Tension member and preparation method and engineering machinery thereof

A technology for components and intermediate components, applied in the field of tension components and their preparation, can solve the problems of large radius capacity restriction of cranes, consumption of lifting capacity, low load capacity, etc., and achieve the effects of light weight, high bearing capacity and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0039] The basic idea of the present invention is to use carbon fiber composite material as the main material of the tension member, because the carbon fiber composite material has the advantages of light weight and high tensile strength, thereby reducing the weight of the tension member and improving its tensile performance .

[0040] Below in conjunction with accompanying drawing, each preferred embodiment of the present invention is described further:

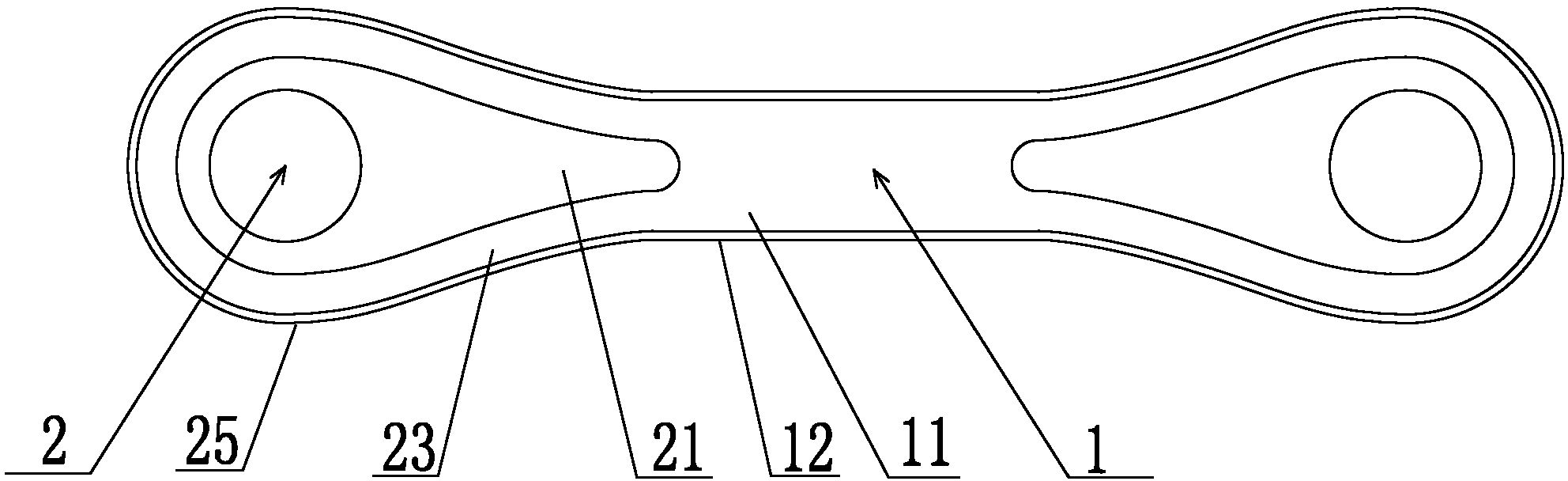

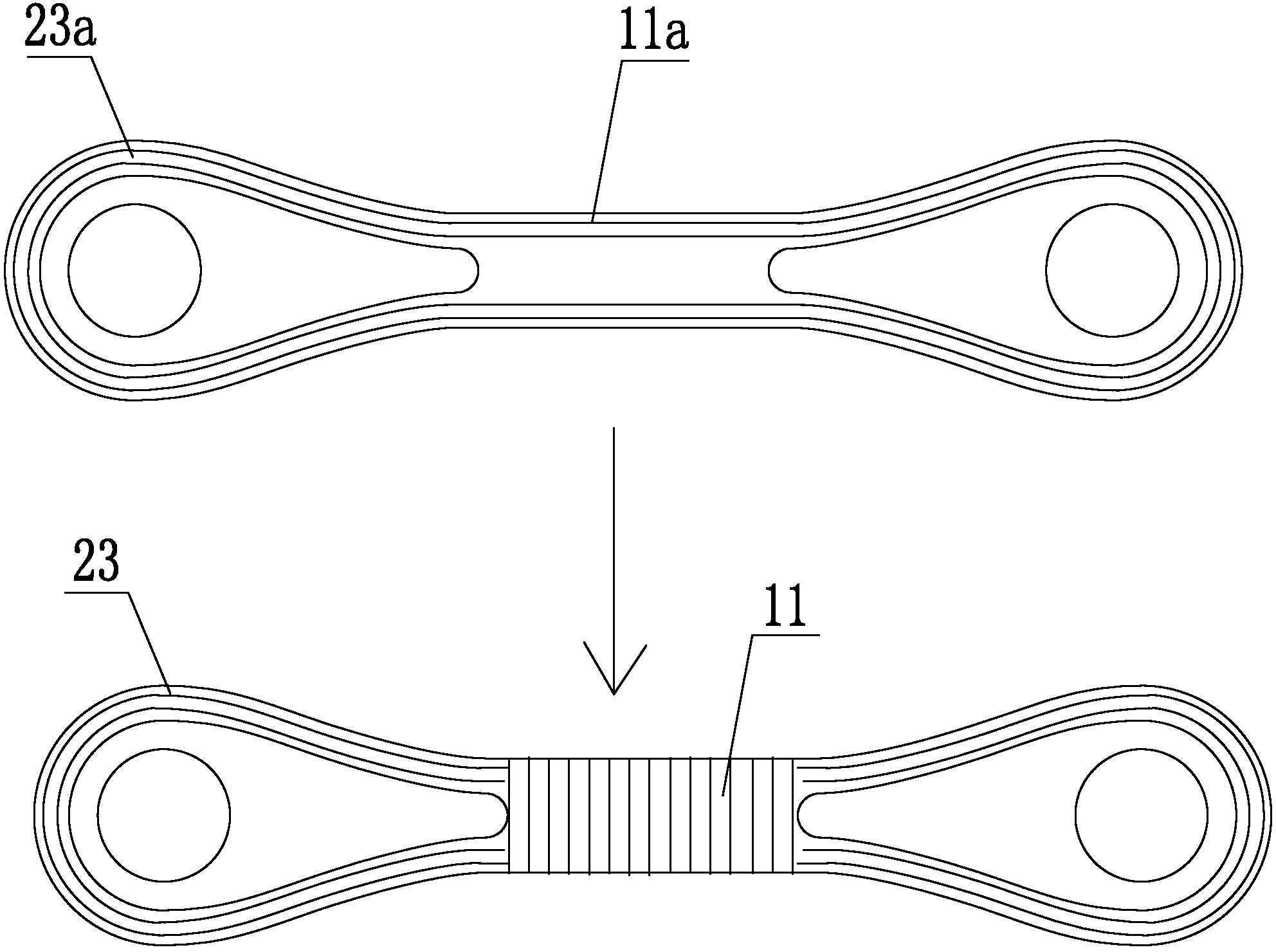

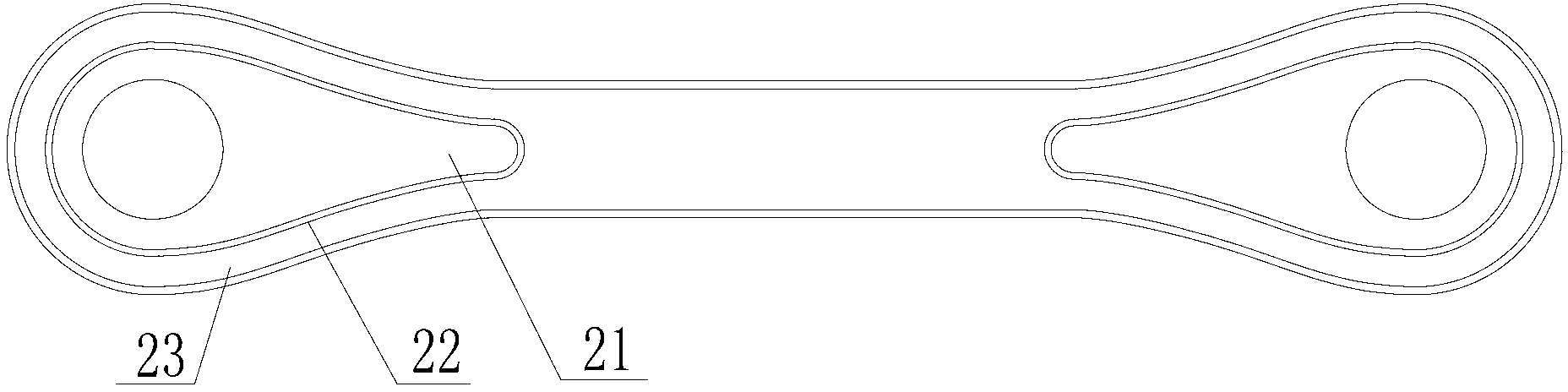

[0041] figure 1 The tension member provided by Embodiment 1 of the present invention is shown, and the tension member includes:

[0042] The middle part 1 includes a carbon fiber composite material body 11 and a first buffer layer 12 coated on the surface of the carbon fiber composite material body 11;

[0043] The connection part 2 provided at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com