Method for preparing alloy nanoparticle

An alloy nanoparticle and nanoparticle technology, which is applied in the field of preparation of inorganic metal nanomaterials, can solve problems such as inability to achieve mass production, and achieve the effects of excellent stability, controllable components and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

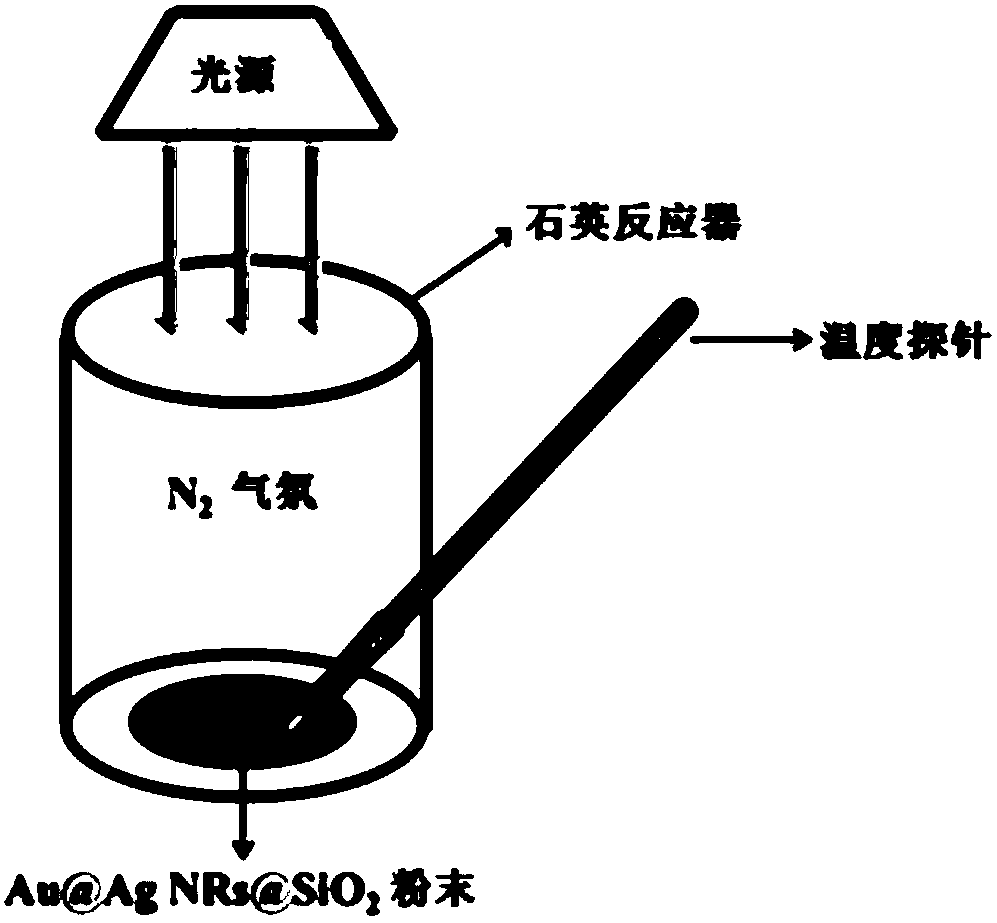

Method used

Image

Examples

Embodiment 1

[0038] Prepare AuAg alloy nanorods, the specific process is as follows:

[0039] 1. The cetyltrimethylammonium bromide of 0.7g, the sodium oleate of 0.124g, the silver nitrate that 1.6mL concentration is 4mmol / L, 0.984mL concentration are the chloroauric acid of 25.4mmol / L and 0.3mL Concentrated hydrochloric acid was added to 50mL of water, and after it was completely dissolved, 0.125mL of ascorbic acid with a concentration of 64mmol / L was added to it, and then 60uL of gold seed solution was added; after standing for 5-6h, the obtained brown liquid was centrifuged to obtain Au nanorods.

