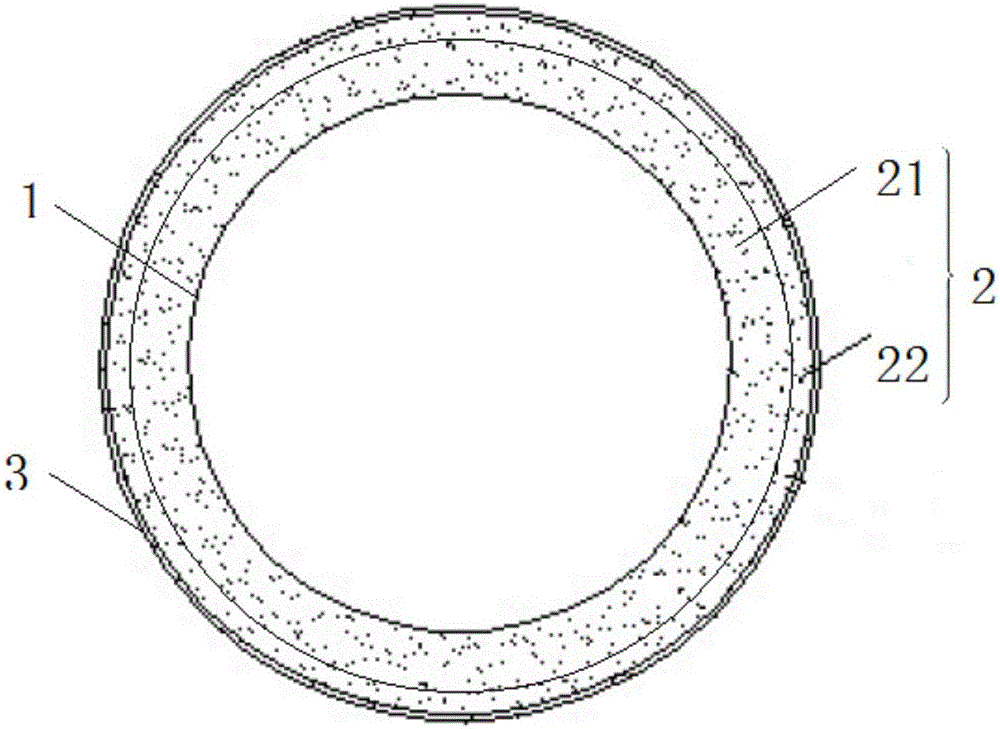

Ultra-large-diameter bamboo winding composite tube and manufacturing method thereof

A super-large diameter, composite pipe technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., to ensure the effect of ensuring resistance to internal pressure, ensuring pipe rigidity, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

