Patents

Literature

108 results about "Boron phosphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron phosphide (BP) (also referred to as boron monophosphide, to distinguish it from boron subphosphide, B₁₂P₂) is a chemical compound of boron and phosphorus. It is a semiconductor.

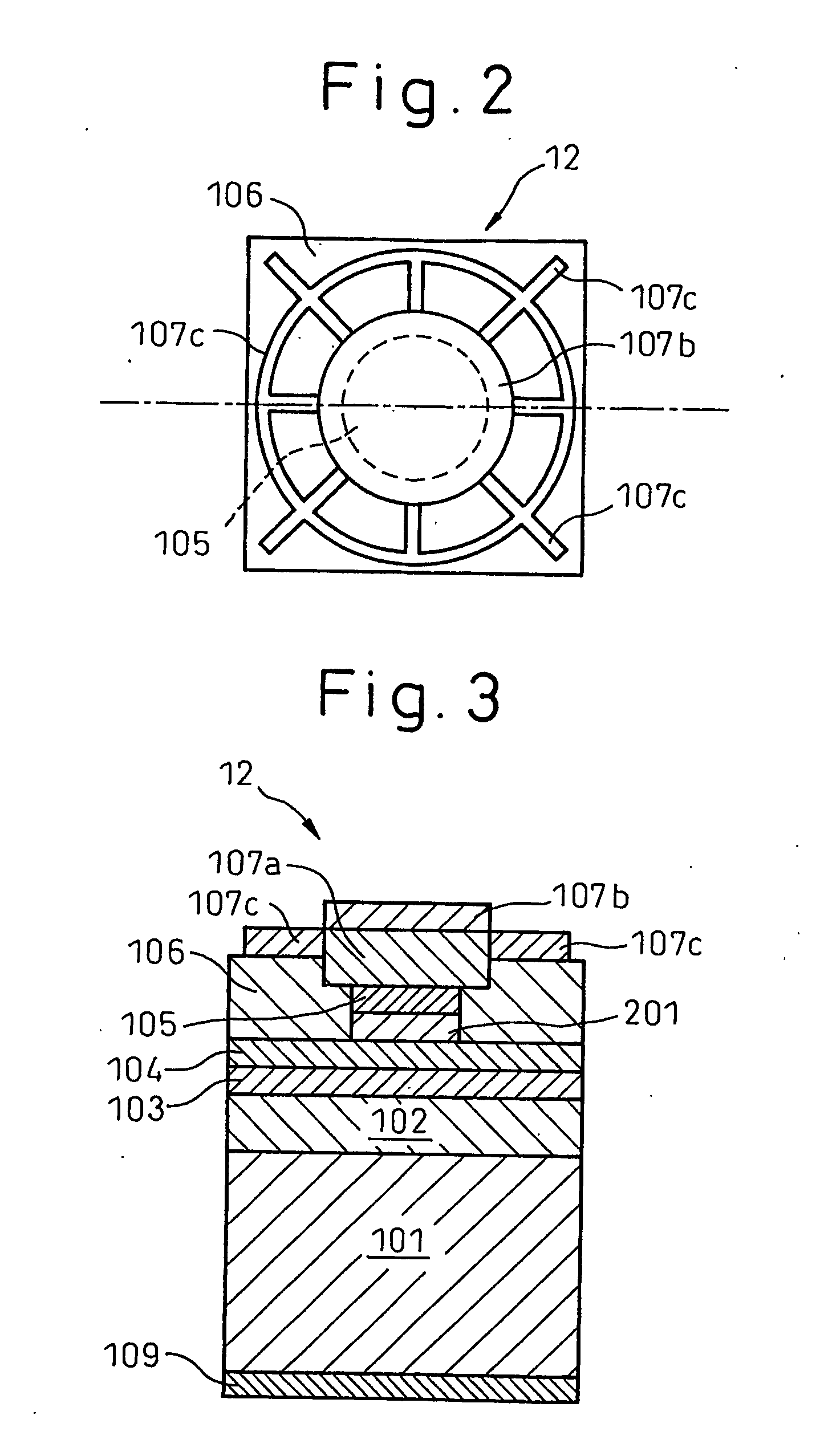

Group-III nitride semiconductor light-emitting diode, light-emitting diode lamp, light source, electrode for group-III nitride semiconductor light-emitting diode, and method for producing the electrode

InactiveUS20020000563A1Easy to displayHigh luminous intensitySemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentLight emission

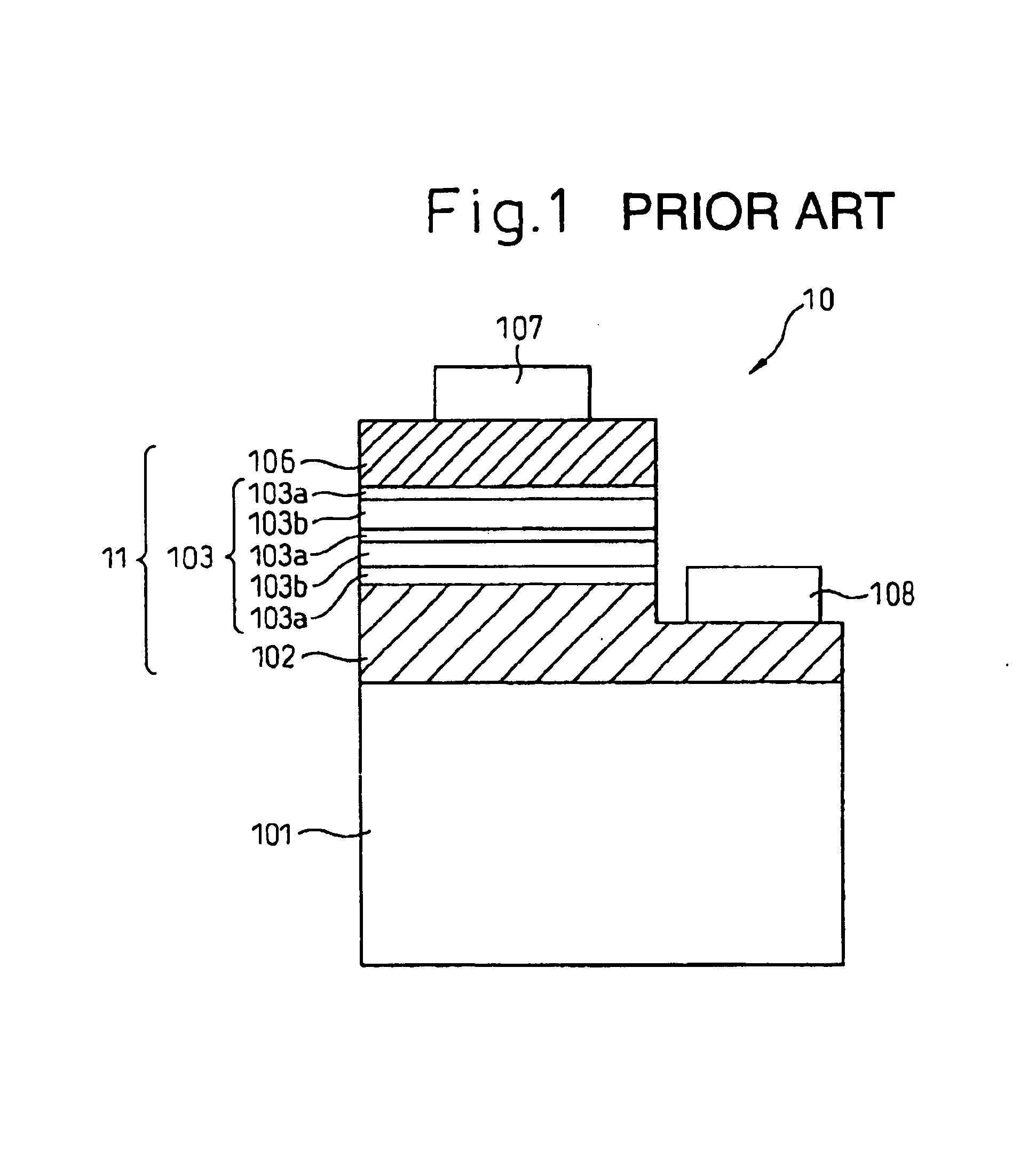

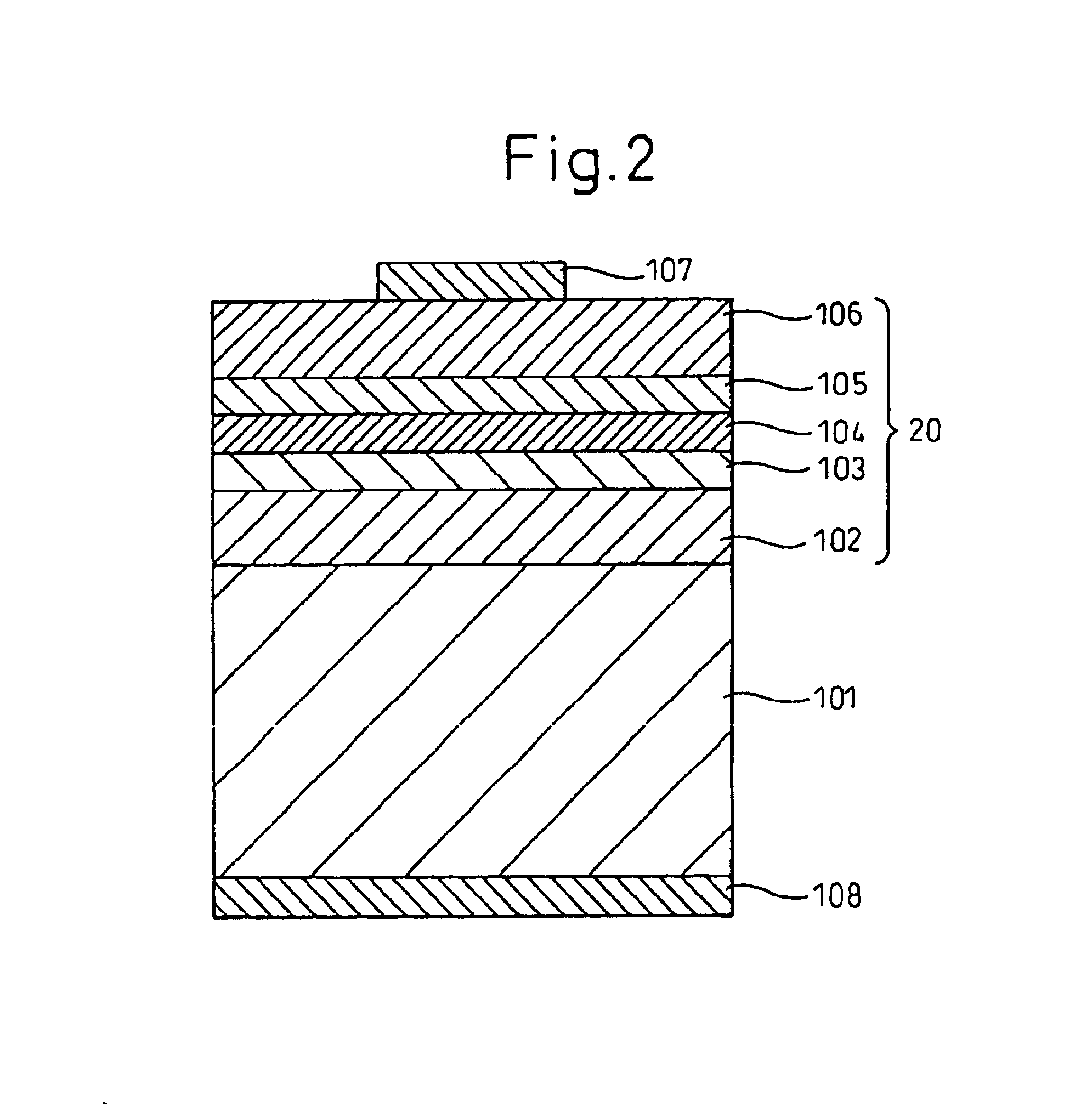

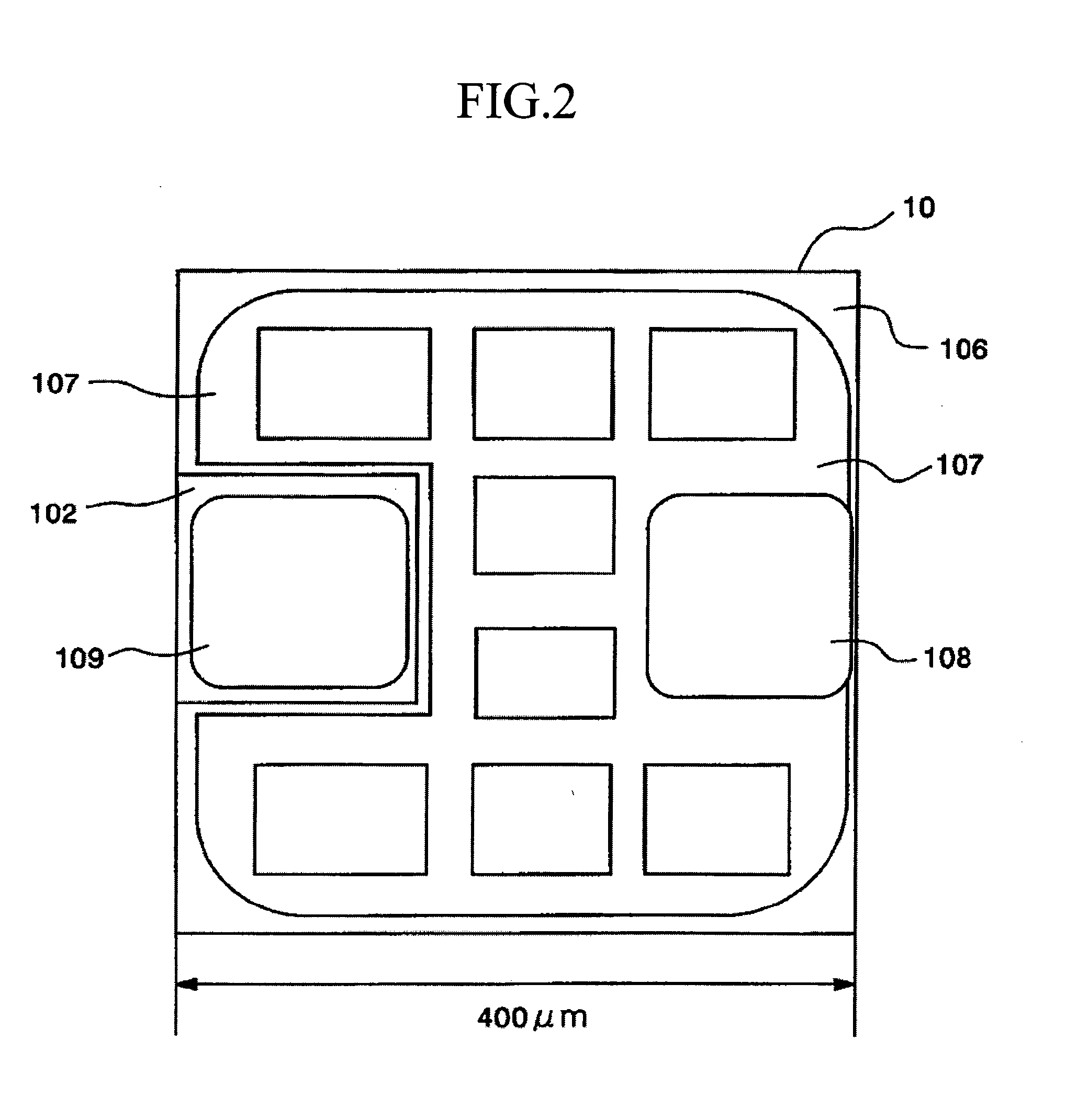

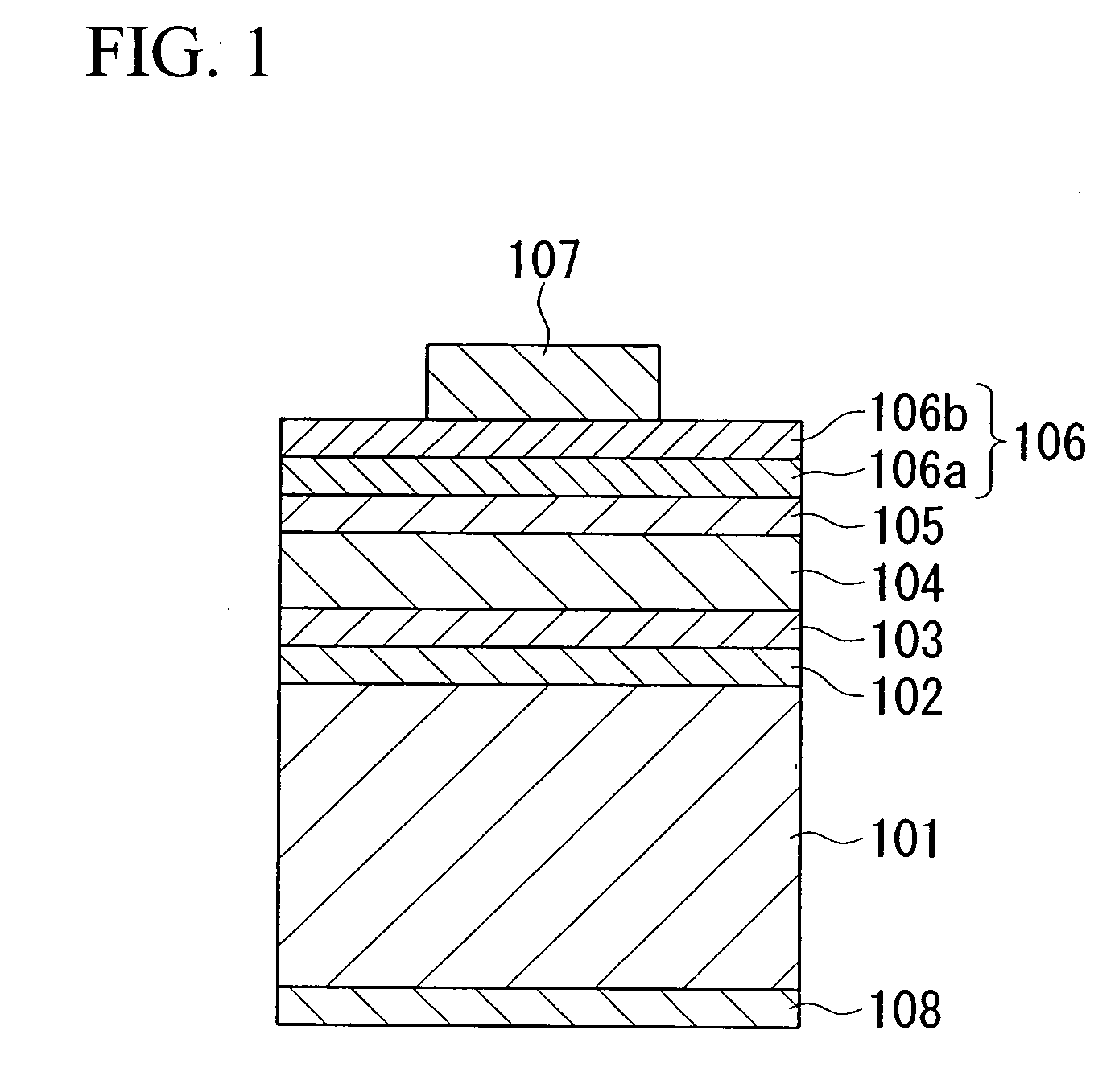

The present invention solves the problem of conventional group-III nitride semiconductor LED in that, since the LED driving current is supplied only from a pad electrode serving also as an ohmic electrode, the driving current cannot diffuse over a wide range of the light-emitting region and a group-III nitride semiconductor LED having high light emission intensity cannot be successfully provided. A group-III nitride semiconductor LED having high light emission intensity, which is fabricated using a stacked layer structure obtained by providing a surface ohmic electrode, a window layer including an electrically conducting transparent oxide crystal layer and a pad electrode on an electrically conducting substrate through a boron phosphide (BP)-based buffer layer to allow the driving current to diffuse over a wide range of the light-emitting region is provided.