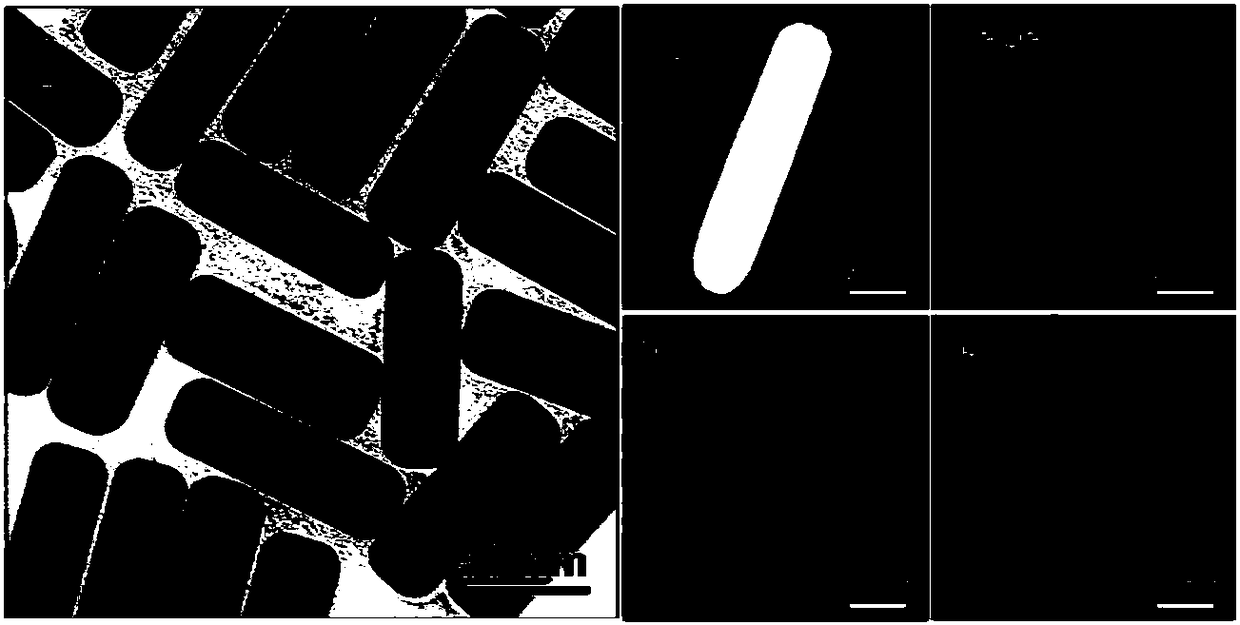

[0040] 2. Disperse the obtained Au nanorods in 30mL of cetyltrimethylammonium chloride solution with a concentration of 80mmol / L, add 1mL of a silver nitrate solution with a concentration of 10mmol / L, and then add 0.5mL of a concentration of 100mmol / L L ascorbic acid. The above solution was placed in a water bath at 65° C. and kept stirring for 3 h. After the reaction was completed, centri...

Embodiment 2

[0045] Prepare AuPd alloy nanorods, the specific process is as follows:

[0046] 1. The cetyltrimethylammonium bromide of 0.7g, the sodium oleate of 0.124g, the silver nitrate that 1.6mL concentration is 4mmol / L, 0.984mL concentration are the chloroauric acid of 25.4mmol / L and 0.3mL Concentrated hydrochloric acid was added to 50mL of water, and after it was completely dissolved, 0.125mL of ascorbic acid with a concentration of 64mmol / L was added to it, and then 60uL of gold seed solution was added; after standing for 5-6h, the obtained brown liquid was centrifuged to obtain Au nanorods.

