Automobile leaf spring bushing

An automobile plate and bushing technology, which is applied to vehicle parts, elastic suspension, suspension and other directions, can solve the problem that the movement of the leaf spring system is not stable and smooth, the damping and buffering performance of the leaf spring bushing is poor, and the assembly and maintenance work Large quantity and other problems, to achieve the effect of low production cost, good shock absorption effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

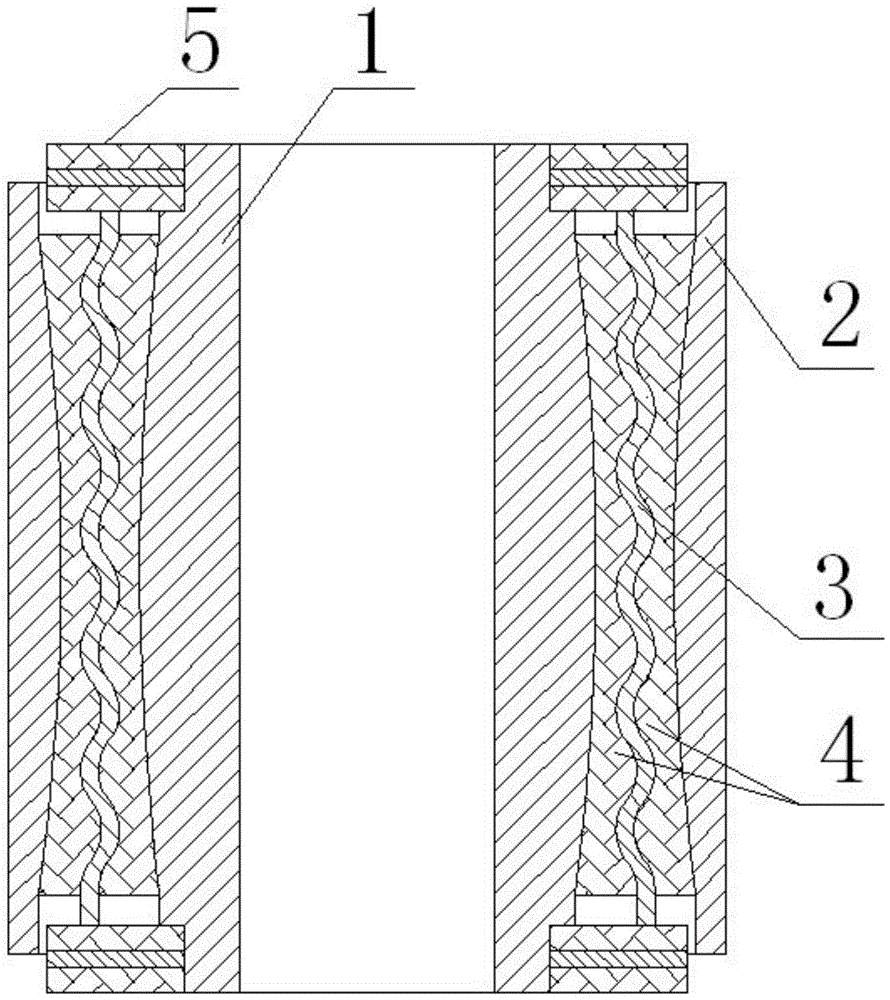

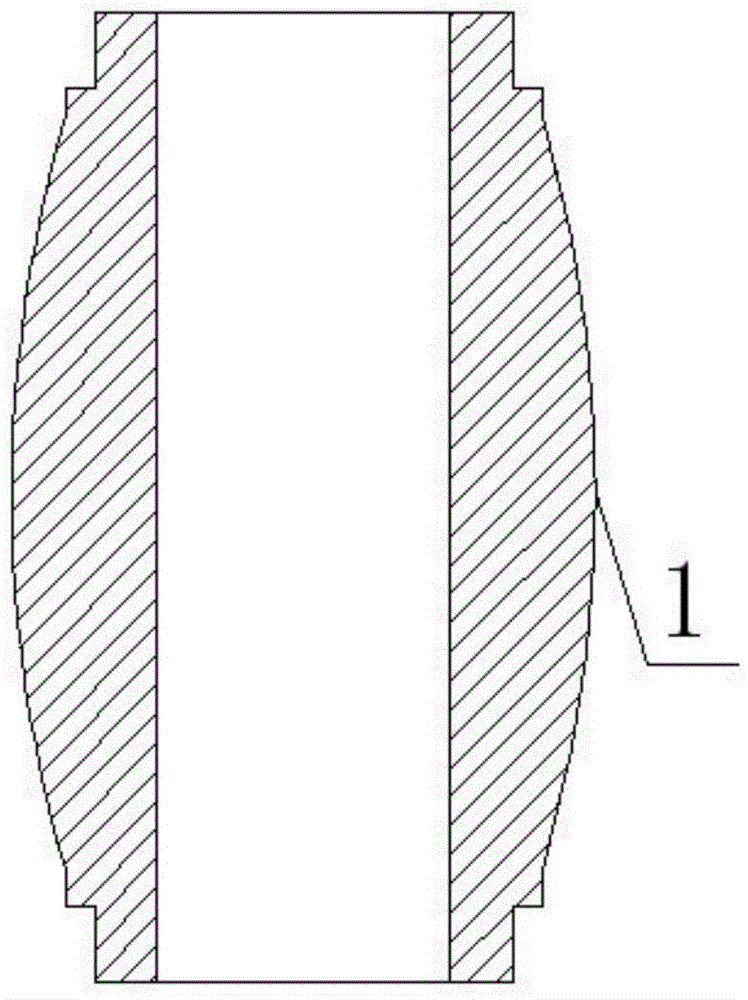

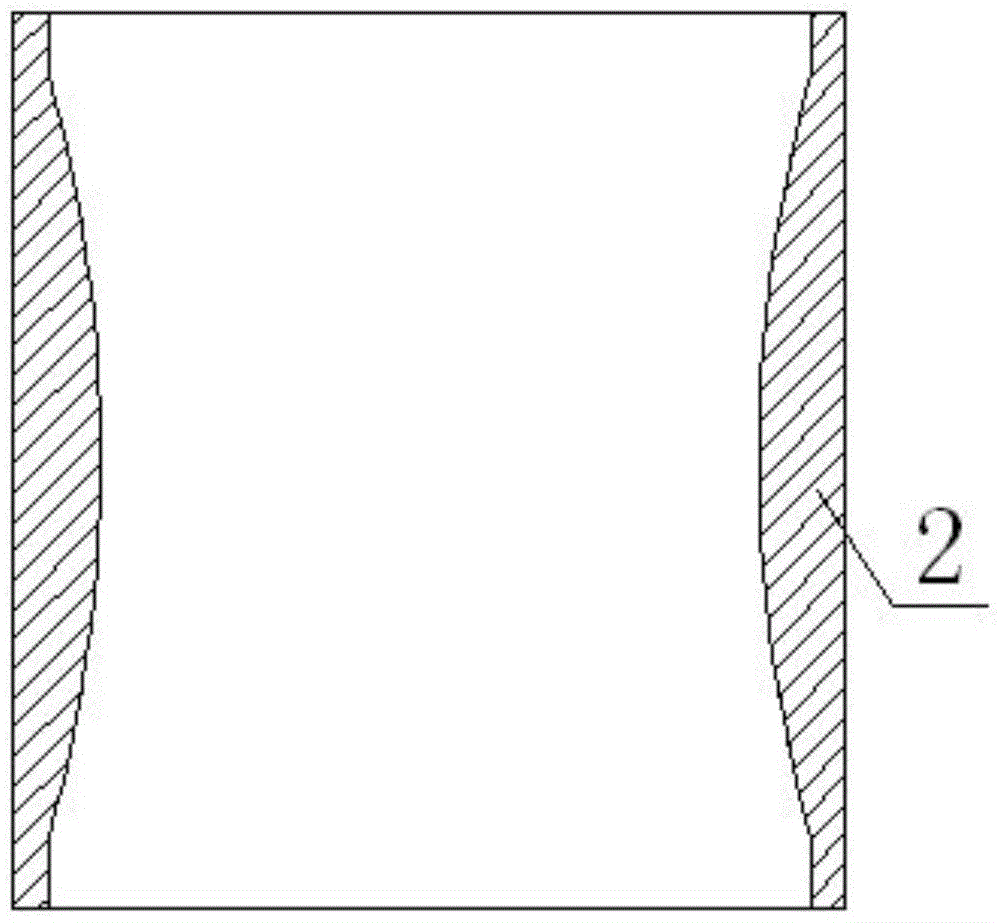

[0023] combine Figure 1~3 , an automobile leaf spring bushing of the present invention, comprising an inner sleeve 1, an outer sleeve 2, a rubber filling layer 4 and a retaining ring 5, wherein the outer surface of the inner sleeve 1 is an outwardly protruding arc on the axial section of the bushing shape, the inner surface of the outer sleeve 2 is an arc protruding inward on the axial section of the bush, such a special structure restricts the movement of the filling rubber layer 4 between the inner sleeve 1 and the outer sleeve 2 along the axial direction of the bush, It not only increases the axial strength of the bushing, but also increases the radial strength of the bushing; there is a high damping alloy layer 3 between the inner sleeve 1 and the outer sleeve 2, which is a copper-zinc-aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com