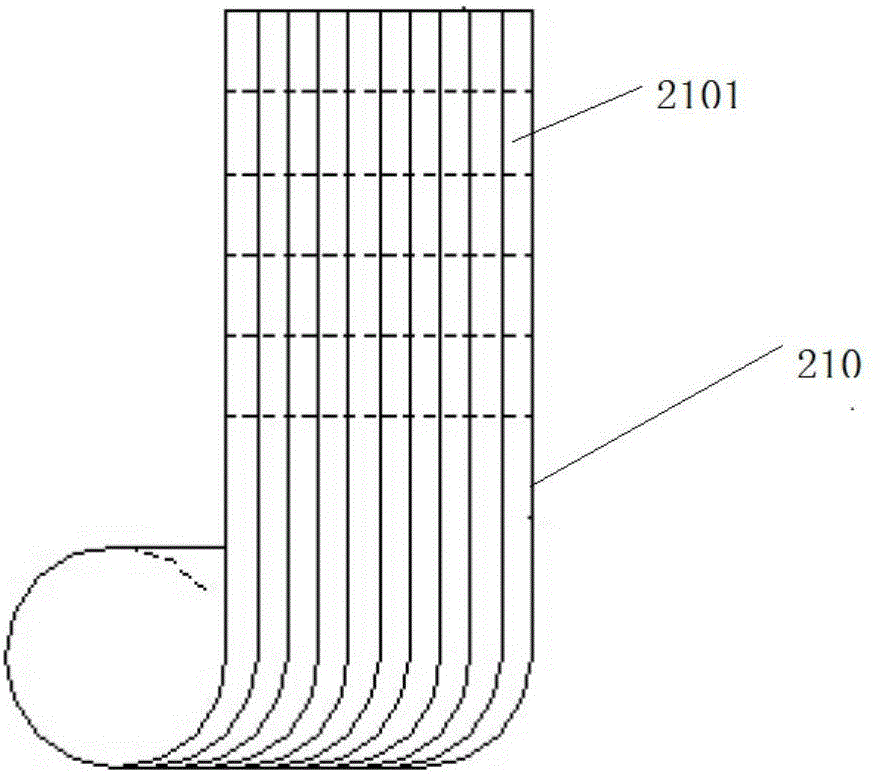

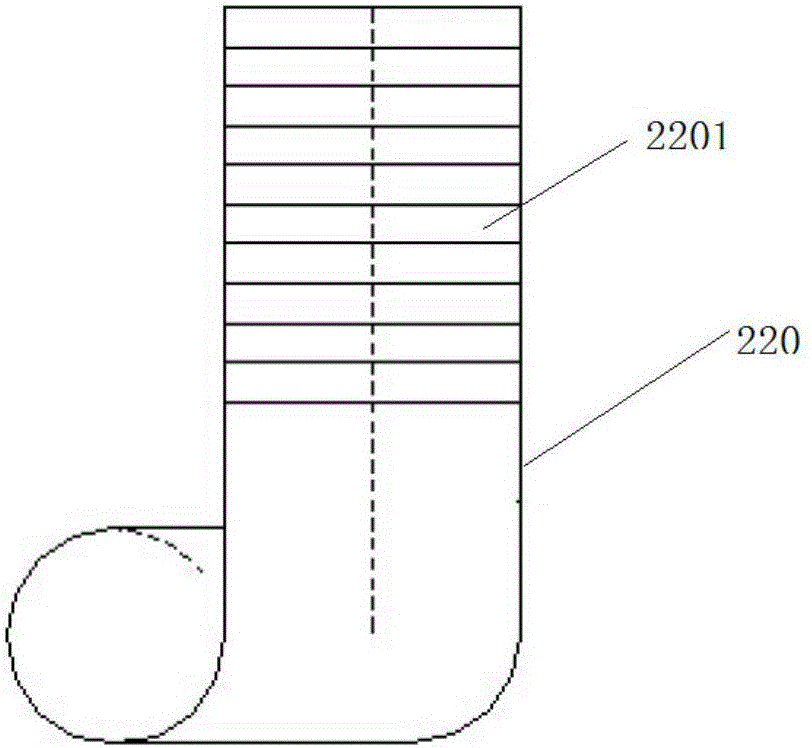

[0045] The bamboo is processed into multiple bamboo strips according to the following two specifications. The size of the first bamboo strip is set to be 1500m in length, 8mm in width, and 0.5mm in thickness. The moisture content can be selected as 10%. The specifications and sizes of the two kinds of bamboo strips are set as 20mm in length, 6mm in width and 1mm in thickness, and the moisture content can be selected as 10%, and then they are treated by degreasing, cleaning and dehydration for later use.

[0046] Then, the above-mentioned first bamboo strips are overlapped one by one along their lengths, and simultaneously arranged in parallel along their width (for example, 6 bamboo strips), finally forming a total length of 150m, a width of about 48mm, and a gap between adjacent bamboo strips. The gap area is 0.09cm 2 In addition, the above-mentioned second bamboo strips are overlapped one by one along the width direction, and the final weaving form has a total length of 150m...

Embodiment 2

[0051] The bamboo is processed into multiple bamboo strips according to the following two specifications. The size of the first bamboo strip is set to be 2000m long, 8mm wide, and 0.5mm thick. The moisture content can be selected as 15%. The specifications and sizes of the two kinds of bamboo strips are set to be 20mm long, 10mm wide, and 0.5mm thick, and the moisture content can be selected as 15%, and then they are degreased, cleaned and dehydrated for later use.

[0052] Then, the above-mentioned first bamboo strips are overlapped one by one along their lengths, and simultaneously arranged in parallel along their width (for example, 6 bamboo strips), finally forming a total length of 150m, a width of about 48mm, and a gap between adjacent bamboo strips. The gap area is 0.12cm 2 In addition, the above-mentioned second bamboo strips are overlapped one by one along the width direction, and the final weaving form has a total length of 150m and a width of 20mm, and the gap area ...

Embodiment 3

[0057] The bamboo is processed into multiple bamboo strips according to the following two specifications. The size of the first bamboo strip is set to be 2500m long, 4mm wide, and 1mm thick. The moisture content can be selected as 15%. The size of the bamboo strips is set as 40mm in length, 4mm in width, and 1mm in thickness, and the moisture content can be selected as 15%, which is then degreased, cleaned and dehydrated for later use.

[0058] Then, the above-mentioned first bamboo strips are overlapped one by one along their lengths, and simultaneously arranged in parallel along their width (for example, 10 bamboo strips), finally forming a total length of 150m, a width of about 40mm, and a gap between adjacent bamboo strips. The gap area is 0.25cm 2 In addition, the above-mentioned second bamboo strips are lapped one by one along the width direction, and the final weaving form has a total length of 150m and a width of 40mm, and the gap area between adjacent bamboo strips is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com