Plastic pipe for reinforcing thermal plasticity

A technology for strengthening thermoplastic and plastic pipes, applied in rigid pipes, pipes, pipes/pipe joints/fittings, etc., it can solve the problems of inconvenient transportation, construction, low pressure resistance, and unsatisfactory, and achieve convenient construction and laying. , strong corrosion resistance, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

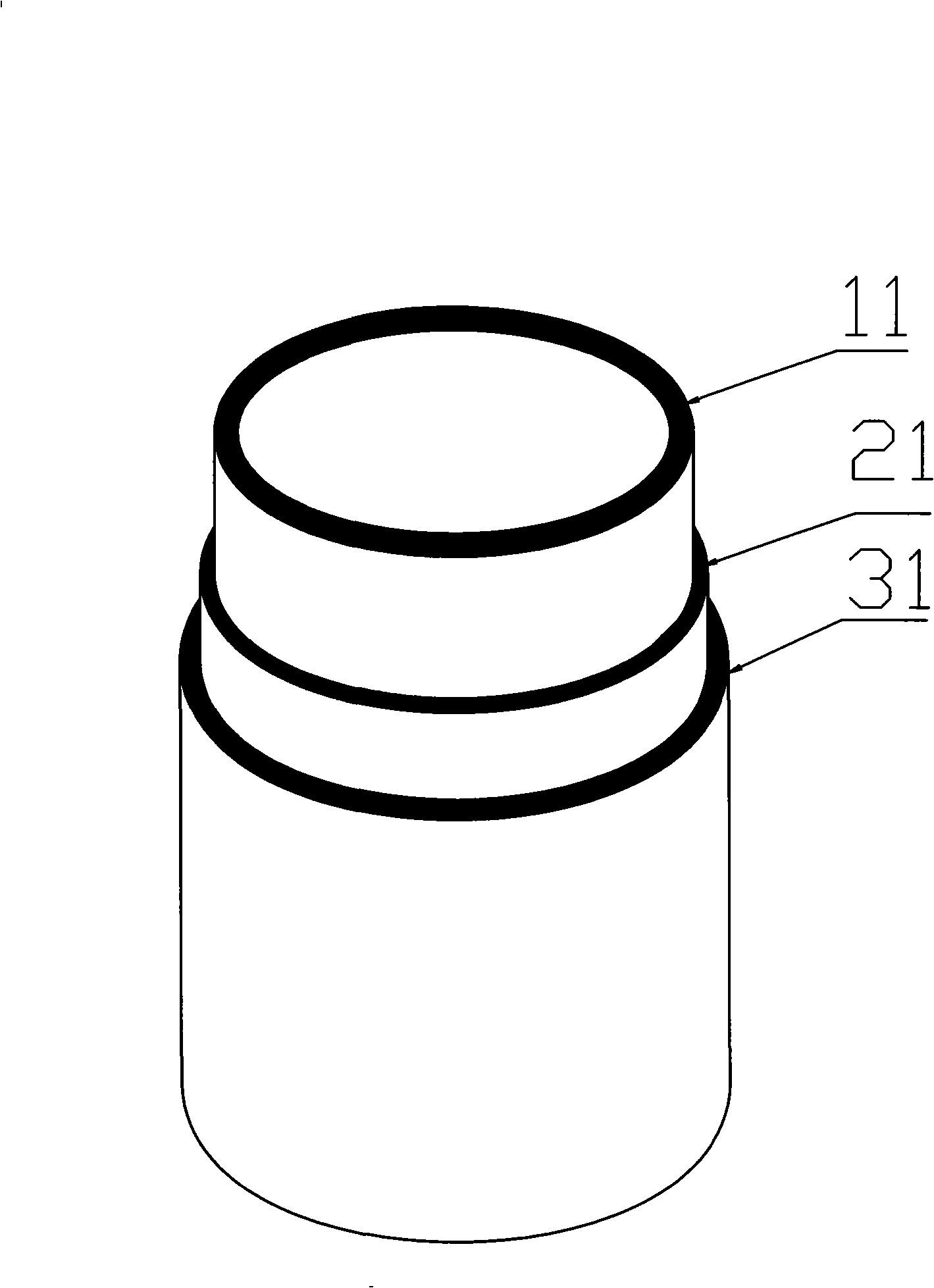

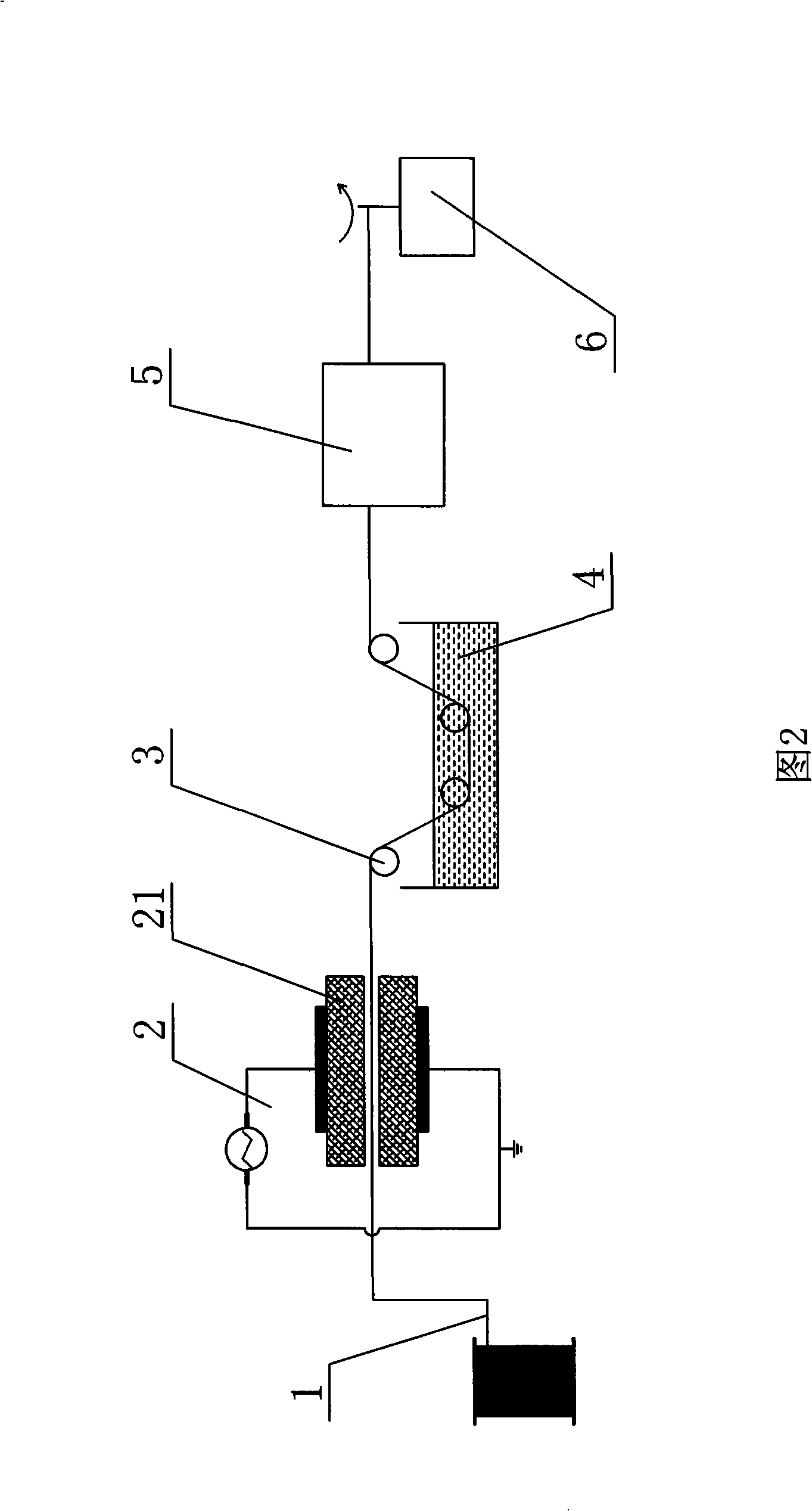

[0013] Such as figure 1 As shown, the reinforced thermoplastic pipe includes an inner layer pipe 11 and an outer layer pipe 31, the inner layer pipe 11 and the outer layer pipe 31 are made of high-density polyethylene (HDPE), and its characteristics are: Between the layer pipe 11 and the outer layer pipe 31 there are at least two reinforcement layers 21 wound by plasma-treated basalt fibers grafted and coated with resin. In the specific production process, when the basalt fiber is wound on the inner layer pipe 11, the inner layer pipe 11 can be heated, so that the resin on the surface of the basalt fiber can be heated and melted during winding, so that it is in contact with the inner layer pipe 11, And between two adjacent layers of basalt fibers can be well compounded, the basalt fibers are wound layer by layer outside the inner tube 11 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com