Nonmetal catalyst used for selective oxidation of methane, optimization method and application thereof

A non-metallic catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, non-metallic elements, etc., can solve the problems of easy over-oxidation, scarce reserves, high price, etc., and achieve the effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

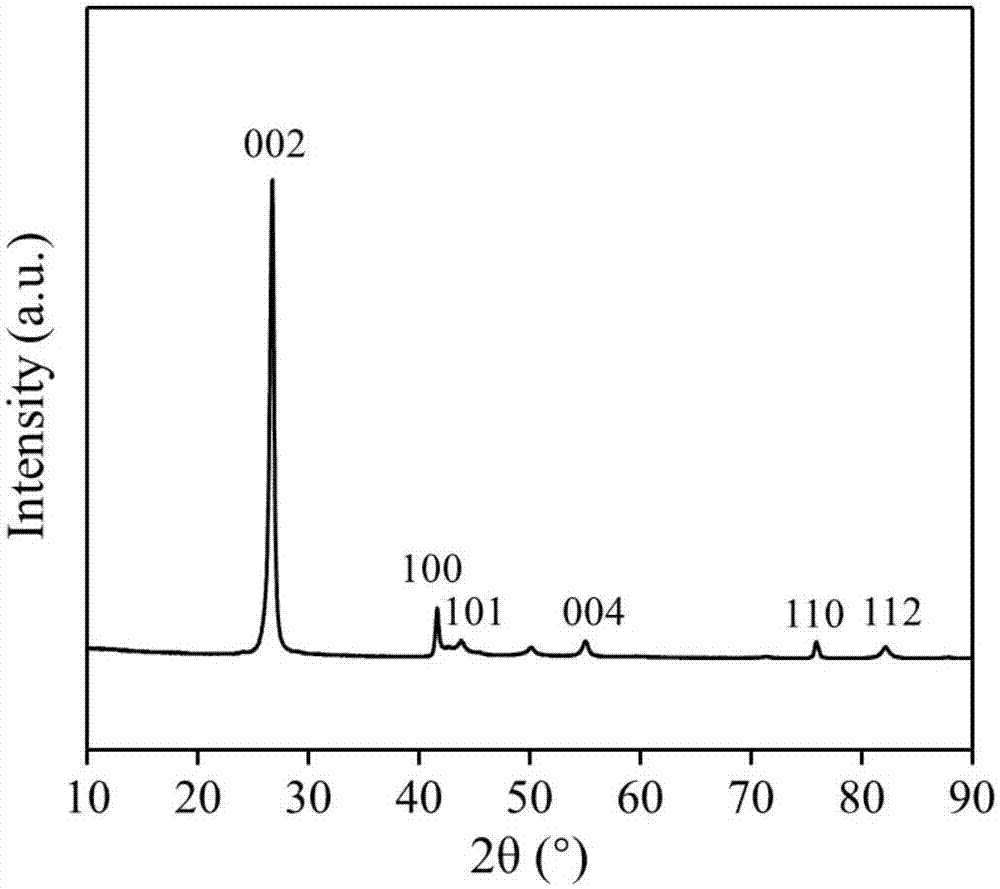

Embodiment 1

[0032] Direct application of unactivated commercial hexagonal boron nitride for partial oxidation of methane.

[0033] The catalyst was evaluated in an isothermal fixed-bed reactor, and the evaluation process was briefly described as follows:

[0034] The mixed gas of methane, oxygen and diluent in different volume ratios is regulated by a mass flow meter, and the oxidation reaction is carried out in a quartz reaction tube with an inner diameter of 8 mm and a length of 400 mm. The reacted gas enters the gas chromatograph to analyze the composition after passing through the cold trap.

[0035] Methane conversion and product selectivity were calculated according to the following formula:

[0036]

[0037]

[0038]

[0039] Weigh 0.1 g of the catalyst for methane oxidation conversion reaction test. The feed gas volume ratio is CH 4 :O 2 :N 2 =2:1:4, temperature 640~740°C, normal pressure reaction, test results are shown in Table 1.

