Graphene/metal composite material and preparation method thereof

A technology of metal composite materials and graphene, which is applied in the field of composite materials, can solve the problems of easy introduction of impurities, no formation of chemical bonds, unavoidable graphene agglomeration, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

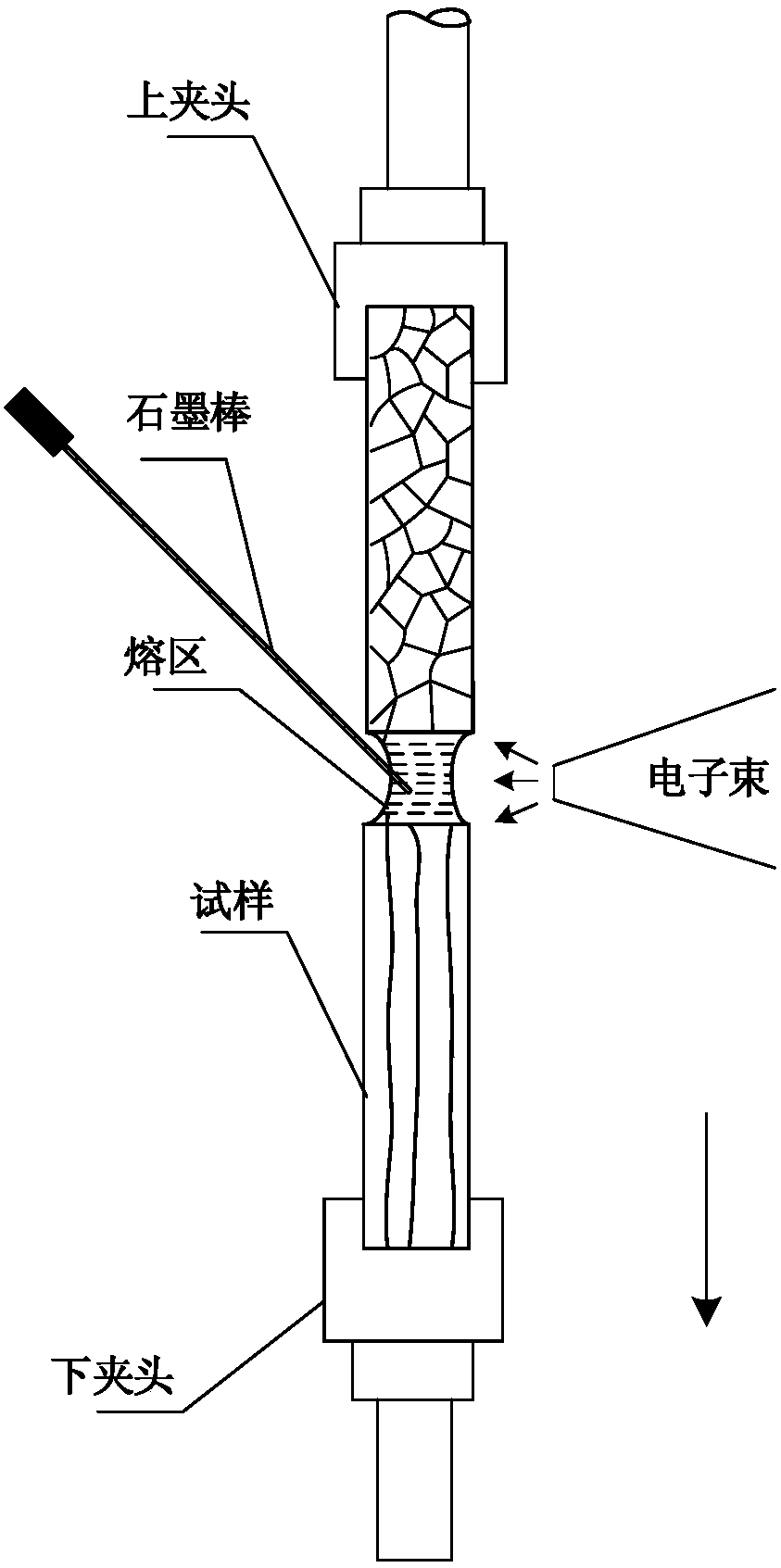

[0029] The graphene / metal composite material of this embodiment is made of the following raw materials in mass percentage: Ag 90%, C 10%. Among them, Ag is a rod material with a purity of 99.99% and a diameter of 5 mm, and the high-purity carbon rod is a graphite rod whose purity meets the requirement of spectral purity, and the diameter of the graphite rod is 1 mm. figure 1 Shown is the schematic diagram of preparing graphene / silver composite material by melting directional solidification method in the electron beam suspension zone of this embodiment, as figure 1 As shown, the specific preparation method of the present embodiment is:

[0030] (1) be 90% according to the mass percent of silver rod and graphite rod: take silver rod and graphite rod in the ratio of 10%;

[0031] (2) Place the weighed silver rod and graphite rod in an acetone solution for ultrasonic cleaning to remove surface impurities and pollutants, and dry them after cleaning. Then, the two ends of the silv...