Owner:SHOWA DENKO KK

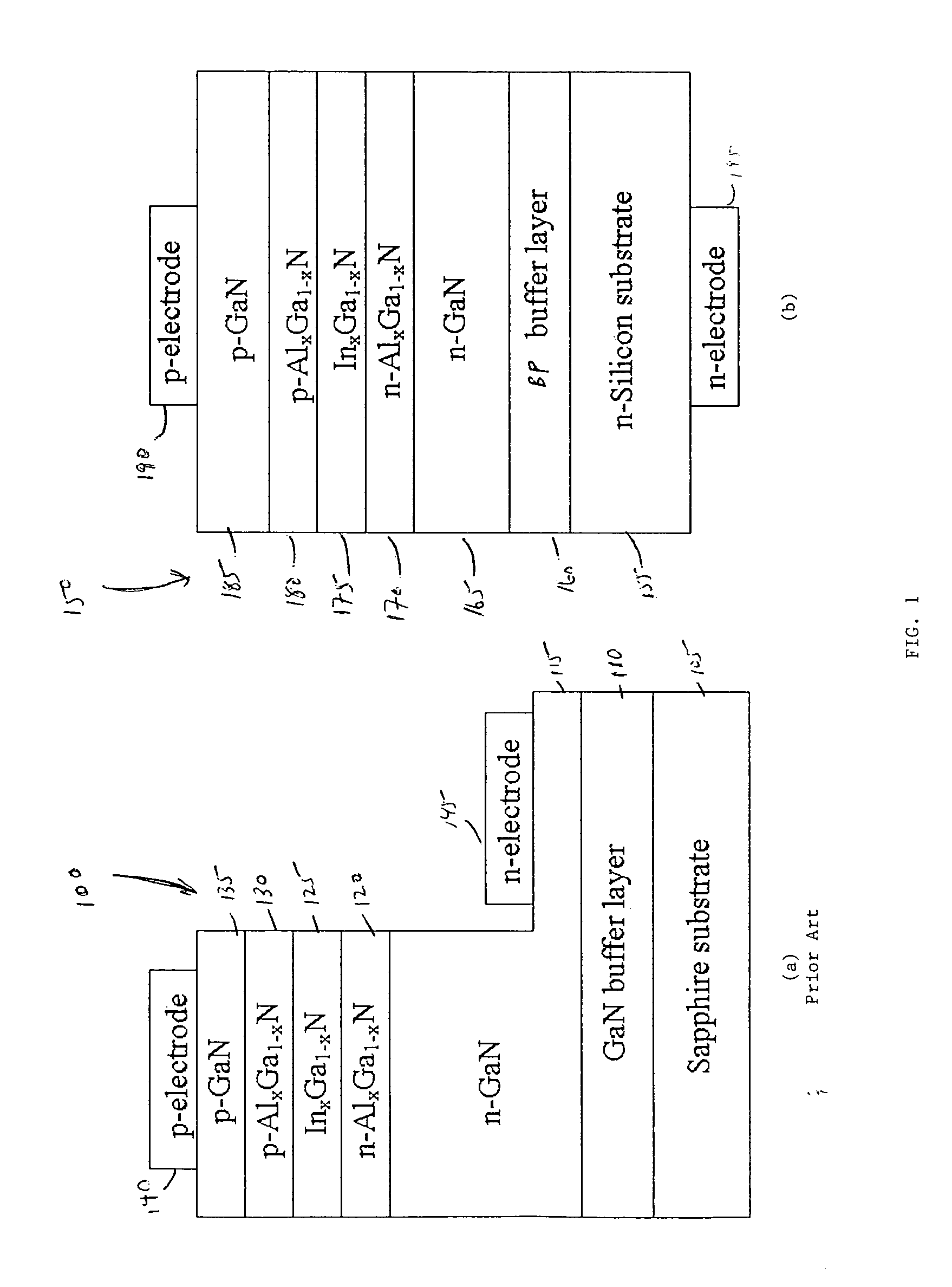

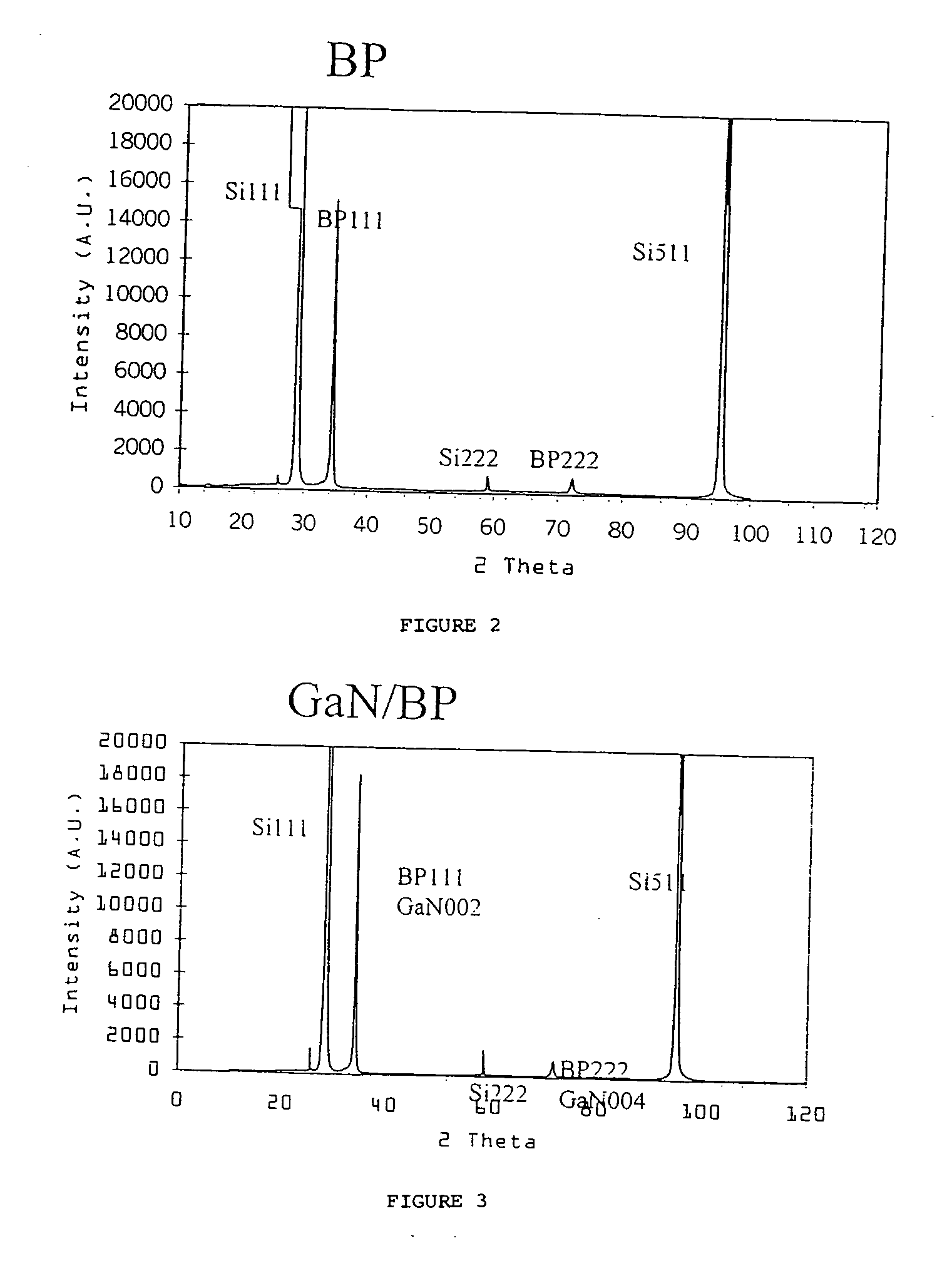

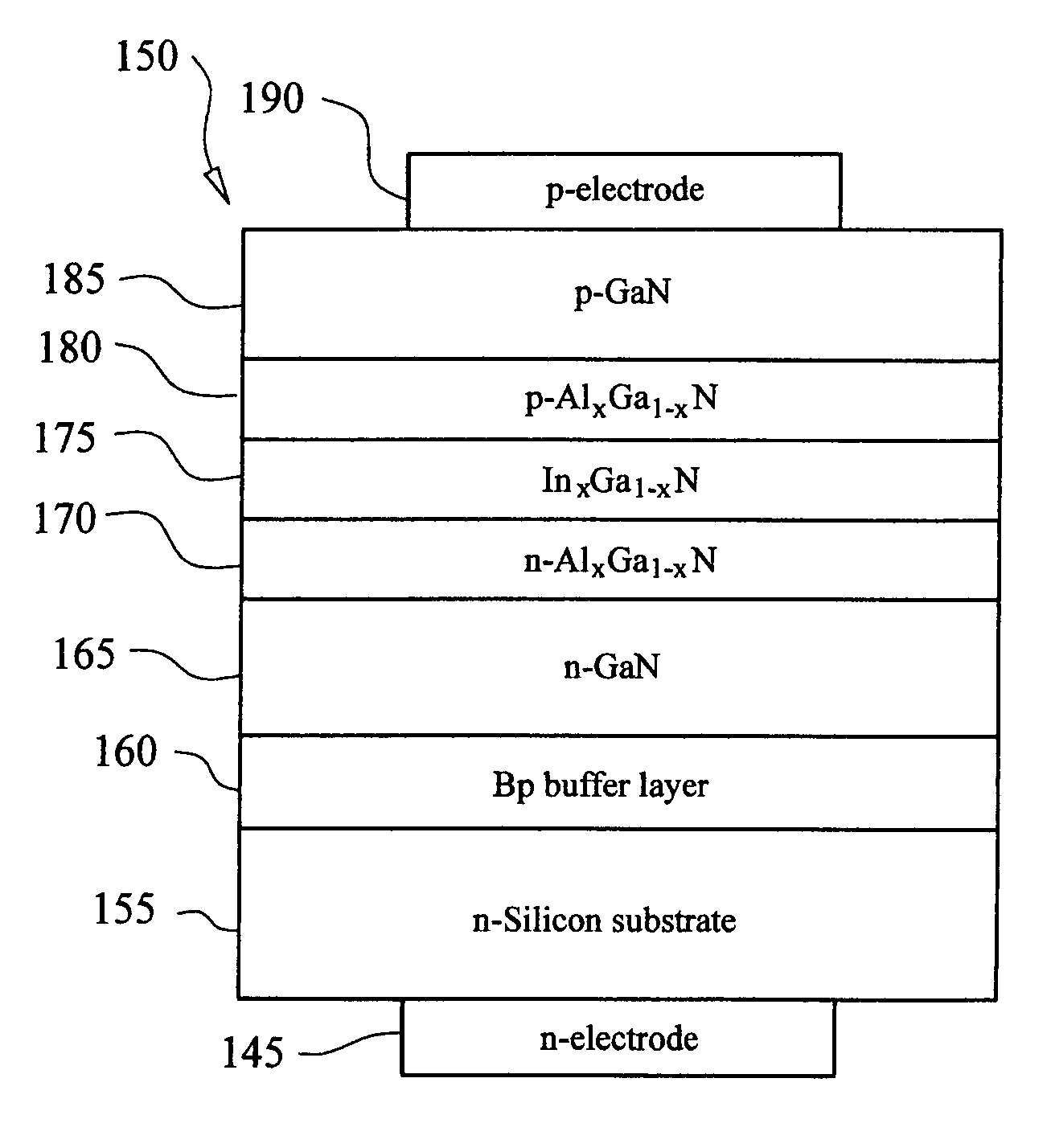

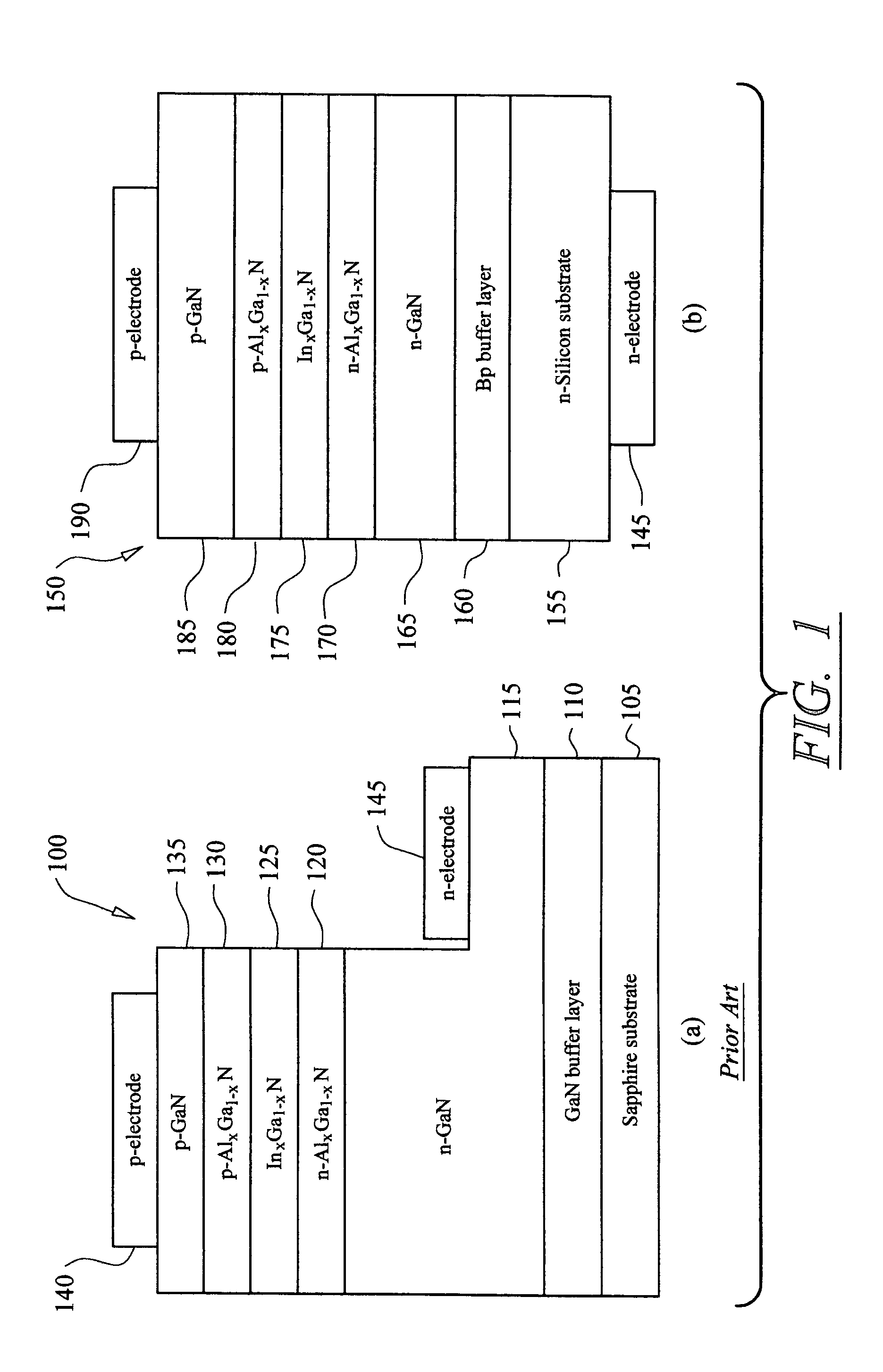

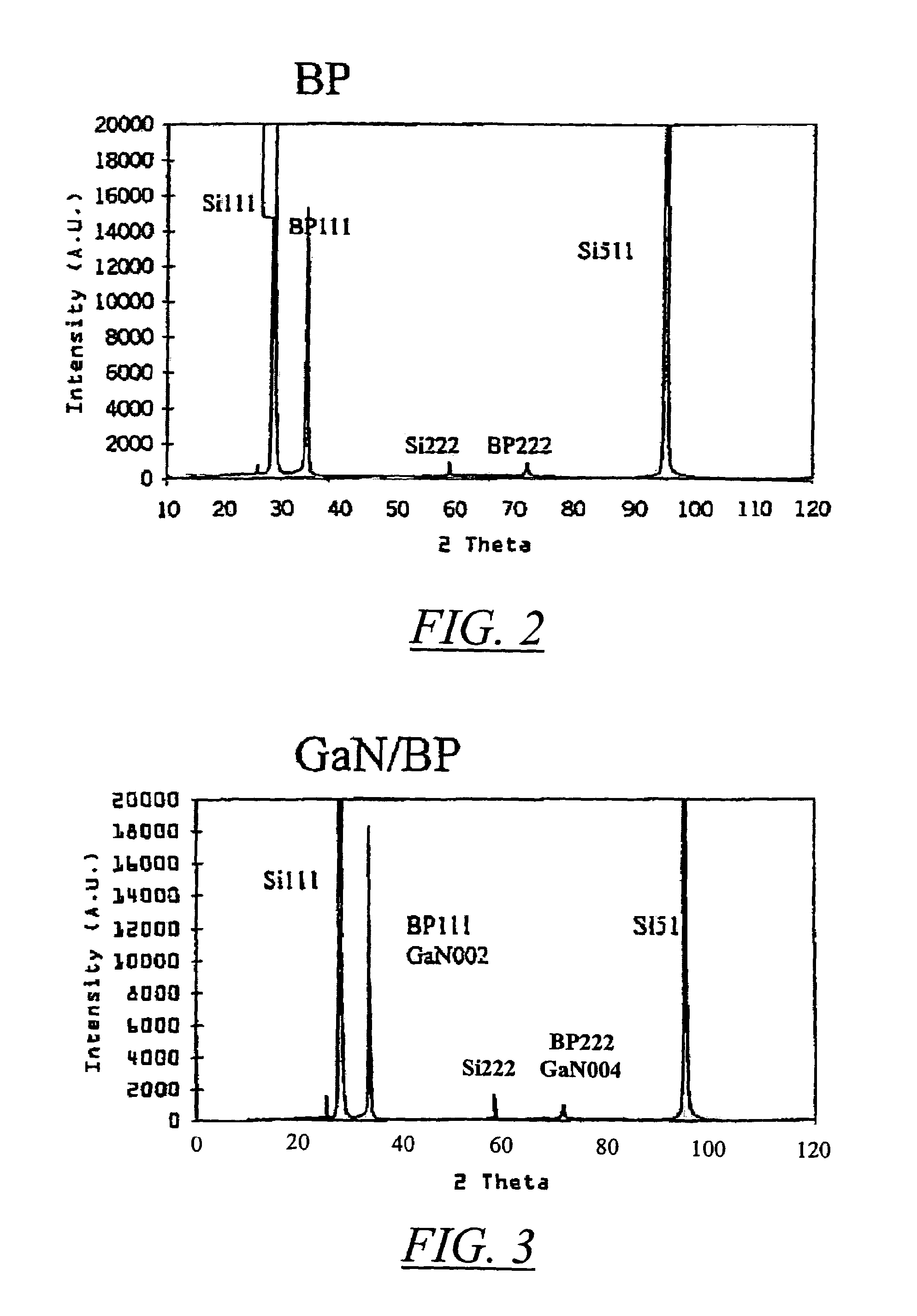

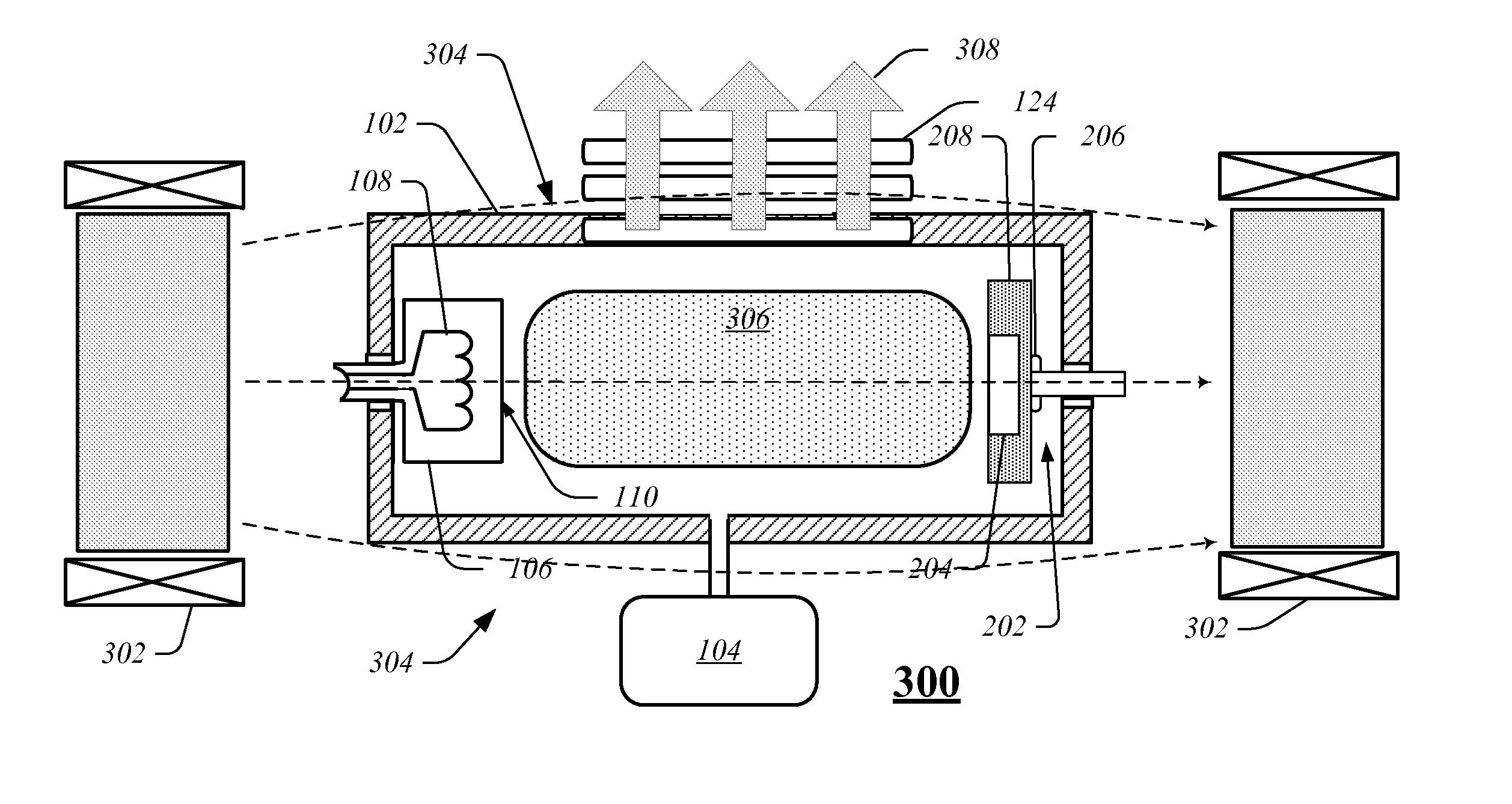

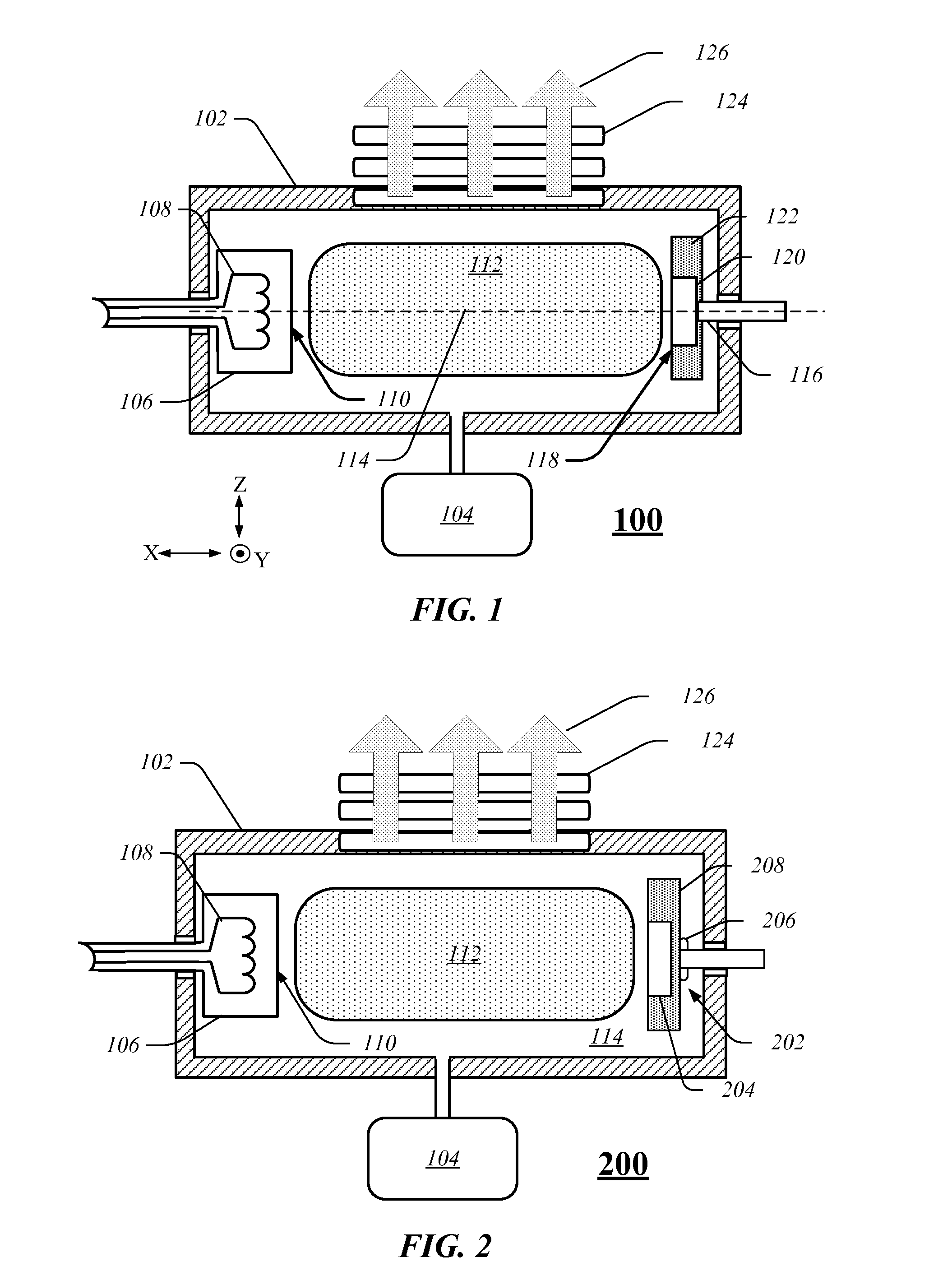

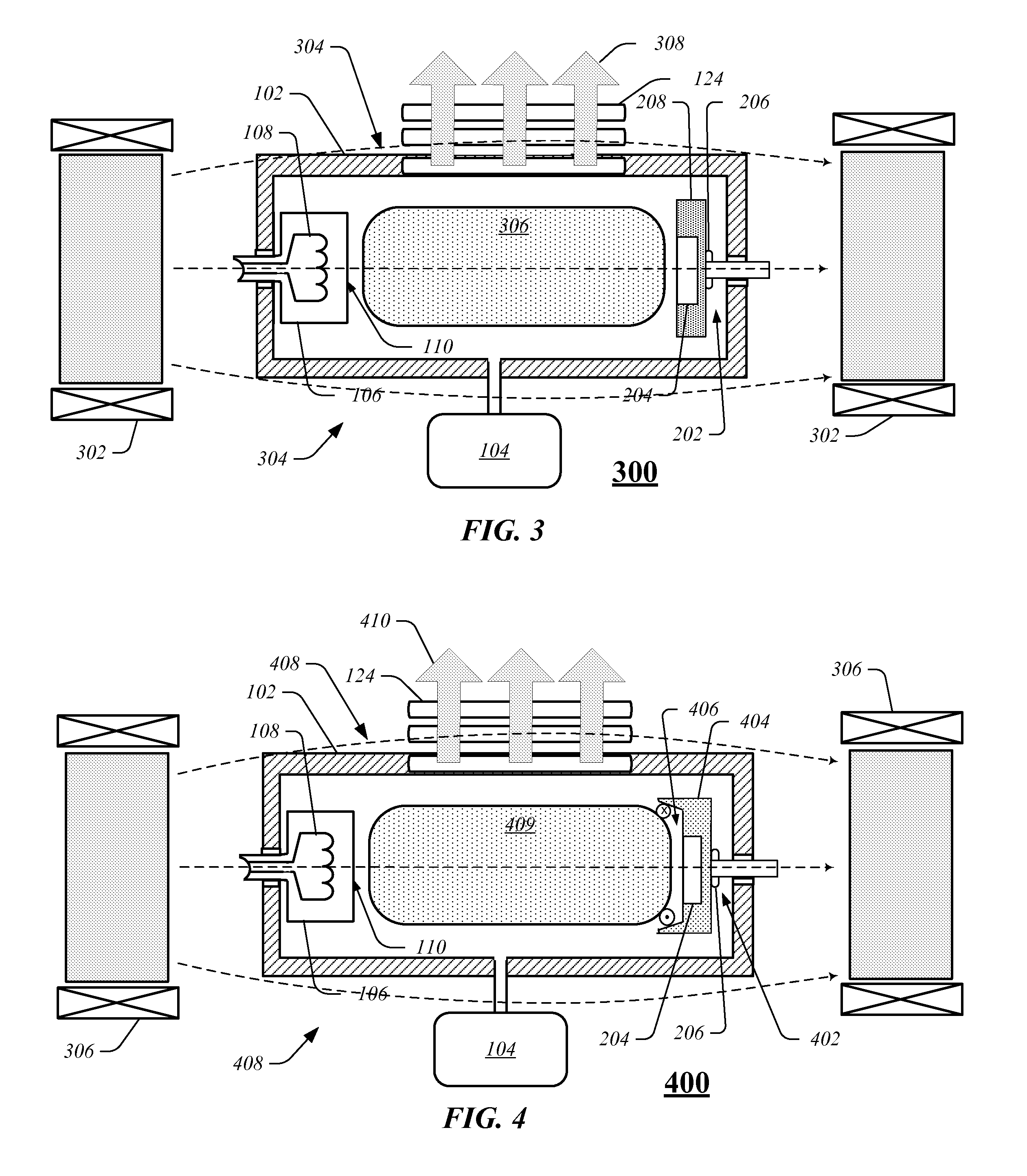

Group III-nitride on Si using epitaxial BP buffer layer

InactiveUS20050087746A1Solid-state devicesSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A semiconductor device and method for forming the same includes a silicon (111) single crystal substrate, and an epitaxial boron phosphide (BP) layer disposed on the substrate. A group III-nitride semiconductor epitaxial layer is disposed on the BP epitaxial layer.

Owner:FLORIDA UNIV OF A FLORIDA +1

Group III-nitride on Si using epitaxial BP buffer layer

InactiveUS6967355B2Solid-state devicesSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A semiconductor device and method for forming the same includes a silicon (111) single crystal substrate, and an epitaxial boron phosphide (BP) layer disposed on the substrate. A group III-nitride semiconductor epitaxial layer is disposed on the BP epitaxial layer.

Owner:FLORIDA UNIV OF A FLORIDA +1

Lifetime ion source

InactiveUS20150034837A1Improve performanceMaterial analysis by optical meansIon beam tubesGas phaseAluminum phosphide

An ion source includes an ion source chamber, a gas source to provide a fluorine-containing gas species to the ion source chamber and a cathode disposed in the ion source chamber configured to emit electrons to generate a plasma within the ion source chamber. The ion source chamber and cathode are comprised of a refractory metal. A phosphide insert is disposed within the ion source chamber and presents an exposed surface area that is configured to generate gas phase phosphorous species when the plasma is present in the ion source chamber, wherein the phosphide component is one of boron phosphide, tungsten phosphide, aluminum phosphide, nickel phosphide, calcium phosphide and indium phosphide.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Boron phosphide-based semiconductor light-emitting device, production method thereof and light-emitting diode

InactiveUS6936863B2Reduced stabilityHinders provisionSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystal substrateLight emitting device

A boron phosphide-based semiconductor light-emitting device, which device includes a light-emitting member having a hetero-junction structure in which an n-type lower cladding layer formed of an n-type compound semiconductor, an n-type light-emitting layer formed of an n-type Group III nitride semiconductor, and a p-type upper cladding layer provided on the light-emitting layer and formed of a p-type boron phosphide-based semiconductor are sequentially provided on a surface of a conductive or high-resistive single-crystal substrate and which device includes a p-type Ohmic electrode provided so as to achieve contact with the p-type upper cladding layer, characterized in that a amorphous layer formed of boron phosphide-based semiconductor is disposed between the p-type upper cladding layer and the n-type light-emitting layer. This boron phosphide-based semiconductor light-emitting device exhibits a low forward voltage or threshold value and has excellent reverse breakdown voltage characteristics.