Embodiment 2

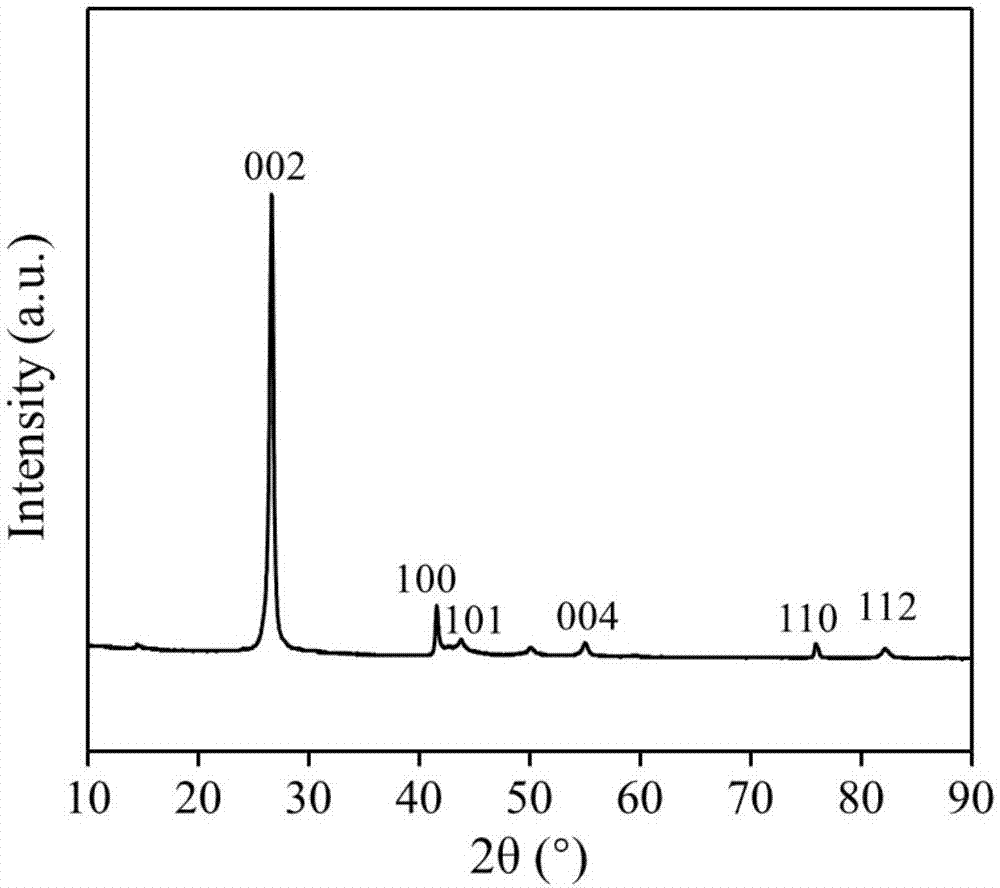

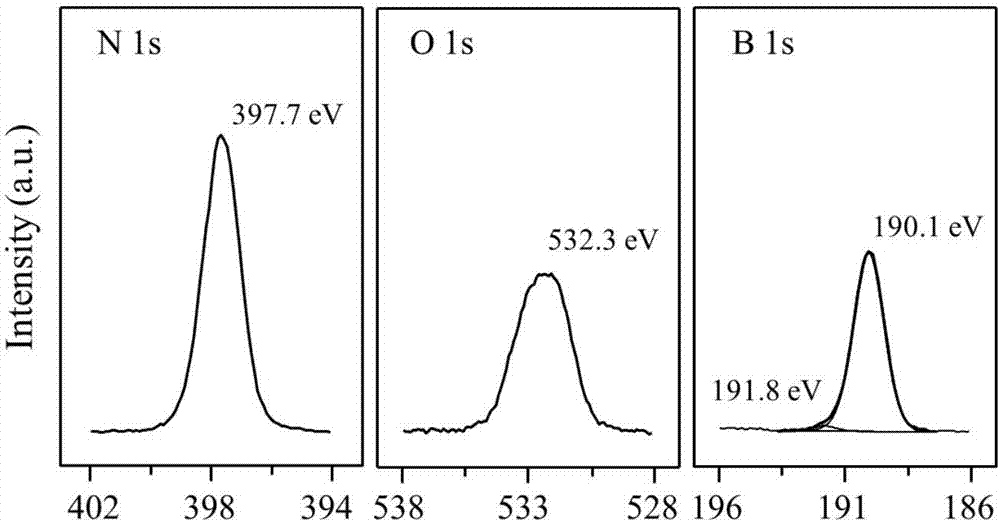

[0041]The boron nitride powder was ball-milled in air atmosphere for 4 hours, and the ball-milled sample was treated in air or oxygen atmosphere at 700°C for 2 hours; the obtained material was activated at 700°C in a humid air atmosphere for 6 hours. Then wash with ammonia water and deionized water to remove impurities existing in the material and impurities introduced during the treatment process to obtain a functionalized catalyst.

[0042] The catalyst testing procedure is the same as in Example 1.

Embodiment 3~5

[0043] Embodiment 3~5, press the operating procedure of embodiment 1, change CH 4 / O 2 The corresponding parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com