Magnetic film deposition chamber and film deposition device

A magnetic thin film and deposition cavity technology, applied in the field of microelectronics, can solve the problems of not having induced magnetic thin film anisotropy, unable to use magnetic thin film production equipment, etc., to achieve the effect of in-plane anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the technical solution of the present invention, the magnetic film deposition chamber and film deposition equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

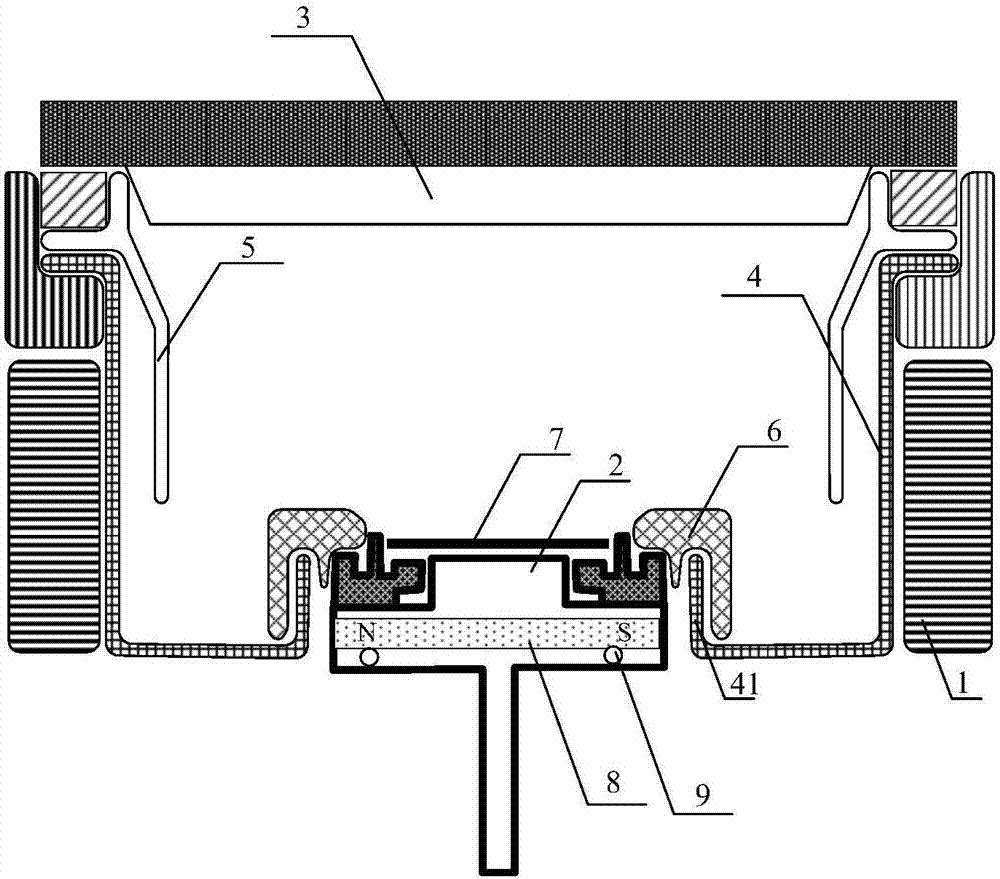

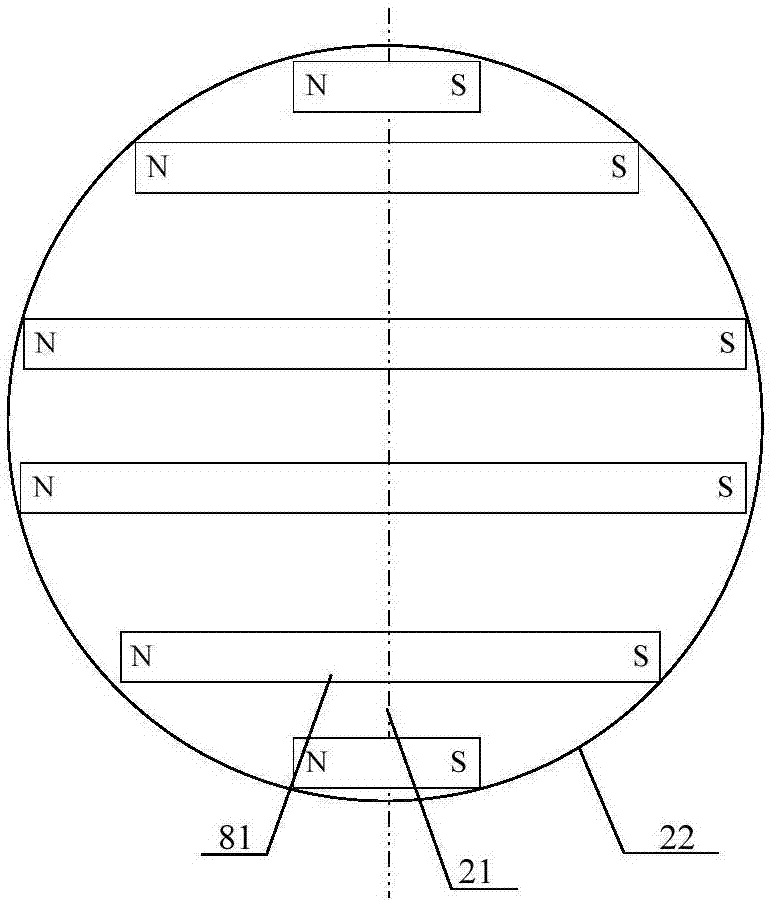

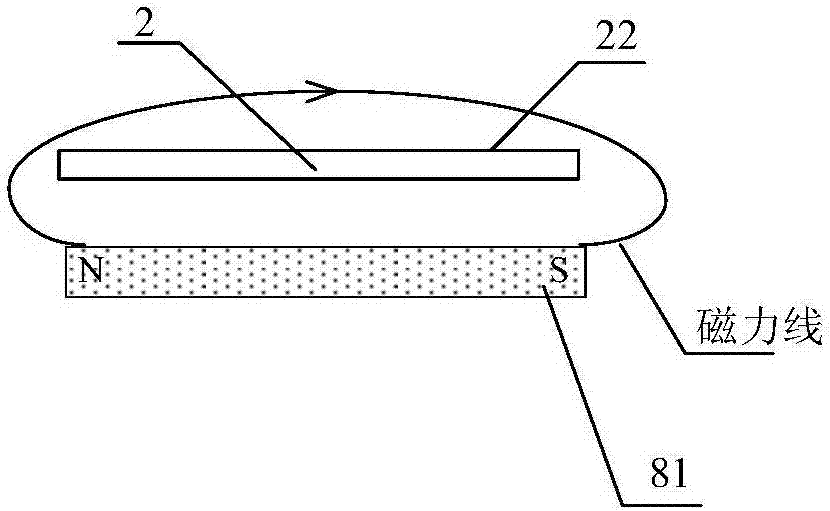

[0046] Please also refer to Figure 1A ~ Figure 1C , the magnetic thin film deposition chamber includes a chamber main body 1 and a shielding assembly, wherein a target 3 is arranged on the top of the chamber main body 1, and in the chamber main body 1 and below the target material 3, a The base 2, the base 2 includes a bearing surface 22 for carrying the workpiece 7 to be processed, the bearing surface 22 is defined to place the workpiece 7 to be processed at a designated position on the base 2, and its shape and size are the same as those of the base 2 The workpiece 7 to be processed has the same shape and size. The above-mentioned shielding assembly includes an upper shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com