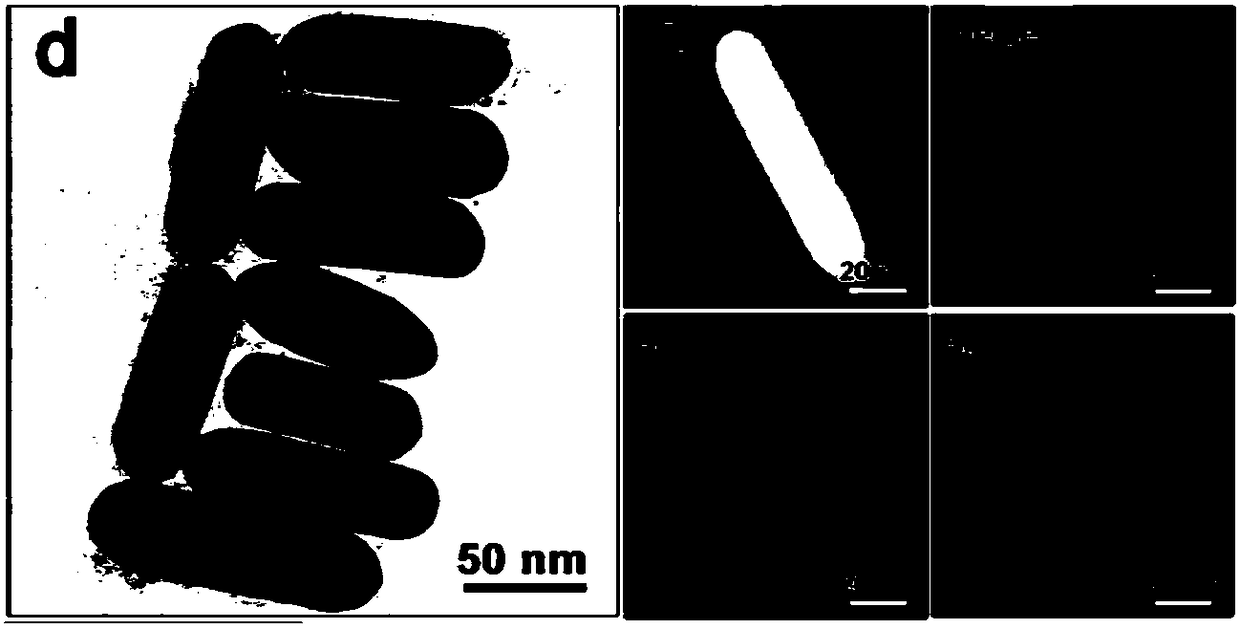

[0047] 2. Disperse the obtained Au nanorods in 50mL of cetyltrimethylammonium bromide solution with a concentration of 100mmol / L, add 100uL of sodium chloropalladate solution with a concentration of 25.4mmol / L, and then add 0.5mL of It is the ascorbic acid of 64mmol / L. The above solution was continuously stirred for 3 h, and after the reaction was completed, it was centrifuged to obtain Au@...

Embodiment 3

[0052] Prepare AuAg alloy nanospheres, the specific process is as follows:

[0053] 1. Heat 60mL of water to boiling, add 3mL of chloroauric acid solution with a concentration of 25.4mmol / L; after boiling again, add 3mL of sodium citrate solution with a mass fraction of 5wt%; after 10min, the reaction stops, wait until the solution temperature After cooling down to room temperature, 4.7 mL of PVP solution (molecular weight = 40000) with a mass concentration of 12.8 g / L was added, stirred for 12 h, and centrifuged to obtain Au nanospheres.

[0054] 2. Disperse the obtained Au nanospheres in 30 mL of PVP solution with a concentration of 80 mmol / L, add 1 mL of silver nitrate solution with a concentration of 10 mmol / L, and then add 0.5 mL of ascorbic acid with a concentration of 100 mmol / L. The above solution was placed in a water bath at 65°C and stirred continuously for 3h. After the reaction is completed, centrifuge to obtain Au@Ag nanospheres with core-shell structure.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com