Owner:SHOWA DENKO KK

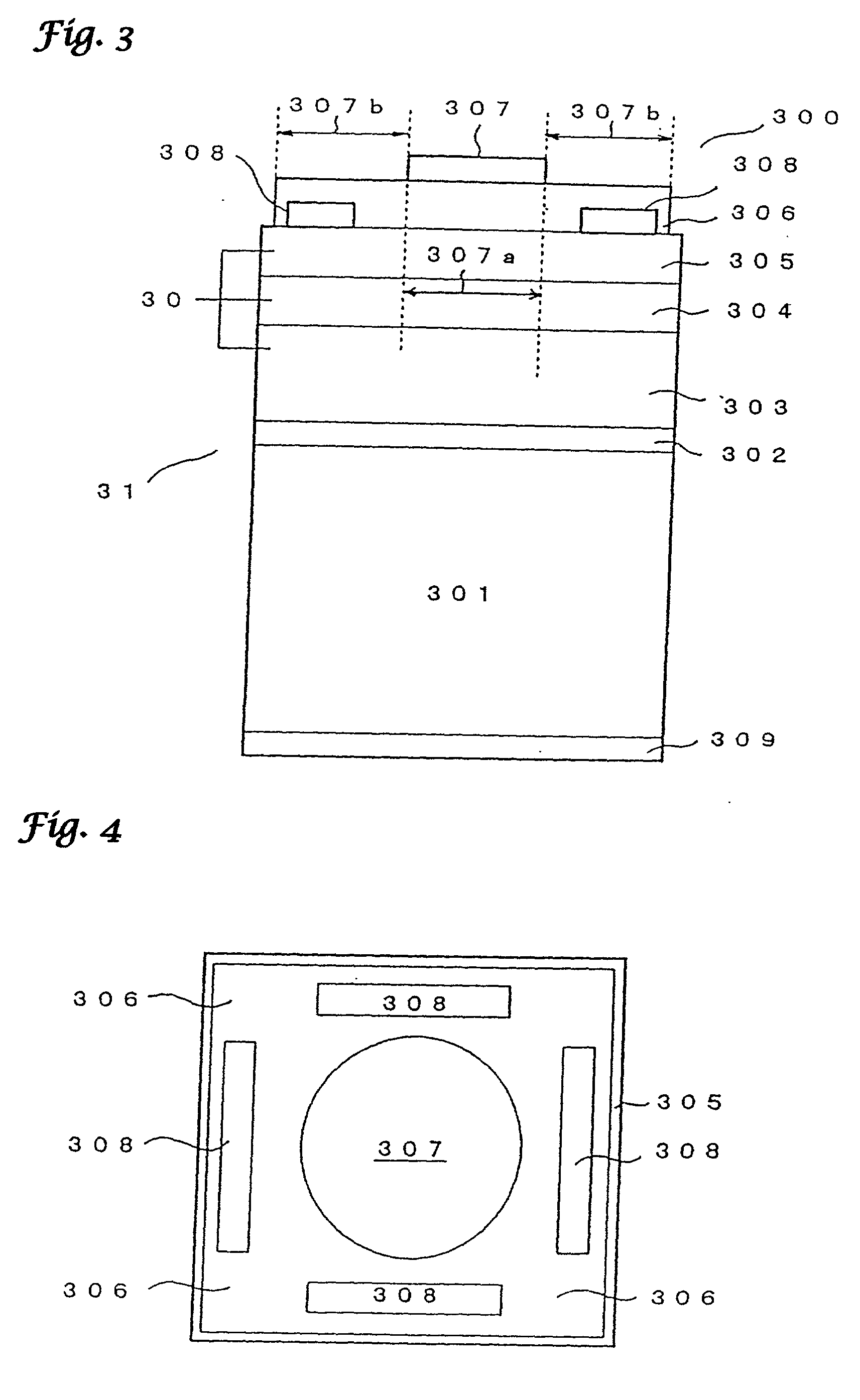

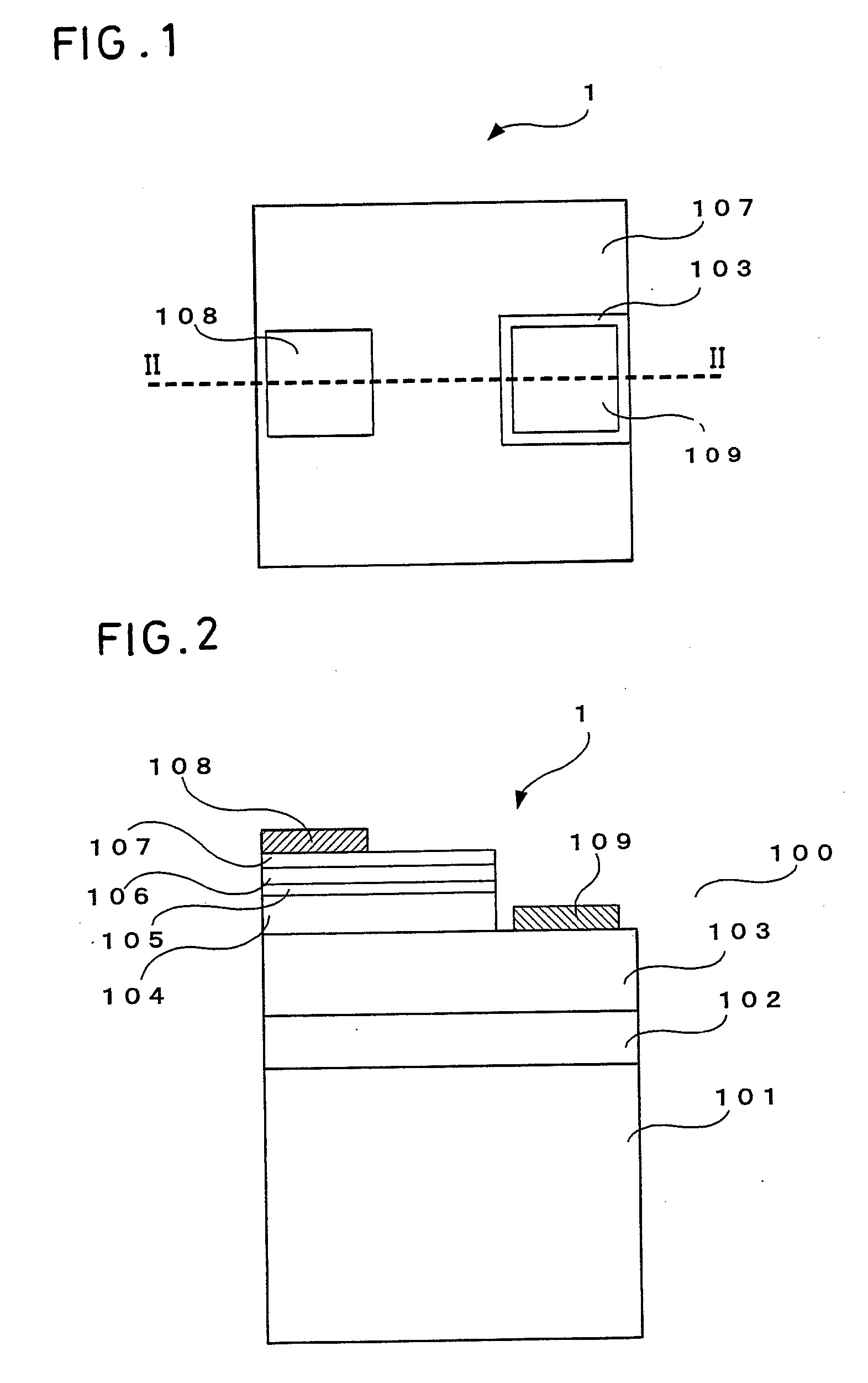

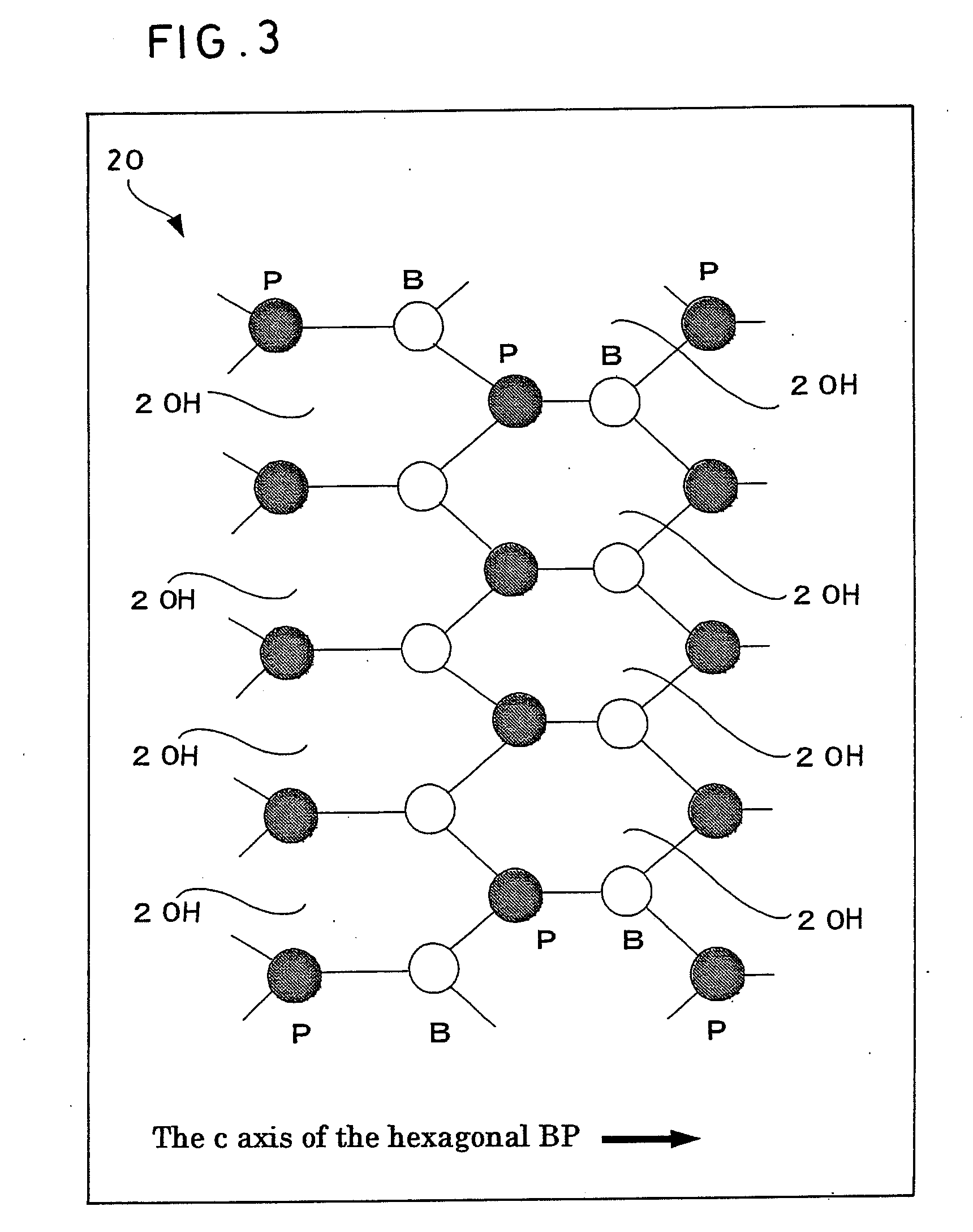

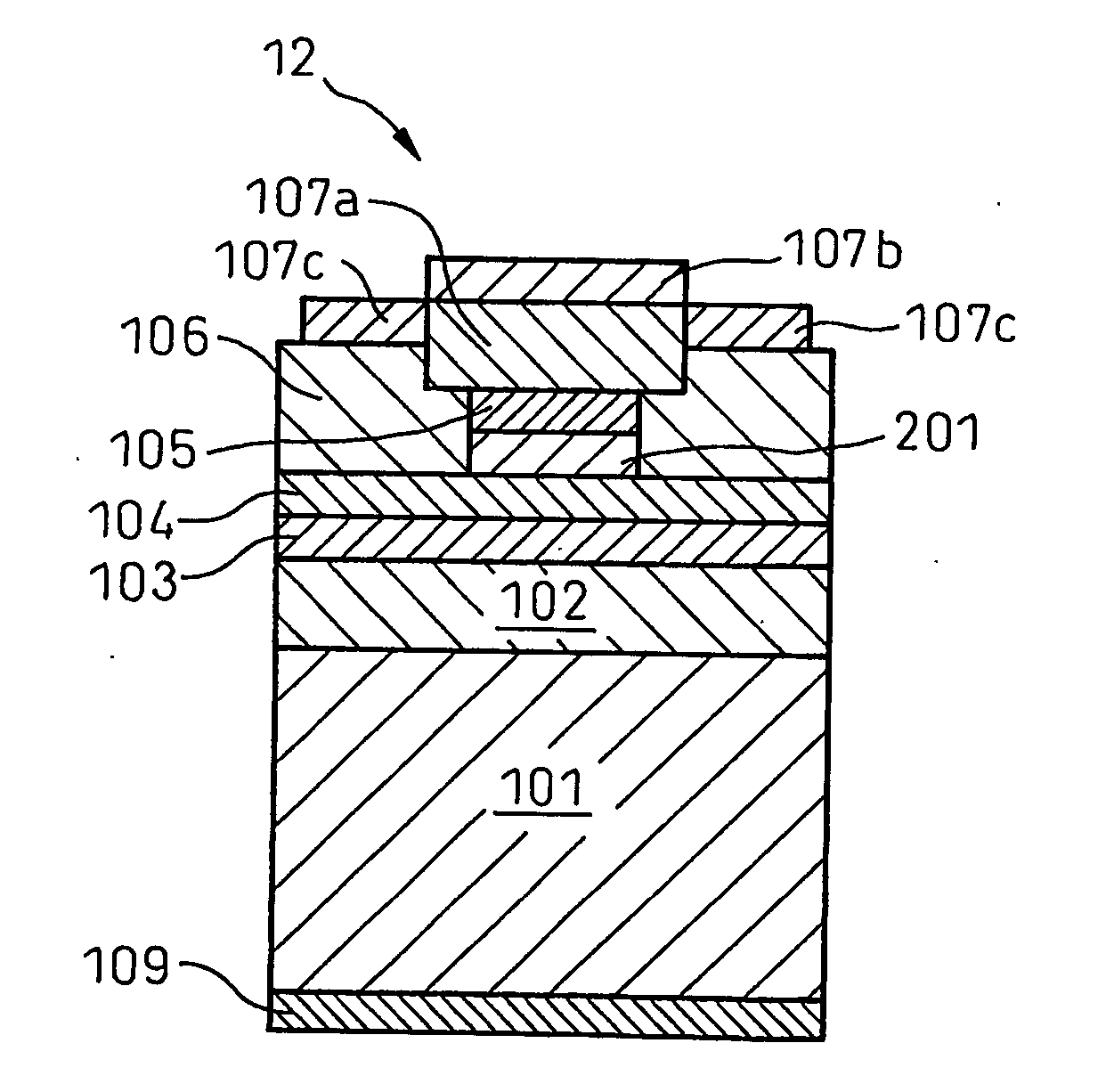

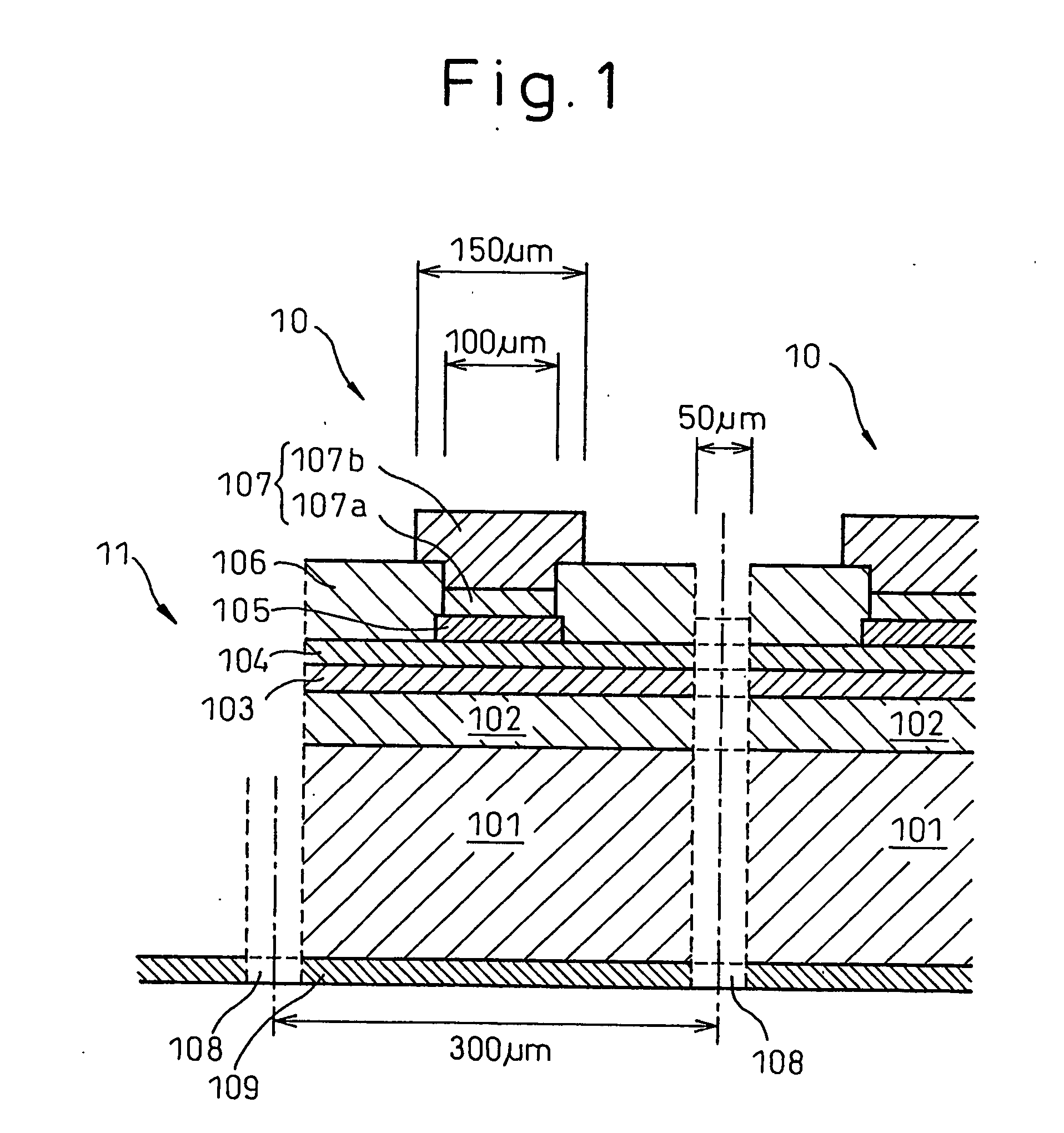

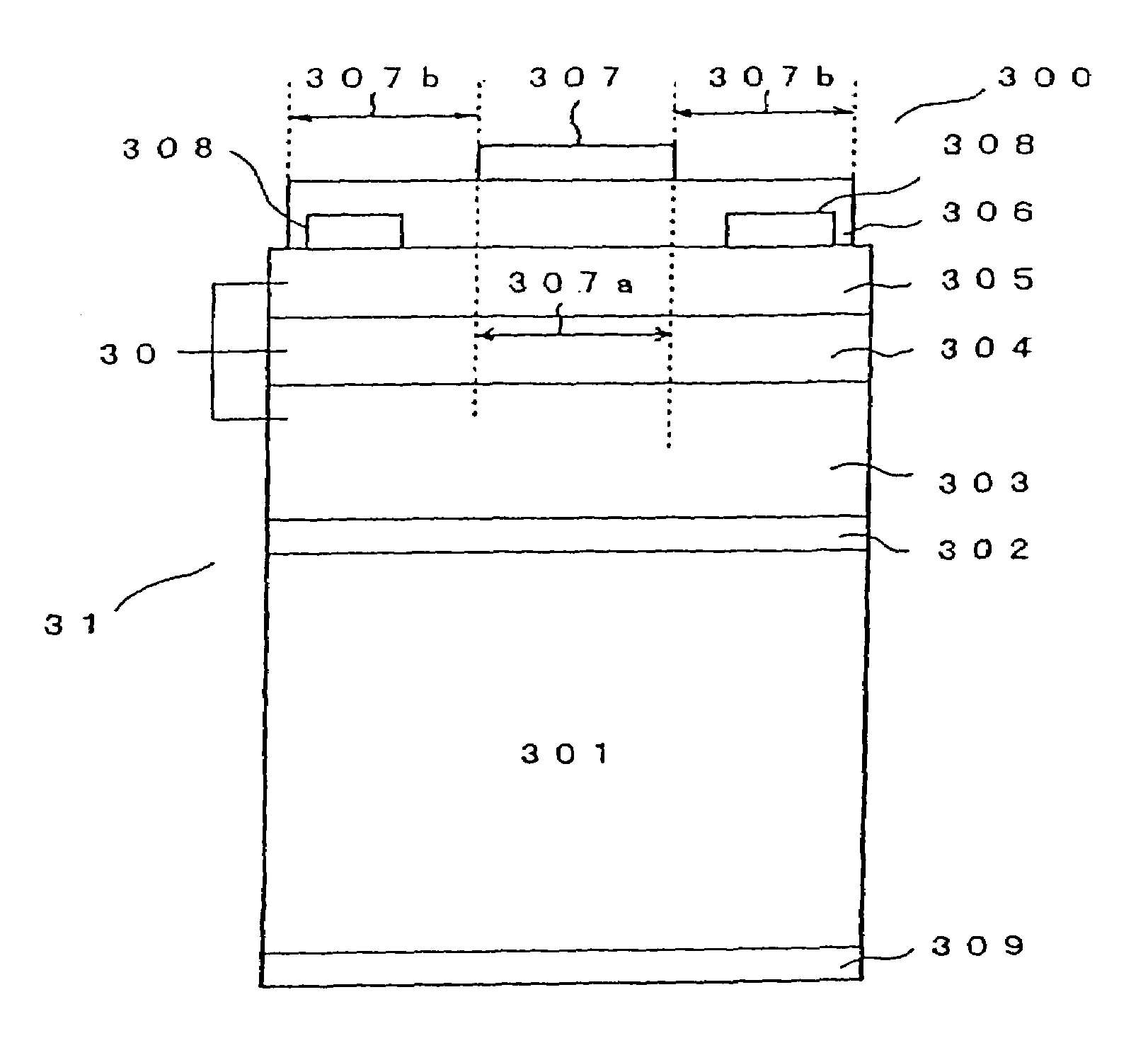

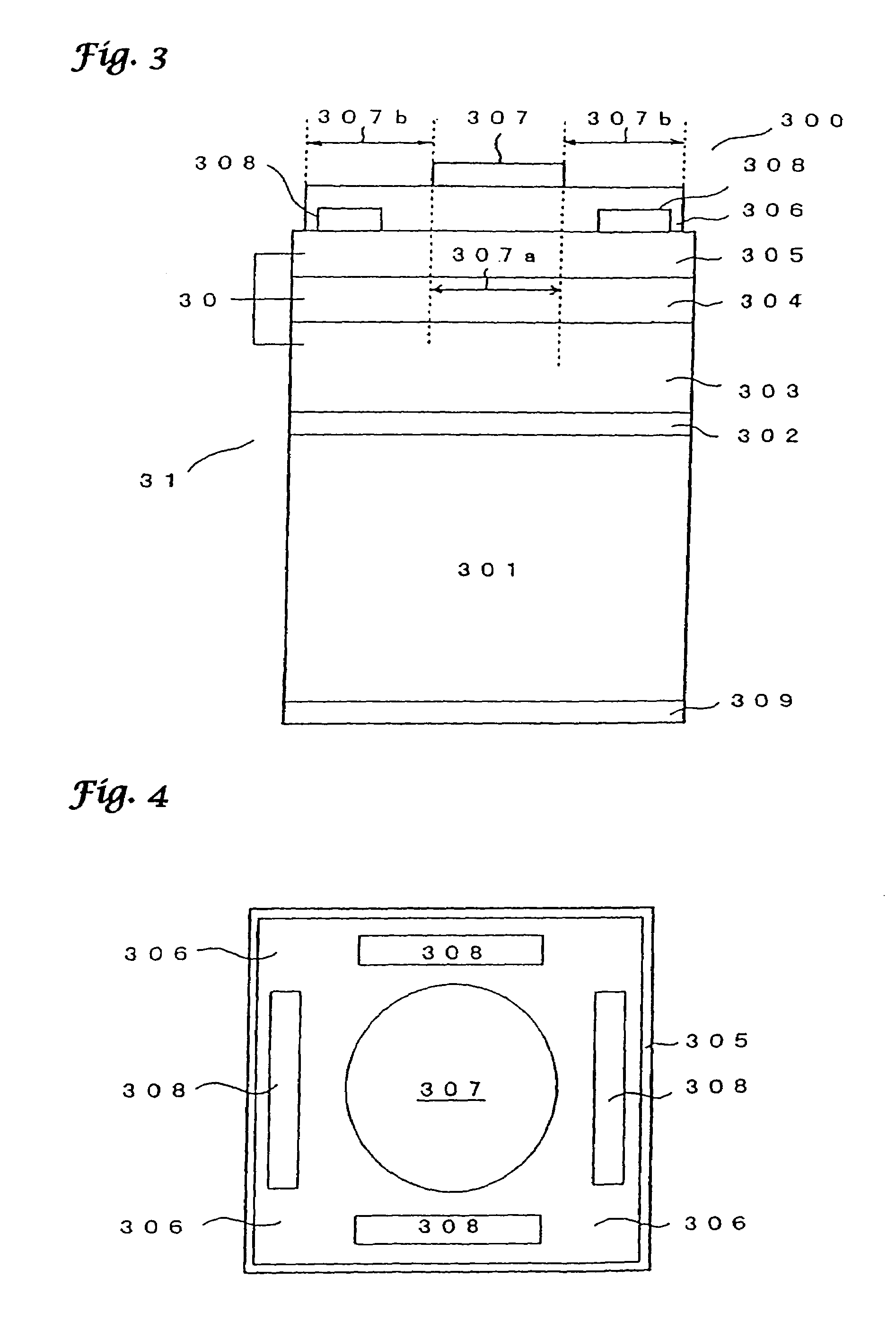

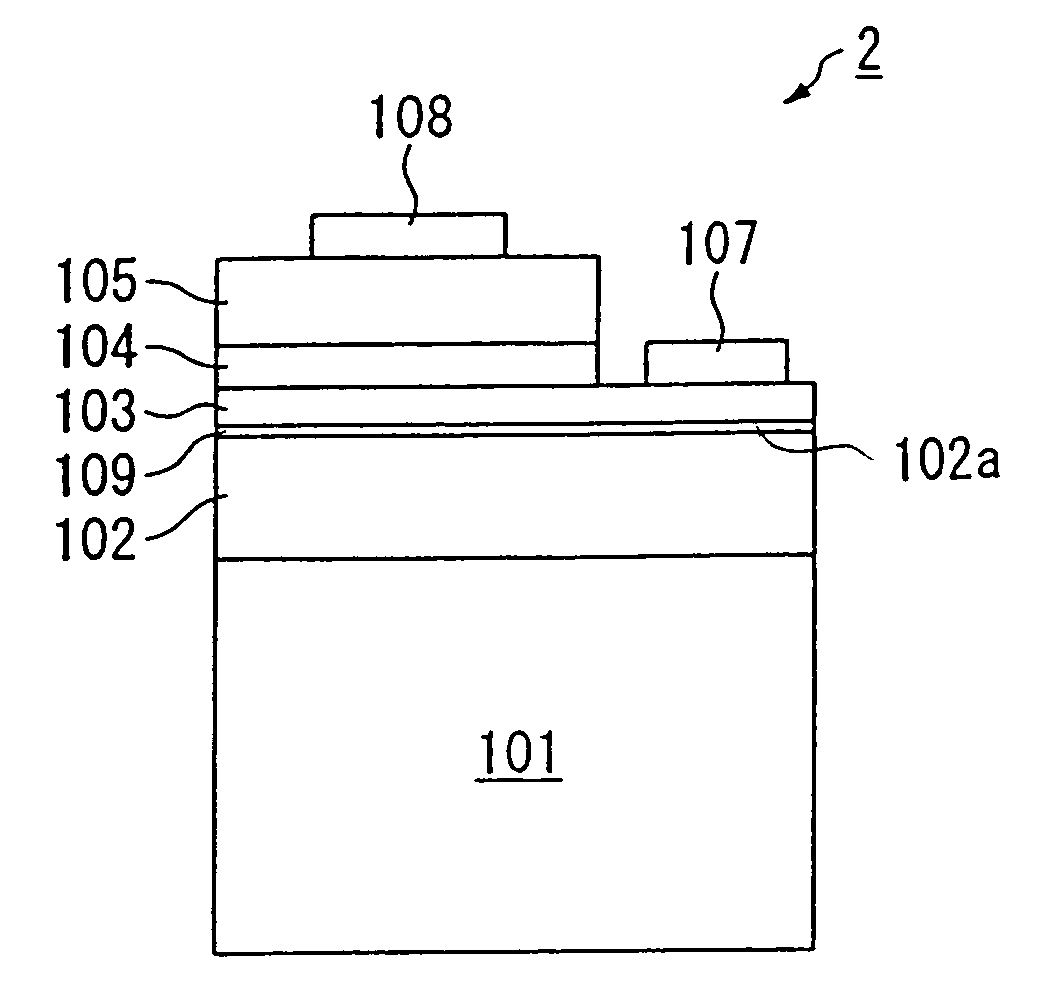

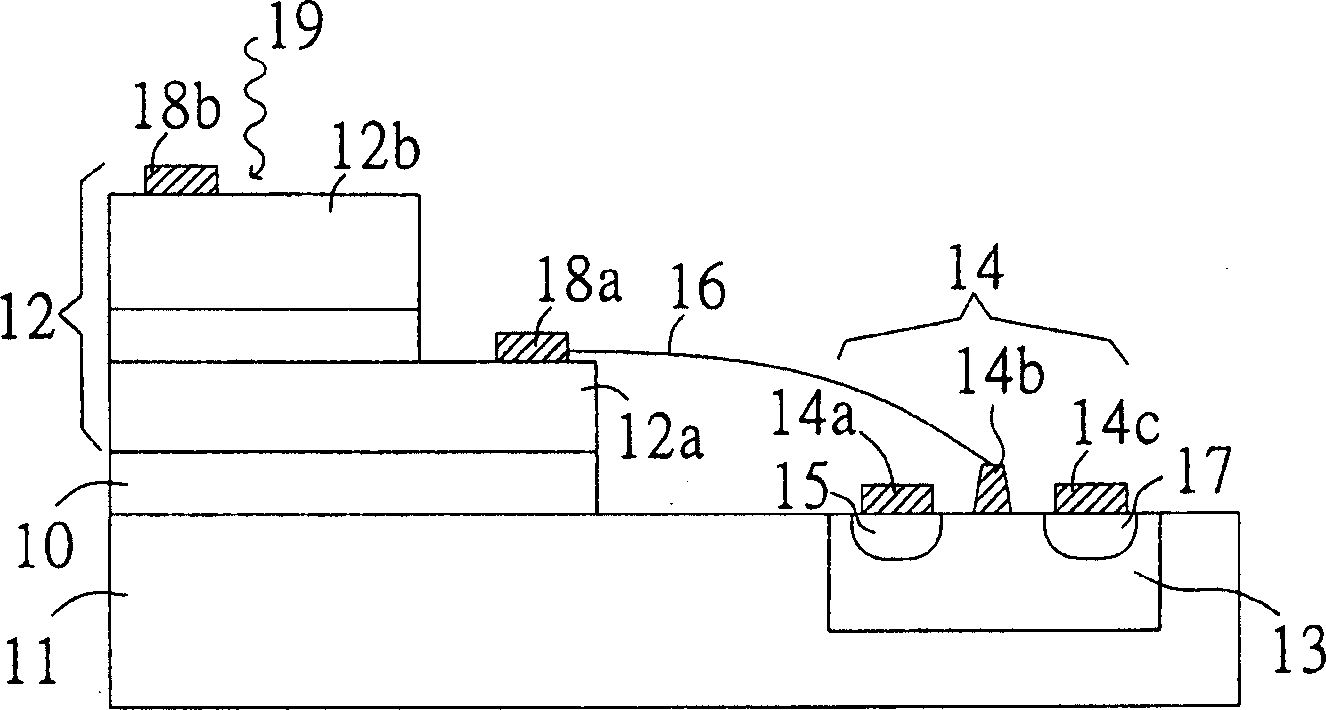

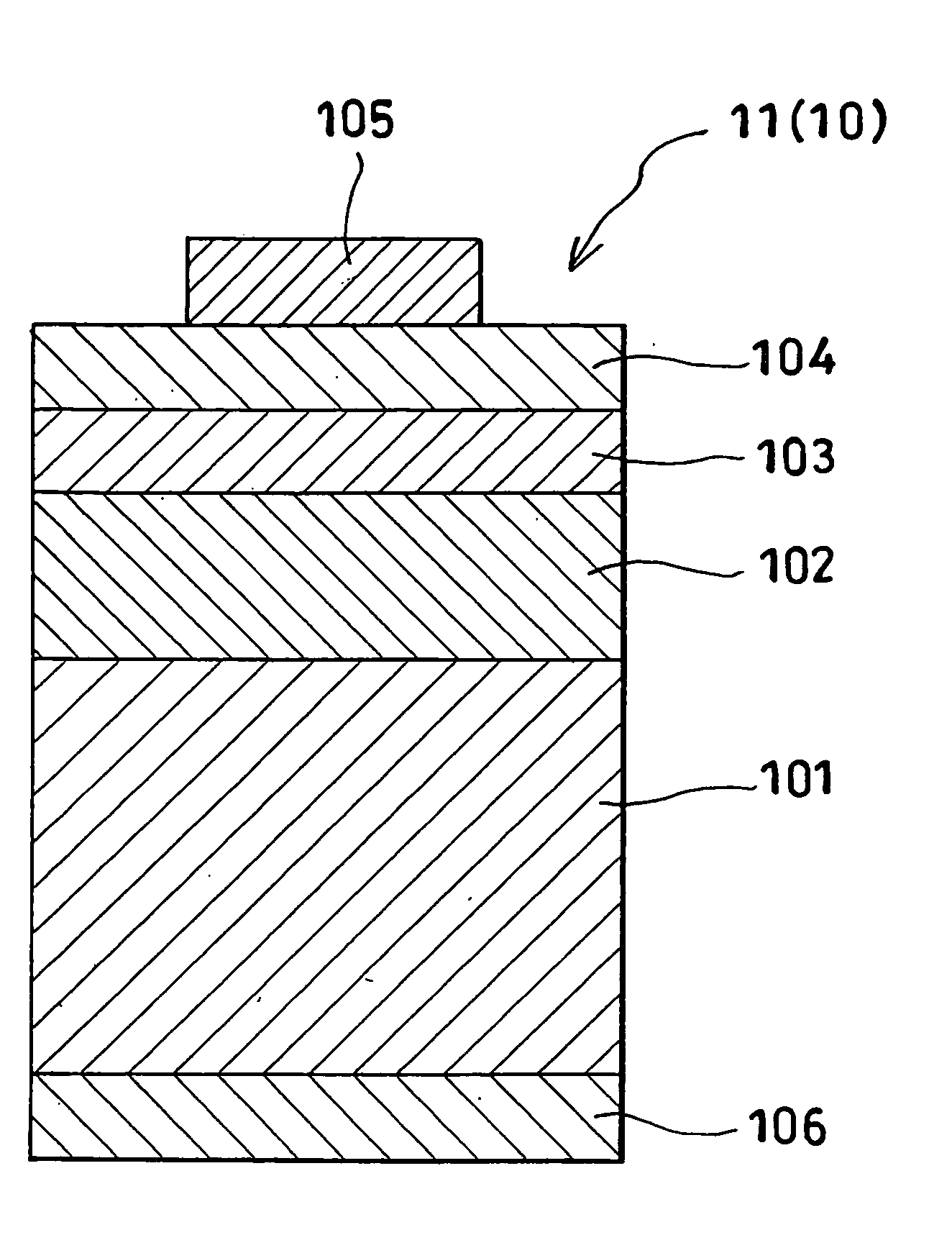

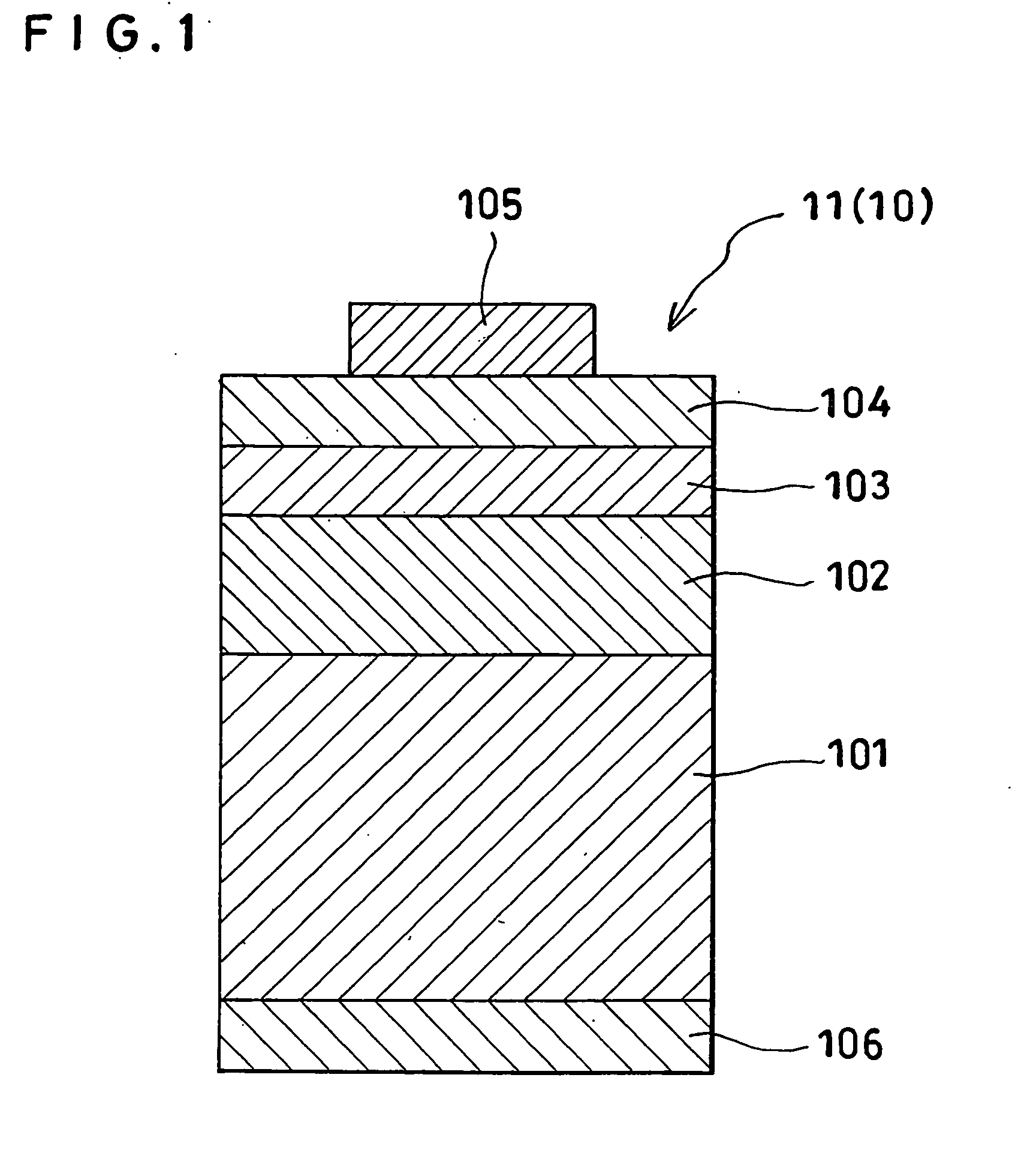

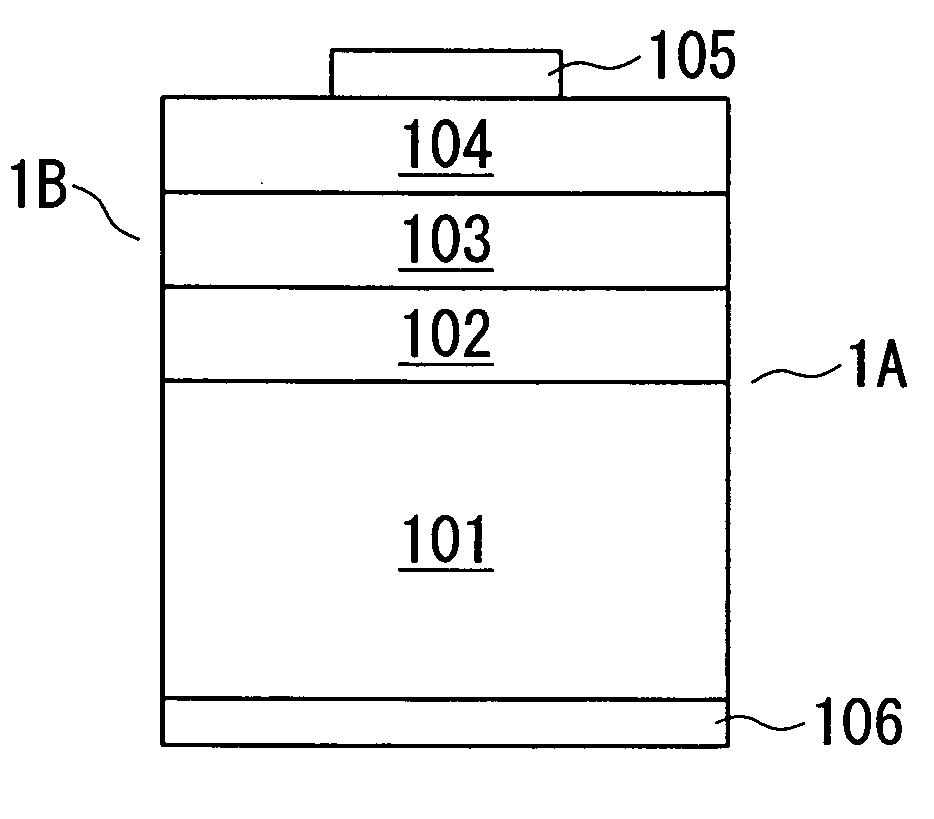

Compound semiconductor device

InactiveUS20090309135A1High Photoelectric Conversion EfficiencyLow flow resistanceSemiconductor devicesSingle crystalCondensed matter physics

