Preparation method and device of high performance polymers pipes

A technology for high-performance polymers and pipes, which is applied in the field of preparation methods and processing devices for realizing the method, can solve the problems of reducing the circumferential strength of pipes, internal stress defects, and different crystallization degrees of materials, and achieves improved performance and reduced internal stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

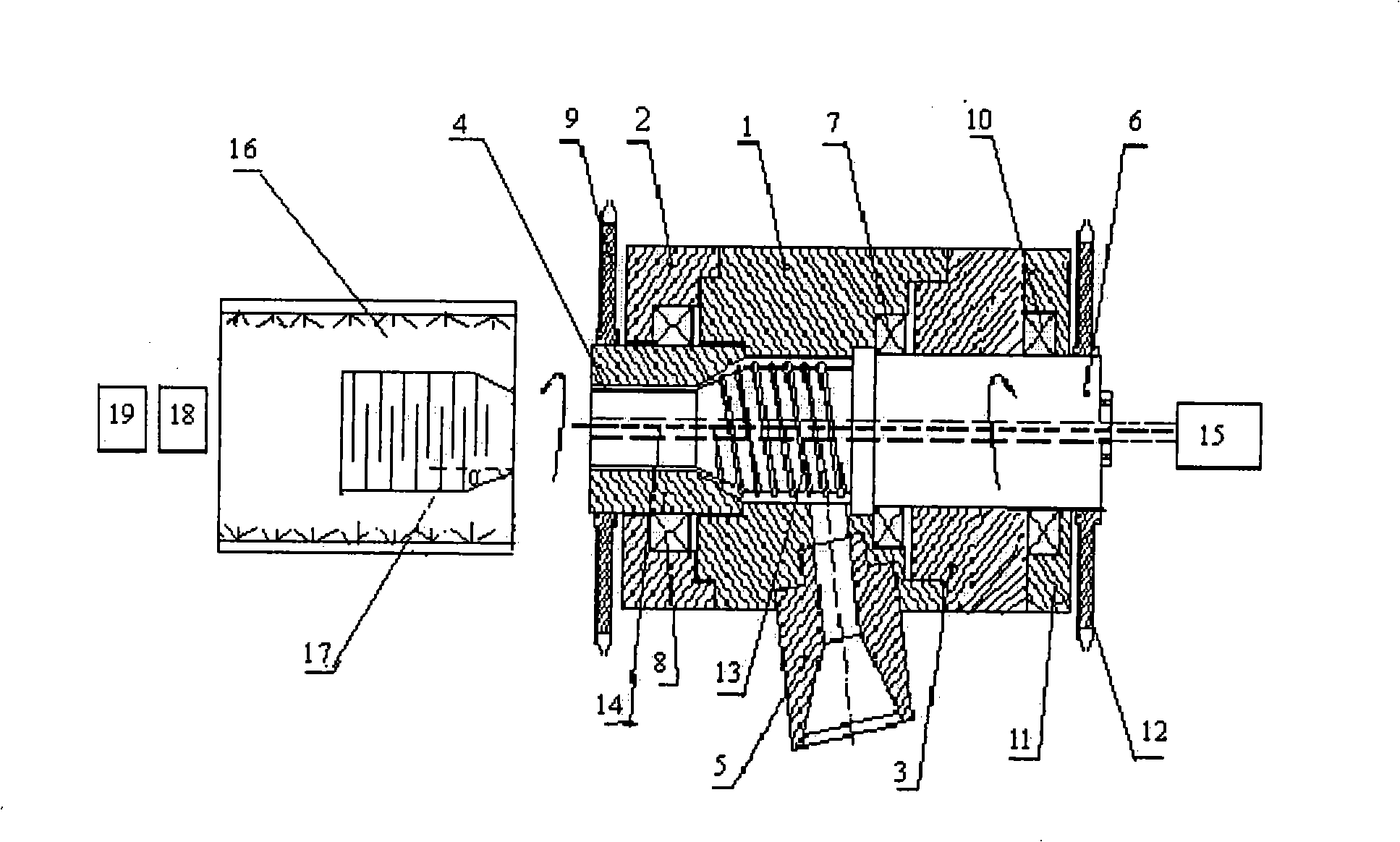

[0030] Such as figure 1 As shown, the device designed by the method of the present invention includes an extruder, a pipe extrusion head, a cooling and setting mechanism 16, a pipe tractor 18, a cutting machine 19, a driving mechanism and a cooling medium delivery mechanism 15 connected in sequence.

[0031] The extruder can adopt single-screw or twin-screw extruder. The pipe extruding head is composed of a head body 1, a front support body 2, a rear support body 3, a pipe extrusion die 4, a lead joint 5, a mandrel 6, bearings 7, 8, 10 and a bearing seat 11, and its outsourcing Covered with a temperature-controlled heating ring. The machine head body 1 is a cavity with two ends open, and a bearing 7 is placed on the stepped step of its rear end, and is fixed therein by the rear support body 3 . The front support body 2 has a stepped through hole in the axial direction, and a bearing 8 is placed in it, and the pipe extrusion die 4 is supported by it, and is connected with the...

