Short fiber reinforced plastic electric melting pipe with optimized injection position and injection mold thereof

A short fiber reinforced, electrofusion pipe fitting technology, which is applied in the directions of pipes/pipe joints/pipe fittings, pipeline connection arrangement, mechanical equipment, etc. The effect of improving the degree of axial orientation and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

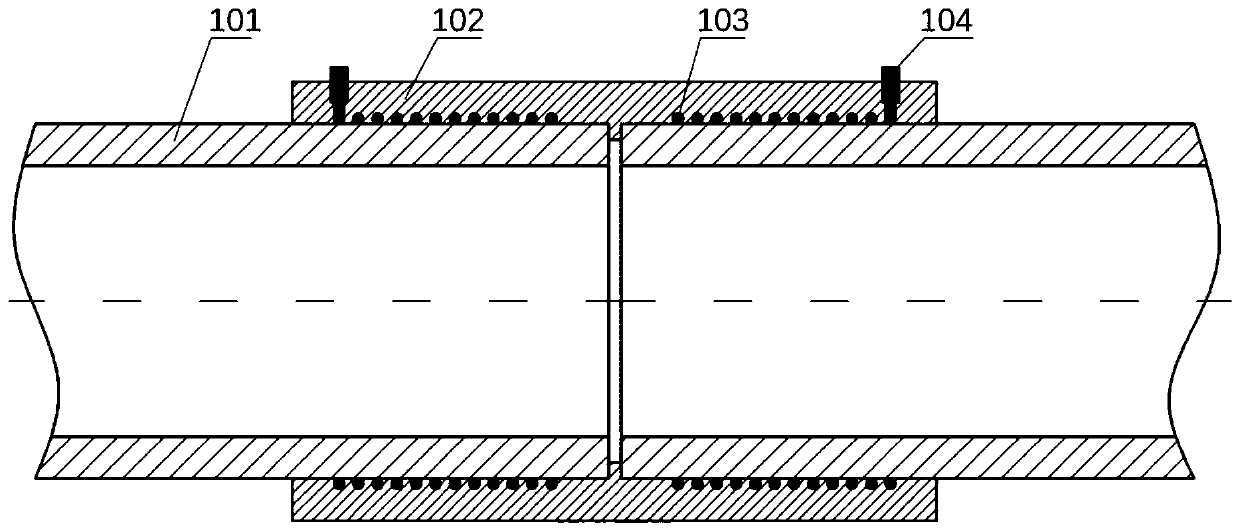

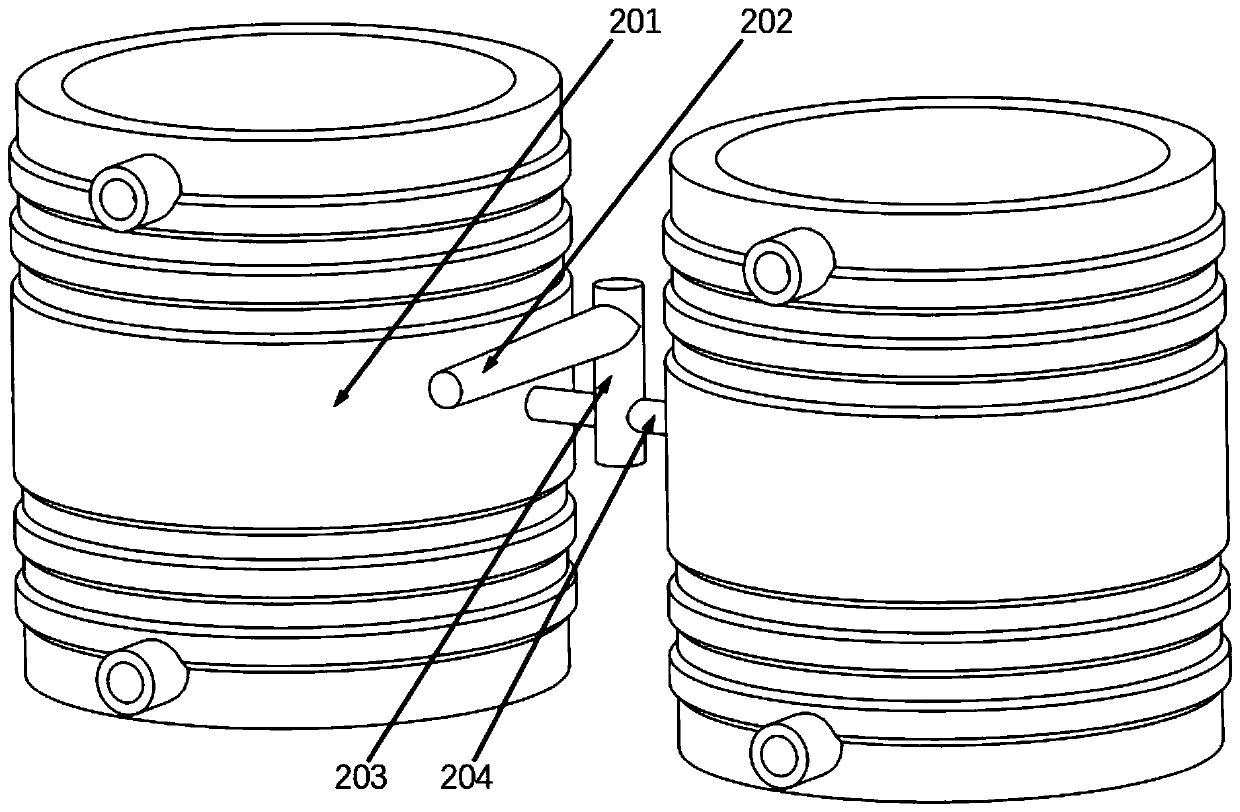

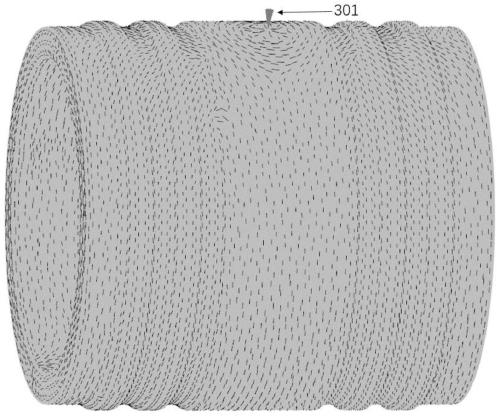

[0051] In this embodiment, an electrofusion pipe fitting with four injection positions is taken as an example. The injection position is set on the end face of the pipe fitting, and the four pouring injection positions are distributed in an array of equal circumferential angles along the axial centerline of the pipe fitting. Chopped carbon fiber reinforced polyethylene composite injection molding electrofusion pipe fittings are used, dispersed chopped carbon fiber is used as the reinforcing fiber, and high-density polyethylene is used as the matrix. The content of the chopped carbon fiber is 10wt%, and the length of the fiber is 6-7mm. In order to make the chopped carbon fiber uniformly dispersed in the high-density polyethylene matrix, the high-density polyethylene is made of powder with a particle size of 32-50 mesh.

[0052] The preparation method of chopped carbon fiber reinforced polyethylene material is carried out according to the following steps:

[0053] (1) The compo...

Embodiment 2

[0061] Such as Figure 5 As shown, the runner system of the short fiber reinforced plastic electrofusion pipe fitting injection mold includes a main runner, four runners and four sprues. In order to facilitate the demoulding of the electrofusion pipe fittings after injection molding, the parting surfaces of the movable mold and the fixed mold of the electrofusion pipe fittings injection mold pass through the axial centerline of the injected electrofusion pipe fittings, and the parting surface is perpendicular to the connection of the injected electrofusion pipe fittings column. In this embodiment, the runner cavity of the injection mold is a cylindrical structure, which is convenient for the part of the runner to be demoulded after injection molding. Half of the runner cylindrical cavity is arranged on the core section, and the other half of the runner cylindrical cavity Arranged on the movable mold and the fixed mold of the injection mold, that is, the end face of the movabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com