Method of preparing super capacitor electrode material polyaniline nano fiber

A technology of supercapacitors and nanofibers, applied in the fields of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of cumbersome post-processing, large amount of emulsifier, high cost, etc., and solve the problem of recycling The effect of poor performance, good cycle life, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

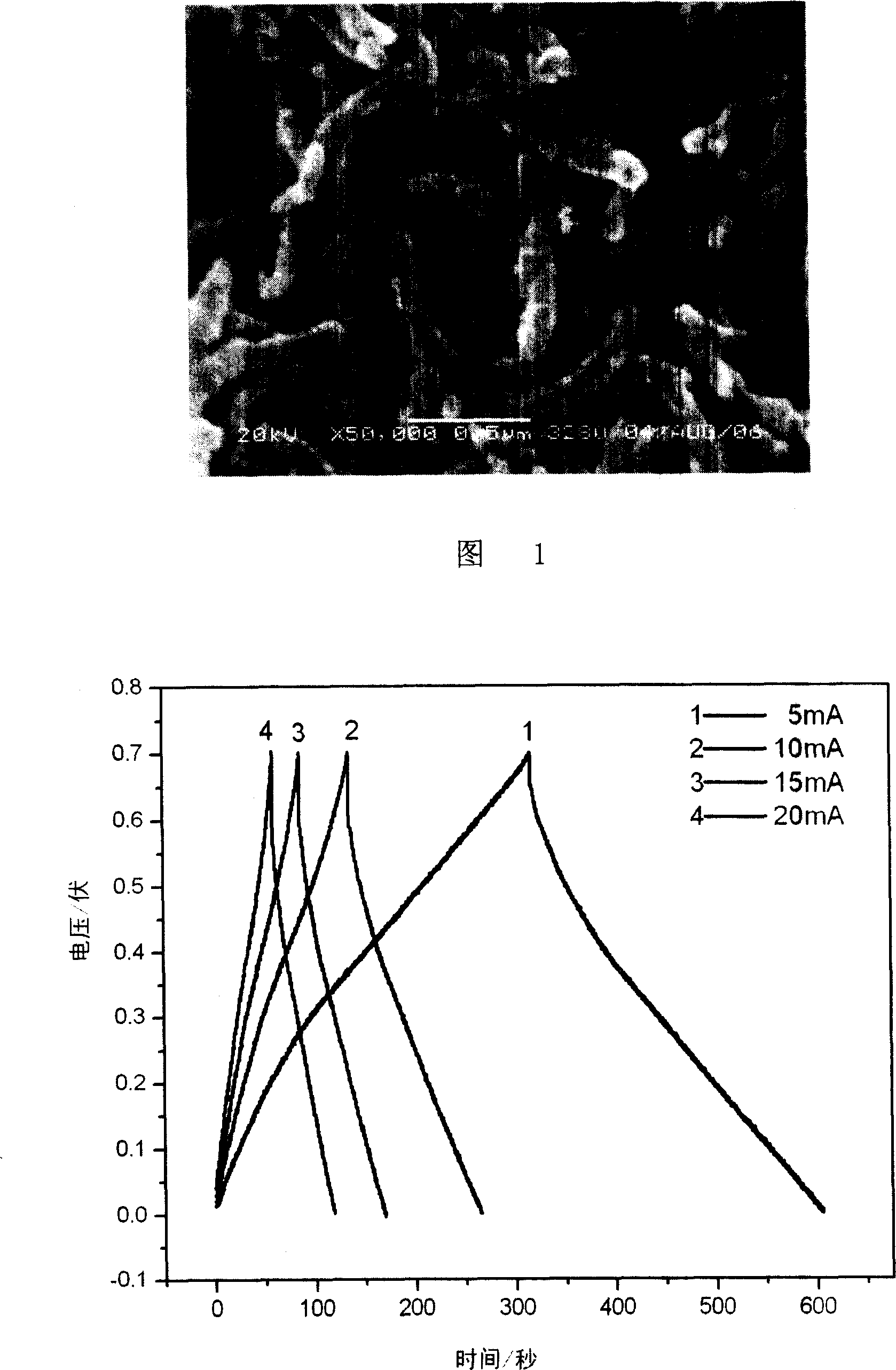

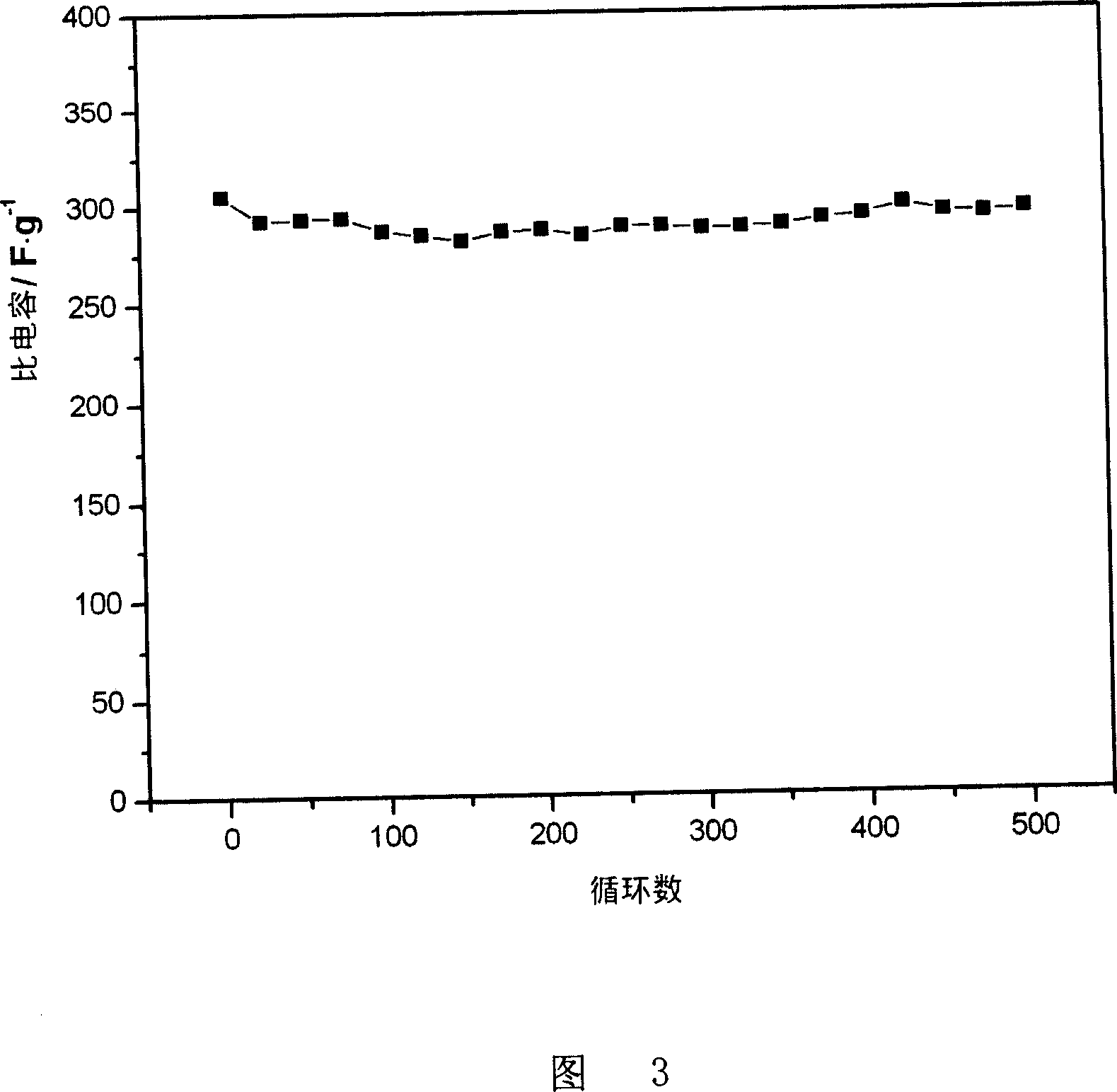

[0015] Embodiment 1: (1) the aniline of 0.93ml is dissolved in 100ml organic solvent CCl 4 Solution A was made in , and 0.57g of ammonium persulfate was dissolved in 100ml of 1mol / L hydrochloric acid to make solution B ([APS] / [AN]=1:4); (2) solution A and solution B were transferred into In the reaction bottle, react at room temperature for 5h; (3) collect the product in solution B, wash the product with water, ethanol and acetone until the washing liquid is colorless; (4) vacuum dry the washed product at 40°C for 48h to obtain Hydrochloric acid doped polyaniline nanofibrous material. The calculated polyaniline single-electrode specific capacitance is 317F / g, and the capacity fading is within 4% after 500 charge-discharge cycles.

Embodiment 2