Embodiment 2

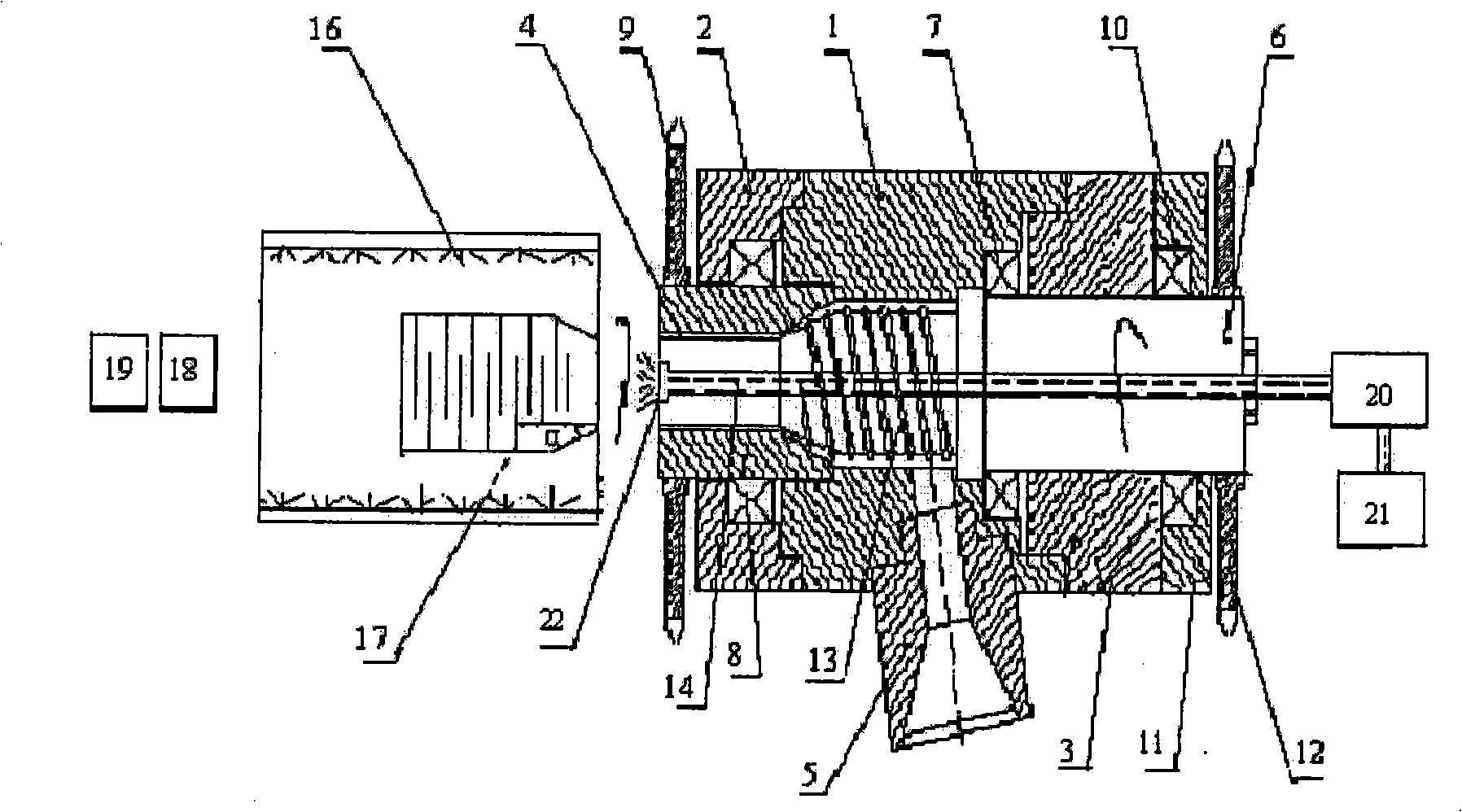

[0034] Such as figure 2 As shown, the device of this embodiment designed by the method of the present invention also includes an extruder, a pipe extrusion head, a cooling and shaping mechanism 16, a pipe tractor 18, a cutting machine 19, a driving mechanism and a cooling medium delivery mechanism 15 connected in sequence.

[0035] Because the cooling medium conveying mechanism 15 in this embodiment is composed of a miniature high-pressure water pump 20, a water storage tank 21 and a nozzle 22, the nozzle 22 is installed on the outlet end of the mandrel cooling medium channel 14 and the sizing sleeve 17 in the cooling and shaping mechanism 16 The opening angle of bell mouth is 5 °, and length is outside the technical characteristic of 30cm, and the shape, structure and connection relation of all other parts are all identical with embodiment 1, so omit and do not describe.

Embodiment 3

[0037] In this embodiment, high-density polyethylene is used as the extruded tube raw material, and figure 1 For the given device, the bell opening angle of the sizing sleeve of the cooling and shaping mechanism is 4°, and the length is 40cm. Vacuum sizing and spraying on the outer wall of the pipe are adopted. The cooling medium channel inside is fed with air at a temperature of 20°C and a pressure of 0.3MPa. The hoop tensile strength of the prepared pipe is 45.6MPa, and the crack growth length of the pipe after 300 hours of environmental stress cracking performance test is 8.9mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hoop tensile strength | aaaaa | aaaaa |

| Hoop tensile strength | aaaaa | aaaaa |

| Hoop tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com