Deformable permanent magnet alloy, deformable permanent magnet alloy thin strip and preparation method thereof

A permanent magnet alloy, thin strip technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of unfavorable practical application of materials, insufficient coercivity, easy surface oxidation, etc., to achieve easy realization, coercivity Large and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for preparing a deformable permanent magnetic alloy thin strip, and the deformable permanent magnetic alloy thin strip prepared by the preparation method. Described preparation method comprises the steps:

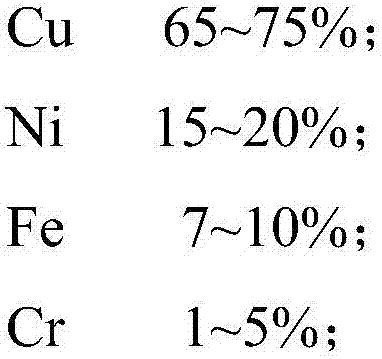

[0024] Step S1, weighing each alloy composition according to the following proportions:

[0025]

[0026] In the prior art, copper-nickel-iron alloy is a common permanent magnetic alloy. In this embodiment, a small amount of Cr is added on the basis of the above-mentioned components, and various components are adjusted accordingly. The addition of Cr, on the one hand, can effectively increase the oxidation resistance of the alloy, and at the same time increase the coercive force of the permanent magnet alloy to a certain extent.

[0027] In step S2, vacuum induction melting is performed on the above-mentioned weighted metal components, and cast into a copper-nickel-iron-chromium alloy ingot.

[0028] The purpose of vacuum induct...

Embodiment 2

[0036] This embodiment provides a deformable permanent magnetic alloy thin strip prepared by the method of Embodiment 1, and describes the preparation process in detail. According to the material composition Cu 65%, Ni 20%, Fe 10%, Cr 5%. Cast into a copper-nickel-iron-chromium alloy ingot by vacuum induction melting. The alloy ingot was forged by extrusion cold forging. Then hot rolling is carried out at 600°C to make a 0.1mm alloy thin strip. Finally, it was tempered at 500° C. for 0.5 hour to obtain sample No. 1 of the prepared permanent magnetic alloy thin strip.

[0037] According to the magnetic test, the coercive force of the prepared alloy thin strip No. 1 is as high as 680Oe, and it still maintains a metallic luster without being oxidized after being placed in the air for one year.

Embodiment 3

[0039] This embodiment also provides a thin strip of deformable permanent magnetic alloy prepared by the method of Embodiment 1, and describes the preparation process in detail. According to the material composition Cu 68%, Ni 19%, Fe 8%, Cr 5%. Cast into a copper-nickel-iron-chromium alloy ingot by vacuum induction melting. The alloy ingot was forged at 950°C. Then it was hot rolled at 900°C to form a 0.2mm alloy thin strip. Finally, it was tempered at 600° C. for 1 hour to obtain sample No. 2 of the prepared permanent magnetic alloy thin strip.

[0040] According to the magnetic test, the coercive force of the prepared alloy thin strip No. 2 is as high as 720Oe, and it still maintains a metallic luster without being oxidized after being placed in the air for one year.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com