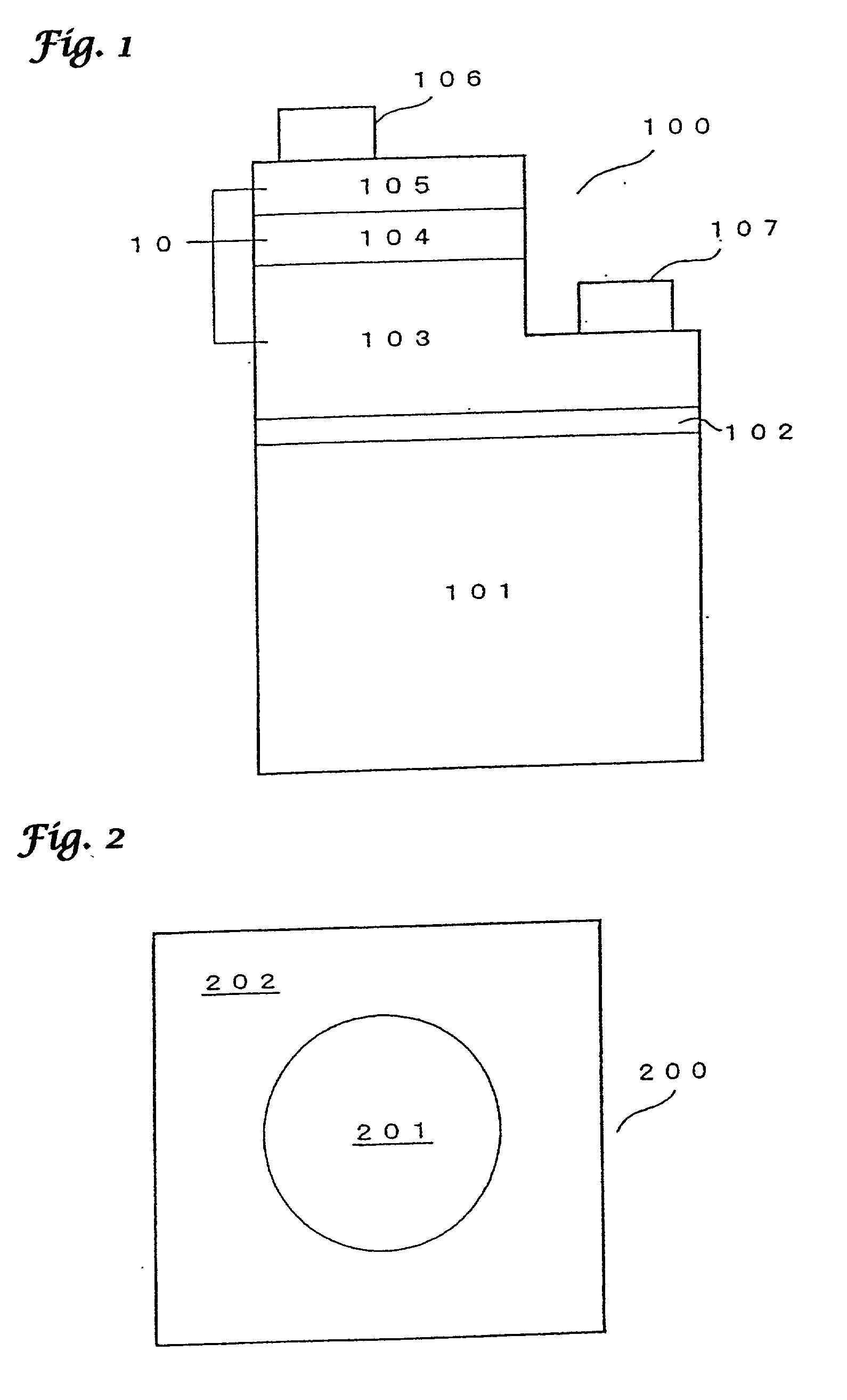

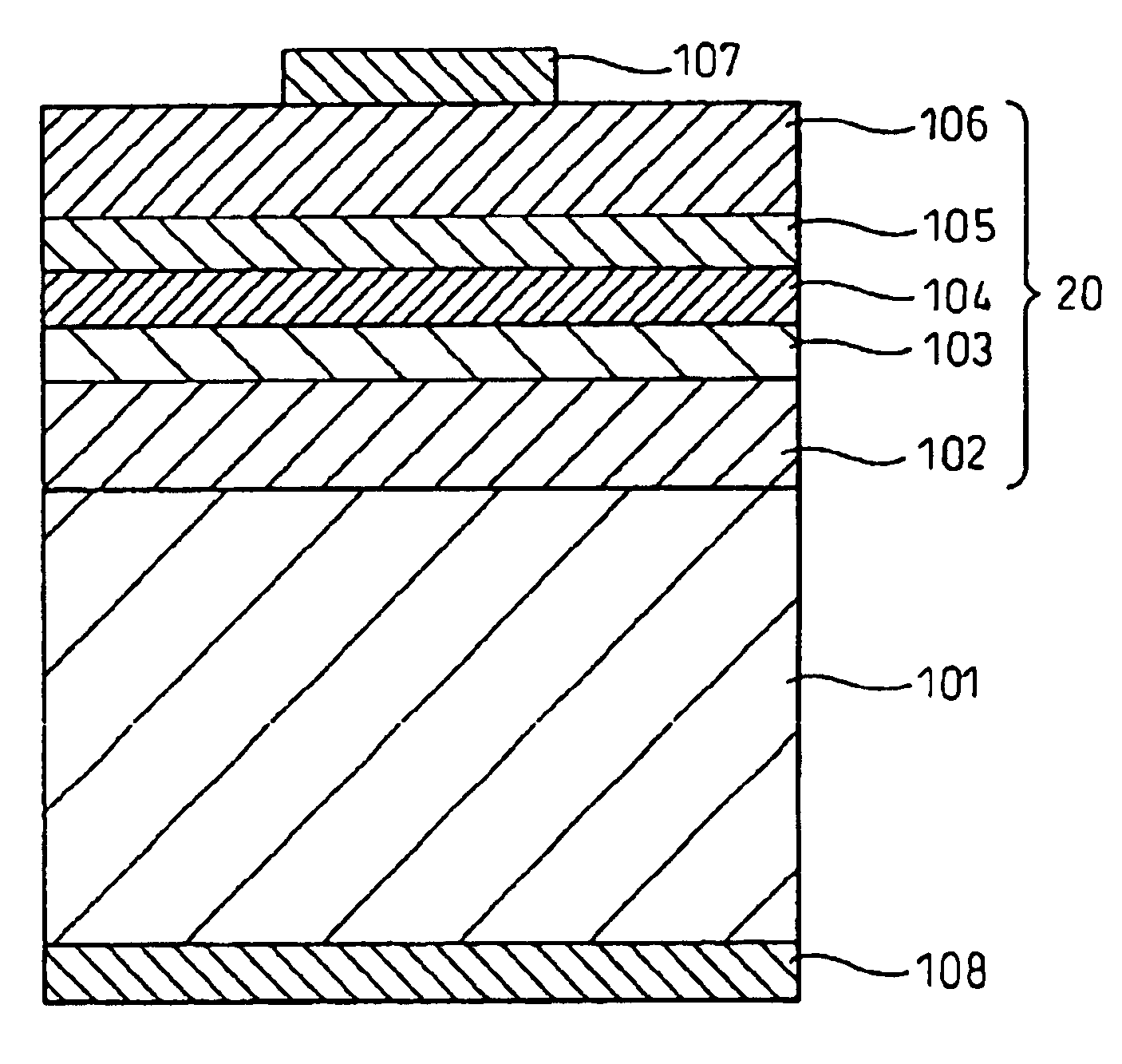

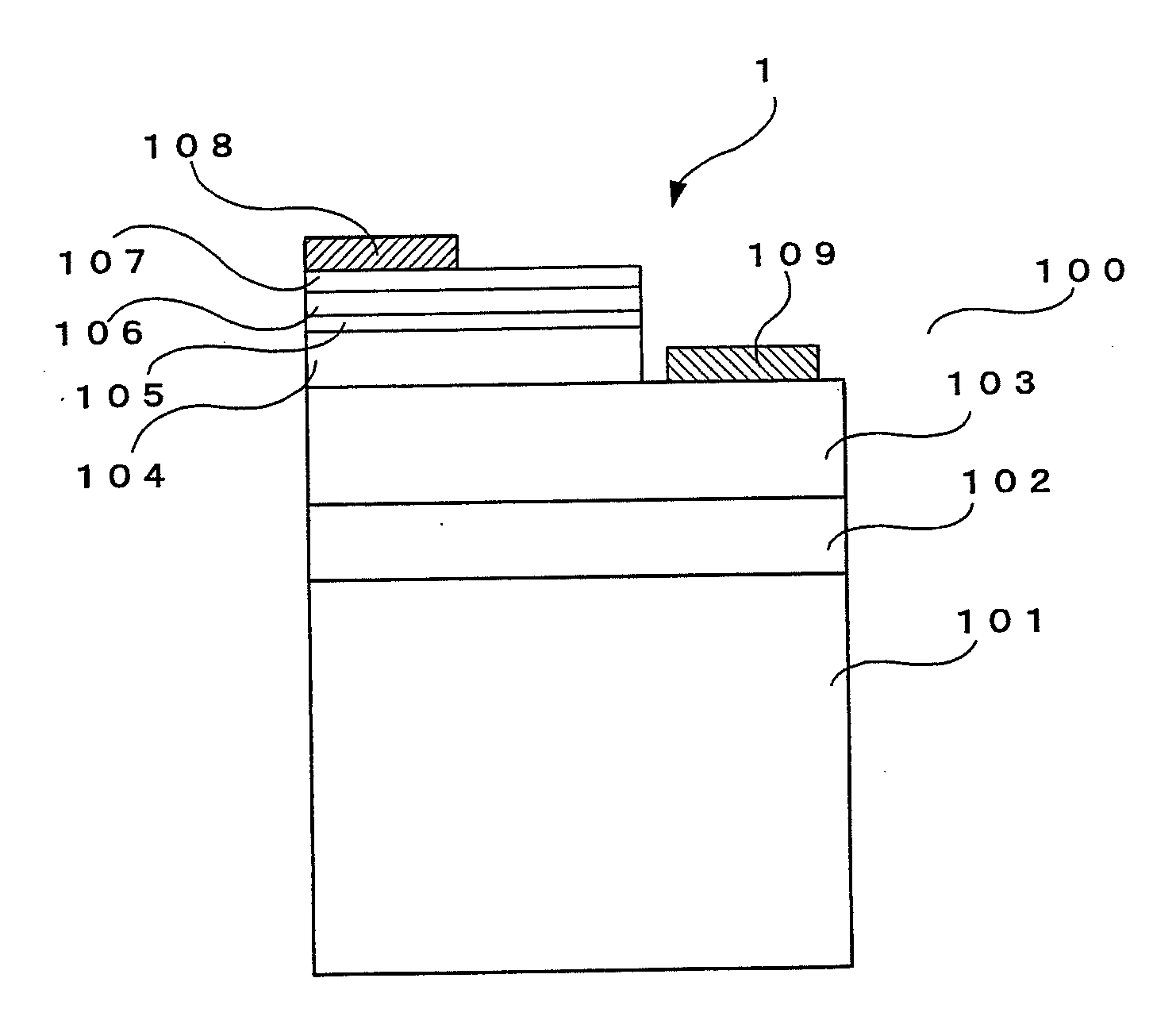

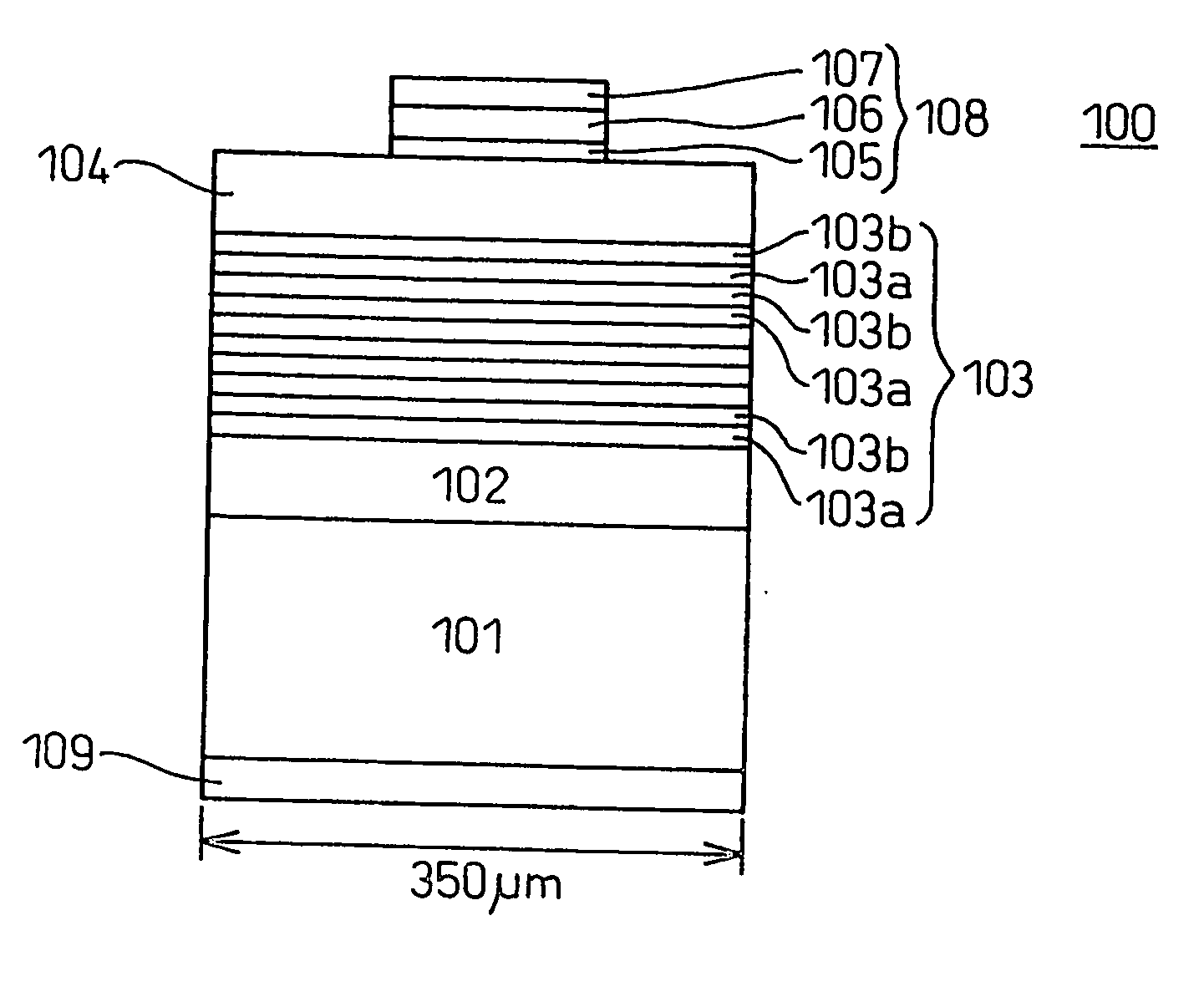

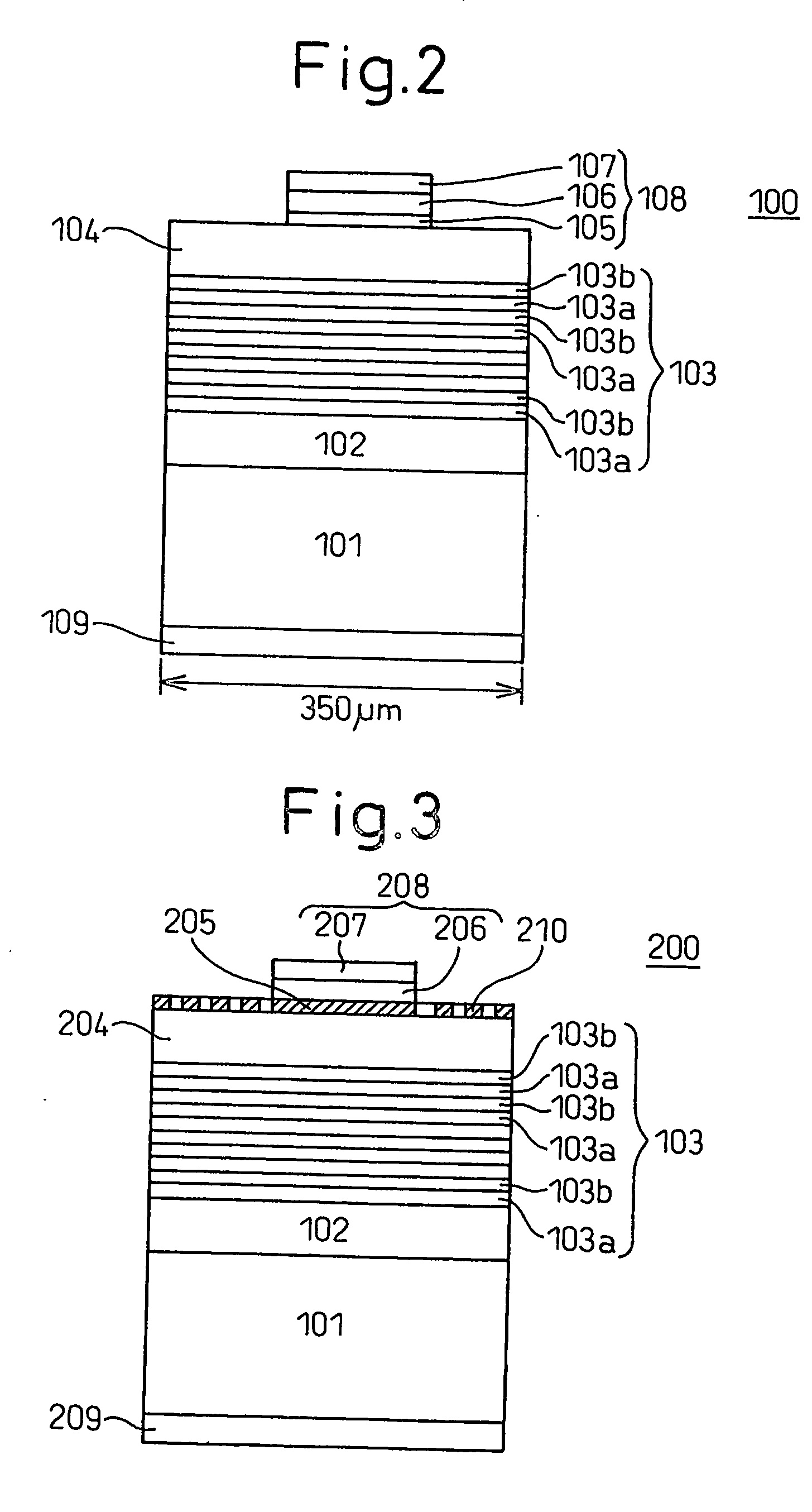

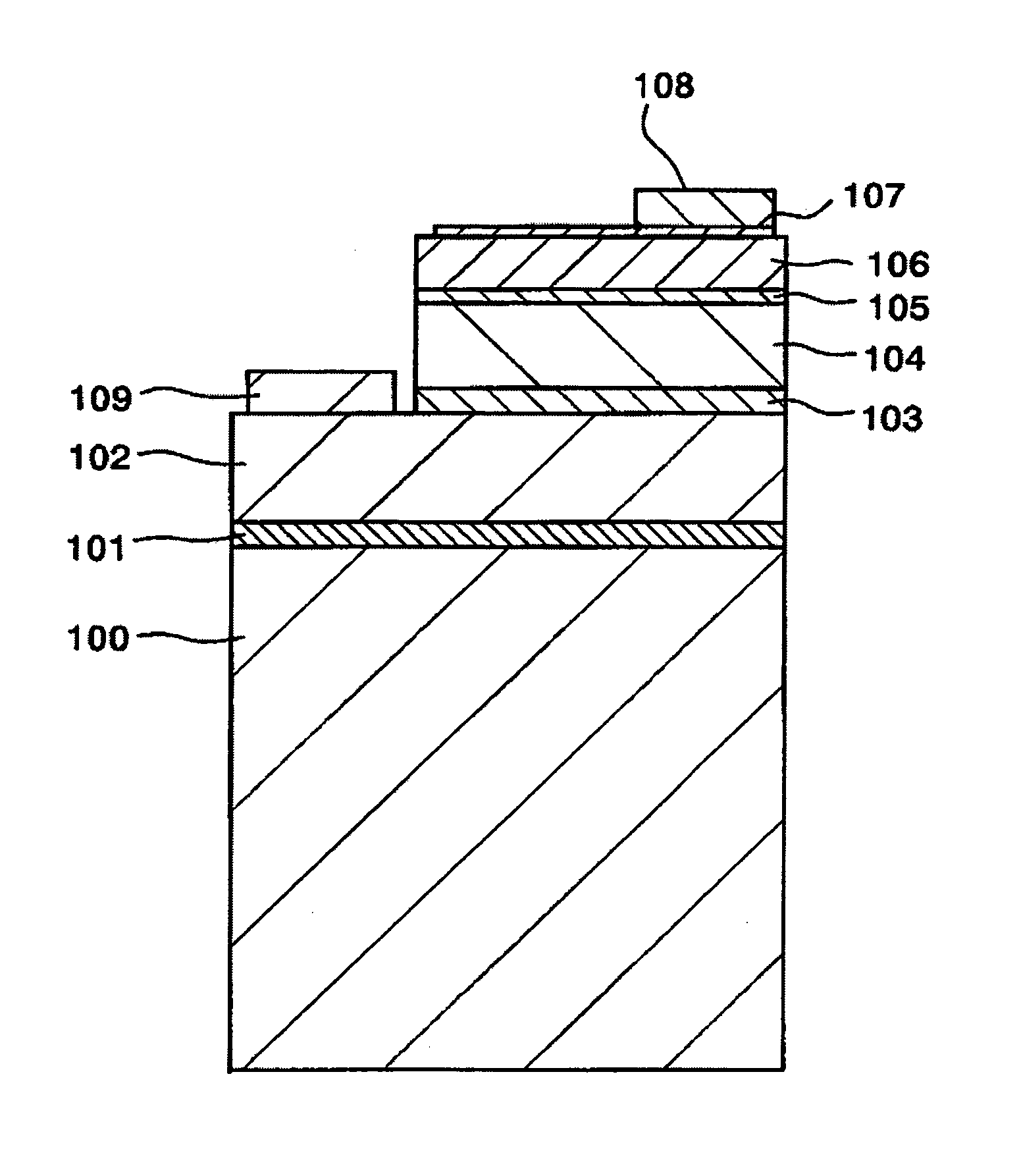

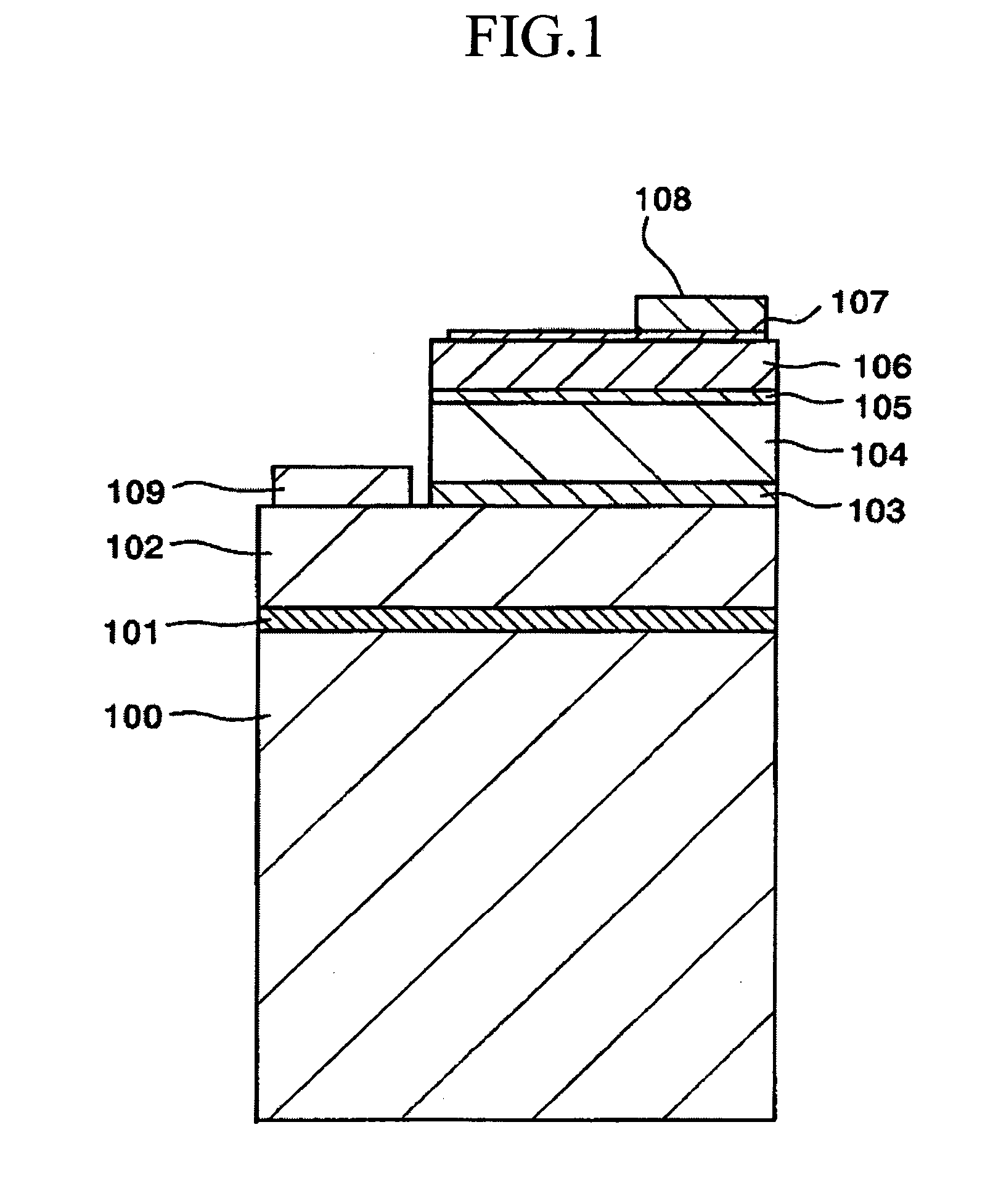

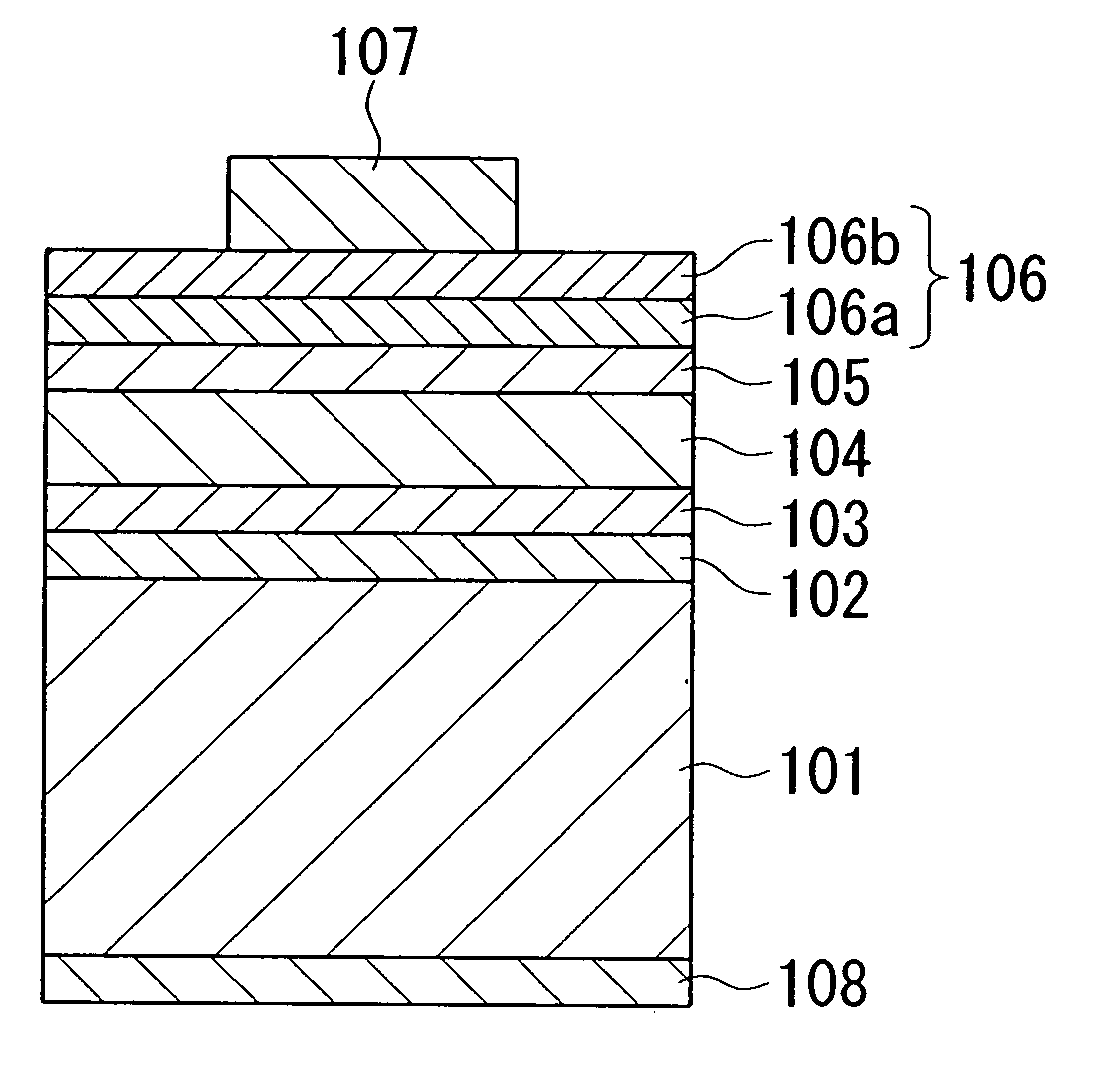

A compound semiconductor device (1) includes a compound semiconductor having a stacked structure (100) of a hexagonal single crystal layer (101), a boron phosphide-based semiconductor layer (102) formed on a surface of the hexagonal single crystal layer and a compound semiconductor layer (103) disposed on the boron phosphide-based semiconductor layer, and electrodes (108, 109) disposed on the stacked structure, wherein the boron phosphide-based semiconductor layer is formed of a hexagonal crystal disposed on a surface formed of a (1.1.-2.0.) crystal face of the hexagonal single crystal layer.

Owner:SHOWA DENKO KK

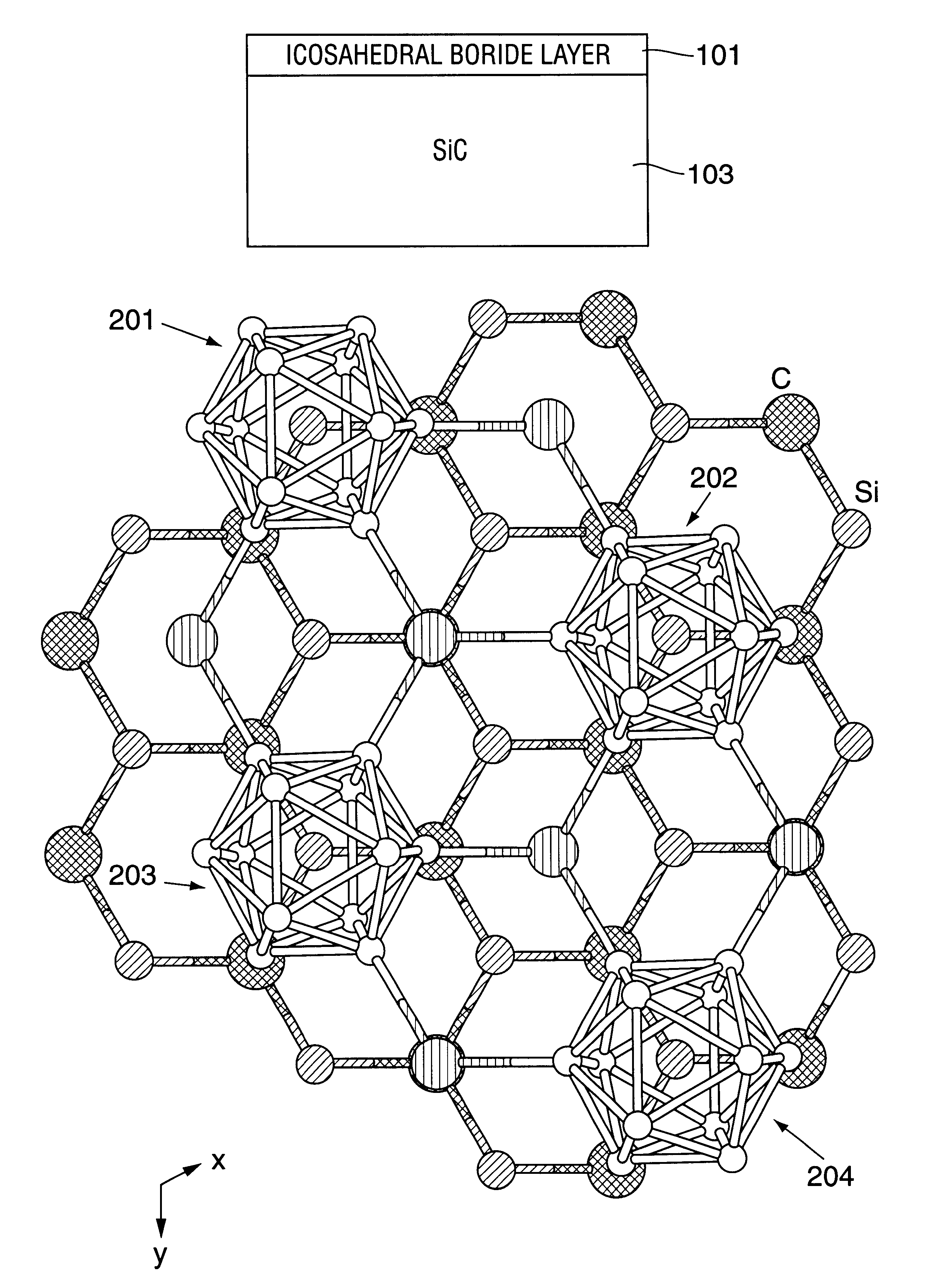

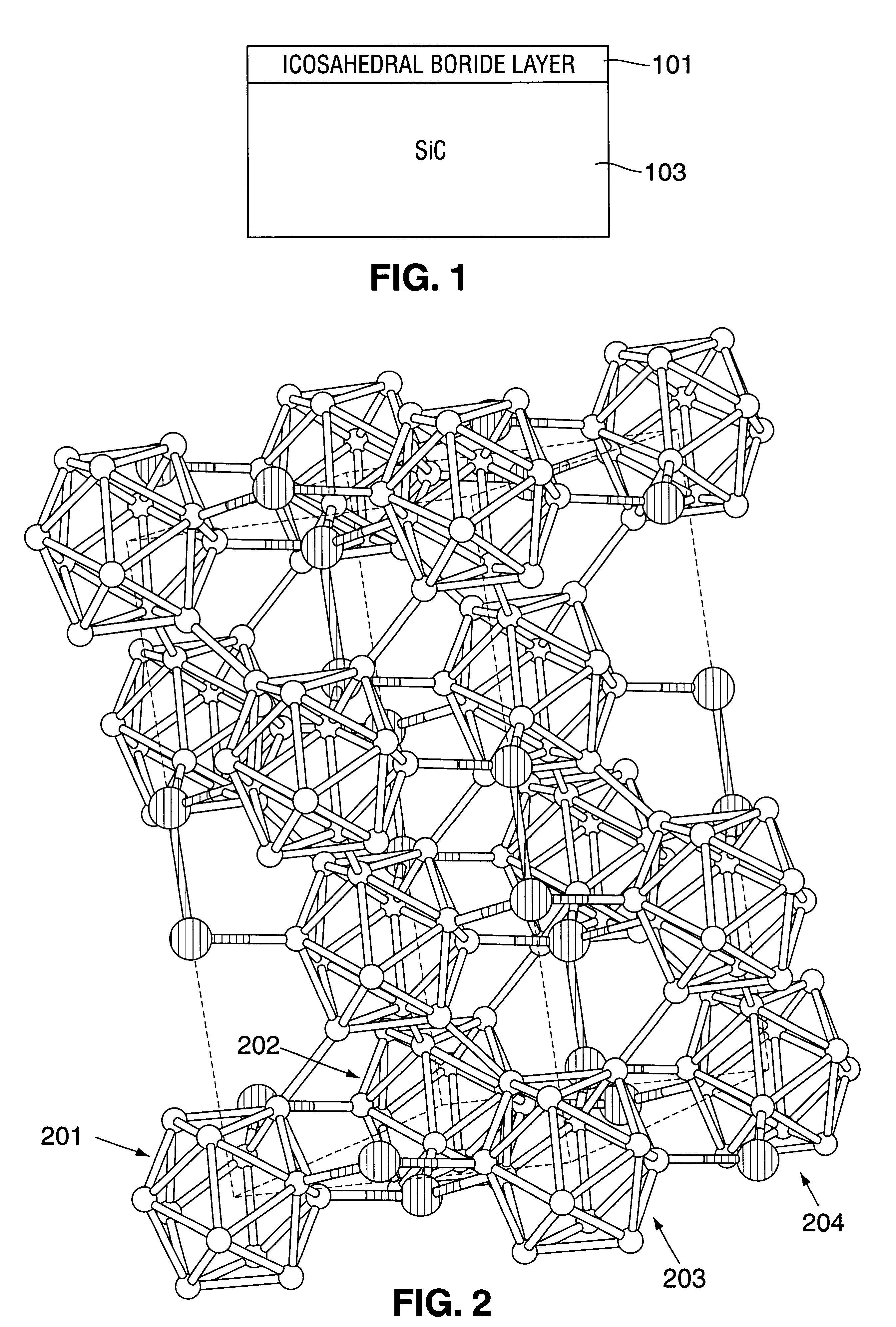

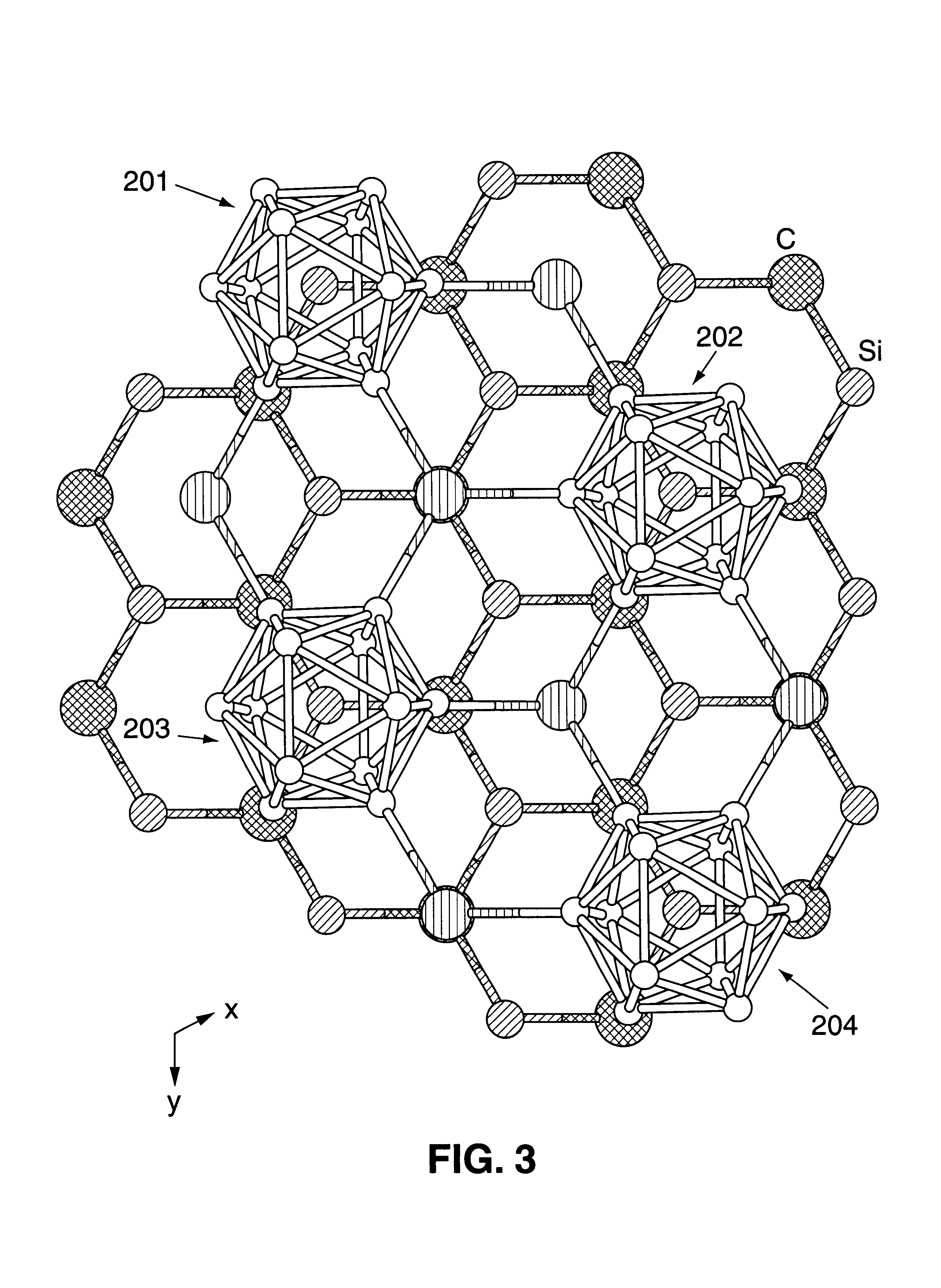

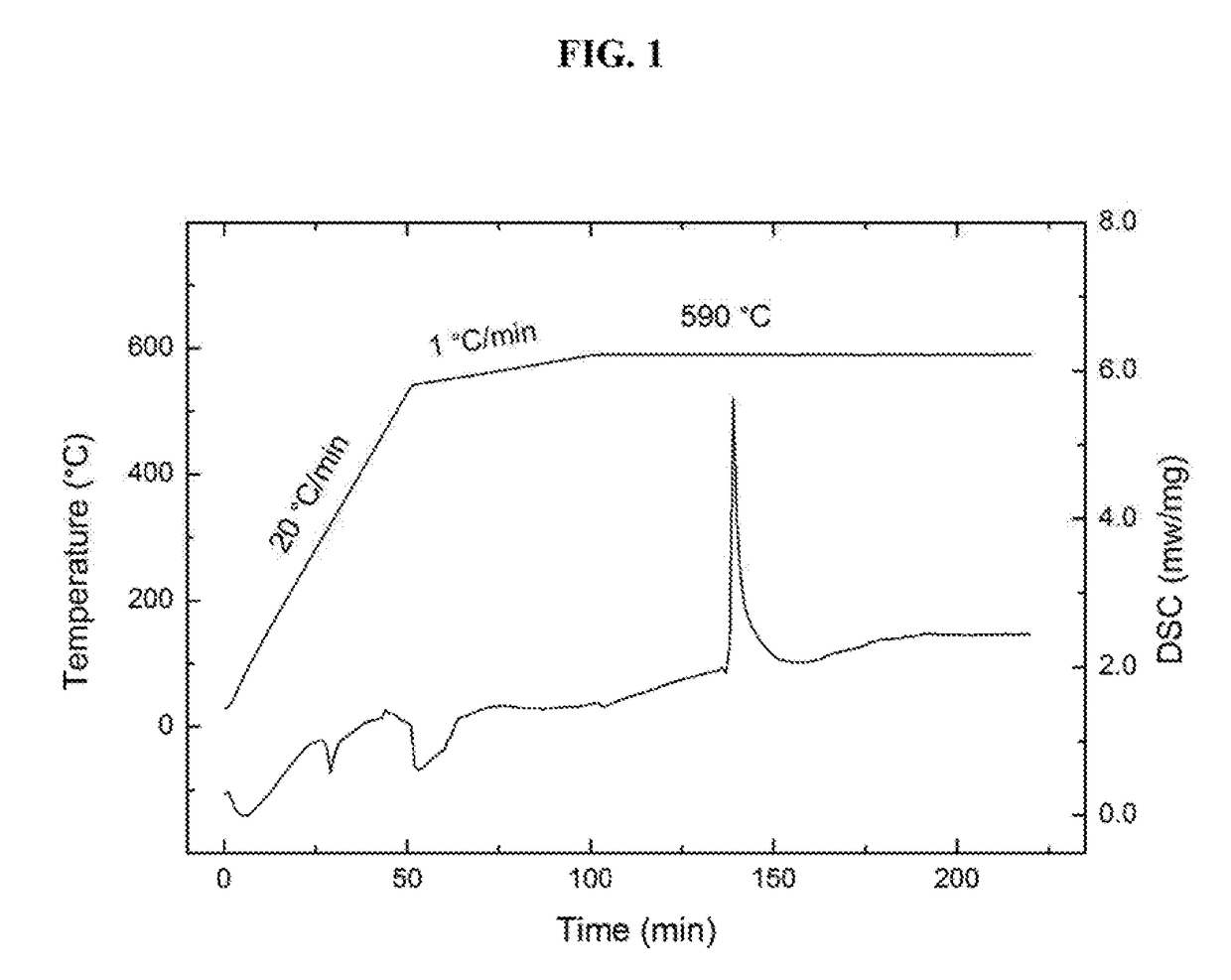

Method of making an icosahedral boride structure

InactiveUS6841456B2High crystallinityReduce impurity concentrationFrom solid stateSemiconductor/solid-state device manufacturingBorideDeposition temperature

A method for fabricating thin films of an icosahedral boride on a silicon carbide (SiC) substrate is provided. Preferably the icosahedral boride layer is comprised of either boron phosphide (B12P2) or boron arsenide (B12As2). The provided method achieves improved film crystallinity and lowered impurity concentrations. In one aspect, an epitaxially grown layer of B12P2 with a base layer or substrate of SiC is provided. In another aspect, an epitaxially grown layer of B12As2 with a base layer or substrate of SiC is provided. In yet another aspect, thin films of B12P2 or B12As2 are formed on SiC using CVD or other vapor deposition means. If CVD techniques are employed, preferably the deposition temperature is above 1050° C., more preferably in the range of 1100° C. to 1400° C., and still more preferably approximately 1150° C.