Embodiment 2

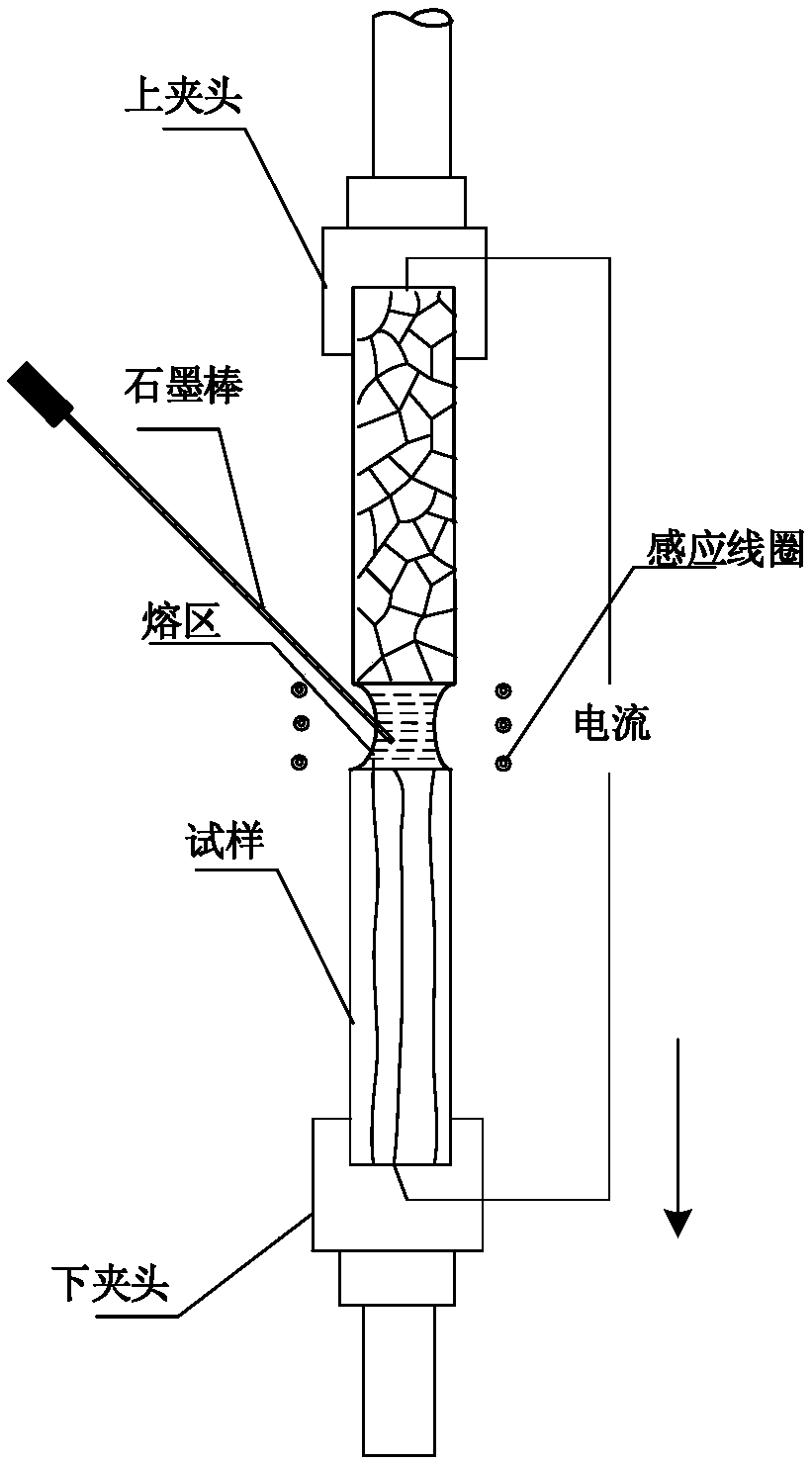

[0036] The graphene / metal composite material of this embodiment is made of the following raw materials in mass percentage: Ag 85%, C 15%. Among them, Ag has a purity of 99.99% and is in the shape of a rod with a diameter of 5 mm. The high-purity carbon rod is a graphite rod whose purity meets the requirement of spectral purity, and the diameter of the graphite rod is 1 mm. figure 2 The schematic diagram of preparing graphene / silver composite material by melting and directional solidification in the induction heating suspension zone provided by the embodiment of the present invention, as figure 2Shown, the concrete preparation method of this graphene / silver composite material is:

[0037] (1) intercept the long above-mentioned silver rod of 20cm, take its quality, then be 85% according to the mass percentage of above-mentioned silver rod and above-mentioned graphite rod: 15% take graphite rod;

[0038] (2) Place the weighed silver rod and graphite rod in an acetone solution ...

