Manufacturing process for carbon fiber composite forming membrane disk

A composite material and manufacturing process technology, which is applied in the field of carbon fiber composite material forming membrane disc manufacturing process, can solve the problems of strong wear resistance, high strength, and inability to produce quality, and achieve good corrosion resistance, fatigue resistance, and The effect of small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

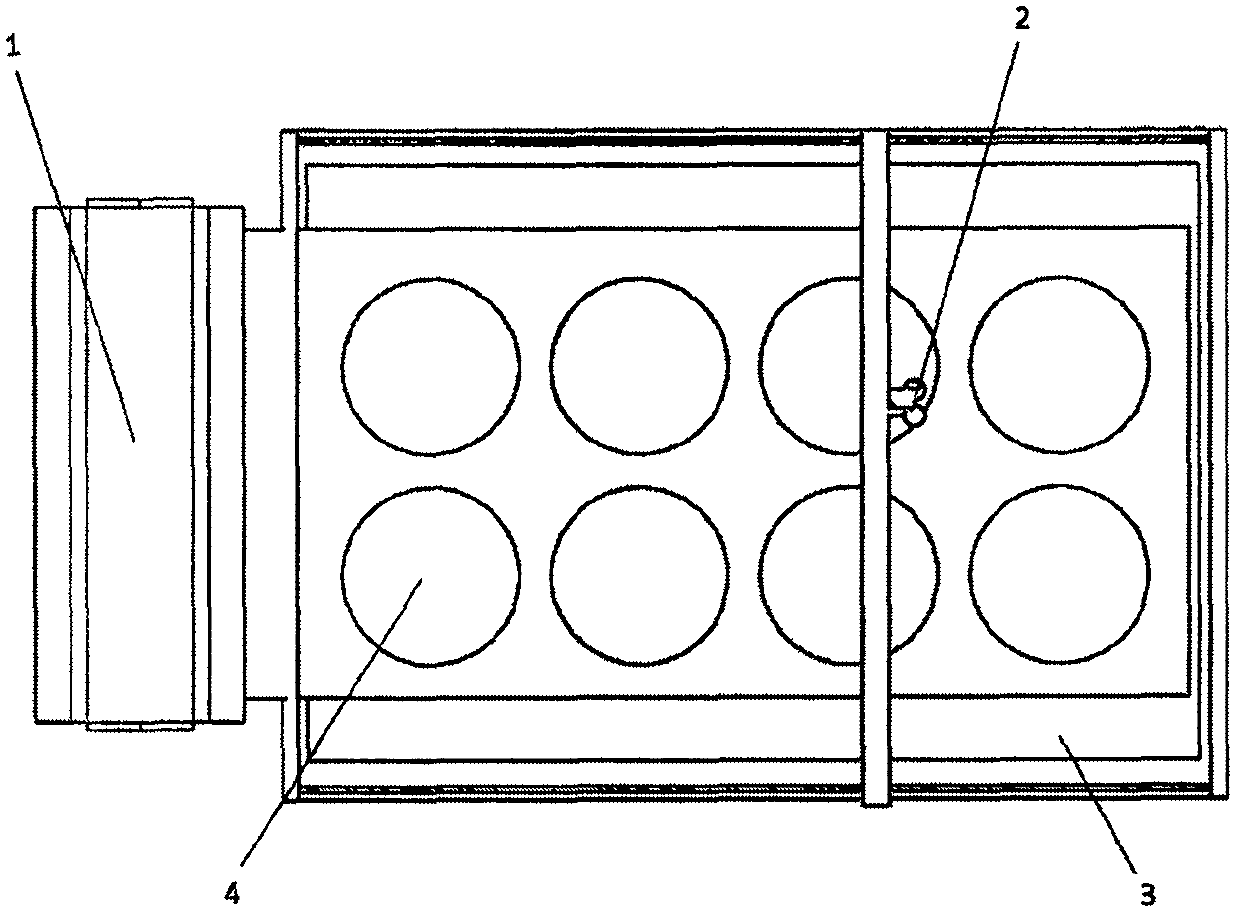

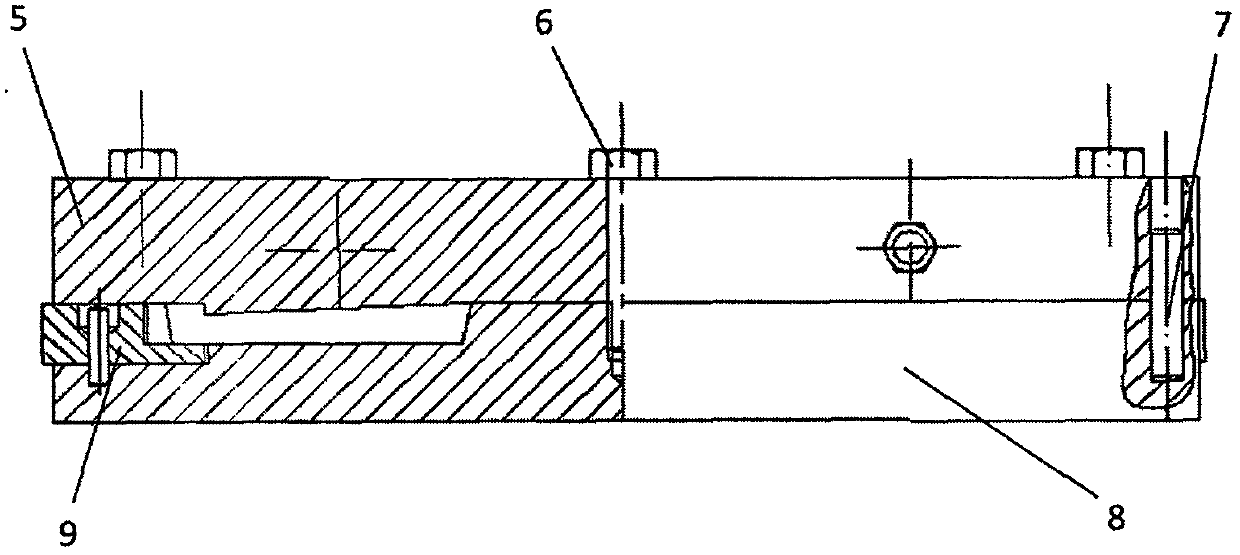

[0023] The manufacturing process of the carbon fiber composite material forming membrane disc of the present embodiment, this kind of carbon fiber composite material forming membrane disc manufacturing process, it relates to the cutting method of the resin-based carbon fiber prepreg cloth, that is, firstly, the rolled prepreg cloth is assembled on the material rack First, limit and fix the edge of the prepreg and the position calibration mechanical structure, use a vibrating cutter to cut the prepreg into multiple prepregs of specified size, collect the cut prepregs, and repeat the above steps Until all the prepregs are cut.

[0024] The prepreg prepared by the cutting method of the resin-based carbon fiber prepreg has uniform thickness and precise size, which significantly improves the compactness, uniformity and dimensional accuracy of the product.

