Device and method for grinding inner surface of elongated cylindrical shell

A shell inner surface, cylindrical technology, applied in the direction of grinding automatic control device, grinding/polishing safety device, grinding machine, etc., can solve the problem that segmental grinding process cannot be realized, and ordinary grinding device is difficult to achieve high-precision inner surface Grinding processing and other issues, to achieve the effect of accurate tool feed, small axial variable, fast positioning and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

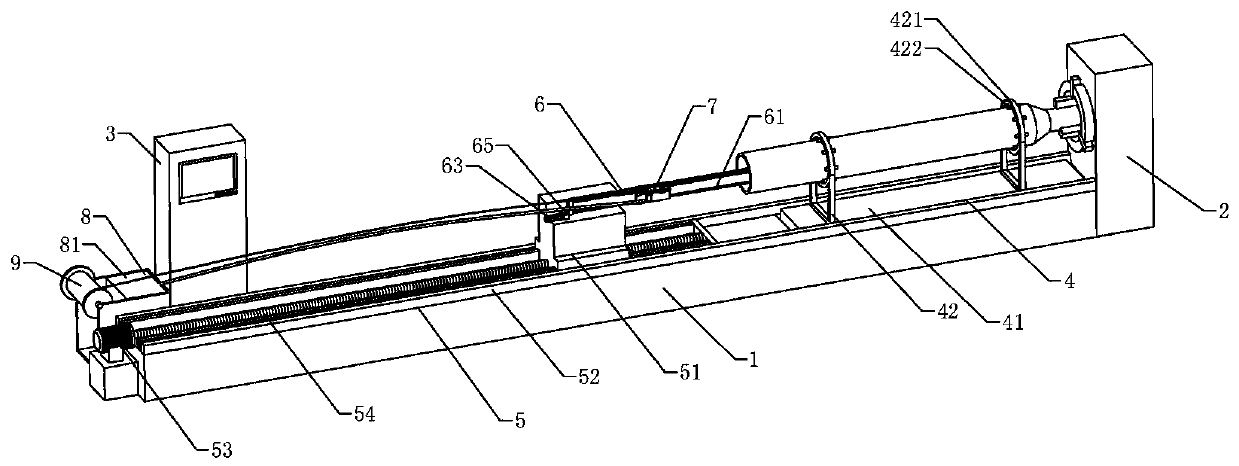

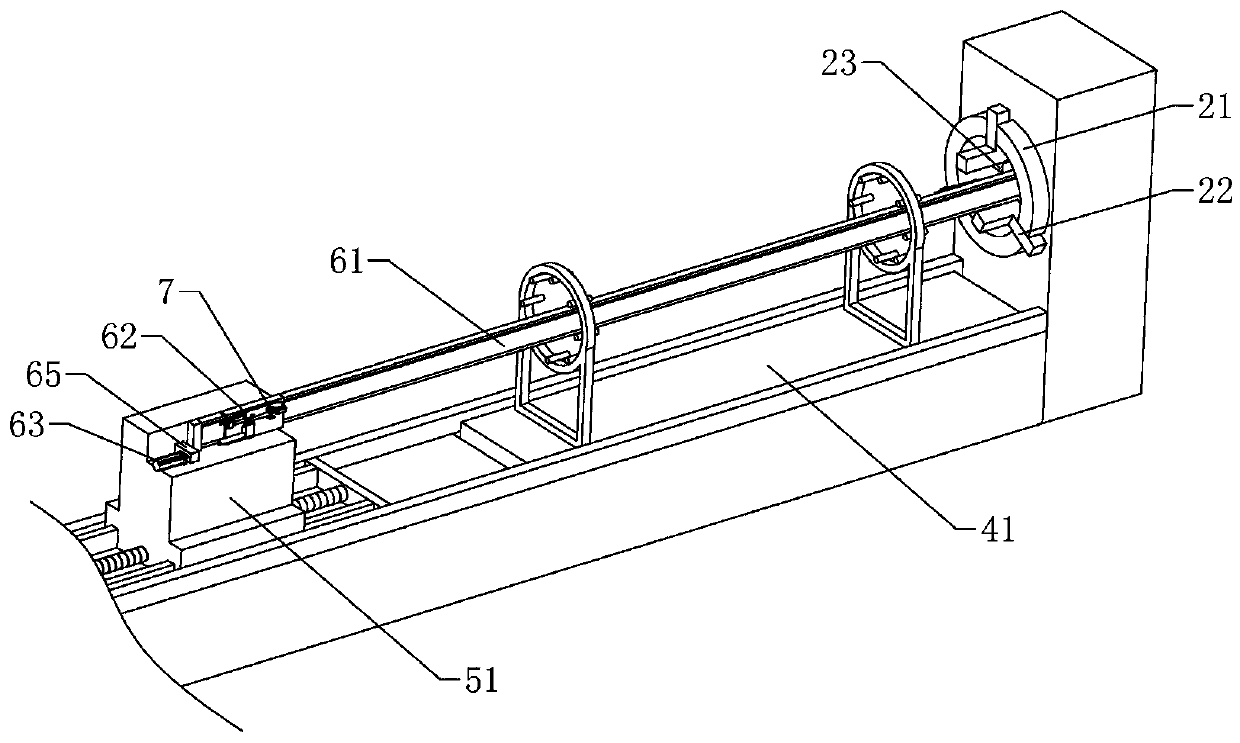

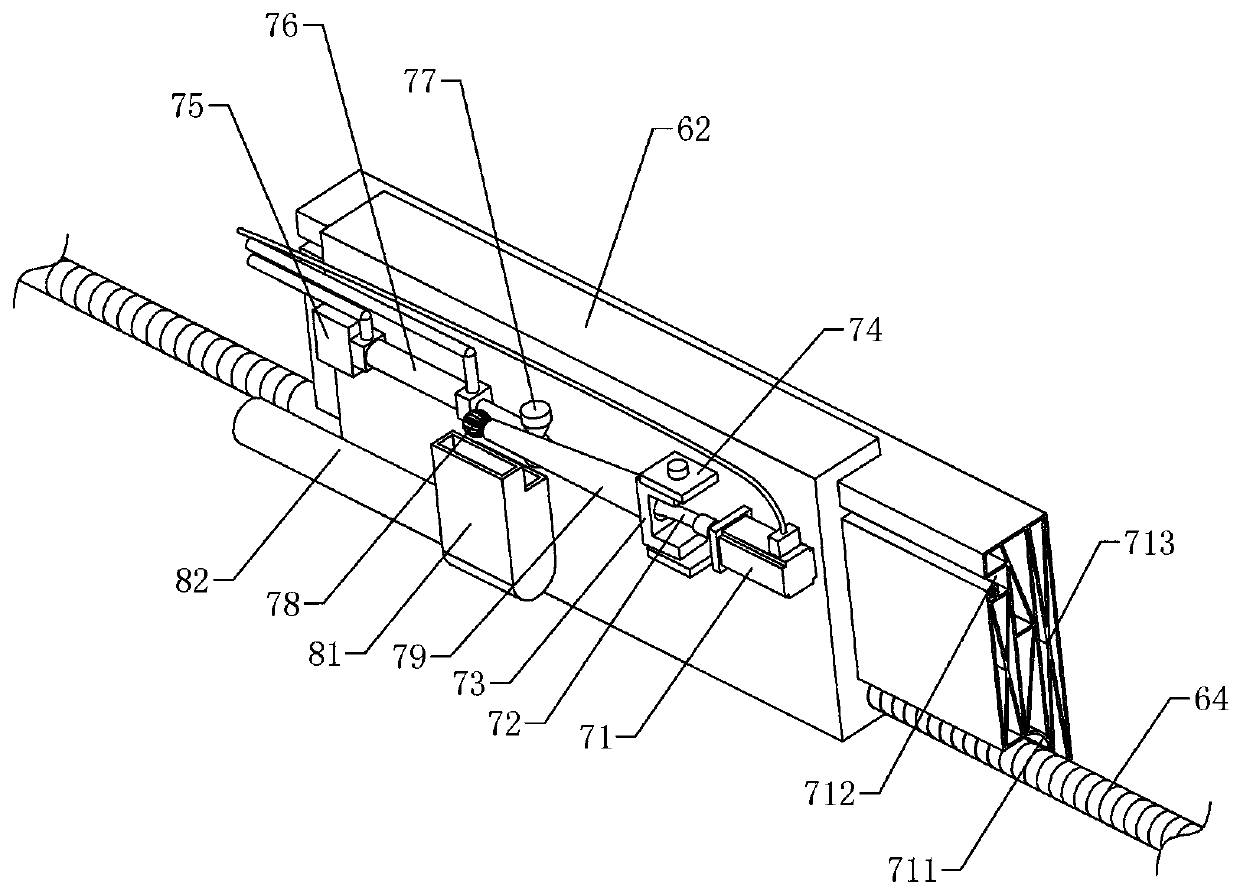

[0029] according to Figure 1 ~ Figure 3 As shown, a grinding device for the inner surface of a slender cylindrical shell includes: a processing table 1, a shell rotating mechanism 2 and a numerical control system 3, and the processing table 1 is provided with a shell supporting mechanism 4, a first pallet mechanism 5 and The second supporting plate mechanism 6; the housing rotating mechanism 2 includes a driving turntable 21, a clamping grip 22 and a pallet clamp 23, and the driving turntable 21 is a hollow turntable driven by a frequency conversion motor and a gearbox, and the gripping grip 22 can be Adjustable and installed on the drive turntable 21, the pallet clamp 23 is arranged on the inner side of the drive turntable 21; the first pallet mechanism 5 includes a sliding pallet 51, a guide rail 52, a first servo motor 53 and a first positioning screw 54, and a guide rail 52 Installed on the top of the processing table 1, the first positioning screw 54 is arranged between ...

Embodiment 2

[0041] The difference from the above-mentioned embodiment 1 is that the grinding device also includes a wire feeding mechanism 9, which includes a wire feeding stick and a wire feeding motor. In the processing steps c and d, the wire feeding motor is started to release the winding The wire on the wire stick ensures the synchronous and coordinated movement of the relevant wires and air pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com