Owner:UNIVERSITY OF NEW MEXICO +1

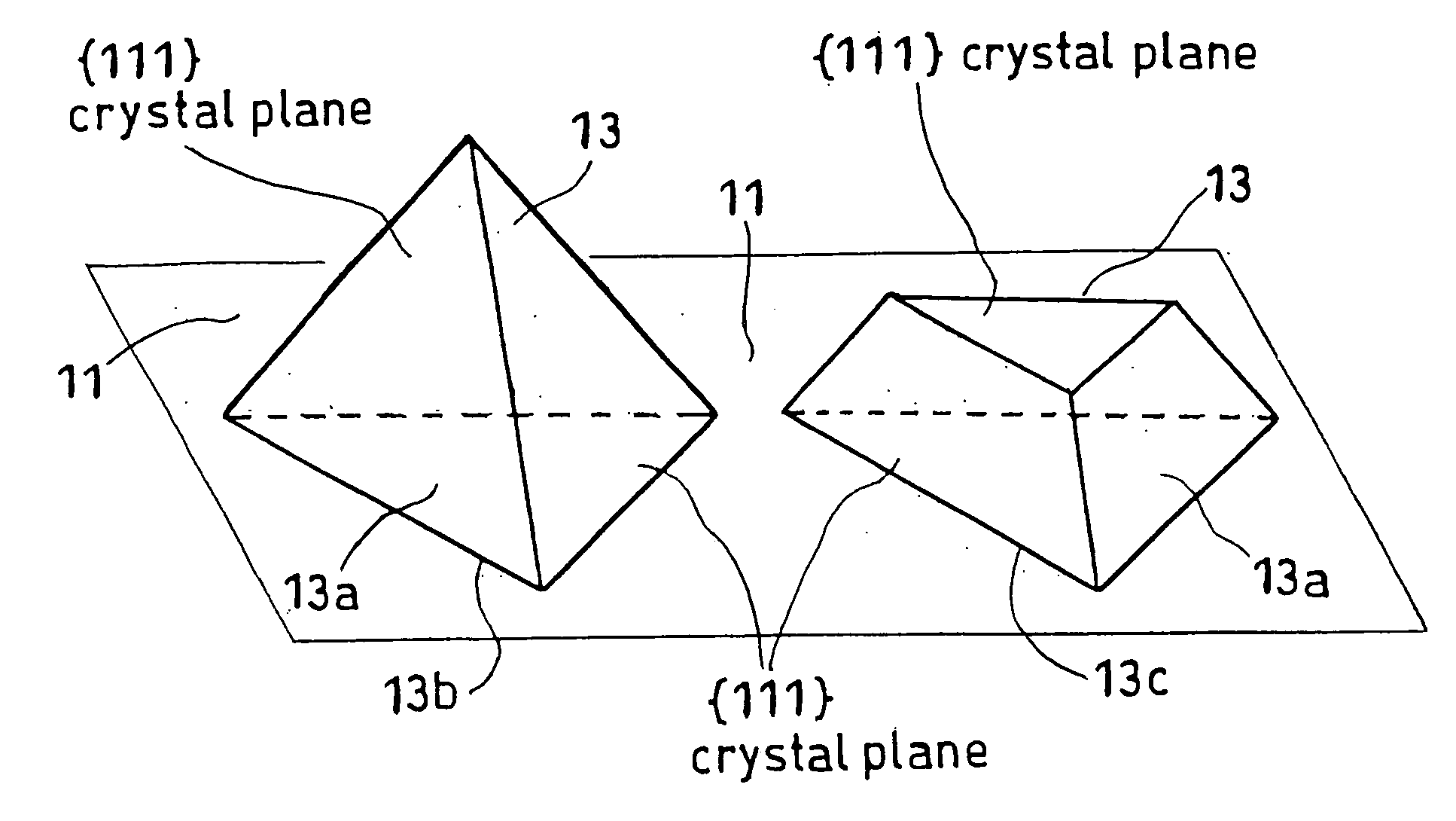

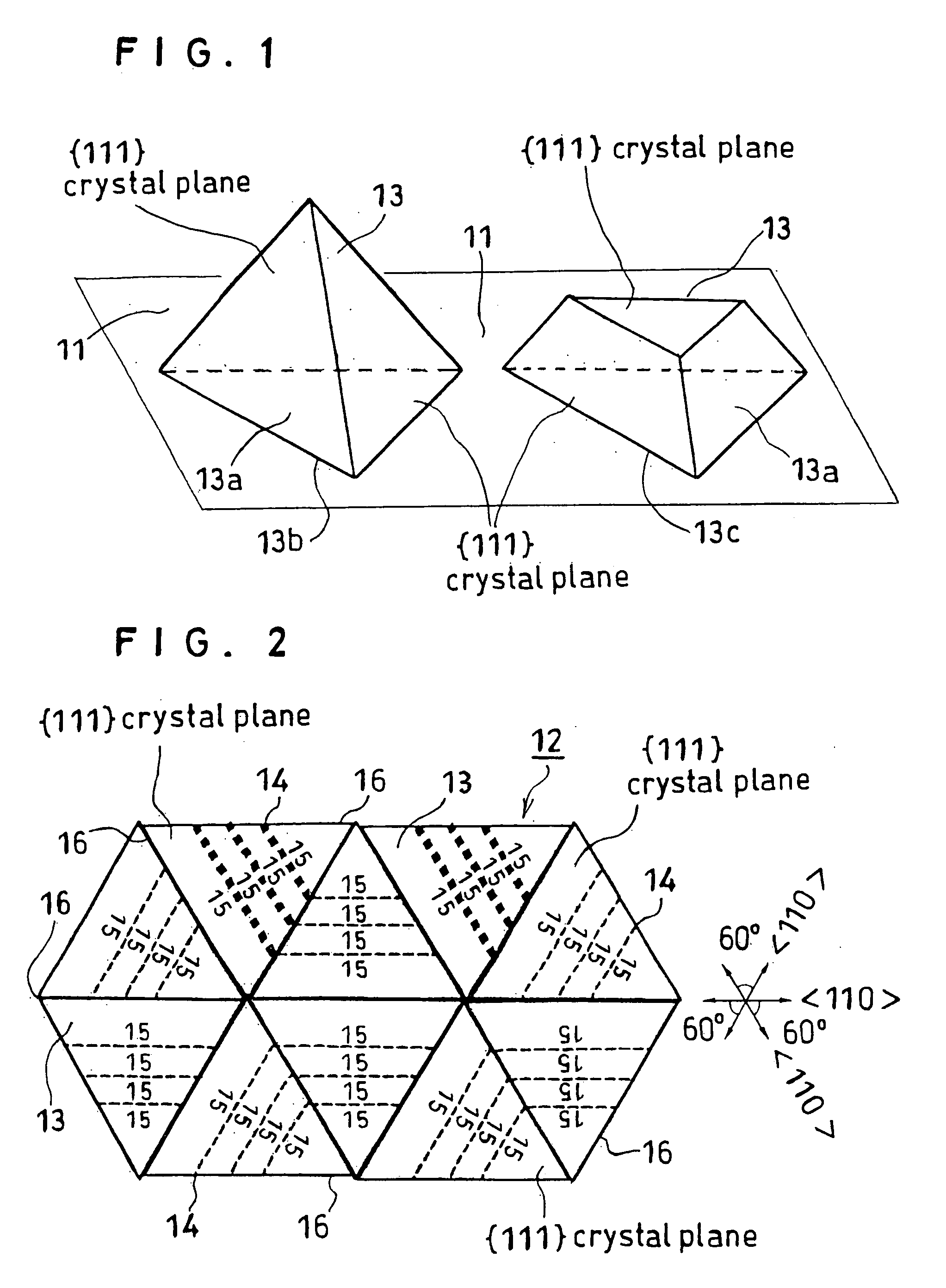

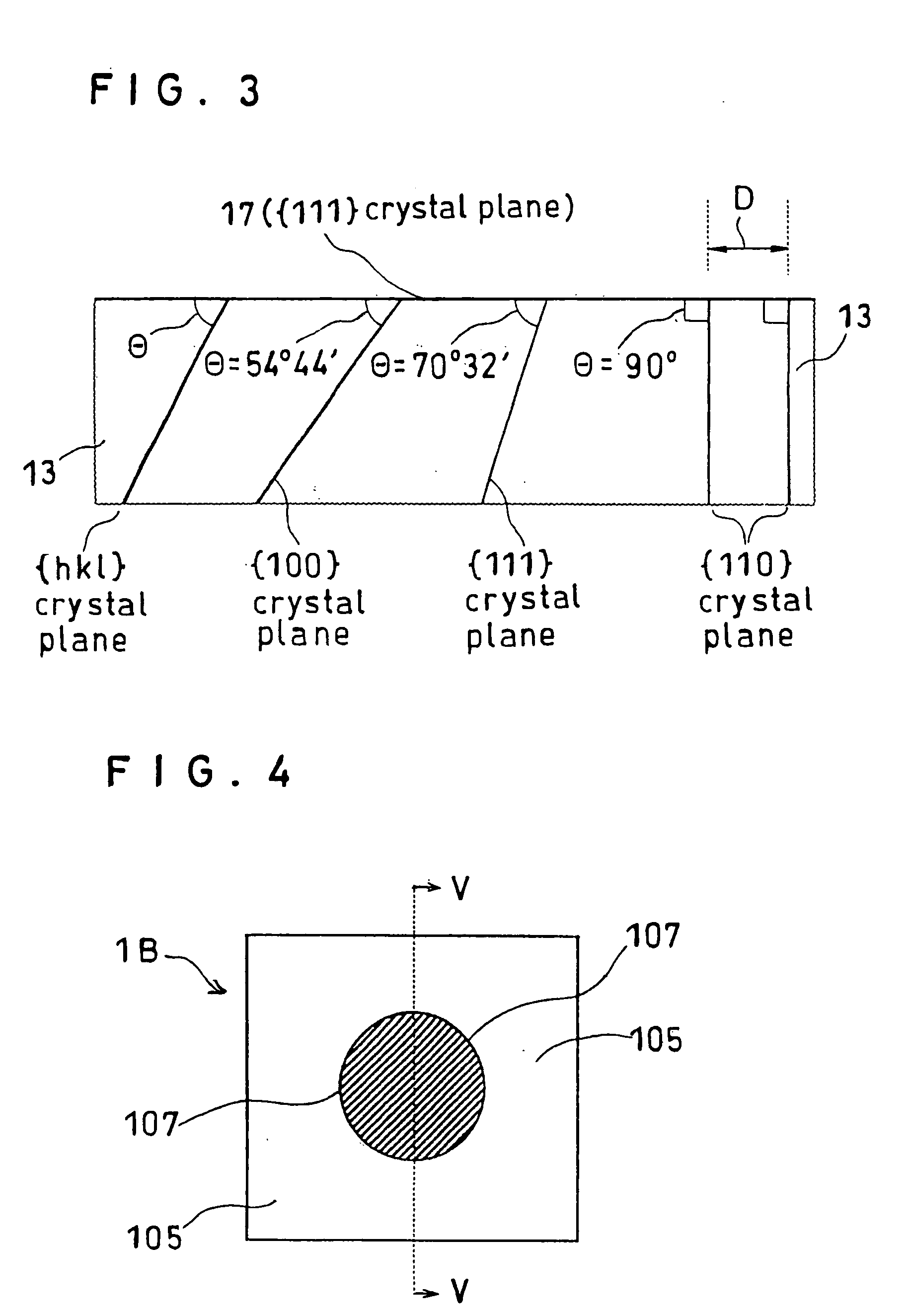

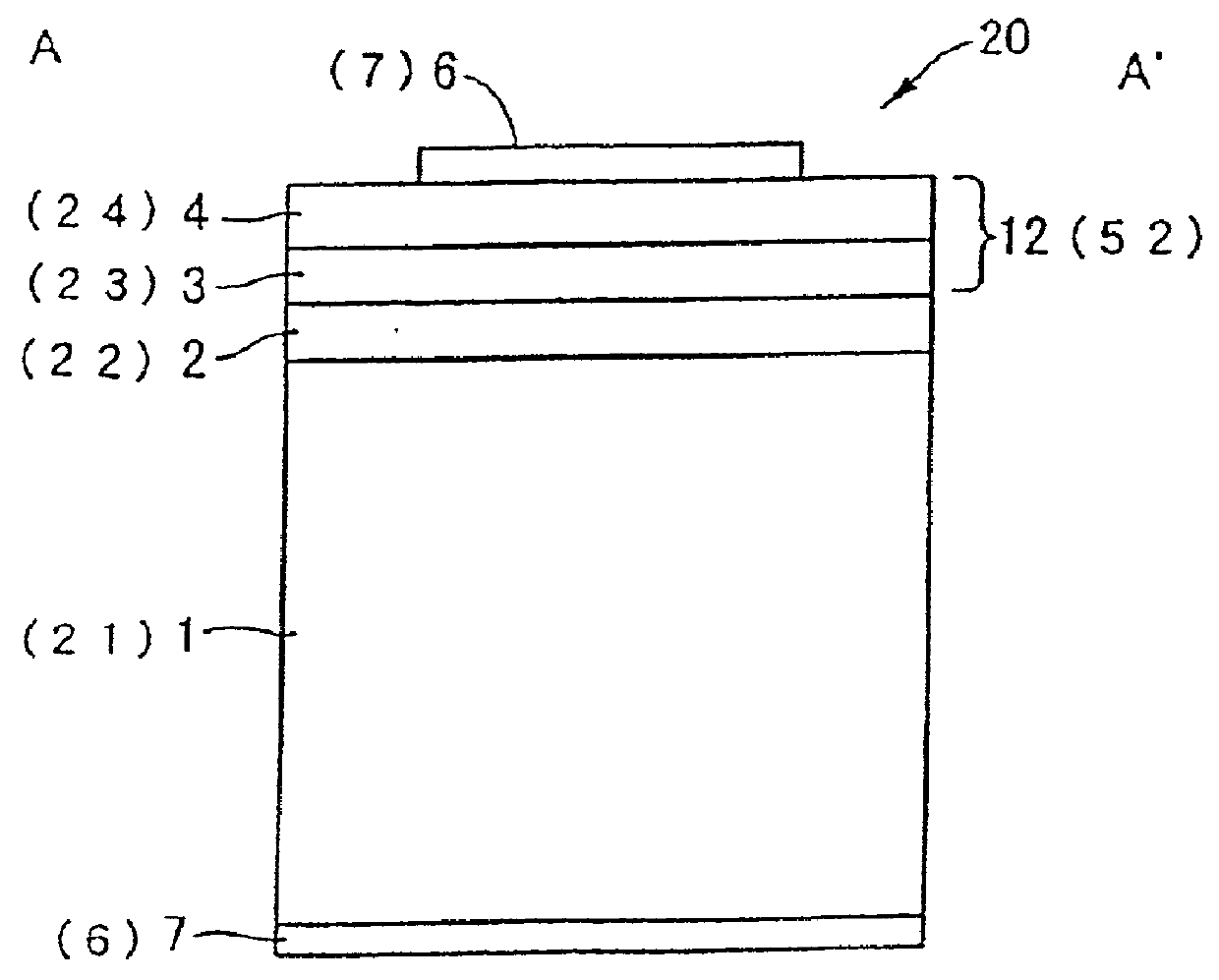

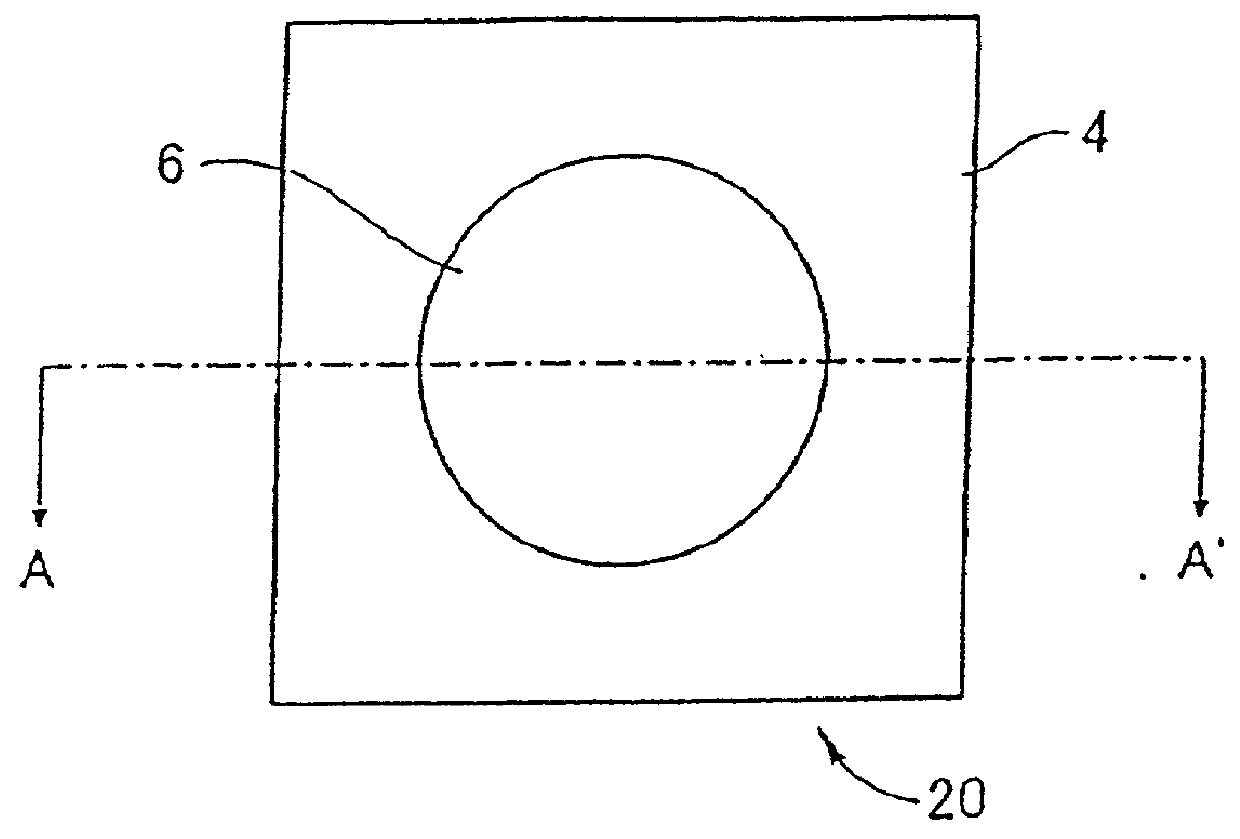

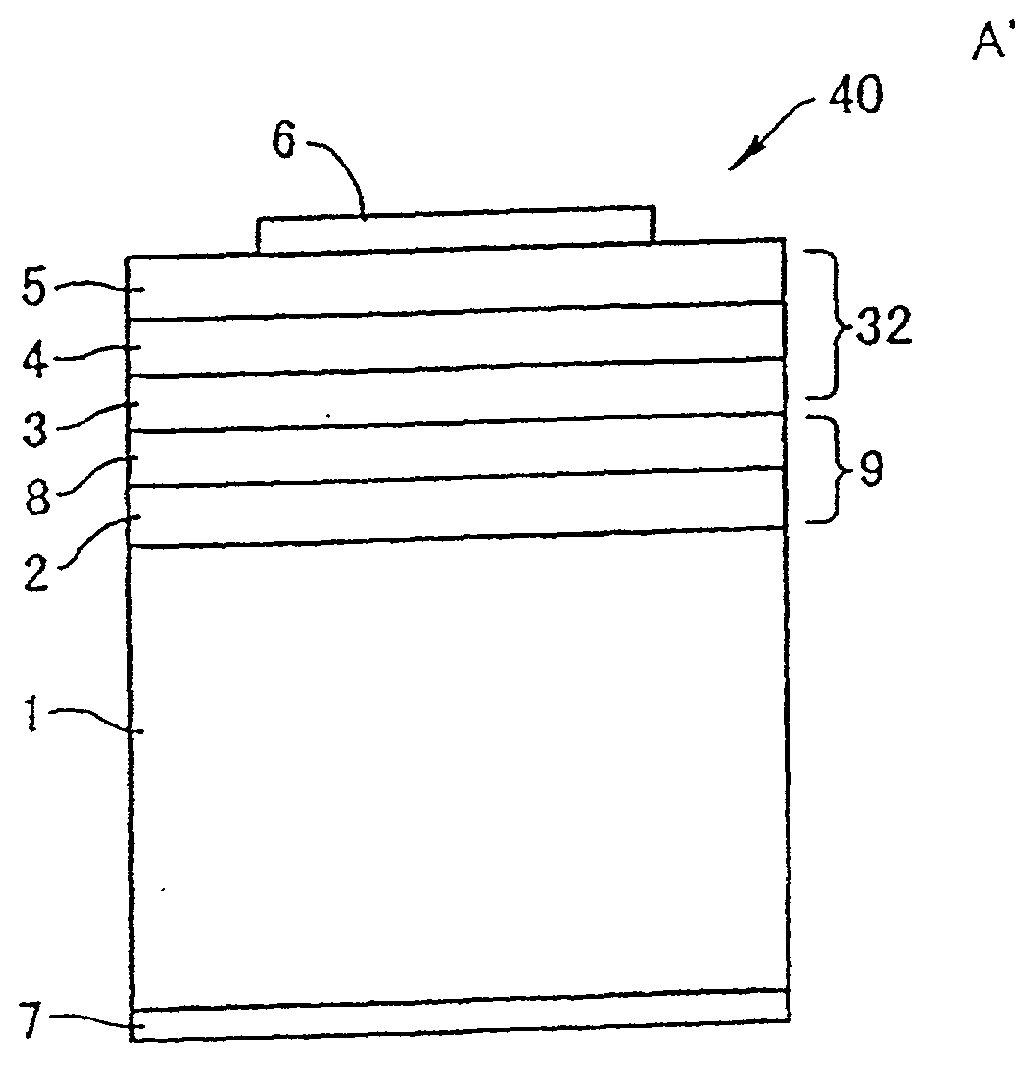

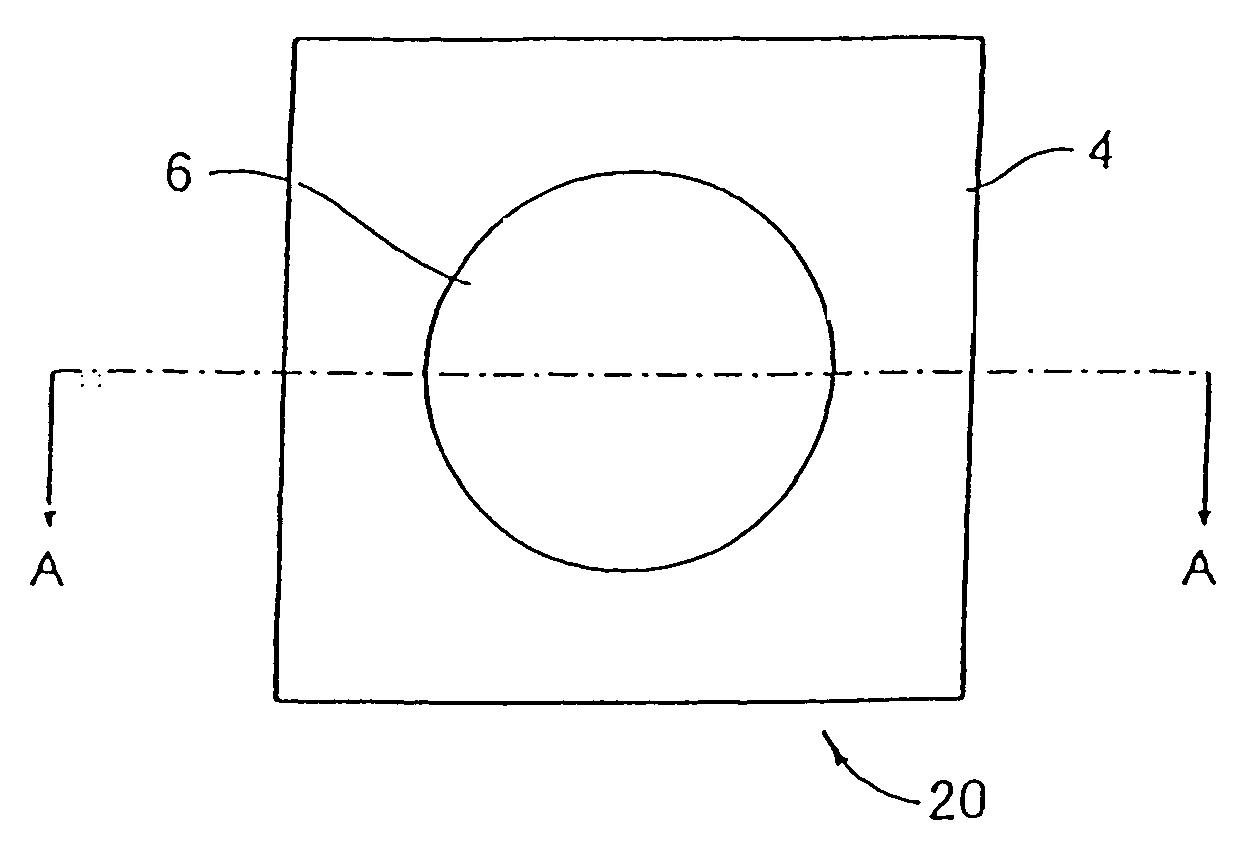

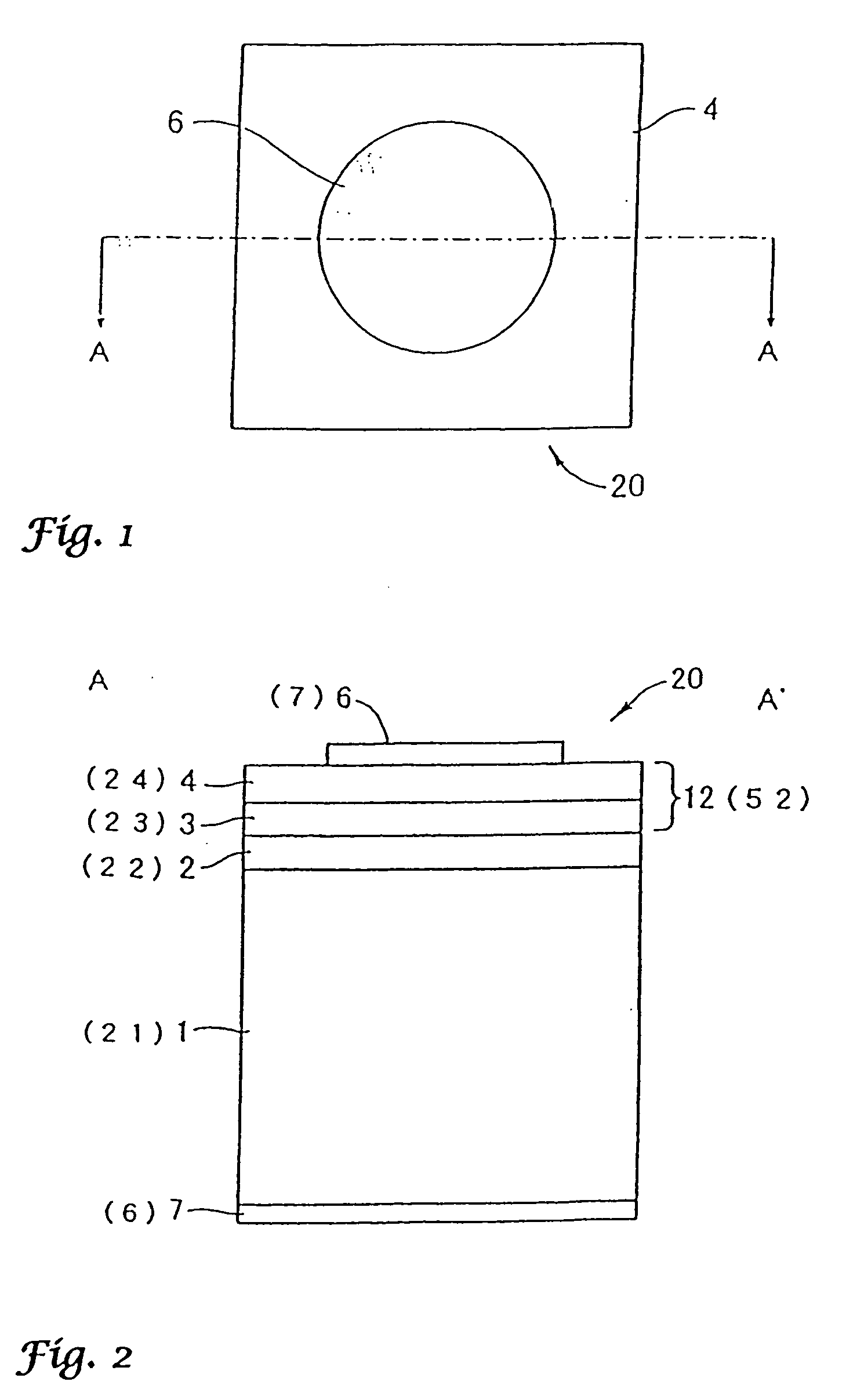

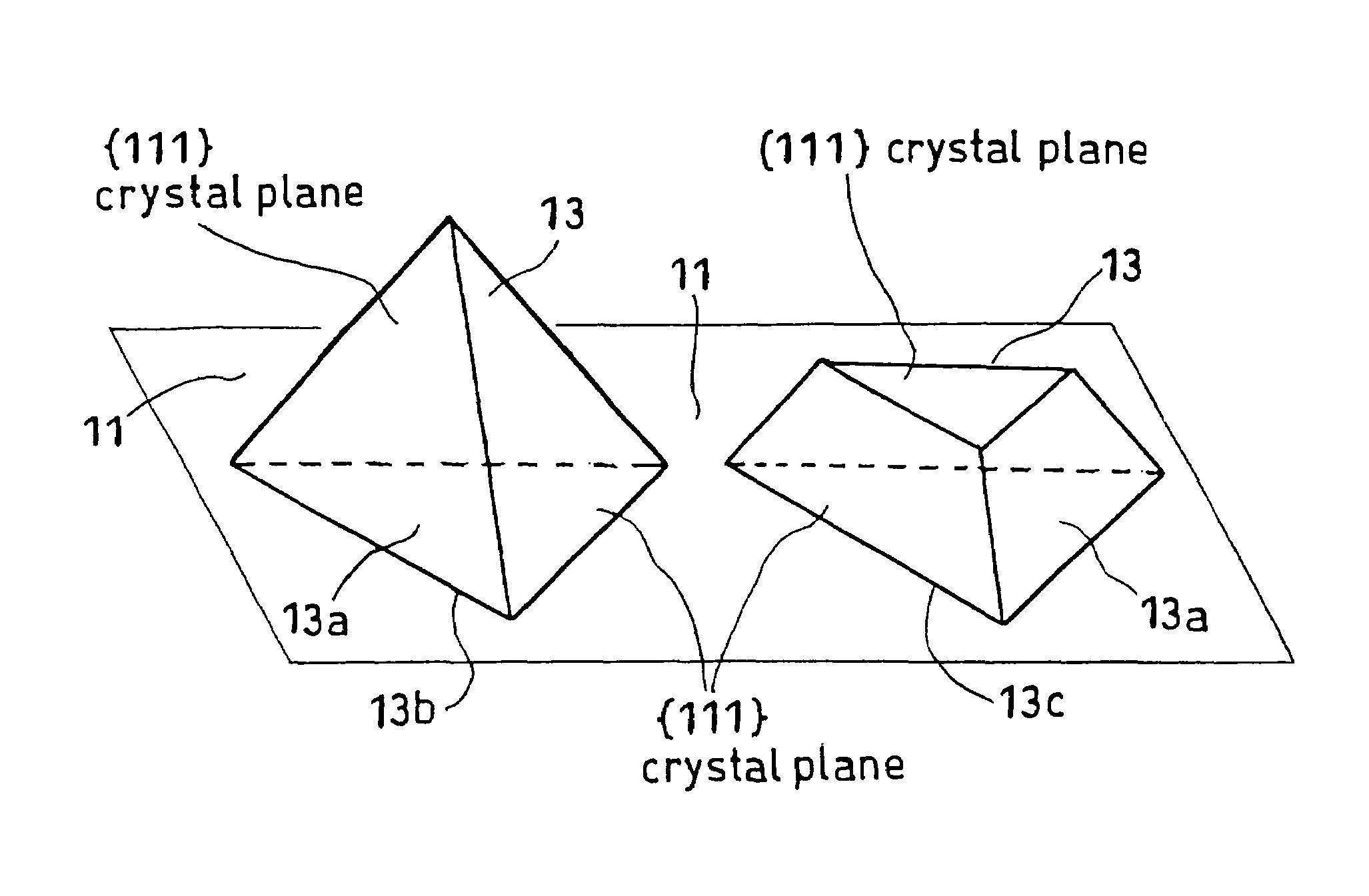

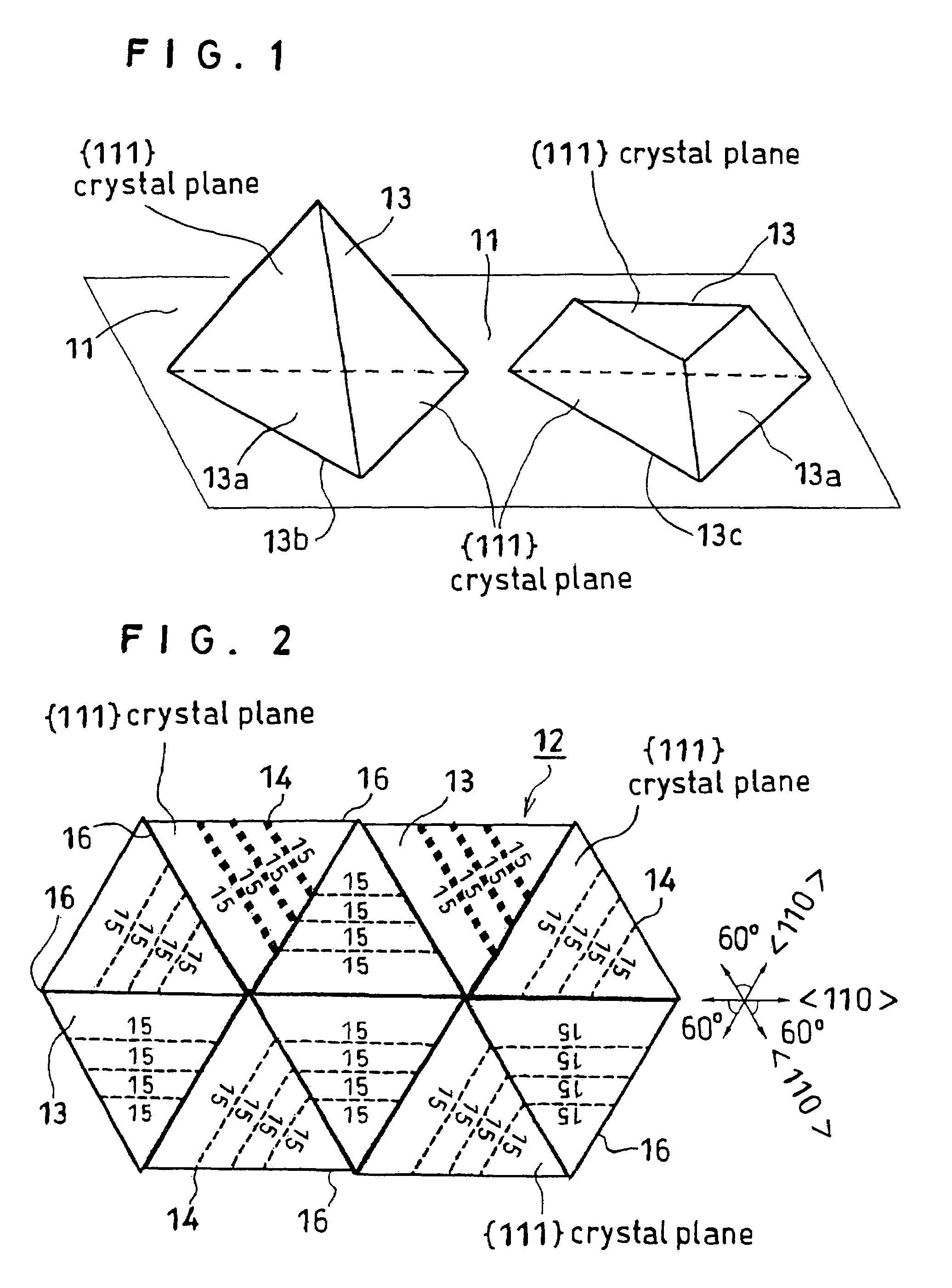

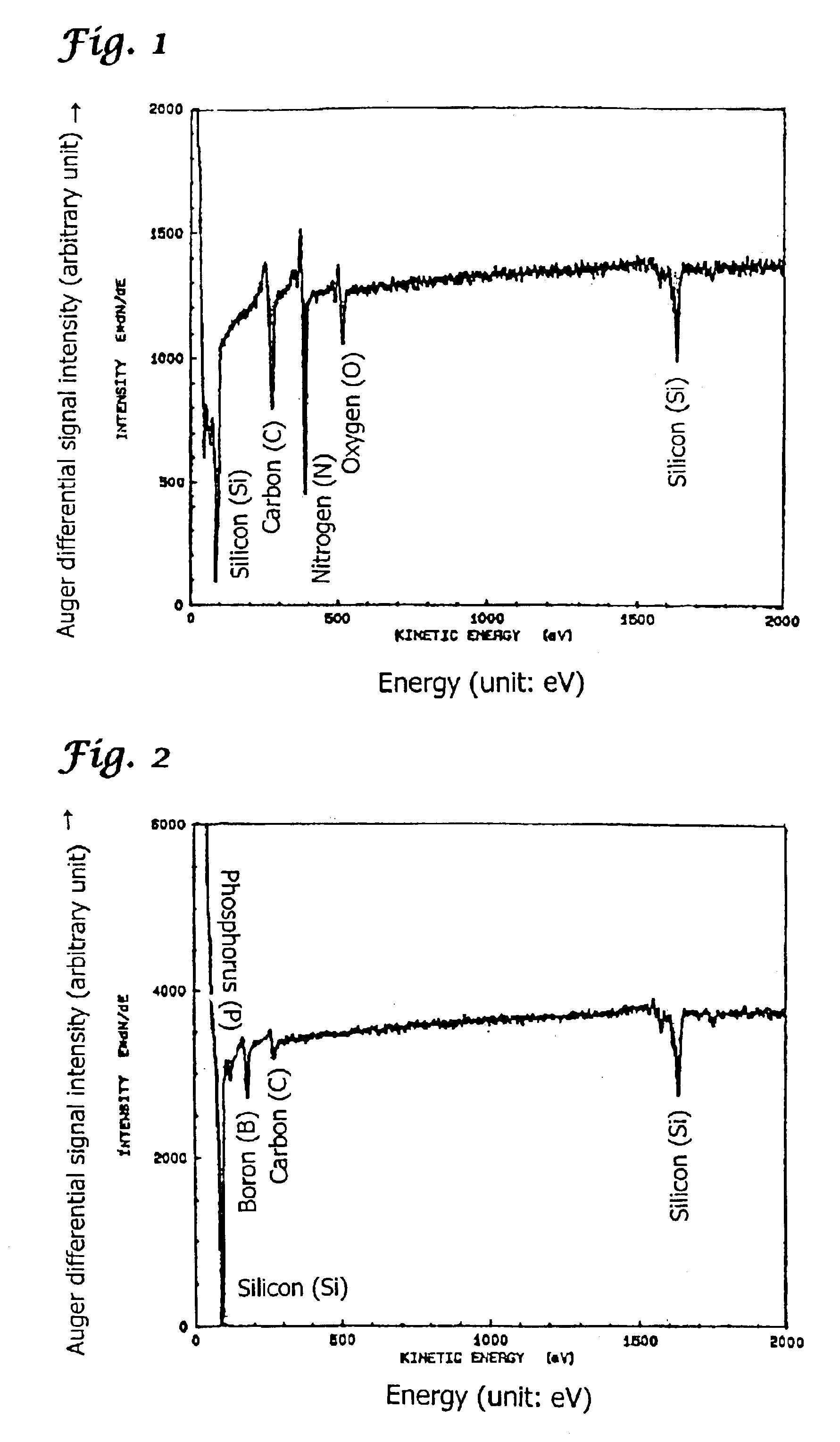

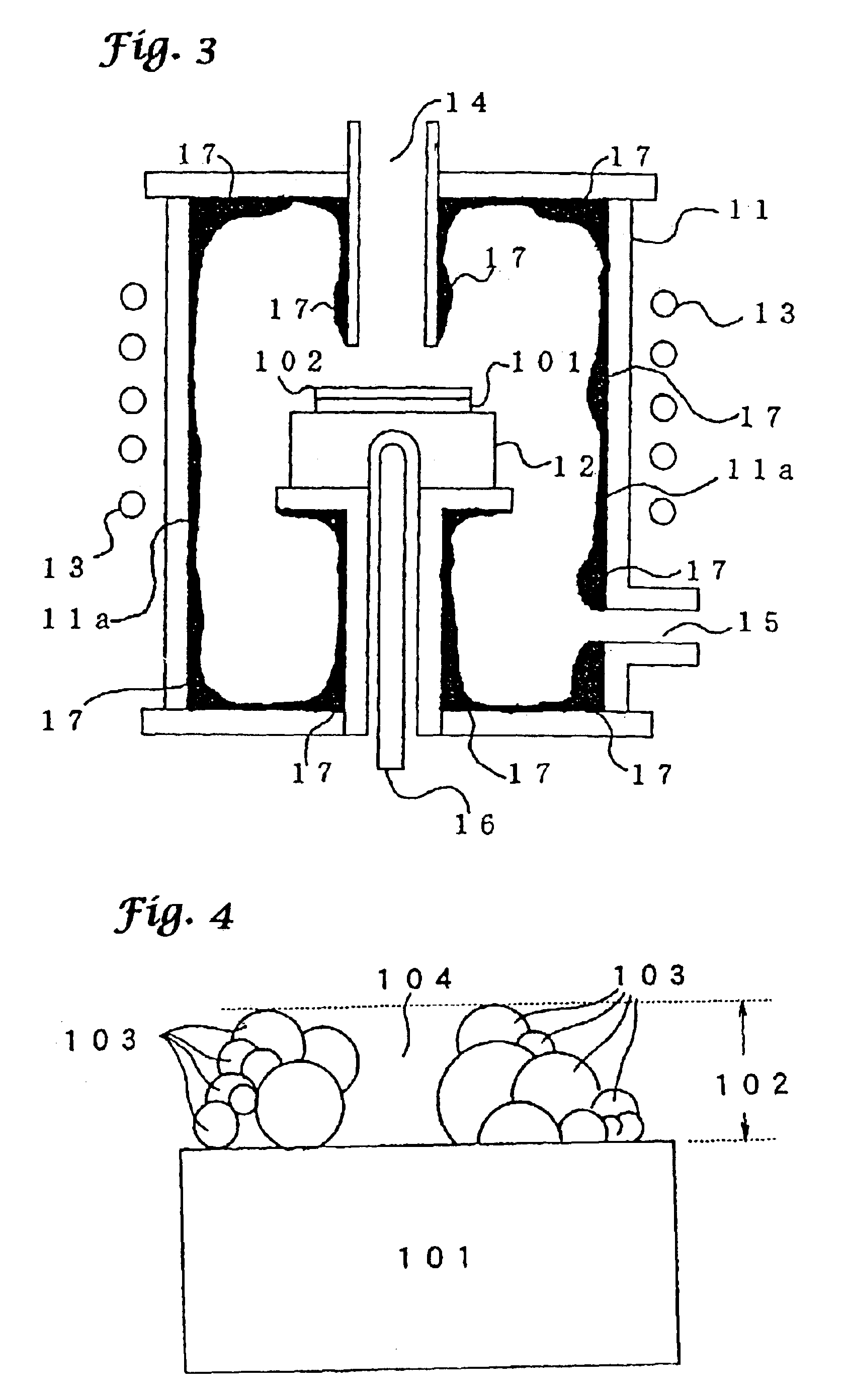

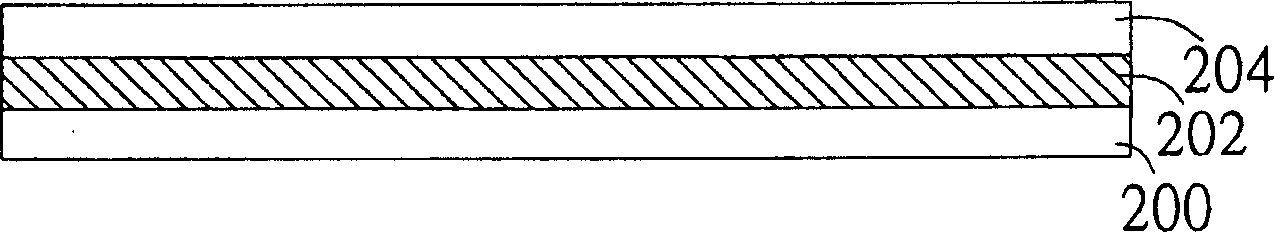

Boron phosphide-based semiconductor device production method thereof light-emitting diode and boron phosphide-based semiconductor layer

InactiveUS20050121693A1High crystallinityReduce dislocation densityPolycrystalline material growthSolid-state devicesDevice materialPhysical chemistry

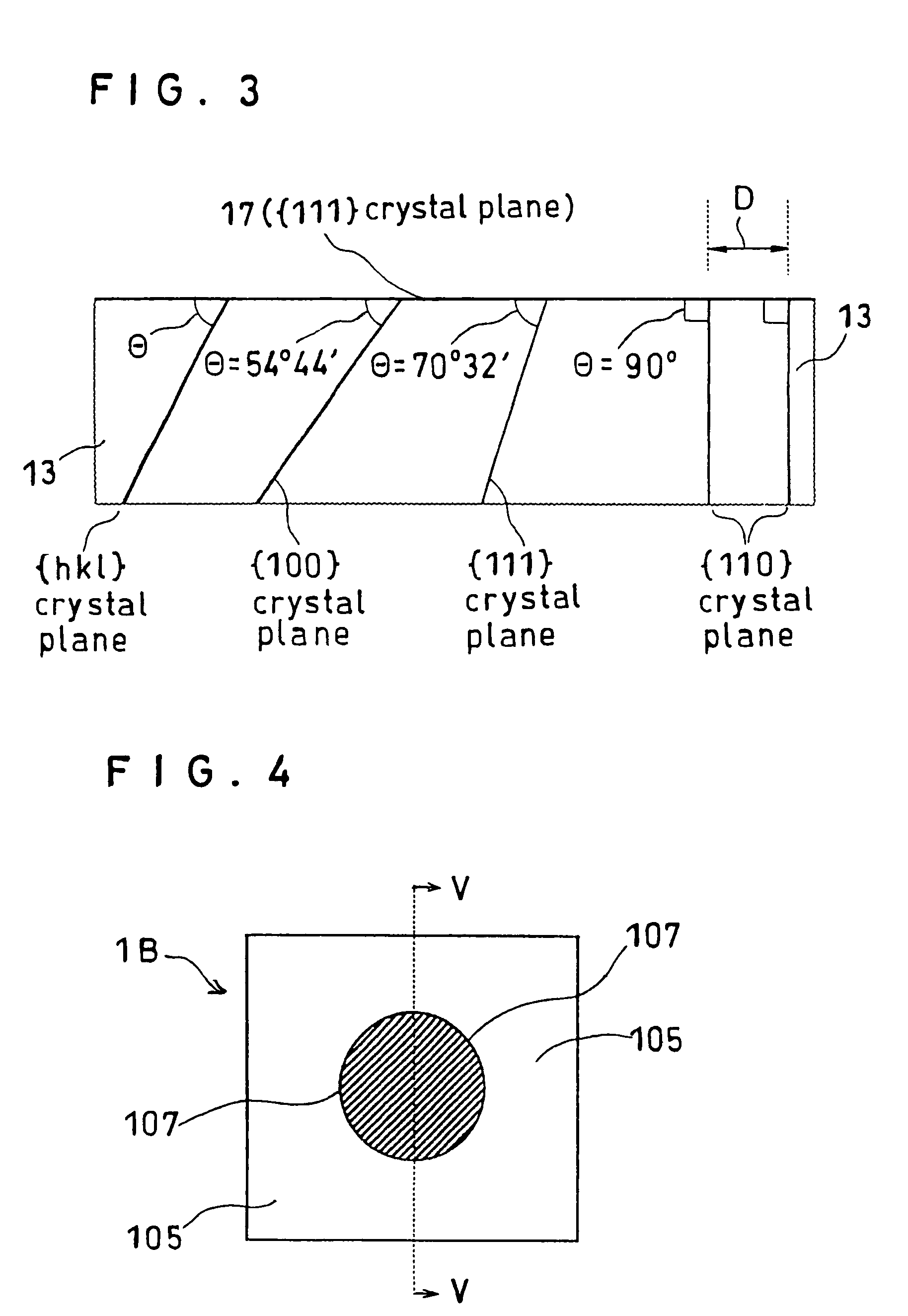

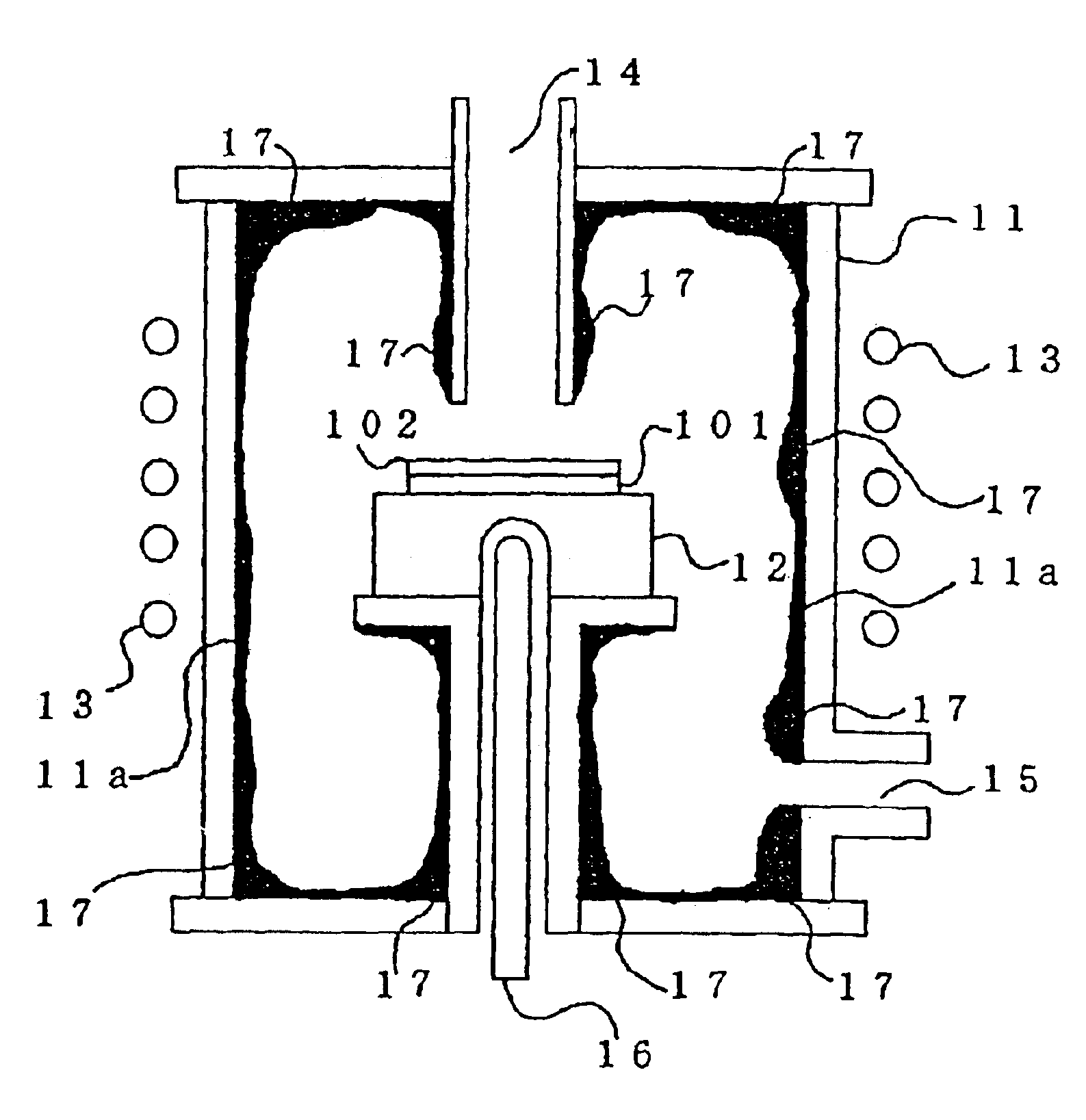

A boron phosphide-based semiconductor device enhanced in properties includes a substrate (11) composed of a {111}-Si single crystal having a surface {111} crystal plane and a boron phosphide-based semiconductor layer formed on the surface of the substrate and composed of a polycrystal layer (12) that is an aggregate of a plurality of a triangular pyramidal single crystal entities (13) of the boron phosphide-based semiconductor crystal, where in each single crystal entity has a twining interface that forms an angle of 60° relative to a <110> crystal direction of the substrate.

