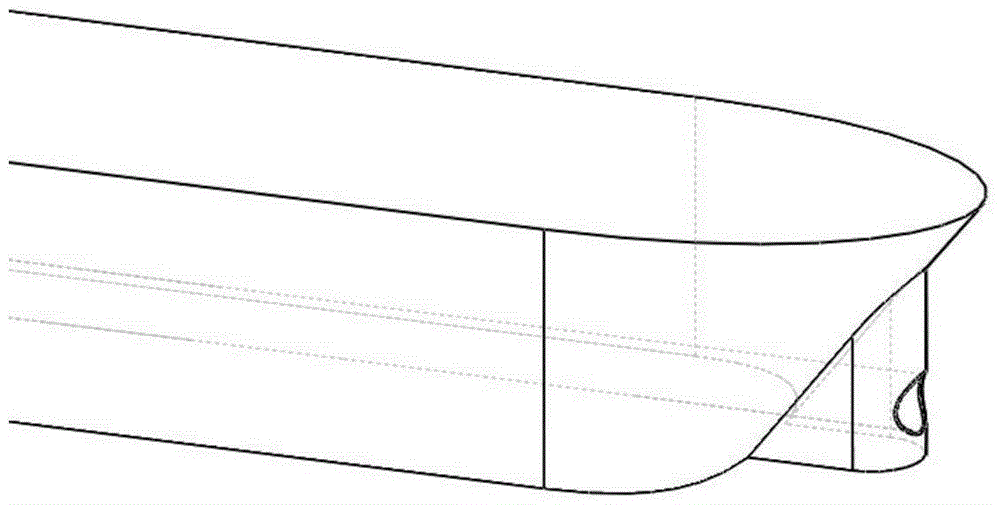

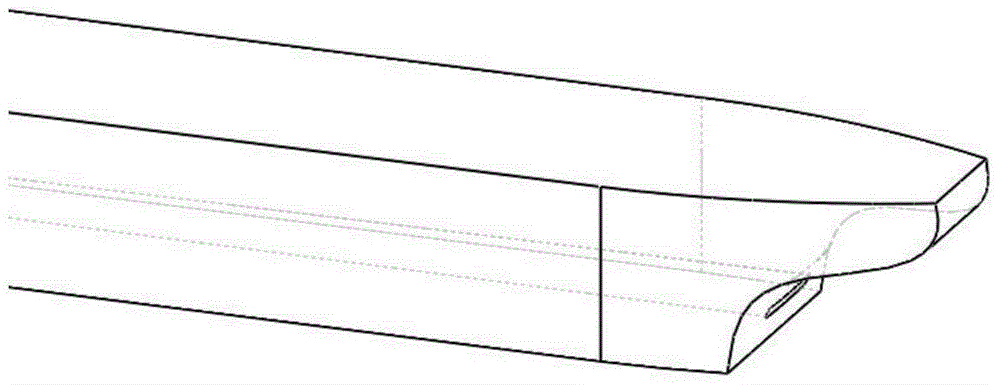

[0031] see figure 1 , figure 2 and image 3 , the invention discloses a combined drag reduction structure of vertical bow and leading edge drainage for low-speed fat and large ships, including a hull, a vertical bow is installed at the bow position of the hull, and a circular bow is opened at the front end of the vertical bow A rectangular hole with rounded corners is opened at the stern of the hull, the circular hole and the rectangular hole with rounded corners are connected back and forth, and a smooth transition is formed inside the hull to form a flow channel for the fluid to pass through, and the parameters of the structure The determination can be made according to a specific method.

[0032] In the first part, the outstanding advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com