[0016] Embodiment 2: (1) the aniline of (1) is dissolved in 100ml organic solvent toluene and is made into solution A, and the ammonium persulfate of 2.28g is dissolved in the 2mol / L hydrochloric acid of 100ml and is made into solution B ([APS] / [AN ]=1:2); (2) solution A and solution B are moved into the reaction bottle successively, and react at room temperature for 10h; (3) collect the product in solution B, wash the product with water, ethanol and acetone, until the washing liquid is free (4) The washed product was vacuum-dried at 60° C. for 24 hours to obtain polyaniline nanofibers doped with hydrochloric acid. The specific capacitance of the polyaniline single electrode prepared in this example is 308 F / g, and the capacity fading within 500 charge-discharge cycles is within 5%.

Embodiment 3

[0017] Embodiment 3: (1) the aniline of 0.465ml is dissolved in 100ml organic solvent CH 2 Cl 2 Solution A is made in the solution A, and the ammonium persulfate of 0.285g is dissolved in the 1mol / L perchloric acid of 100ml to make solution B ([APS] / [AN]=1: 1); (2) solution A and solution B Move them into the reaction bottle in turn, and react at room temperature for 20 hours; (3) collect the product in solution B, wash the product with water, ethanol and acetone until the washing liquid is colorless; (4) vacuum-dry the washed product at 80°C for 12 hours , to obtain perchloric acid-doped polyaniline nanofiber materials. The specific capacitance of the polyaniline single electrode prepared in this example is 302 F / g, and the capacity fading is within 4% after 500 charge-discharge cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com