Owner:SHOWA DENKO KK

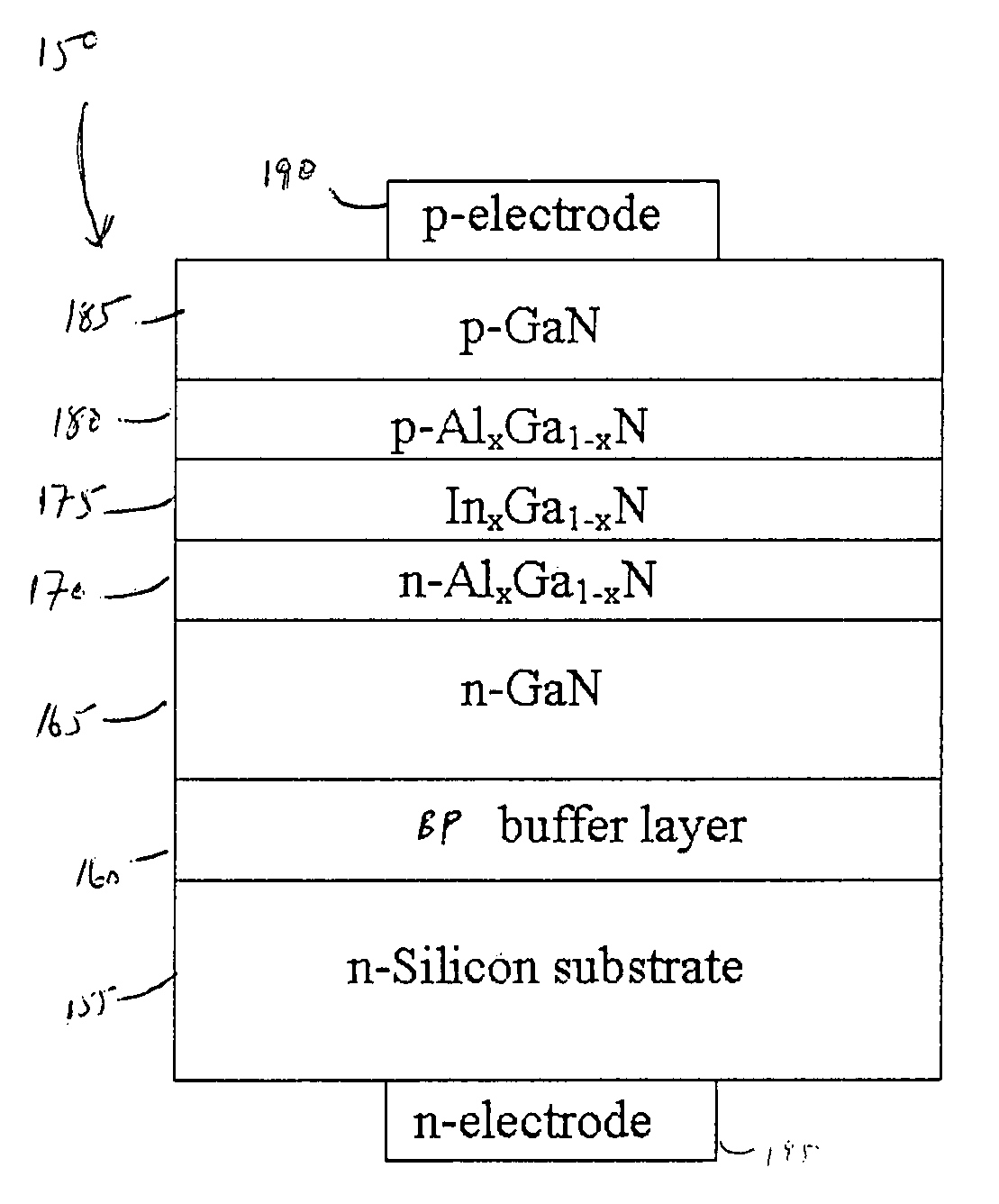

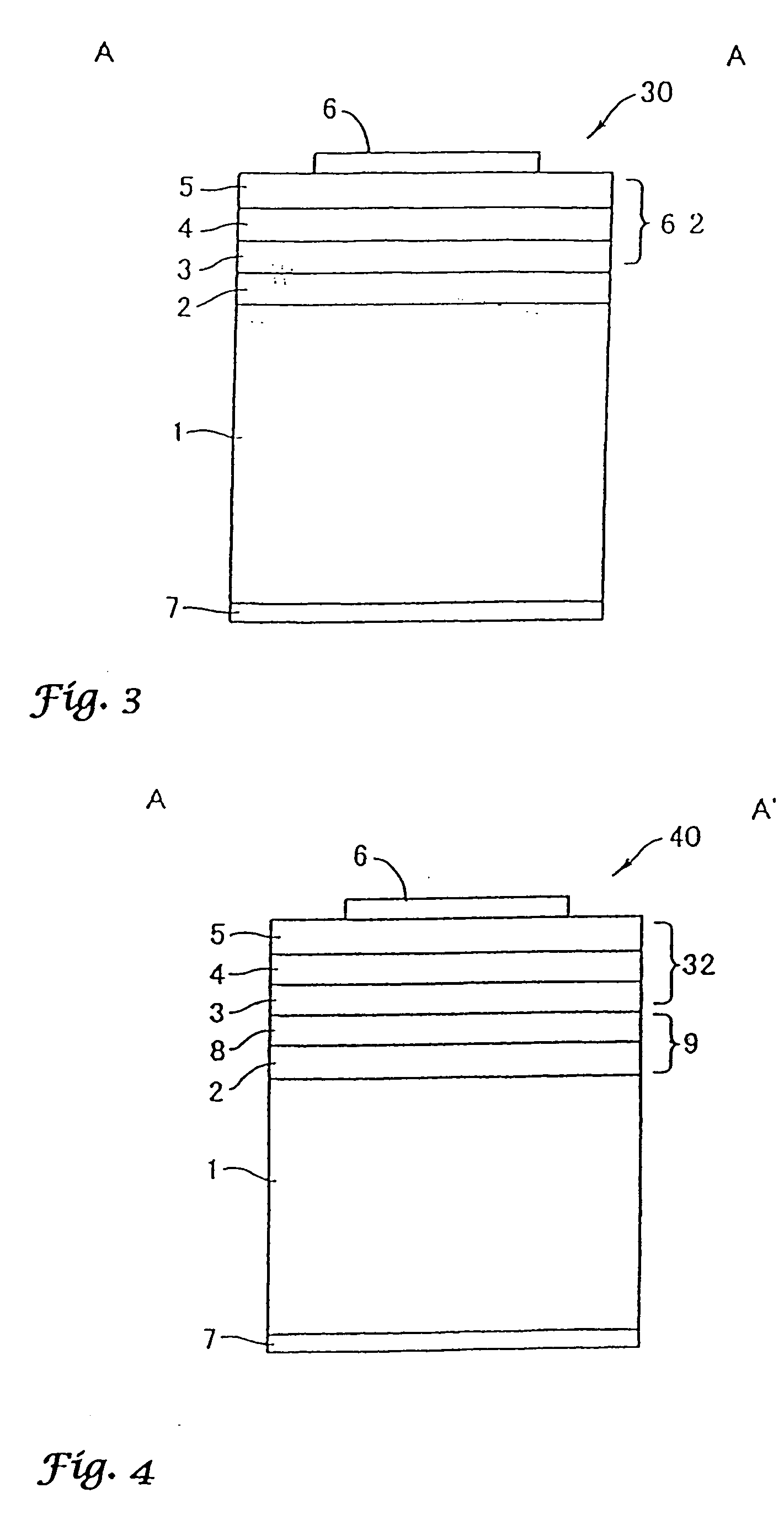

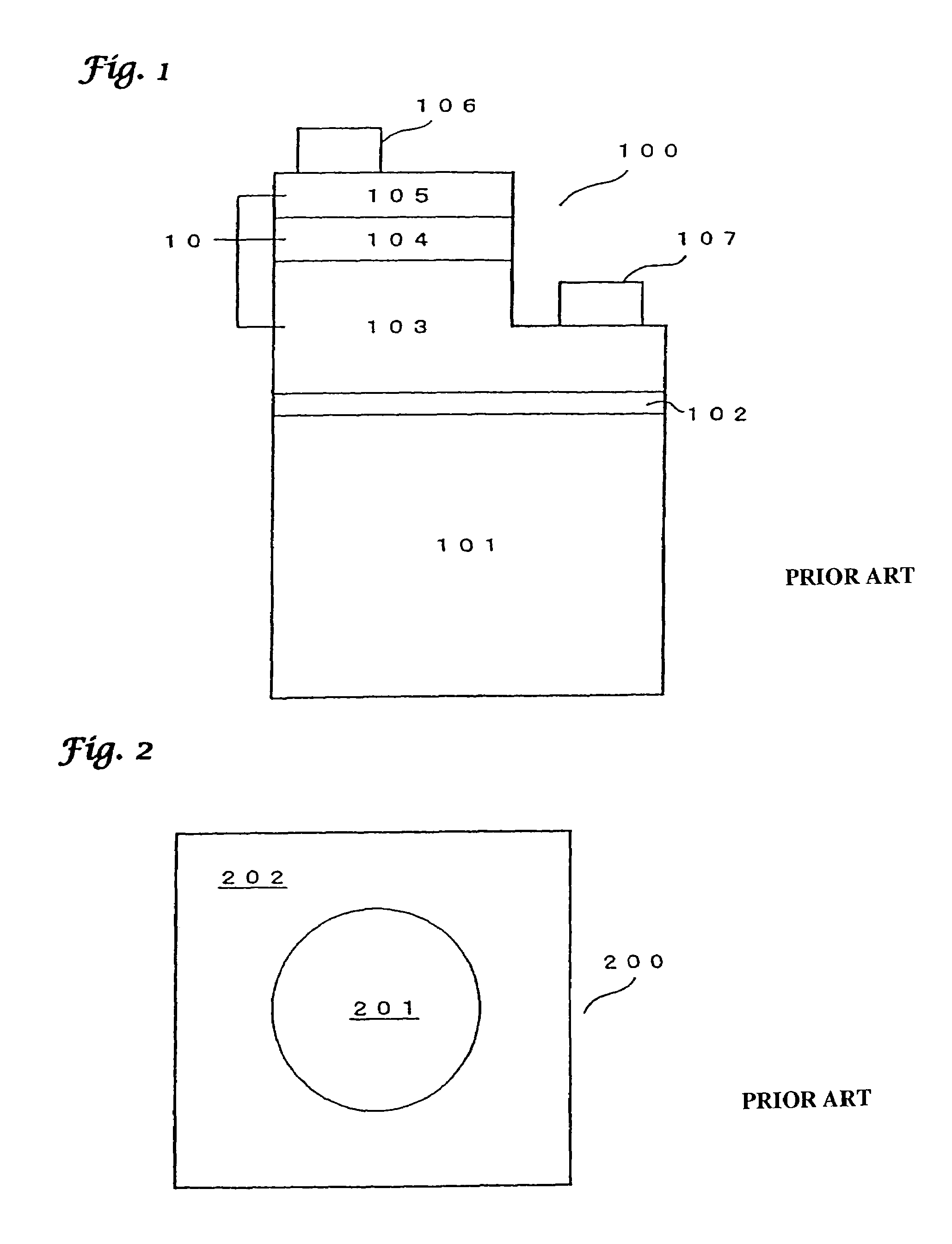

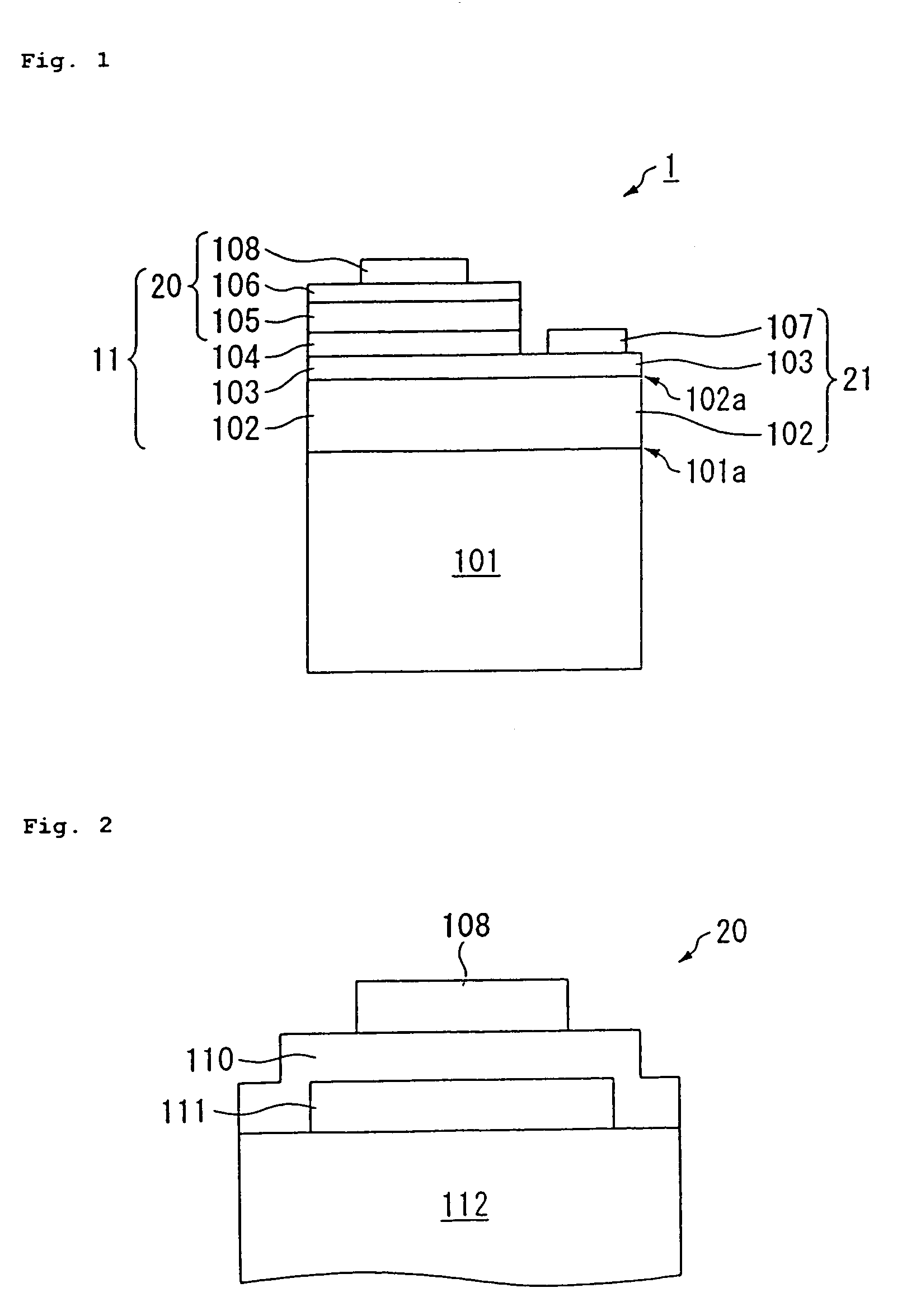

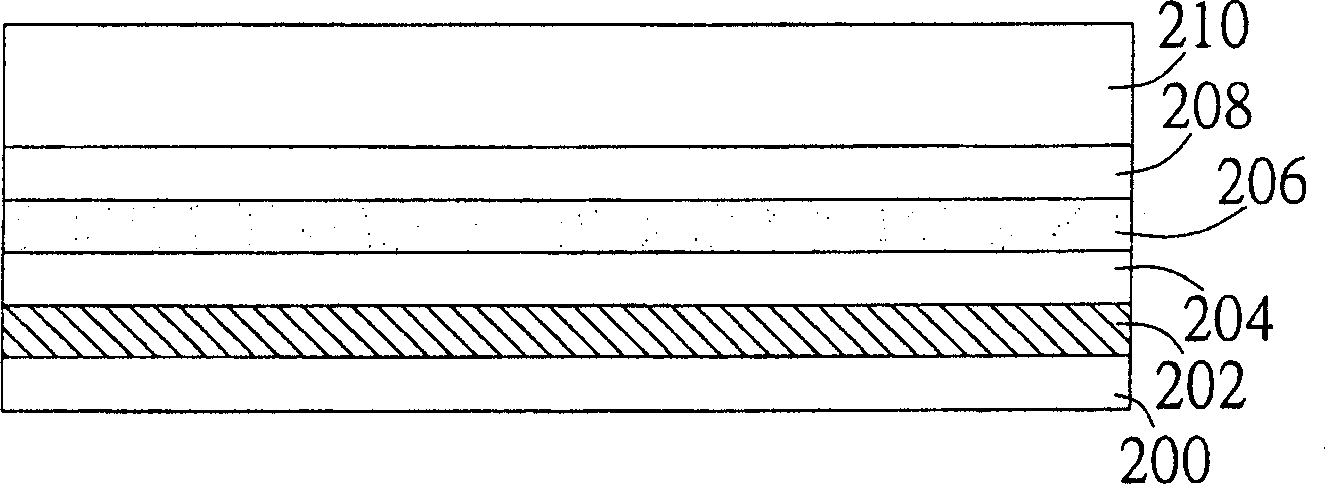

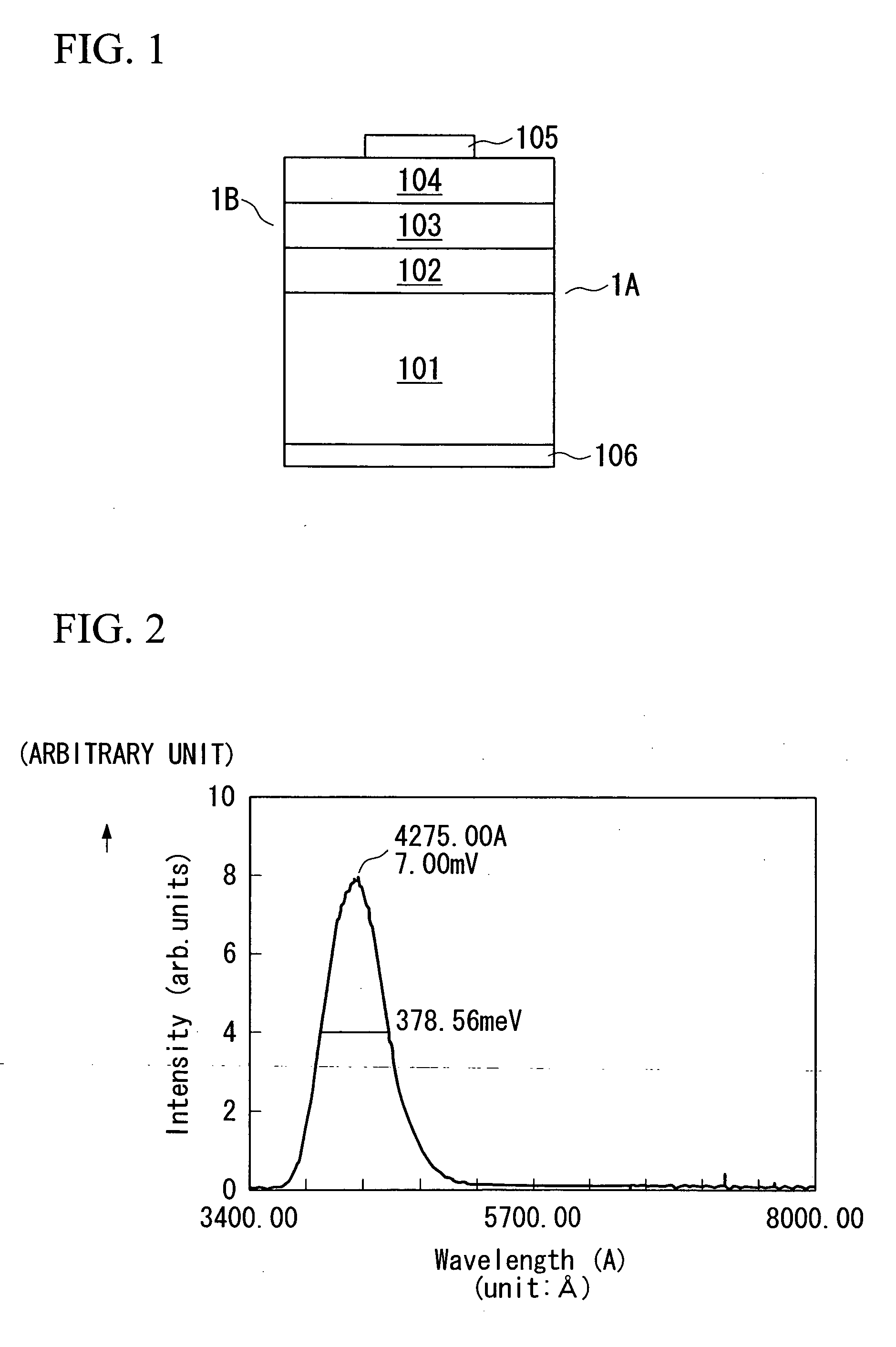

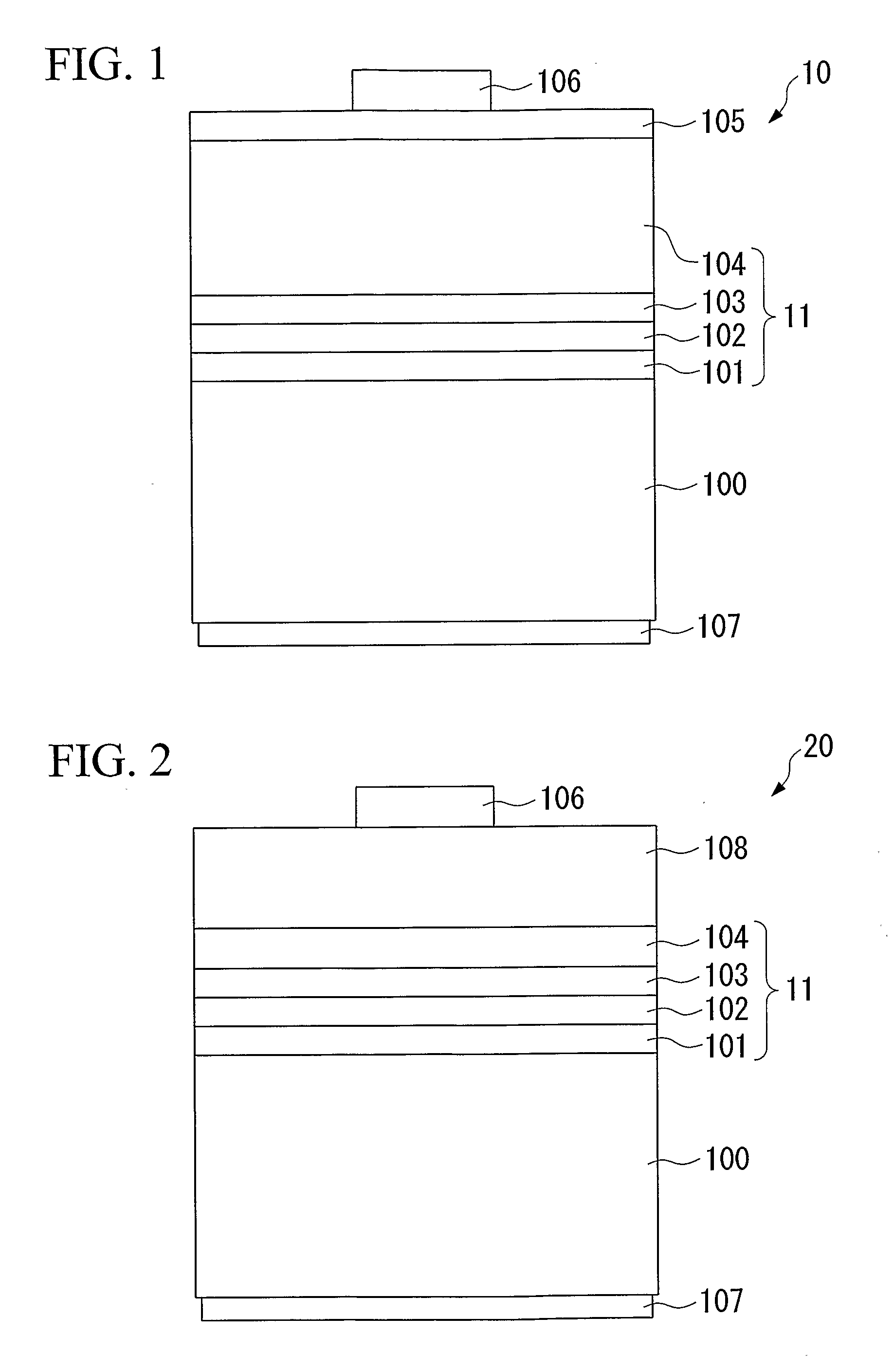

Group-III nitride semiconductor light-emitting device and production method thereof

InactiveUS20010054717A1High crystallinityLow densityTransistorSolid-state devicesLattice mismatchCrystallinity

A high emission intensity group-III nitride semiconductor light-emitting device obtained by eliminating crystal lattice mismatch with substrate crystal and using a gallium nitride phosphide-based light emitting structure having excellent crystallinity. A gallium nitride phosphide-based multilayer light-emitting structure is formed on a substrate via a boron phosphide (BP)-based buffer layer. The boron phosphide-based buffer layer is preferably grown at a low temperature and rendered amorphous so as to eliminate the lattice mismatch with the substrate crystal. After the amorphous buffer layer is formed, it is gradually converted into a crystalline layer to fabricate a light-emitting device while keeping the lattice match with the gallium nitride phosphide-based light-emitting part.

Owner:SHOWA DENKO KK

Group-III nitride semiconductor light-emitting device and production method thereof

InactiveUS20040144990A1Easy to makeEasy to separateSemiconductor/solid-state device manufacturingSemiconductor devicesLattice mismatchCrystallinity

A high emission intensity group-III nitride semiconductor light-emitting device obtained by eliminating crystal lattice mismatch with substrate crystal and using a gallium nitride phosphide-based light emitting structure having excellent crystallinity. A gallium nitride phosphide-based multilayer light-emitting structure is formed on a substrate via a boron-phosphide (BP)-based buffer layer. The boron phosphide-based buffer layer is preferably grown at a low temperature and rendered amorphous so as to eliminate the lattice mismatch with the substrate crystal. After the amorphous buffer layer is formed, it is gradually converted into a crystalline layer to fabricate a light-emitting device while keeping the lattice match with the gallium nitride phosphide-based light-emitting part.

Owner:RESONAC HOLDINGS CORPORATION

Boron phosphide-based semiconductor light-emitting device and production method thereof

InactiveUS20060163588A1Solid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceLight emitting device

Owner:SHOWA DENKO KK

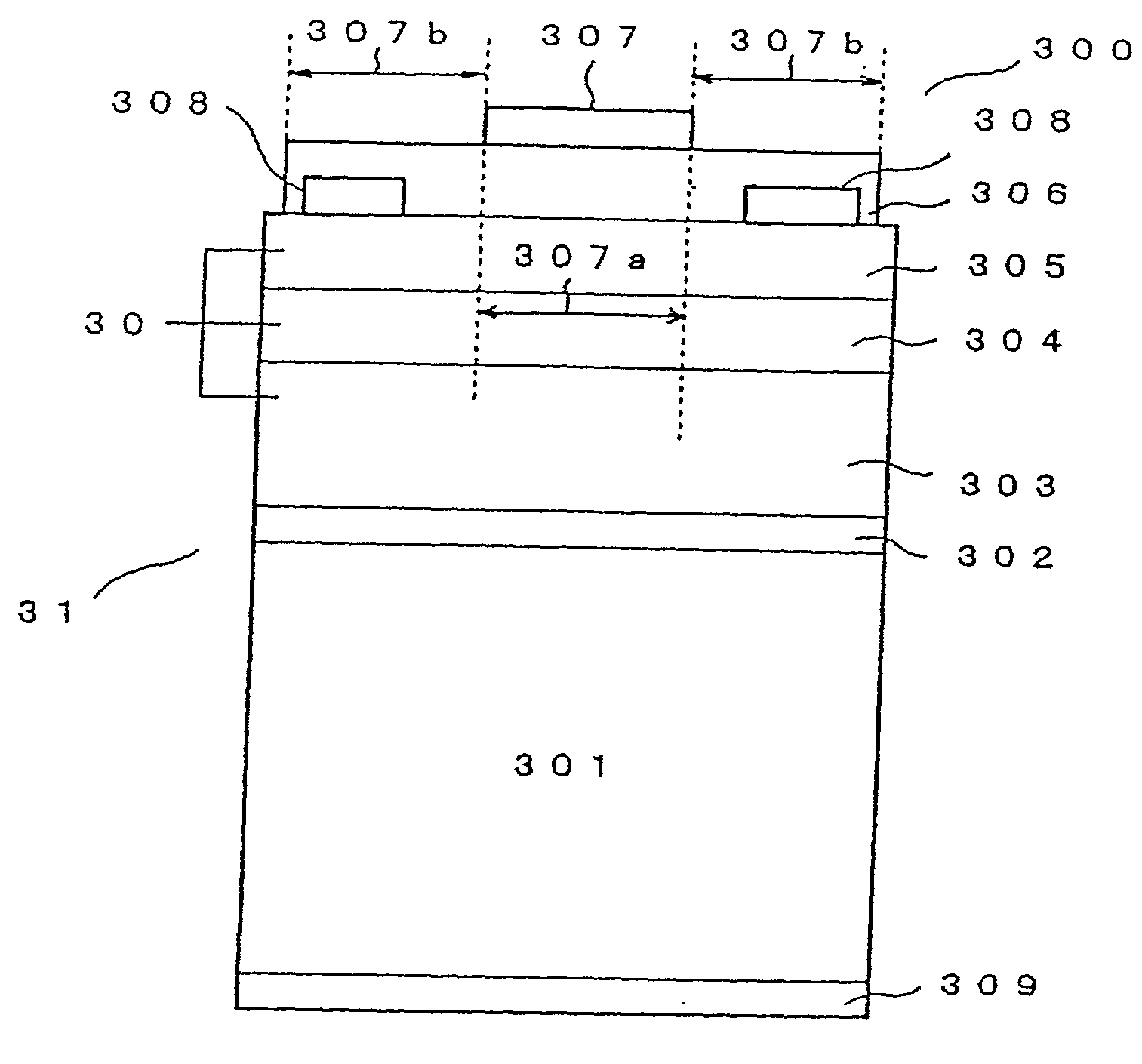

Group-III nitride semiconductor light-emitting diode, light-emitting diode lamp, light source, electrode for group-III nitride semiconductor light-emitting diode, and method for producing the electrode

InactiveUS6984851B2Semiconductor/solid-state device manufacturingSemiconductor devicesDriving currentLuminous intensity

The present invention solves the problem of conventional group-III nitride semiconductor LED in that, since the LED driving current is supplied only from a pad electrode serving also as an ohmic electrode, the driving current cannot diffuse over a wide range of the light-emitting region and a group-III nitride semiconductor LED having high light emission intensity cannot be successfully provided. A group-III nitride semiconductor LED having high light emission intensity, which is fabricated using a stacked layer structure obtained by providing a surface ohmic electrode, a window layer including an electrically conducting transparent oxide crystal layer and a pad electrode on an electrically conducting substrate through a boron phosphide (BP)-based buffer layer to allow the driving current to diffuse over a wide range of the light-emitting region is provided.