Embodiment 3

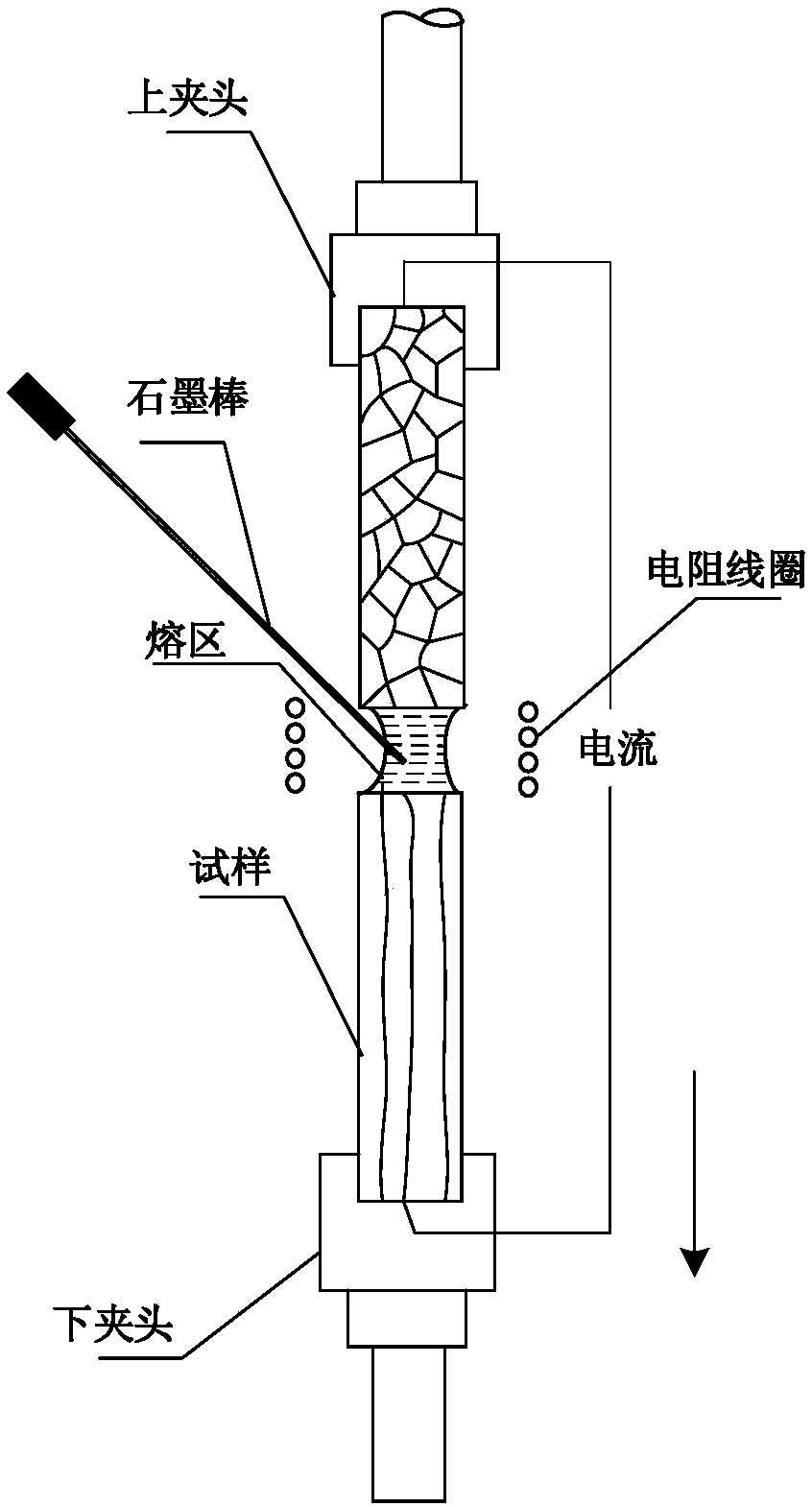

[0043] The graphene / metal composite material of this embodiment is made of the following raw materials in mass percentage: Ag 70%, C 30%. Among them, Ag has a purity of 99.99% and is in the shape of a rod with a diameter of 5 mm. The high-purity carbon rod is a graphite rod whose purity meets the requirement of spectral purity, and the diameter of the graphite rod is 1 mm. image 3 The schematic diagram of preparing graphene / silver composite material by melting and directional solidification in the resistance heating suspension zone provided by the embodiment of the present invention, as image 3 Shown, the concrete preparation method of this graphene / silver composite material is:

[0044] (1) intercept the long above-mentioned silver rod of 20cm, take its quality, then be 70%: 30% take graphite rod according to the mass percentage of above-mentioned silver rod and above-mentioned graphite rod;

[0045] (2) Place the weighed silver rod and graphite rod in an acetone solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com