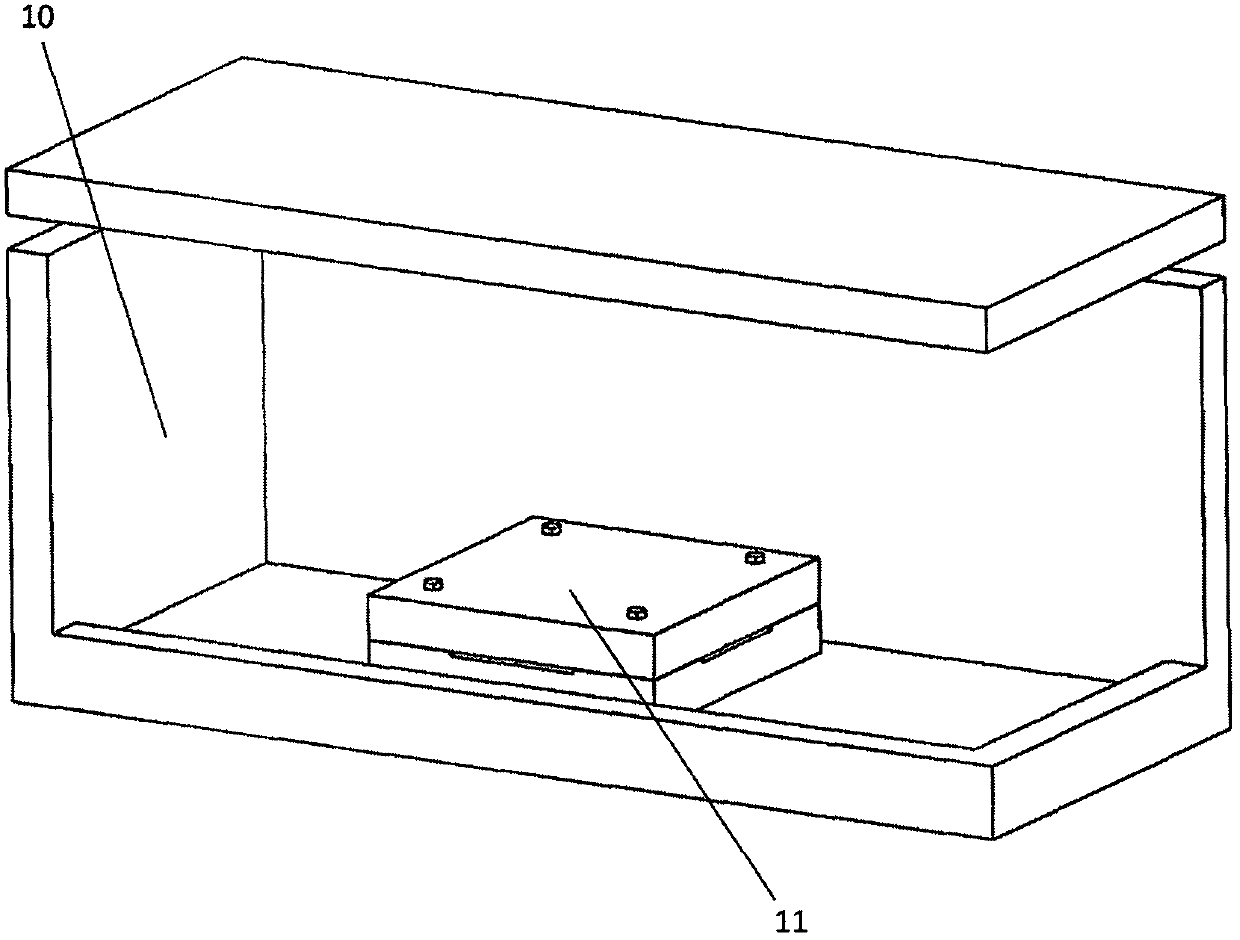

[0025] The manufacturing process of the carbon fiber composite molded film disk involves a preheating processing method, that ...

specific Embodiment approach 2

[0038] The difference from Embodiment 1 is that in the manufacturing process of the carbon fiber composite material forming membrane disc in this embodiment, the cutting is carried out according to the graphics drawn by the cutting machine as described in step 1, and the above steps are repeated until all the prepregs are cut. In the process, the prepreg is cut by the cutting method of the vibrating cutting knife of the coordinate cutting machine.

specific Embodiment approach 3

[0039] The difference from Embodiment 1 or Embodiment 2 is that, in the manufacturing process of the carbon fiber composite material molding disc of this embodiment, when using the heating device in step 2 to preheat and heat the prepreg obtained by cutting the prepreg in step 1, the The heating device is a digital heating platform device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com