Owner:SHOWA DENKO KK

Ohmic electrode structure, compound semiconductor light emitting device having the same and led lamp

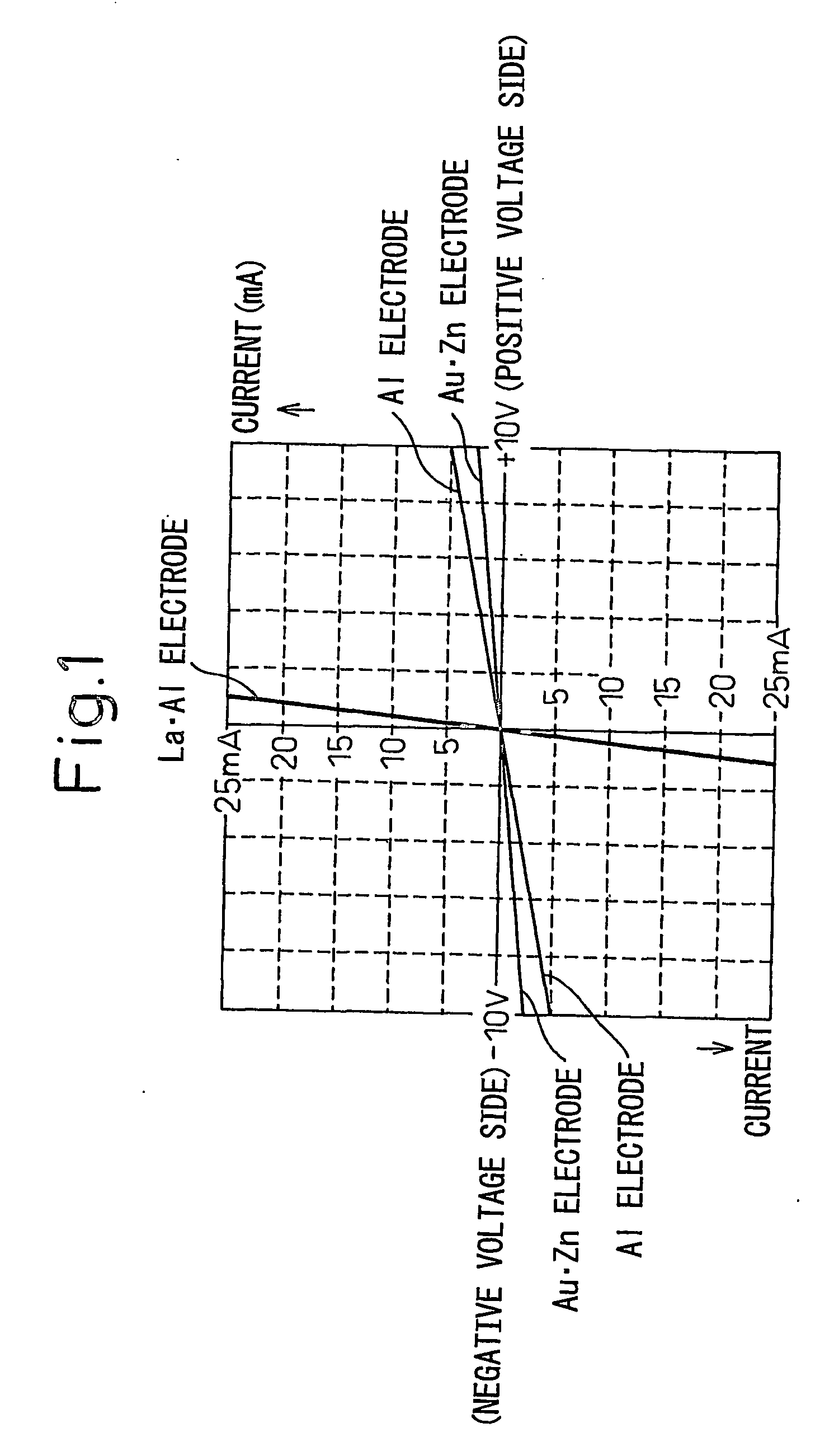

InactiveUS20060214182A1Solid-state devicesSemiconductor/solid-state device manufacturingOhmic contactLanthanide

An Ohmic electrode structure comprising a p-conductivity-type boron phosphide-based semiconductor layer containing boron and phosphorus as constitutional elements and having a surface; and an electrode disposed on said surface of said semiconductor layer and having an Ohmic contact with said semiconductor layer, wherein at least a surface portion of said electrode which is in contact with said semiconductor layer is formed from a lanthanide element or a lanthanide element-containing alloy. A compound semiconductor light-emitting device comprising a light-emitting layer formed of a compound semiconductor may advantageously comprise the Ohmic electrode structure

Owner:SHOWA DENKO KK

Semiconductor device, semiconductor layer and production method thereof

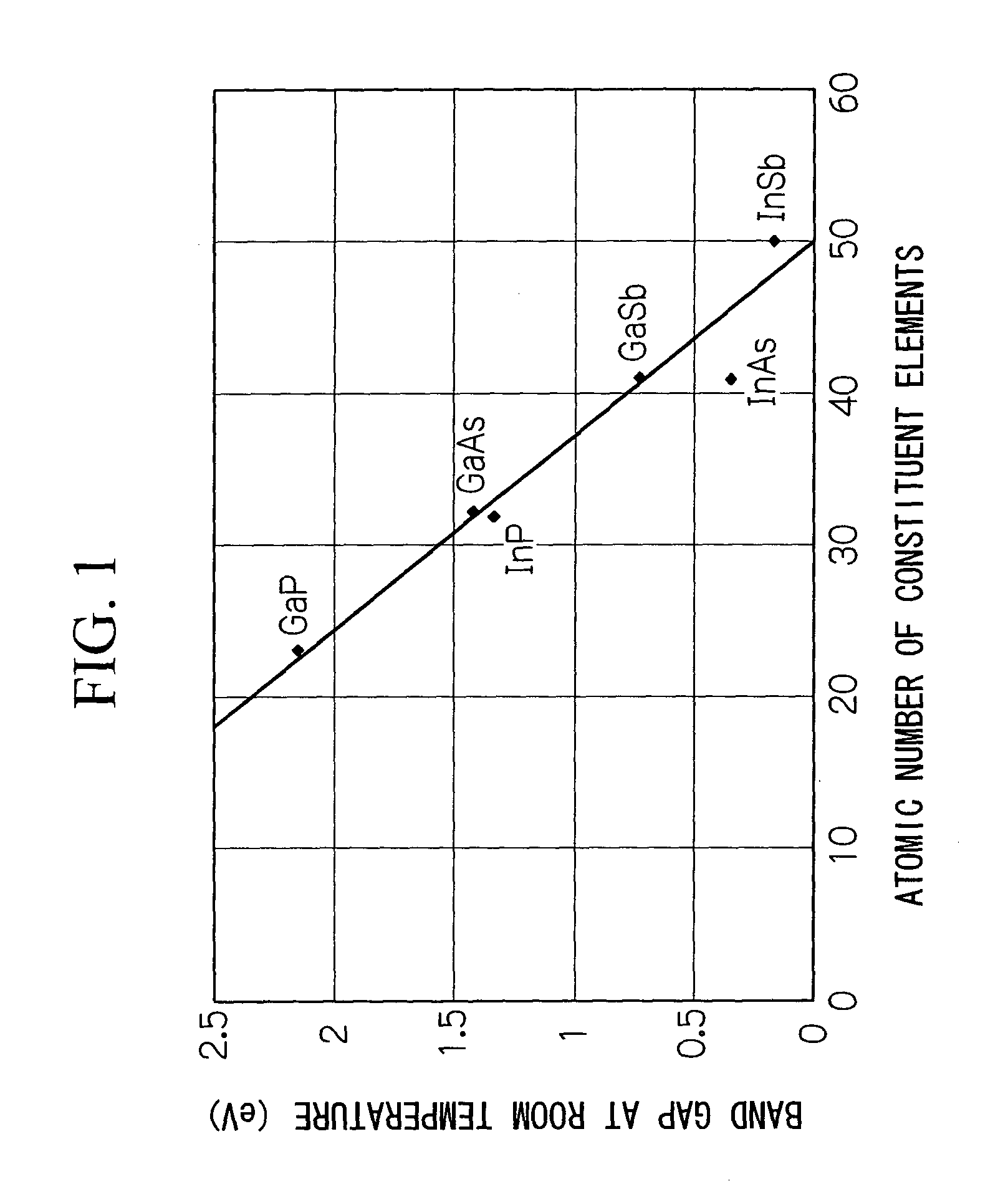

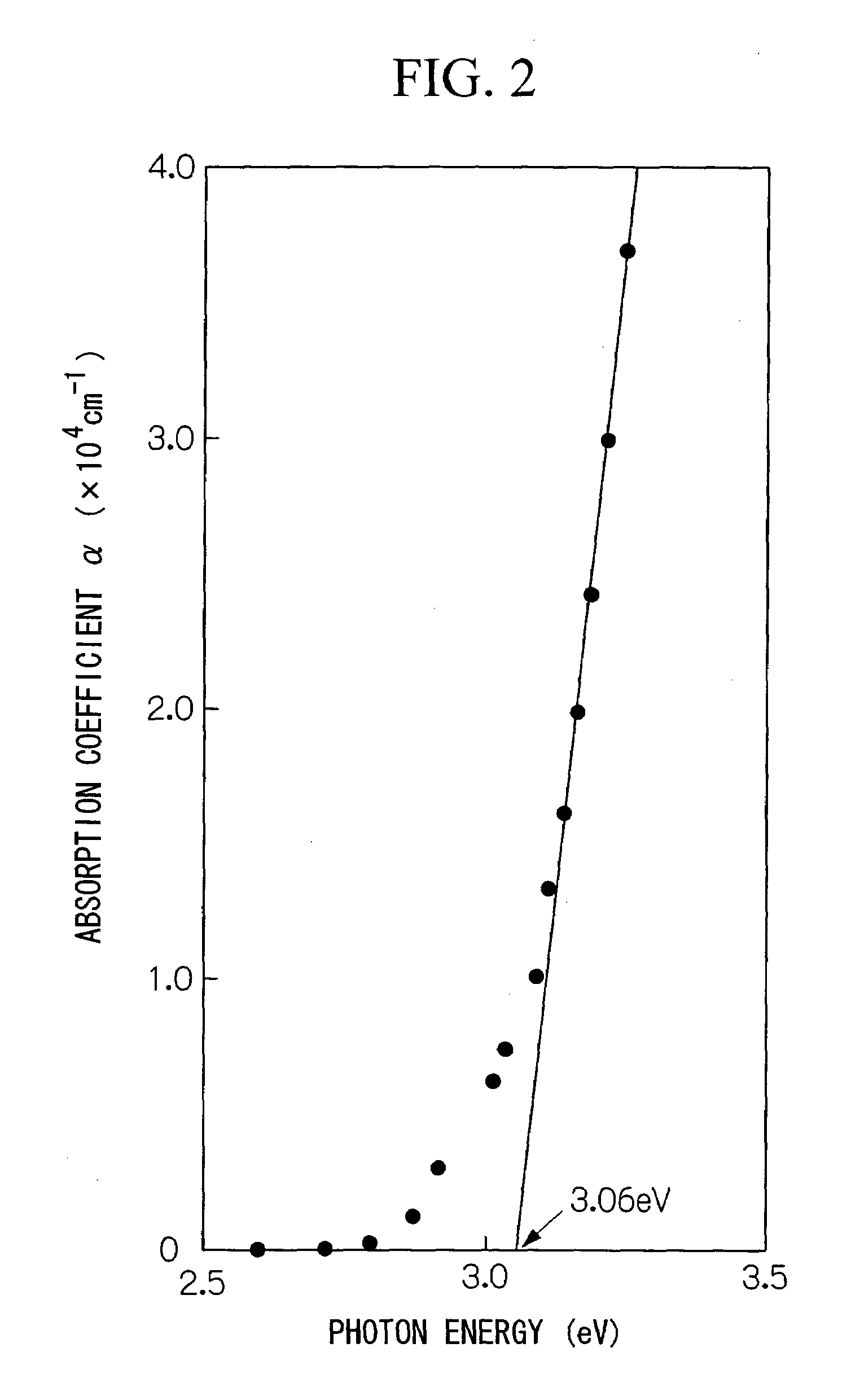

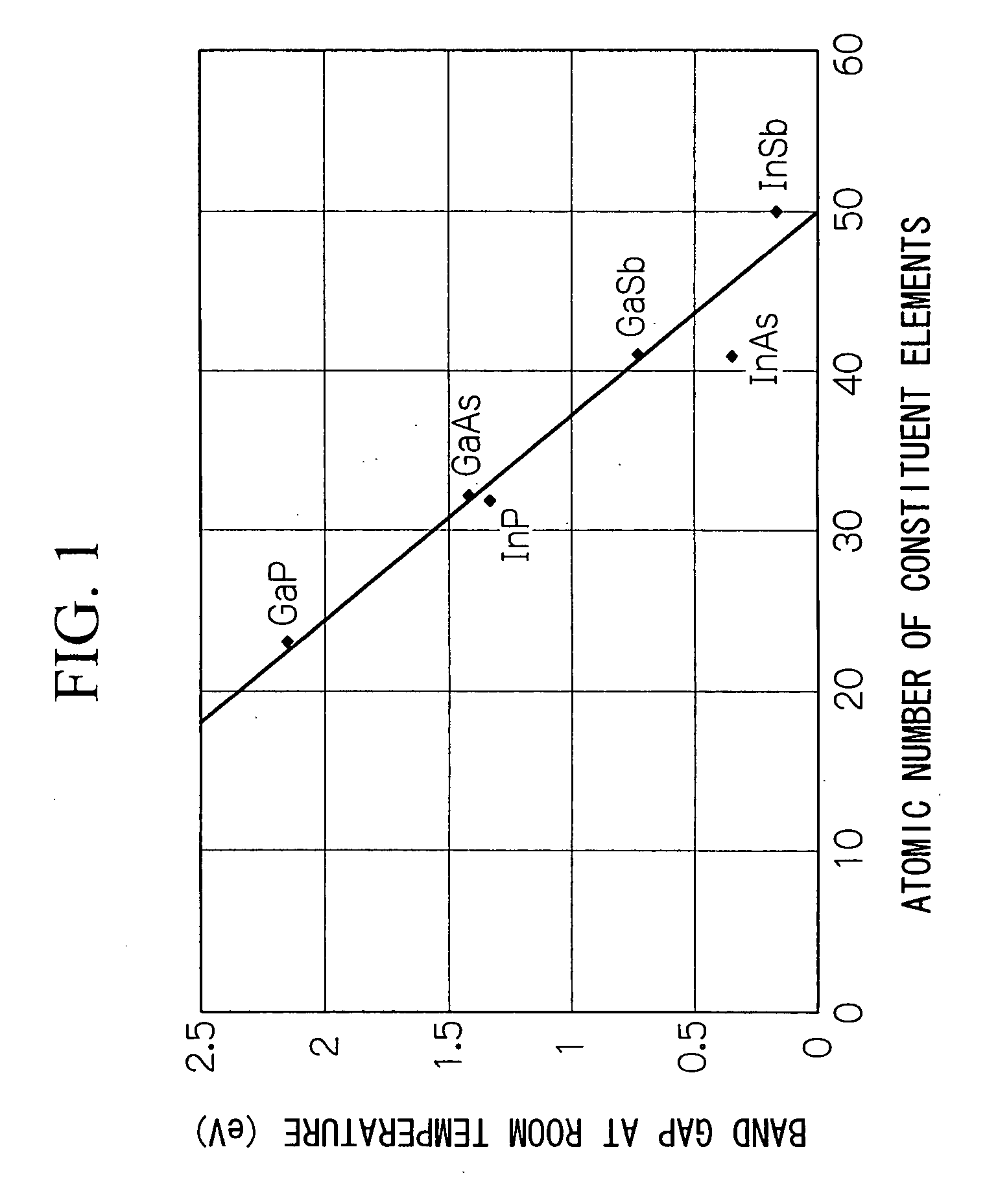

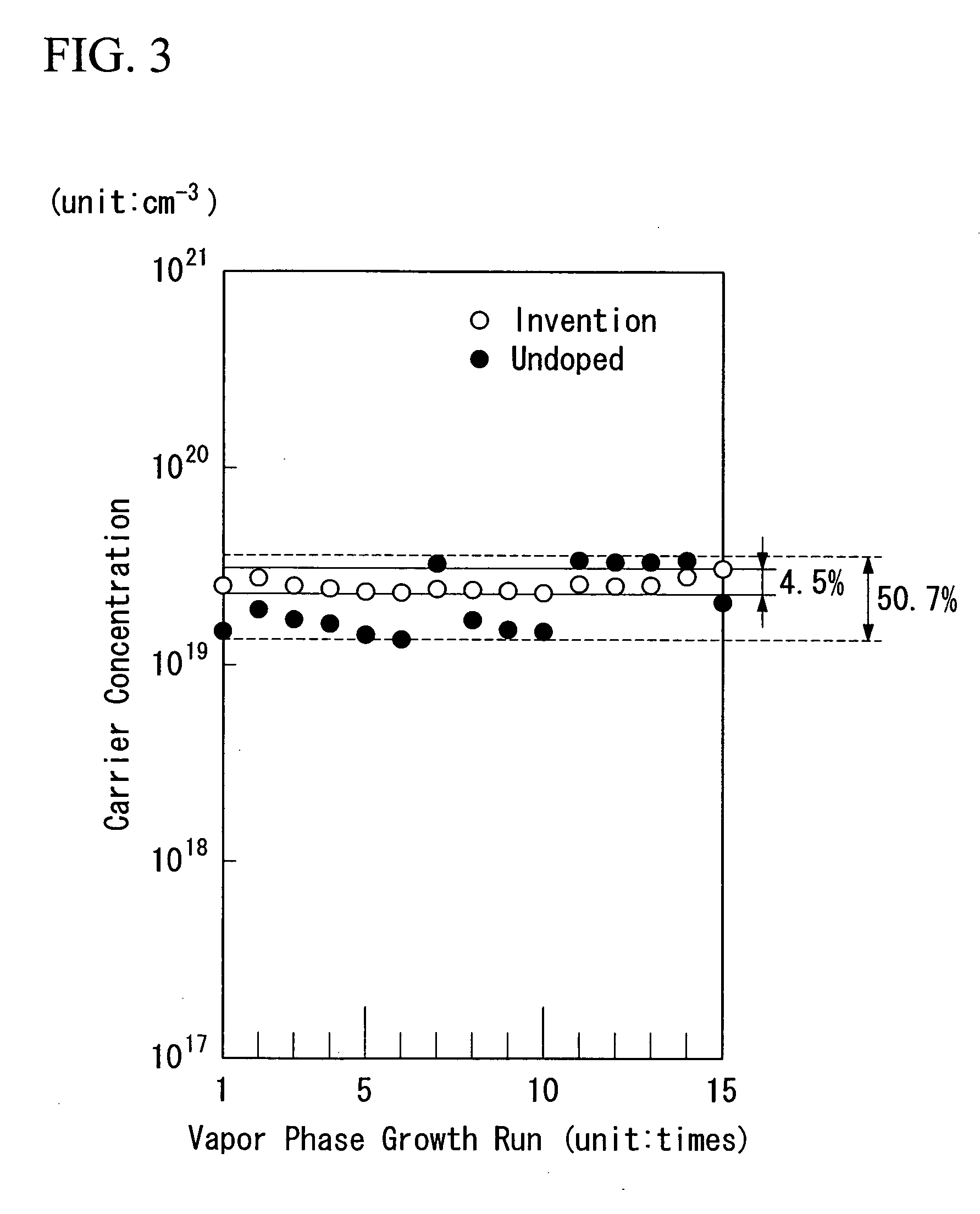

InactiveUS7315050B2Polycrystalline material growthFinal product manufactureRoom temperatureVapor phase

A semiconductor device is prepared by the use of a vapor phase method and is provided with a semiconductor layer composed of boron phosphide (BP) having a band gap at room temperature of not less than 2.8 eV and not more than 3.4 eV or a boron phosphide (BP)-base mixed crystal which contains the boron phosphide (BP) and which is represented by the formula: BalphaAlbetaGagammaIn1-alpha-beta-gammaPdeltaAsepsilonN1-delta-epsilon (0<alpha<=1, 0<=beta<1, 0<=gamma<1, 0<alpha+beta+gamma<=1, 0<delta<=1, 0<=epsilon<1, 0<delta+epsilon<=1).

Owner:SHOWA DENKO KK

Group-III nitride semiconductor device, production method thereof and light-emitting diode

InactiveUS7034330B2Reduce contact resistanceFree from local breakdownSemiconductor/solid-state device manufacturingSemiconductor devicesVapor phaseLight-emitting diode

A Group-III nitride semiconductor device including a crystal substrate, an electrically conducting Group-III nitride semiconductor (AlXGaYIn1−(X+Y)N: 0≦X<1, 0<Y≦1 and 0<X+Y≦1) crystal layer vapor-phase grown on the crystal substrate, an ohmic electrode and an electrically conducting boron phosphide crystal layer provided between the ohmic electrode and the Group-III nitride semiconductor crystal layer, the ohmic electrode being disposed in contact with the boron phosphide crystal layer. Also disclosed is a method for producing the Group-III nitride semiconductor device, and a light-emitting diode including the Group-III nitride semiconductor device.

Owner:SHOWA DENKO KK

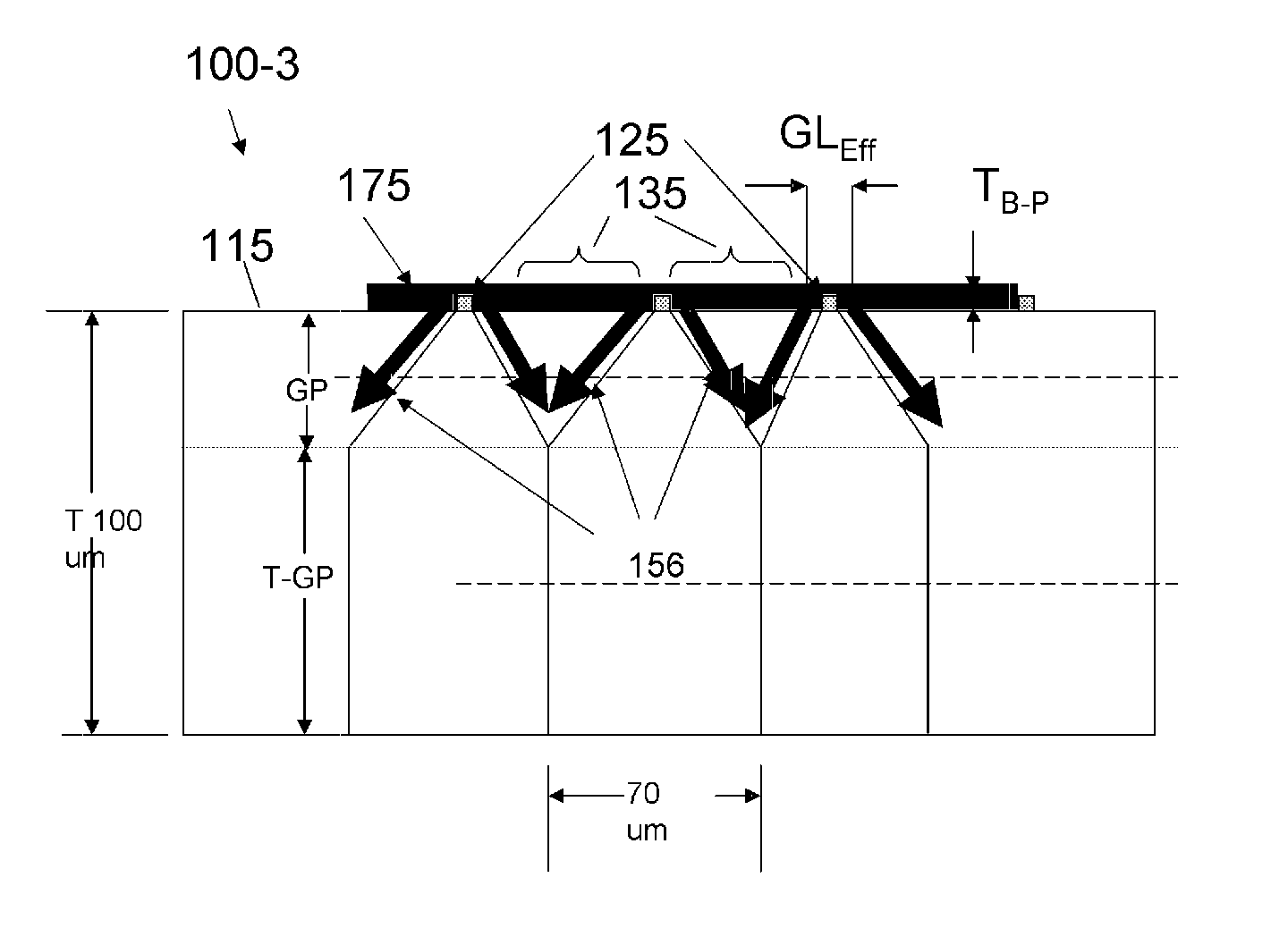

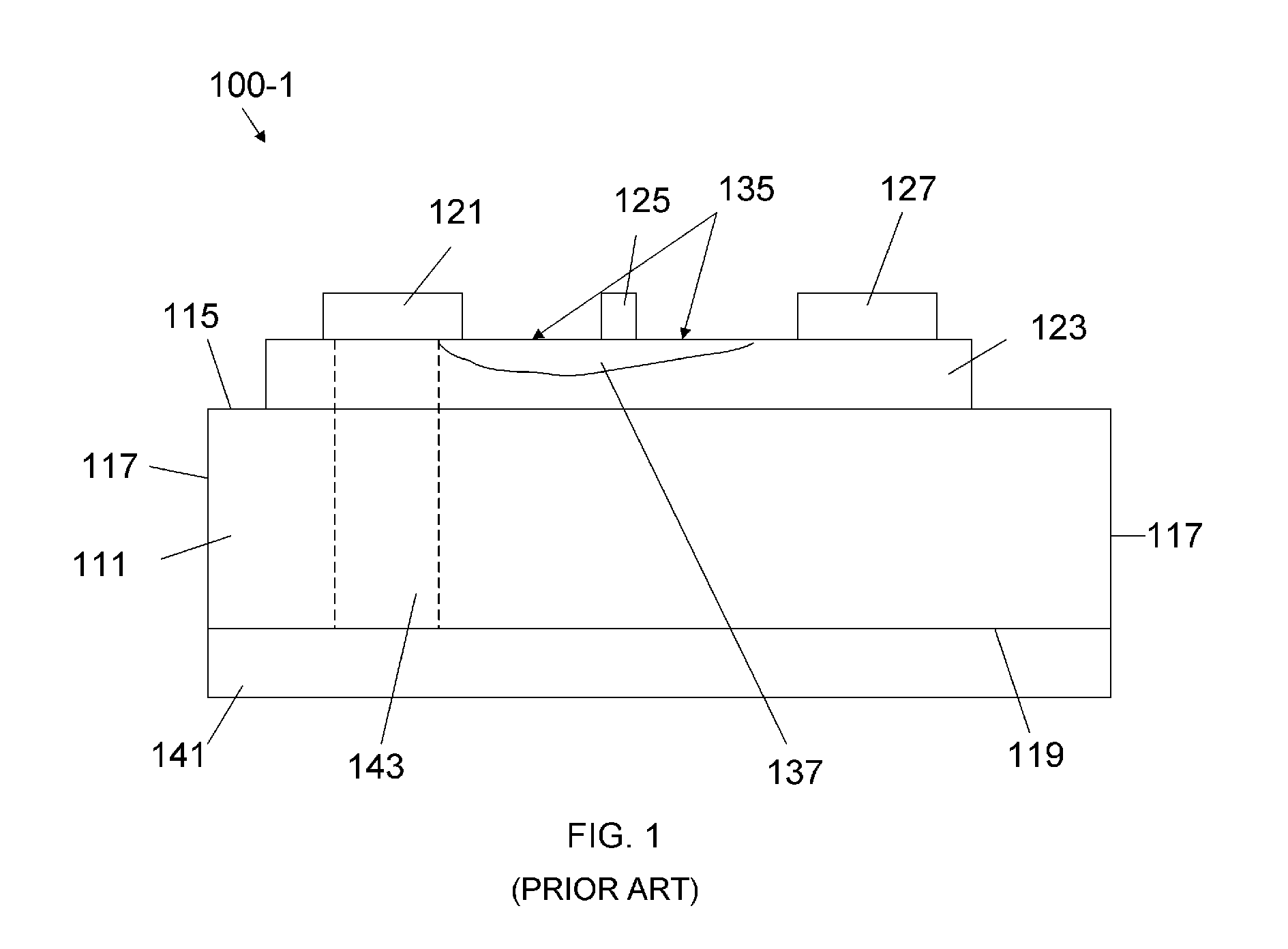

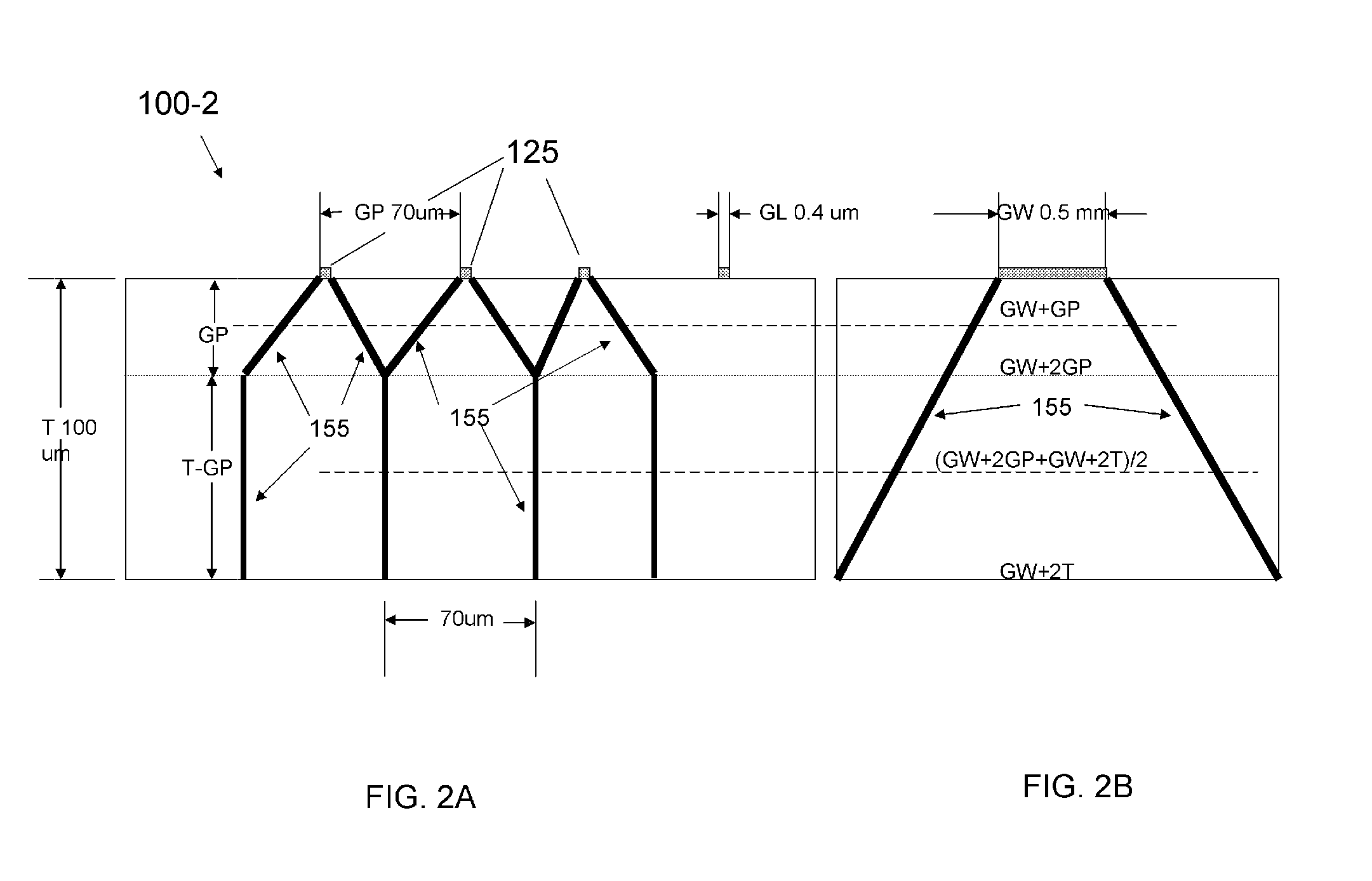

Topside Thermal Management of Semiconductor Devices

InactiveUS20070194384A1Improved thermal managementSemiconductor/solid-state device detailsSolid-state devicesDevice materialChemical vapor deposition

A semiconductor device including at least one gate terminal in operational contact with an active layer or top surface of the semiconductor substrate includes a deposited layer of boron phosphide covering the gate terminal and at least a portion of the active layer or the top surface next to and extending from the gate terminal. According to an aspect, the layer of boron phosphide is deposited by a chemical vapor deposition (CVD) process. The boron phosphide layer will have a thickness less than or equal to about 10 microns. The boron phosphide provides a heat spreading coating across the die surface, thus increasing the surface area that conducts the heat from the die. Since the boron phosphide coating is in intimate contact with the gate terminal(s) and the immediately adjacent passivation surfaces of the device, generated heat can rapidly spread away from the active junction or channel. The additional thermal path(s) provided by the boron phosphide coating may terminate away from the active region to further conduct away the heat through thermally unused areas of the device.

Owner:LOCKHEED MARTIN CORP

High-temperature resistant automobile air-conditioning wiring harness and preparation method thereof

InactiveCN108059724AImprove high temperature resistanceHigh strengthChemical industryElectric/fluid circuitFiberAdhesive

The invention discloses a high-temperature resistant automobile air-conditioning wiring harness and a preparation method thereof. The high-temperature resistant automobile air-conditioning wiring harness consists of two parts, namely a wiring harness shell and a thermal-insulating membrane, wherein the wiring harness shell consists of natural rubber, a PEEK (Polyetheretherketone) material and polyvinyl chloride; the thermal-insulating membrane consists of silicon carbide powder, a high-temperature resistant fiber, boron phosphide, polyethylene and a high-temperature adhesive. As the wiring harness shell is made of three raw materials, namely the natural rubber, the PEEK material and the polyvinyl chloride, as master batch, the strength of the wiring harness shell can be improved, and the preparation efficiency can be improved; the constitution components, namely the silicon carbide powder, he high-temperature resistant fiber, the boron phosphide, the polyethylene and the like, of the thermal-insulating membrane, are very good in thermal resistance, so that the thermal resistance of the prepared thermal-insulating membrane is improved; finally by using the high-temperature adhesive,the wiring harness shell and the thermal-insulating membrane can be well adhered, and due to a water cooling mode, the toughness of the thermal-insulating membrane can be ensured.

Owner:SUZHOU RENWEIFENG SOFTWARE TECH

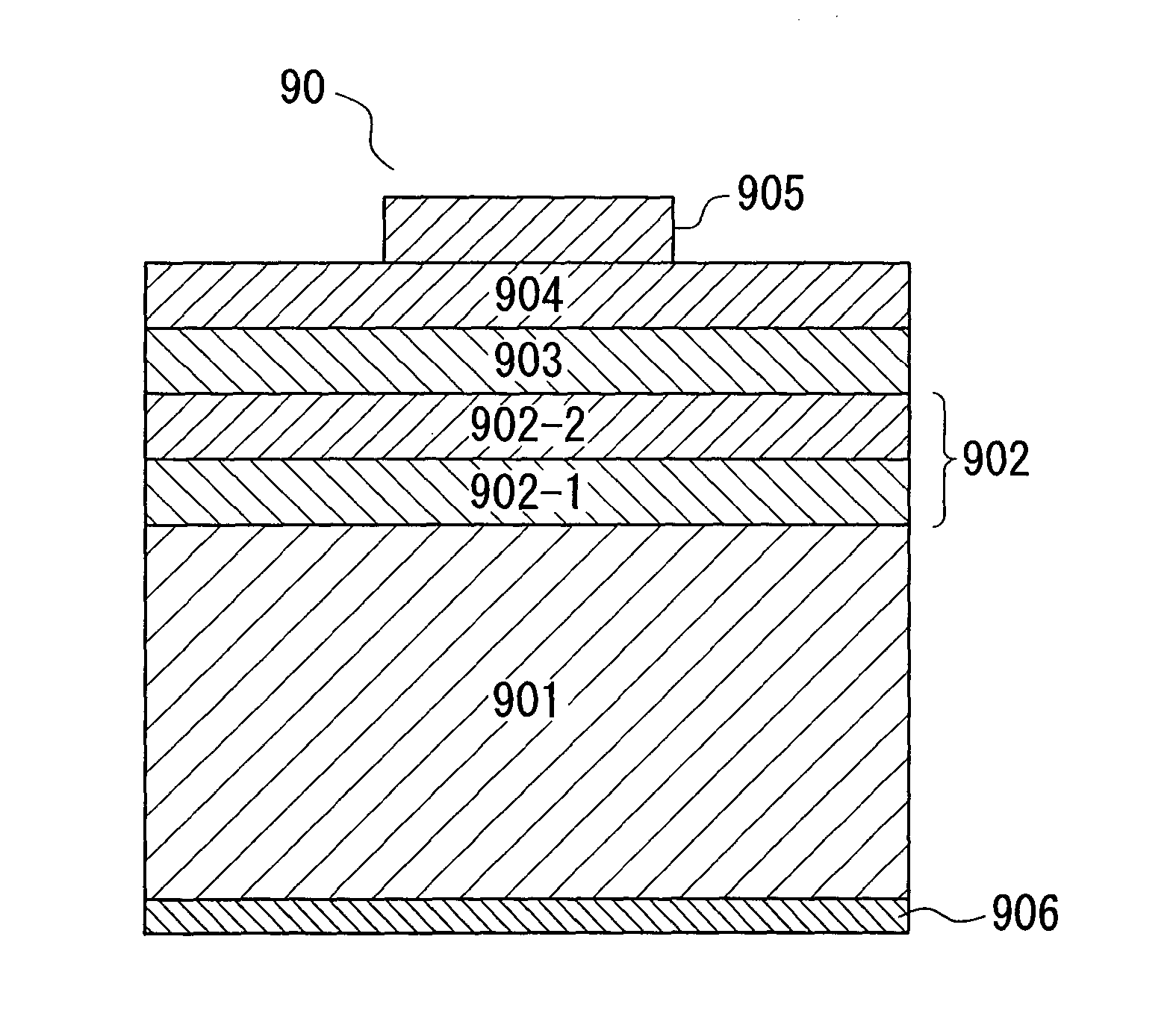

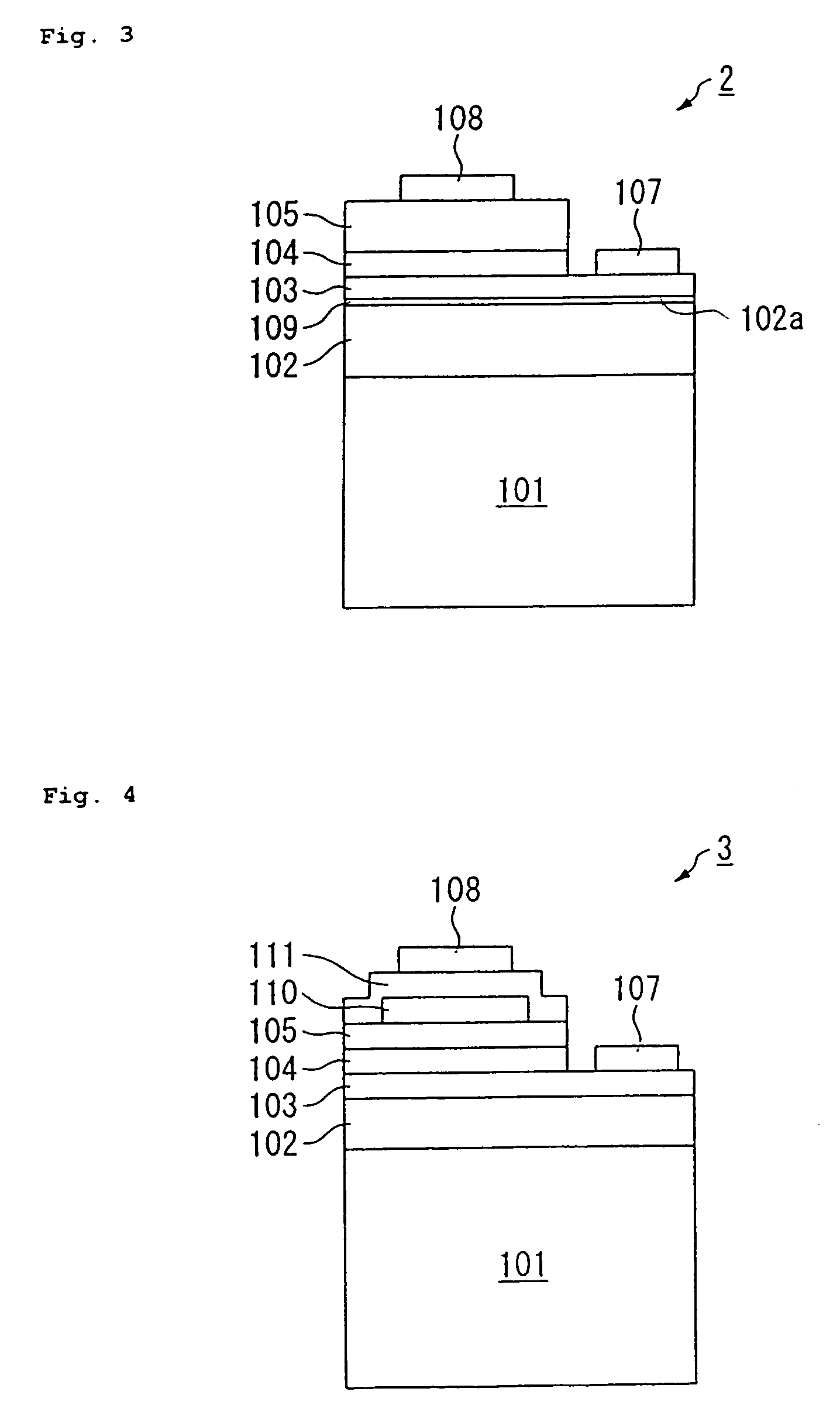

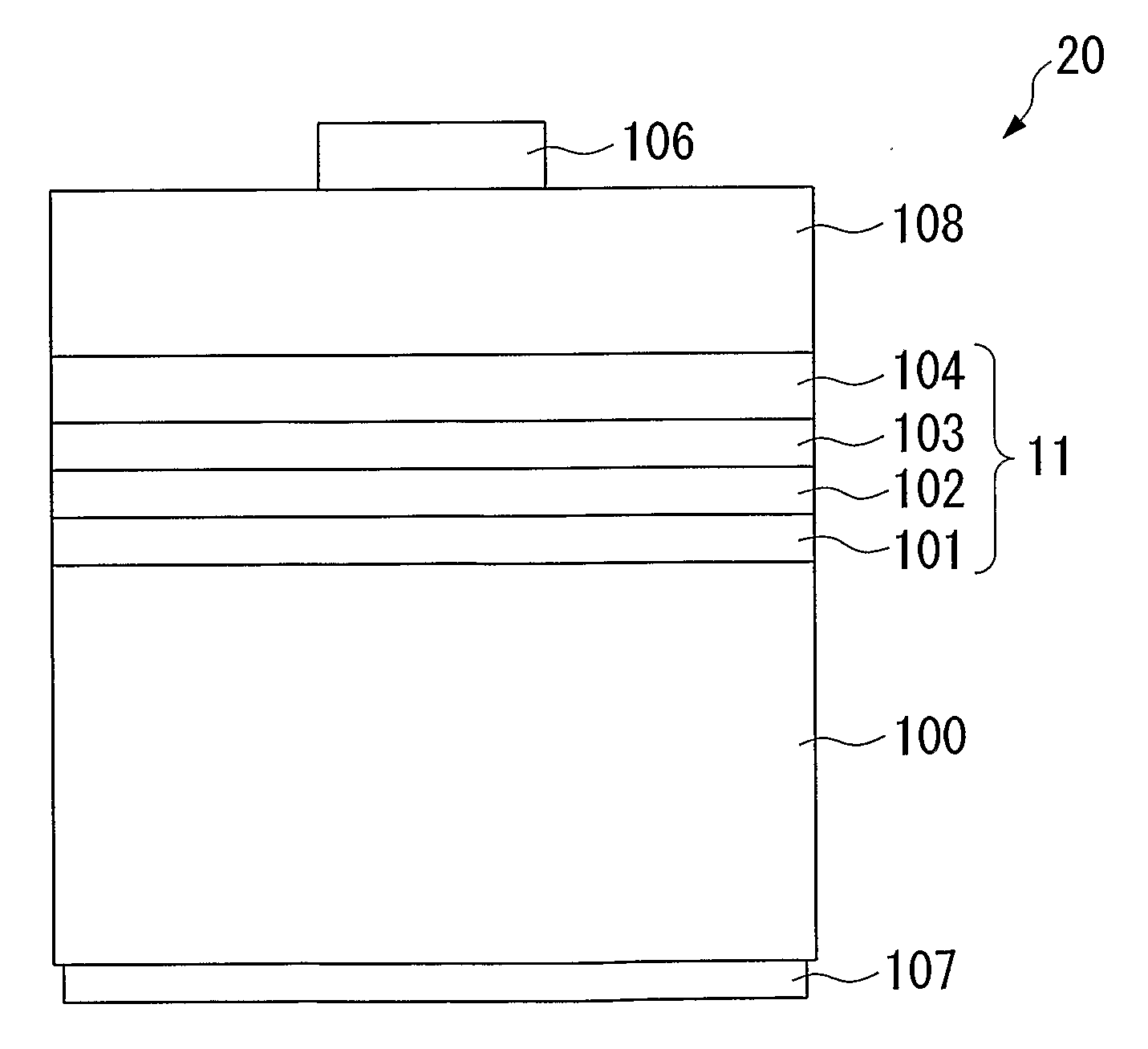

Compound Semiconductor Light-Emitting Device

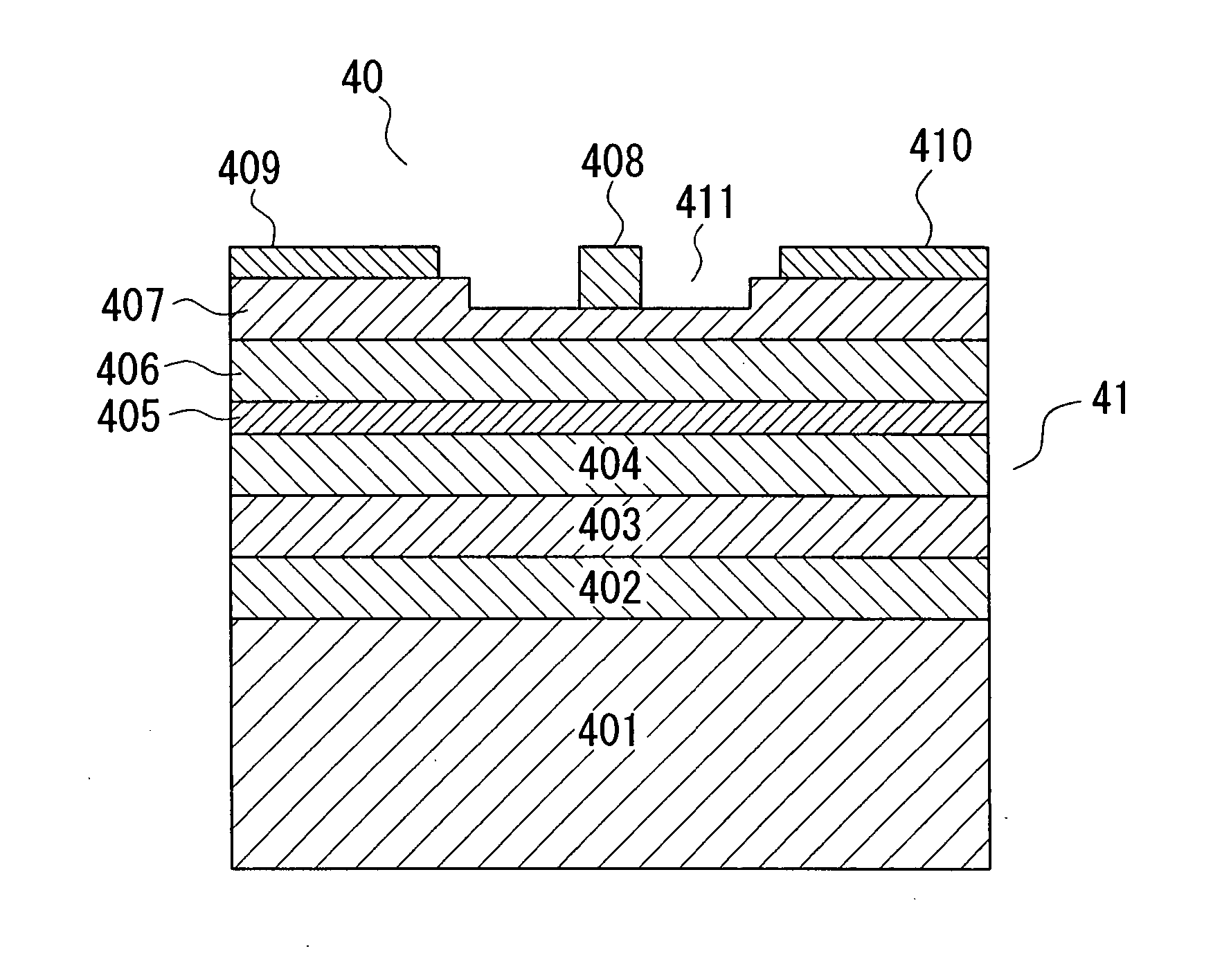

InactiveUS20070221946A1High surface flatnessLower forward voltageSemiconductor devicesLight emitting deviceMaterials science

This pn-junction compound semiconductor light-emitting device includes a crystal substrate; an n-type light-emitting layer formed of a hexagonal n-type Group III nitride semiconductor and provided on the crystal substrate; a p-type Group III nitride semiconductor layer formed of a hexagonal p-type Group III nitride semiconductor and provided on the n-type light-emitting layer; a p-type boron-phosphide-based semiconductor layer having a sphalerite crystal type and provided on the p-type Group III nitride semiconductor layer; and a thin-film layer composed of an undoped hexagonal Group III nitride semiconductor formed on the p-type Group III nitride semiconductor layer, wherein the p-type boron-phosphide-based semiconductor layer is joined to the thin-film layer composed of an undoped hexagonal Group III nitride semiconductor.

Owner:SHOWA DENKO KK

Semiconductor device, semiconductor layer and production method thereof

InactiveUS20070259510A1Polycrystalline material growthFinal product manufactureDevice materialRoom temperature

A semiconductor device is prepared by the use of a vapor phase method and is provided with a semiconductor layer composed of boron phosphide (BP) having a band gap at room temperature of not less than 2.8 eV and not more than 3.4 eV or a boron phosphide (BP)-base mixed crystal which contains the boron phosphide (BP) and which is represented by the formula: BαAlβGaγIn1-α-β-γPδAs∈N1-δ-∈ (0<α≦1, 0≦β<1, 0≦γ<1, 0<α+β+γ≦1, 0<δ≦1, 0≦∈<1, 0<δ+∈≦1).

Owner:SHOWA DENKO KK

Boron phosphide-based semiconductor device, production method thereof, light-emitting diode and boron phosphide-based semiconductor layer

InactiveUS7465499B2High crystallinityReduce dislocation densityPolycrystalline material growthSolid-state devicesDevice materialSingle crystal

Owner:RESONAC HOLDINGS CORPORATION

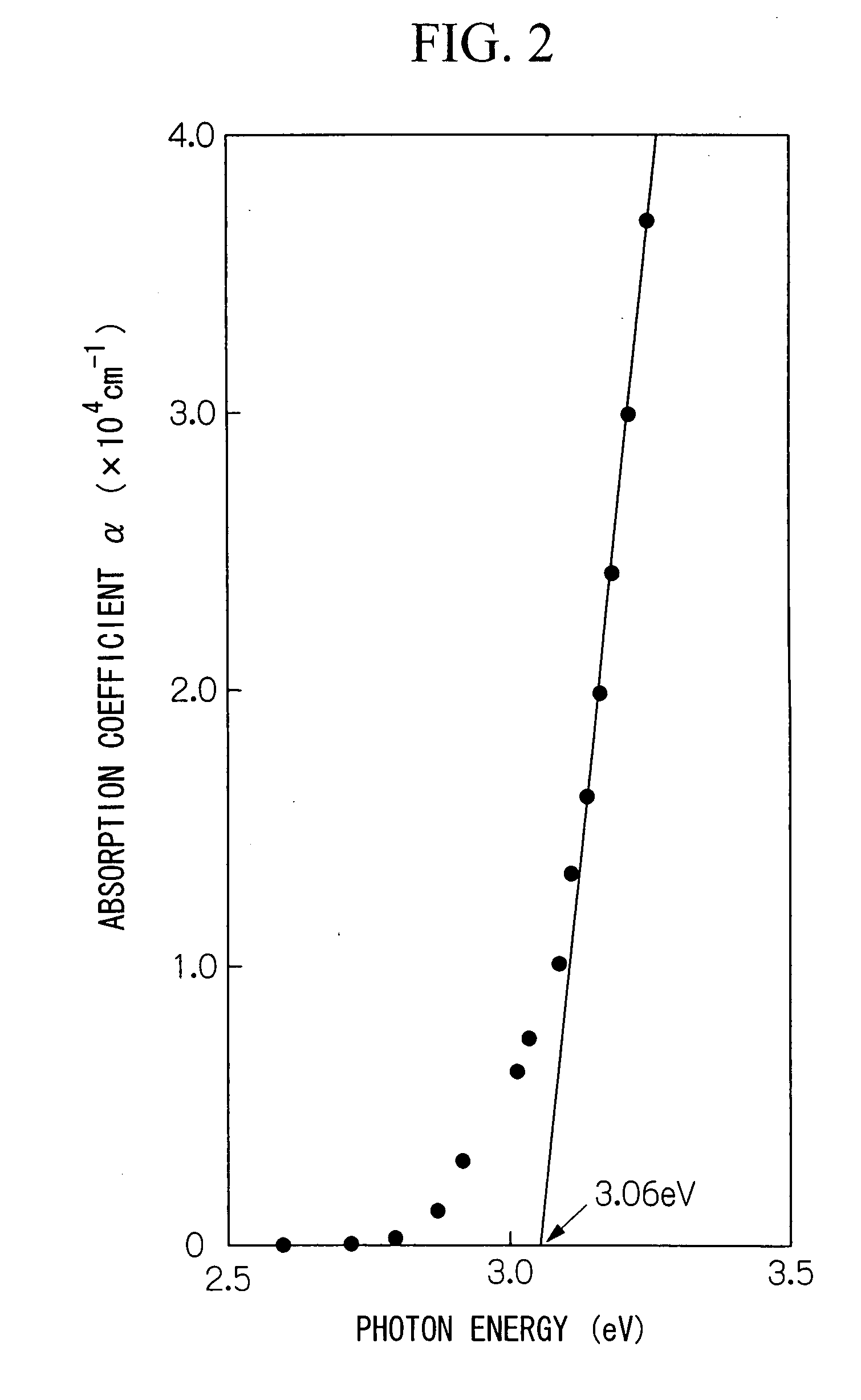

Boron phosphide-based compound semiconductor device, production method thereof and light-emitting diode

InactiveUS20060043506A1Improve device performanceImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice PropertiesRoom temperature

A boron phosphide-based compound semiconductor device with excellent device properties, comprising a boron phosphide-based compound semiconductor layer having a wide bandgap is provided. The boron phosphide-based compound semiconductor layer consists of an amorphous layer and a polycrystal layer provided to join with the amorphous layer, and the room-temperature bandgap of the boron phosphide-based compound semiconductor layer is from 3.0 eV to less than 4.2 eV.

Owner:SHOWA DENKO KK

Boron phosphide-based semiconductor layer and vapor phase growth method thereof

InactiveUS6846754B2Improve continuityImprove surface flatnessPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseOptoelectronics

Owner:SHOWA DENKO KK

Method for making optically-controlled transistor and its structure

InactiveCN1516292AHigh sensitivityFinal product manufactureSemiconductor devicesElectron currentLight beam

The invention discloses a phototransistor making method and structure, firstly forming a boron phosphide buffer layer on the silicon substrate, then forming the first aluminium nitride to compensate stress, then forming the gallium nitride layer and n-type aluminium nitride layer as the heterogenous junction, then making selective extension or anisotropic etching on the gallium nitride material to form prism shaped light accepting layer with cubic crystal lattice, wherein the light accepting layer gathers the incident light beam to excite the electrons in the n-type aluminium nitride layer and forming high-speed two dimensional electron current in the gallium nitride layer, heightening the power and sensitivity of the phototransistor.

Owner:VTERA TECH

Antioxidation anticorrosion transformer oil containing multiple nanoparticles and preparation method thereof

ActiveCN104130829AImprove insulation performanceSmall dielectric coefficientAdditivesButylated hydroxytolueneOxidation resistant

Disclosed antioxidation anticorrosion transformer oil containing multiple nanoparticles is characterized by being prepared from the following raw materials in parts by weight: 1000-1500 parts of cycloalkyl base oil, 2-4 parts of aluminium nitride, 0.2-0.5 parts of molybdenum disulfide, 0.3-0.5 parts of polyisobutylene, 0.5-1.0 parts of active alumina micro powder, 0.2-0.5 parts of resorcinol, 0.2-0.5 parts of nanometer tantalum carbide powder, 0.2-0.5 parts of butylated hydroxytoluene, 2-4 parts of boron phosphide, and 0.5-1.0 parts of an auxiliary agent. The nanoparticles are prepared by utilizing an absolute-ethanol ball milling method, and employed equipment is simple and easy to operate. The added multiple nanoparticles help the transformer oil to improve insulating property and heat conduction property and enable the dielectric coefficient to be small. The added auxiliary agent improves the anti-oxidation, anti-corrosion and insulating properties of the transformer oil. The problems that transformer oil is easy to oxidize and corrode, is not long in service life and the like are effectively solved, and the safety coefficient of the transformer oil is substantially improved.

Owner:桐乡市华宇电力设备股份有限公司

Boron Phosphide-Based Semiconductor Light-Emitting Device

InactiveUS20070194335A1High crystallinitySufficient layer thicknessSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalLight emitting device

A boron phosphide-based semiconductor light-emitting device includes a substrate of silicon single crystal, a first cubic boron phosphide-based semiconductor layer that is provided on a surface of the substrate and contains twins, a light-emitting layer that is composed of a hexagonal Group III nitride semiconductor and provided on the first cubic boron phosphide-based semiconductor layer and a second cubic boron phosphide-based semiconductor layer that is provided on the light-emitting layer, contains twins and has a conduction type different from that of the first cubic boron phosphide-based semiconductor layer.

Owner:SHOWA DENKO KK

Nonmetal catalyst used for selective oxidation of methane, optimization method and application thereof

InactiveCN107876076ASuitable active siteImprove catalytic performanceHydrogenCatalyst activation/preparationHexagonal boron nitrideBoron nitride

The invention discloses a nonmetal catalyst used for selective oxidation of methane, an optimization method and an application thereof and belongs to the technical field of industrial catalysis. The catalyst is a solid nonmetal boron-containing catalyst and comprises hexagonal boron nitride, cubic boron nitride, rhombohedral boron nitride, boron phosphide and boron phosphate. Activation treatmentis carried out for optimizing the number of hydroxyl functional groups on the surface of the catalyst. The catalyst is used for the selective oxidation of methane, wherein products may include H2, CO,ethylene, ethane and a less amount of CO2. Compared with a metal catalyst in the prior art, the nonmetal catalyst is abundant in raw material reserves, is environment-friendly, has good high-temperature stability and simple preparation method, and has huge industrial development and application prospect.

Owner:DALIAN UNIV OF TECH

Preparation method of organic silicon pouring sealant with high thermal conductivity

InactiveCN107286902AImprove thermal conductivityGood mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkSealant

The invention discloses a preparation method of an organic silicon pouring sealant with high thermal conductivity. The preparation method comprises steps as follows: boron phosphide and concentrated nitric acid are mixed and stirred for 5 h and are filtered, solids are washed with deionized water and dried, and pretreated boron phosphide is obtained; prepared boron phosphide, h-BN and isopropyl alcohol are mixed and stirred uniformly and are subjected to ultrasonic treatment for 1 h under 1000W powder, hydroxyl silicone oil is added, ultrasonic treatment is continued for 2-5 h, a product is filtered and dried after ultrasonic treatment, and modified composite filler is prepared; the organic silicon pouring sealant is prepared from vinyl silicone oil, hydrogen-containing silicone oil, the modified composite filler, a dispersing agent, a cross-linking agent, a catalyst, an inhibitor and an antifoaming agent through mixing, stirring and defoaming. The organic silicon pouring sealant prepared with the method is excellent in mechanical property and good in thermal conductivity.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

Boron phosphide-based semiconductor device and production method thereof

InactiveUS20040232404A1Get stableForm is disadvantageousPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A boron phosphide-based semiconductor device includes a single crystal substrate having formed thereon a boron-phosphide (BP)-based semiconductor layer containing boron and phosphorus as constituent elements, where phosphorus (P) occupying the vacant lattice point (vacancy) of boron (B) and boron occupying the vacant lattice point (vacancy) of phosphorus are present in the boron-phosphide (BP)-based semiconductor layer. The boron phosphide-based semiconductor device includes a p-type boron phosphide-based semiconductor layer in which boron occupying the vacancy of phosphorus is contained in a higher atomic concentration than phosphorus occupying the vacancy of boron and a p-type impurity of Group II element or Group IV element is added.

Owner:SHOWA DENKO KK

Compound semiconductor light-emitting diode

InactiveUS20070164304A1Improve featuresGood ohmic contactSemiconductor/solid-state device manufacturingSemiconductor devicesRoom temperatureLight-emitting diode

A compound semiconductor light-emitting diode comprising a light-emitting layer composed of a Group III-V compound semiconductor, and a current diffusion layer provided on the light-emitting layer and composed of a Group III-V compound semiconductor, characterized in that the current diffusion layer is composed of a conductive boron-phosphide-based semiconductor and has a bandgap at room temperature wider than that of the light-emitting layer.

Owner:SHOWA DENKO KK

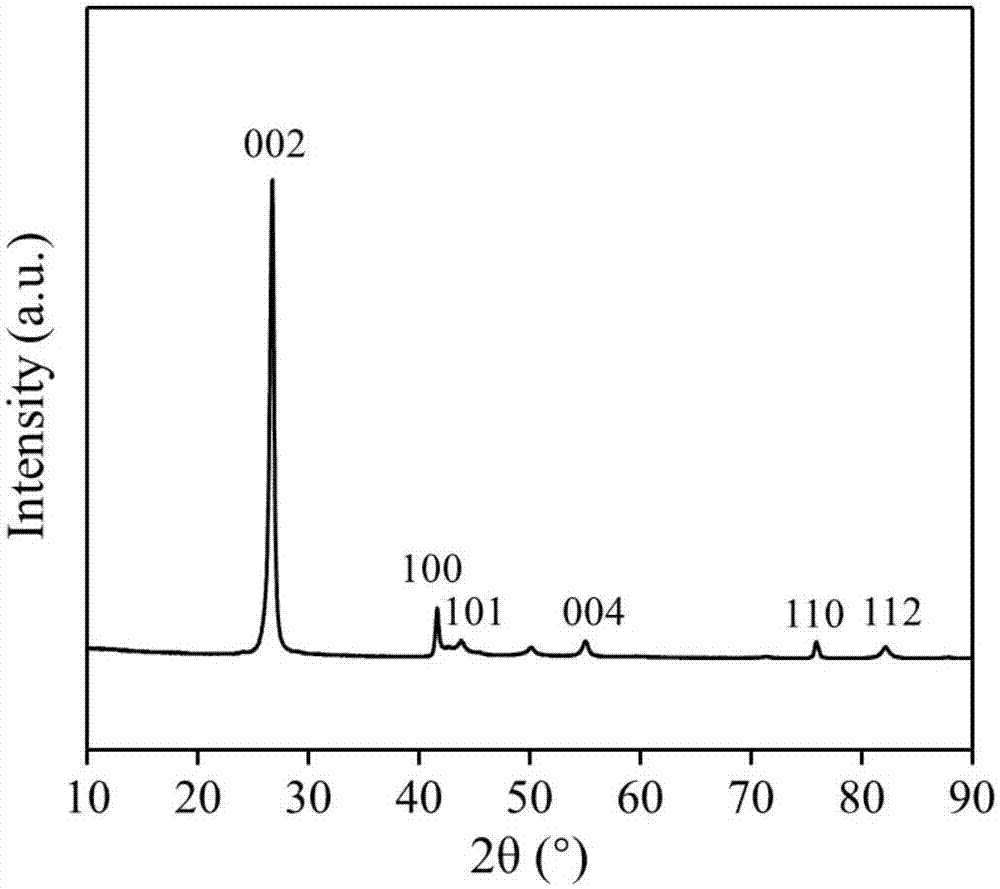

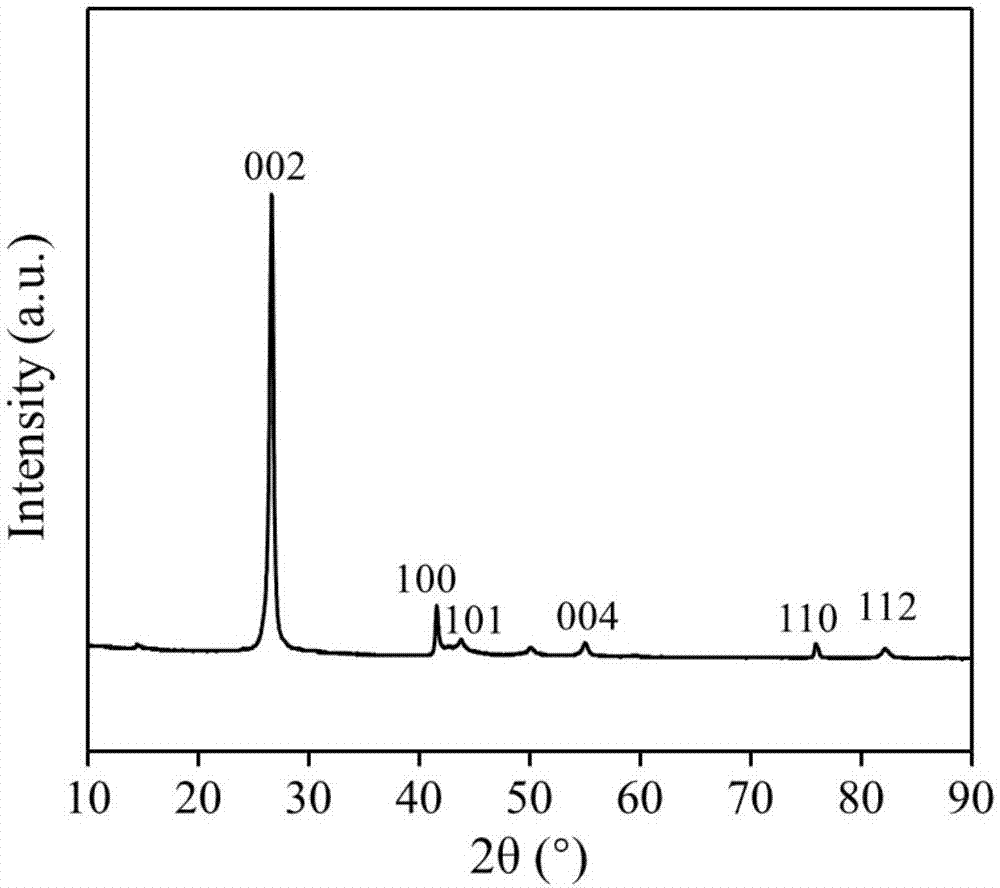

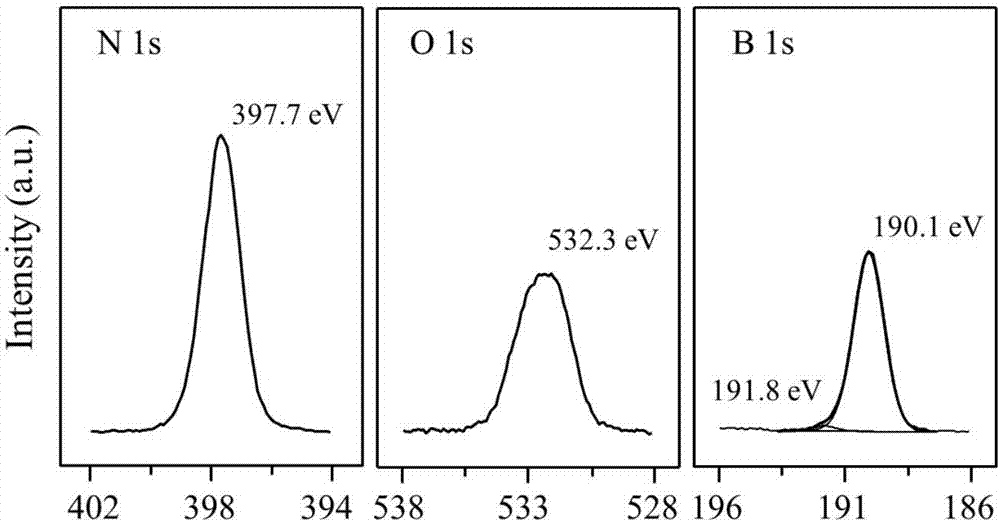

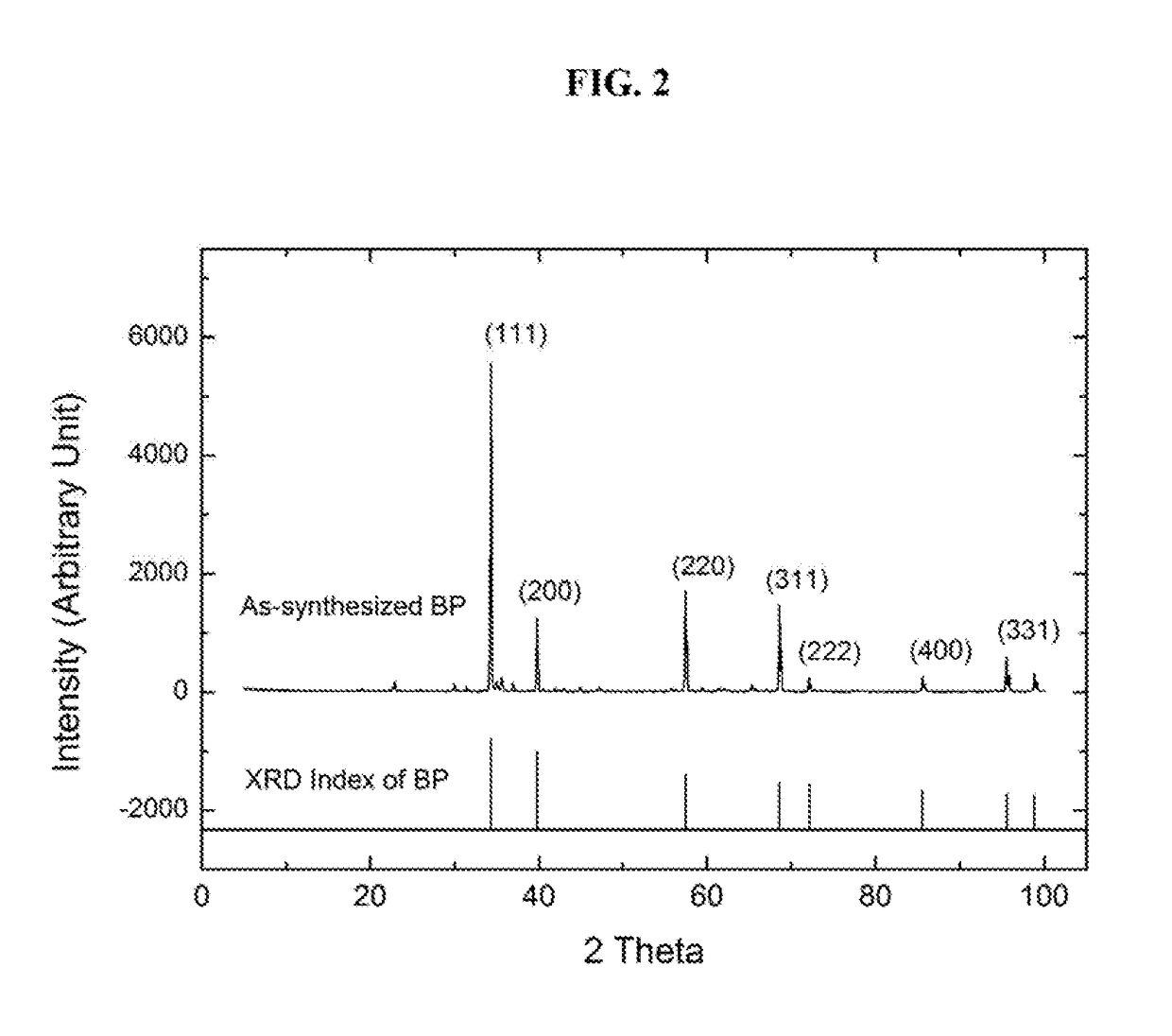

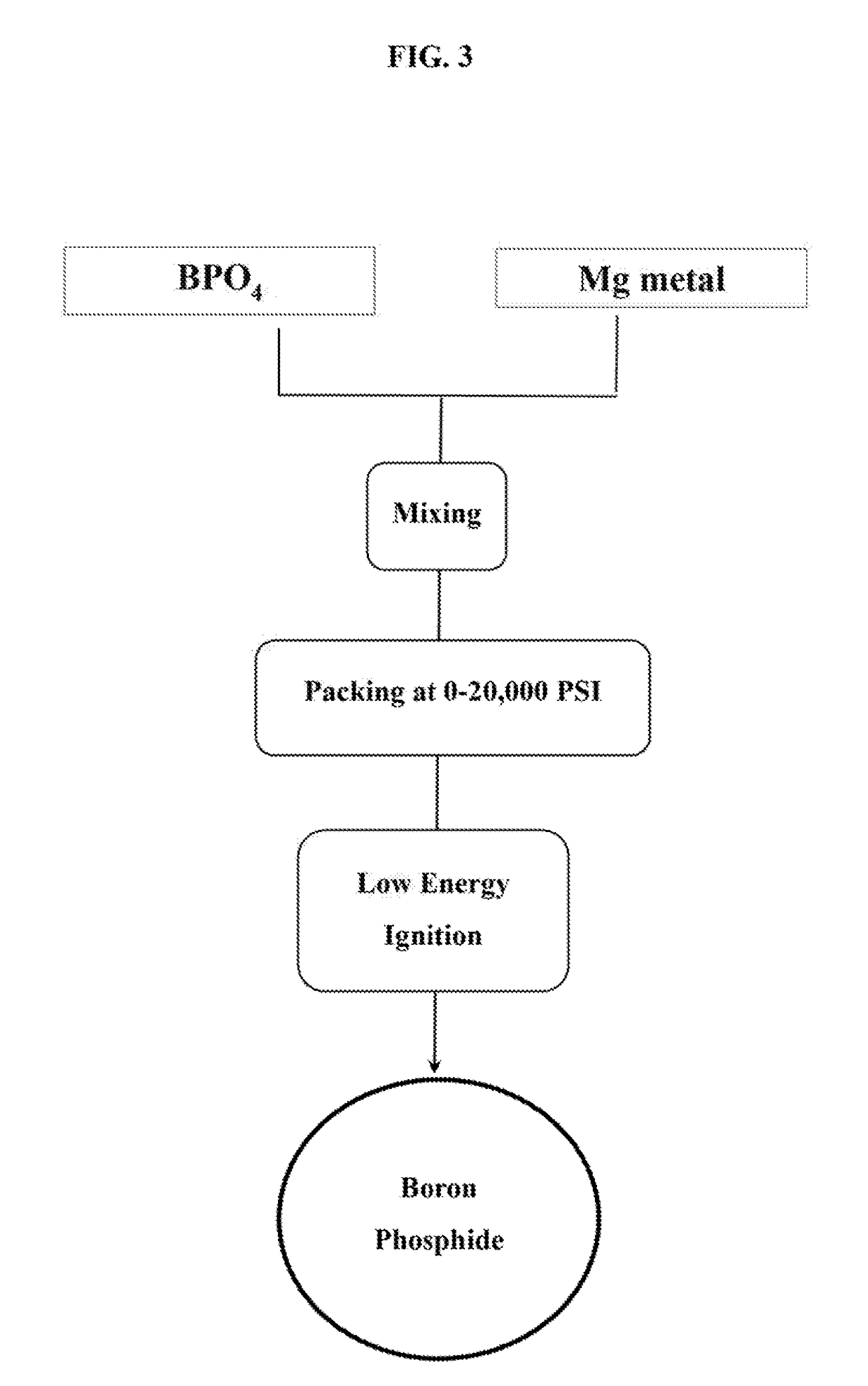

High-yield synthesis of nanostructured boron phosphide by a pyrotechnic method

A simplified method for synthesizing boron phosphide at high yields. The method requires mixing of boron phosphate and magnesium metal without diluents into a homogenous mixture, loosely packing the mixture at less than 20,000 psi and igniting the mixture using an energy input that is not greater than 20% of the reaction energy output to create a self-propagating high-temperature reaction wherein the boron phosphate and magnesium metal is completely burned during the reaction to synthesize boron phosphide at high yields.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com